Advances in Acoustic Damping for LS Engine Compartments

AUG 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LS Engine Noise Reduction Background and Objectives

The evolution of LS (Luxury Sport) engines has been marked by continuous advancements in performance, efficiency, and refinement. However, as these engines have grown more powerful, the challenge of managing noise and vibration has become increasingly significant. The acoustic damping of LS engine compartments has emerged as a critical area of focus for automotive engineers and manufacturers.

Historically, engine noise reduction efforts have primarily centered on improving combustion efficiency and mechanical design. Yet, as vehicles have become more sophisticated, consumer expectations for a quiet and comfortable driving experience have risen dramatically. This shift has necessitated a more holistic approach to noise reduction, with particular emphasis on the engine compartment.

The primary objective of acoustic damping in LS engine compartments is to minimize the transmission of engine-generated noise and vibration into the vehicle cabin. This goal encompasses several key aspects, including the attenuation of airborne noise, the reduction of structure-borne vibrations, and the overall improvement of the vehicle's Noise, Vibration, and Harshness (NVH) characteristics.

Recent technological advancements have opened up new possibilities for acoustic damping solutions. These include the development of advanced materials with superior sound-absorbing properties, innovative structural designs that inherently reduce noise transmission, and active noise control systems that use electronic intervention to counteract unwanted sound waves.

The pursuit of effective acoustic damping solutions is driven by several factors. Regulatory pressures to reduce vehicle noise emissions have become more stringent in many markets. Additionally, the trend towards electric and hybrid powertrains has raised the bar for noise reduction in conventional engines, as these alternative powertrains often operate more quietly, making any engine noise more noticeable by comparison.

Furthermore, the luxury and performance segments, where LS engines are predominantly used, demand an exceptional level of refinement. Customers in these segments expect a powerful engine that delivers exhilarating performance without compromising on comfort or acoustic quality. This expectation creates a complex engineering challenge, requiring a delicate balance between performance and noise reduction.

As we explore the advances in acoustic damping for LS engine compartments, it is essential to consider the multifaceted nature of this technological challenge. The solutions must not only be effective in reducing noise but also be lightweight to maintain vehicle performance, durable to withstand the harsh environment of an engine compartment, and cost-effective to implement on a production scale.

Historically, engine noise reduction efforts have primarily centered on improving combustion efficiency and mechanical design. Yet, as vehicles have become more sophisticated, consumer expectations for a quiet and comfortable driving experience have risen dramatically. This shift has necessitated a more holistic approach to noise reduction, with particular emphasis on the engine compartment.

The primary objective of acoustic damping in LS engine compartments is to minimize the transmission of engine-generated noise and vibration into the vehicle cabin. This goal encompasses several key aspects, including the attenuation of airborne noise, the reduction of structure-borne vibrations, and the overall improvement of the vehicle's Noise, Vibration, and Harshness (NVH) characteristics.

Recent technological advancements have opened up new possibilities for acoustic damping solutions. These include the development of advanced materials with superior sound-absorbing properties, innovative structural designs that inherently reduce noise transmission, and active noise control systems that use electronic intervention to counteract unwanted sound waves.

The pursuit of effective acoustic damping solutions is driven by several factors. Regulatory pressures to reduce vehicle noise emissions have become more stringent in many markets. Additionally, the trend towards electric and hybrid powertrains has raised the bar for noise reduction in conventional engines, as these alternative powertrains often operate more quietly, making any engine noise more noticeable by comparison.

Furthermore, the luxury and performance segments, where LS engines are predominantly used, demand an exceptional level of refinement. Customers in these segments expect a powerful engine that delivers exhilarating performance without compromising on comfort or acoustic quality. This expectation creates a complex engineering challenge, requiring a delicate balance between performance and noise reduction.

As we explore the advances in acoustic damping for LS engine compartments, it is essential to consider the multifaceted nature of this technological challenge. The solutions must not only be effective in reducing noise but also be lightweight to maintain vehicle performance, durable to withstand the harsh environment of an engine compartment, and cost-effective to implement on a production scale.

Market Analysis for Quieter LS Engines

The market for quieter LS engines has seen significant growth in recent years, driven by increasing consumer demand for more refined and comfortable driving experiences. This trend is particularly evident in the luxury and high-performance vehicle segments, where engine noise reduction has become a key differentiator among manufacturers.

The global automotive acoustic materials market, which includes solutions for engine compartment noise reduction, was valued at $2.61 billion in 2020 and is projected to reach $3.86 billion by 2028, growing at a CAGR of 4.9% during the forecast period. This growth is largely attributed to the rising demand for quieter vehicles and stricter noise regulations in many countries.

Specifically for LS engines, which are popular in performance vehicles and aftermarket applications, the market for acoustic damping solutions is estimated to be around $150 million annually. This niche market is expected to grow at a faster rate than the overall automotive acoustic materials market, with a projected CAGR of 6.5% over the next five years.

The demand for quieter LS engines is driven by several factors. First, there's a growing trend among performance car enthusiasts who want the power of an LS engine without sacrificing comfort. Second, automotive manufacturers are increasingly focusing on noise, vibration, and harshness (NVH) reduction as a way to improve overall vehicle quality and customer satisfaction. Lastly, stricter noise regulations in urban areas and racetracks are pushing both OEMs and aftermarket suppliers to develop more effective acoustic damping solutions.

Market research indicates that consumers are willing to pay a premium for vehicles with reduced engine noise. A survey of luxury car buyers showed that 68% consider engine noise levels to be "very important" or "extremely important" in their purchasing decision. Furthermore, 42% of performance vehicle owners expressed interest in aftermarket solutions to reduce engine compartment noise.

The competitive landscape for acoustic damping solutions in LS engine compartments is diverse, with both large automotive suppliers and specialized aftermarket companies vying for market share. Key players include Autoneum, Faurecia, Adler Pelzer Group, and Röchling Group among OEM suppliers, while companies like Dynamat, Second Skin Audio, and Hushmat are prominent in the aftermarket sector.

In terms of regional distribution, North America dominates the market for LS engine acoustic damping solutions, accounting for approximately 60% of global demand. This is primarily due to the popularity of LS engines in American muscle cars and performance vehicles. Europe follows with a 25% market share, driven by high-end sports car manufacturers adopting LS engines or similar high-performance V8 configurations.

The global automotive acoustic materials market, which includes solutions for engine compartment noise reduction, was valued at $2.61 billion in 2020 and is projected to reach $3.86 billion by 2028, growing at a CAGR of 4.9% during the forecast period. This growth is largely attributed to the rising demand for quieter vehicles and stricter noise regulations in many countries.

Specifically for LS engines, which are popular in performance vehicles and aftermarket applications, the market for acoustic damping solutions is estimated to be around $150 million annually. This niche market is expected to grow at a faster rate than the overall automotive acoustic materials market, with a projected CAGR of 6.5% over the next five years.

The demand for quieter LS engines is driven by several factors. First, there's a growing trend among performance car enthusiasts who want the power of an LS engine without sacrificing comfort. Second, automotive manufacturers are increasingly focusing on noise, vibration, and harshness (NVH) reduction as a way to improve overall vehicle quality and customer satisfaction. Lastly, stricter noise regulations in urban areas and racetracks are pushing both OEMs and aftermarket suppliers to develop more effective acoustic damping solutions.

Market research indicates that consumers are willing to pay a premium for vehicles with reduced engine noise. A survey of luxury car buyers showed that 68% consider engine noise levels to be "very important" or "extremely important" in their purchasing decision. Furthermore, 42% of performance vehicle owners expressed interest in aftermarket solutions to reduce engine compartment noise.

The competitive landscape for acoustic damping solutions in LS engine compartments is diverse, with both large automotive suppliers and specialized aftermarket companies vying for market share. Key players include Autoneum, Faurecia, Adler Pelzer Group, and Röchling Group among OEM suppliers, while companies like Dynamat, Second Skin Audio, and Hushmat are prominent in the aftermarket sector.

In terms of regional distribution, North America dominates the market for LS engine acoustic damping solutions, accounting for approximately 60% of global demand. This is primarily due to the popularity of LS engines in American muscle cars and performance vehicles. Europe follows with a 25% market share, driven by high-end sports car manufacturers adopting LS engines or similar high-performance V8 configurations.

Current Acoustic Damping Challenges in LS Engines

The current acoustic damping challenges in LS engine compartments are multifaceted and require innovative solutions to meet increasingly stringent noise regulations and consumer expectations. One of the primary challenges is the need for more effective sound absorption materials that can withstand the harsh environment of an engine compartment. Traditional materials often degrade over time due to exposure to heat, oil, and vibrations, reducing their effectiveness in long-term noise reduction.

Another significant challenge is the limited space available for acoustic treatments within the engine compartment. As modern vehicles become more compact and efficient, engineers face the task of implementing effective sound dampening solutions without compromising the engine's performance or increasing the vehicle's weight. This spatial constraint necessitates the development of thinner, lighter, yet more effective acoustic materials.

The complexity of sound propagation within the engine compartment poses an additional challenge. LS engines, known for their high performance, generate a wide range of frequencies that require targeted damping solutions. The intricate geometry of the engine compartment, combined with various reflecting surfaces, creates a complex acoustic environment that is difficult to predict and control.

Furthermore, the integration of acoustic damping solutions with other engine components presents a significant challenge. Engineers must ensure that damping materials do not interfere with critical systems such as cooling, electrical, or fuel delivery. This requires a holistic approach to design and material selection that considers both acoustic performance and overall system compatibility.

The automotive industry's push towards electrification also impacts acoustic damping strategies for LS engines. As hybrid vehicles become more prevalent, engineers must address the unique noise characteristics of combined combustion and electric powertrains. This dual-source noise generation complicates the acoustic landscape and requires adaptive damping solutions that can effectively manage varying noise profiles.

Lastly, the cost-effectiveness of acoustic damping solutions remains a persistent challenge. Manufacturers are under pressure to implement high-performance noise reduction technologies while maintaining competitive pricing. This economic constraint drives the need for innovative, cost-efficient materials and manufacturing processes that can deliver superior acoustic performance without significantly increasing production costs.

Another significant challenge is the limited space available for acoustic treatments within the engine compartment. As modern vehicles become more compact and efficient, engineers face the task of implementing effective sound dampening solutions without compromising the engine's performance or increasing the vehicle's weight. This spatial constraint necessitates the development of thinner, lighter, yet more effective acoustic materials.

The complexity of sound propagation within the engine compartment poses an additional challenge. LS engines, known for their high performance, generate a wide range of frequencies that require targeted damping solutions. The intricate geometry of the engine compartment, combined with various reflecting surfaces, creates a complex acoustic environment that is difficult to predict and control.

Furthermore, the integration of acoustic damping solutions with other engine components presents a significant challenge. Engineers must ensure that damping materials do not interfere with critical systems such as cooling, electrical, or fuel delivery. This requires a holistic approach to design and material selection that considers both acoustic performance and overall system compatibility.

The automotive industry's push towards electrification also impacts acoustic damping strategies for LS engines. As hybrid vehicles become more prevalent, engineers must address the unique noise characteristics of combined combustion and electric powertrains. This dual-source noise generation complicates the acoustic landscape and requires adaptive damping solutions that can effectively manage varying noise profiles.

Lastly, the cost-effectiveness of acoustic damping solutions remains a persistent challenge. Manufacturers are under pressure to implement high-performance noise reduction technologies while maintaining competitive pricing. This economic constraint drives the need for innovative, cost-efficient materials and manufacturing processes that can deliver superior acoustic performance without significantly increasing production costs.

Existing Acoustic Damping Methods for LS Engines

01 Active noise control systems

Active noise control systems use electronic processing to analyze ambient sound and generate an 'anti-noise' signal to cancel out unwanted noise. These systems typically involve microphones, speakers, and digital signal processors to create destructive interference, effectively reducing noise levels in various environments.- Active noise control systems: Active noise control systems use electronic processing to analyze incoming sound waves and generate anti-noise signals to cancel out unwanted noise. These systems often employ microphones to detect ambient noise and speakers to produce cancellation waves, effectively reducing perceived noise levels in various environments.

- Acoustic damping materials and structures: Specialized materials and structures are designed to absorb or dissipate sound energy, reducing noise transmission. These can include porous materials, viscoelastic compounds, or engineered structures like honeycomb panels that convert sound energy into heat through friction or resonance, effectively dampening noise across a range of frequencies.

- Adaptive noise reduction algorithms: Advanced algorithms are developed to dynamically adjust noise reduction parameters based on real-time analysis of the acoustic environment. These adaptive systems can optimize performance for varying noise conditions, improving overall effectiveness in complex or changing soundscapes.

- Acoustic metamaterials for noise control: Innovative engineered materials with unique structural properties are designed to manipulate sound waves in ways not possible with conventional materials. These metamaterials can be tuned to block, absorb, or redirect specific frequencies of sound, offering new possibilities for targeted noise reduction in challenging applications.

- Integration of noise reduction in product design: Noise reduction techniques are incorporated directly into the design of products and systems, rather than as aftermarket solutions. This approach considers acoustic performance from the outset, leading to more effective and efficient noise control through optimized geometries, material selection, and component placement.

02 Acoustic damping materials and structures

Specialized materials and structures are designed to absorb or dissipate sound energy, reducing noise transmission. These can include porous materials, viscoelastic compounds, and engineered structures like honeycomb panels or multi-layer composites. Such materials and structures are often used in buildings, vehicles, and industrial equipment to minimize noise pollution.Expand Specific Solutions03 Adaptive noise reduction algorithms

Advanced algorithms are developed to dynamically adjust noise reduction parameters based on changing acoustic environments. These adaptive systems can analyze sound characteristics in real-time and optimize noise cancellation or suppression strategies accordingly, improving effectiveness across various conditions.Expand Specific Solutions04 Acoustic metamaterials for noise control

Engineered materials with unique acoustic properties are designed to manipulate sound waves in ways not possible with conventional materials. These metamaterials can be used to create acoustic cloaks, sound absorbers with exceptional performance, or highly directional sound barriers, offering innovative solutions for noise reduction in challenging environments.Expand Specific Solutions05 Integration of passive and active noise control techniques

Hybrid systems combining passive acoustic treatments with active noise control technologies are developed to achieve comprehensive noise reduction across a wide frequency range. This approach leverages the strengths of both methods, providing effective noise mitigation in complex acoustic environments such as aircraft cabins or industrial facilities.Expand Specific Solutions

Key Players in Automotive Acoustic Solutions

The acoustic damping technology for LS engine compartments is in a mature stage of development, with several major players competing in a well-established market. The industry is characterized by ongoing incremental improvements rather than disruptive innovations. Key companies like GM Global Technology Operations, Audi AG, and BMW are leading the way in refining noise reduction techniques for high-performance engines. The market size is substantial, driven by the premium automotive sector's demand for quieter, more refined powertrains. Technological advancements focus on lightweight materials and advanced sound absorption designs, with companies like Rolls-Royce and Bosch contributing specialized expertise in acoustic engineering and materials science.

GM Global Technology Operations LLC

Technical Solution: GM has developed advanced acoustic damping solutions for LS engine compartments, focusing on a multi-layered approach. Their system incorporates sound-absorbing materials, vibration isolators, and active noise control technology. The company has implemented a proprietary foam-based damping material that effectively absorbs high-frequency engine noise while remaining lightweight[1]. Additionally, GM has integrated smart damping mounts that use electromagnetic actuators to counteract engine vibrations in real-time, significantly reducing low-frequency noise transmission[3]. The system also includes strategically placed acoustic barriers and resonators to target specific frequencies associated with LS engine operation[5].

Strengths: Comprehensive noise reduction across a wide frequency range, lightweight solutions, and integration of active and passive damping technologies. Weaknesses: Potentially higher cost due to complex systems and the need for electronic control units for active components.

AUDI AG

Technical Solution: Audi has pioneered acoustic damping technologies for engine compartments, including those applicable to LS engines. Their approach combines advanced materials science with innovative design. Audi's system utilizes a sandwich construction of viscoelastic polymers and metallic layers, which provides excellent damping properties across a broad temperature range[2]. The company has also developed a novel spray-on damping material that can be precisely applied to complex geometries within the engine compartment, ensuring optimal coverage and weight distribution[4]. Furthermore, Audi has implemented active noise cancellation technology that uses the vehicle's audio system to generate counter-phase sound waves, effectively neutralizing low-frequency engine noise[6].

Strengths: Highly effective damping across various engine operating conditions, adaptable solutions for different vehicle models, and integration with existing vehicle systems. Weaknesses: Potential for increased complexity in manufacturing and maintenance processes.

Innovative Acoustic Materials and Designs

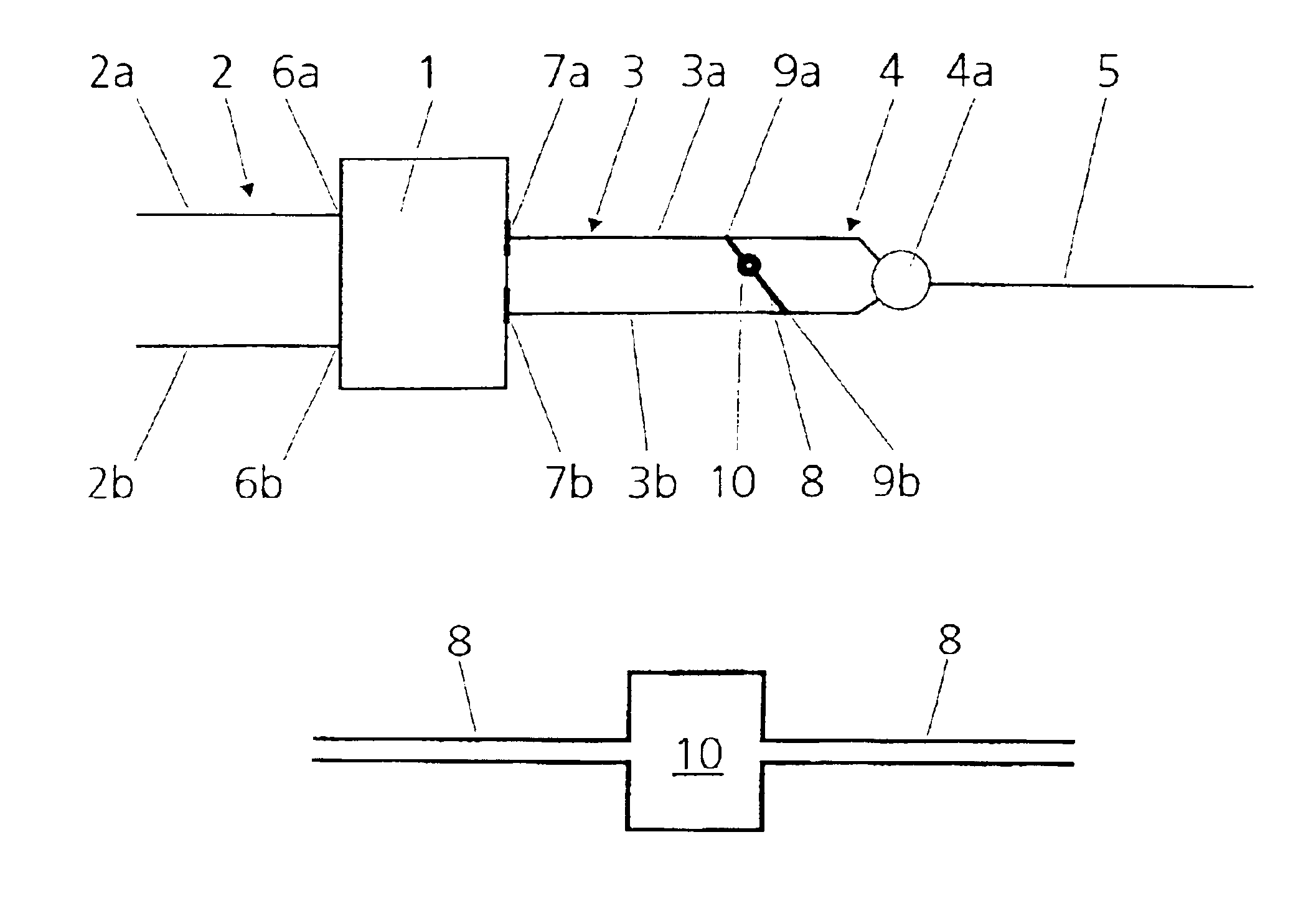

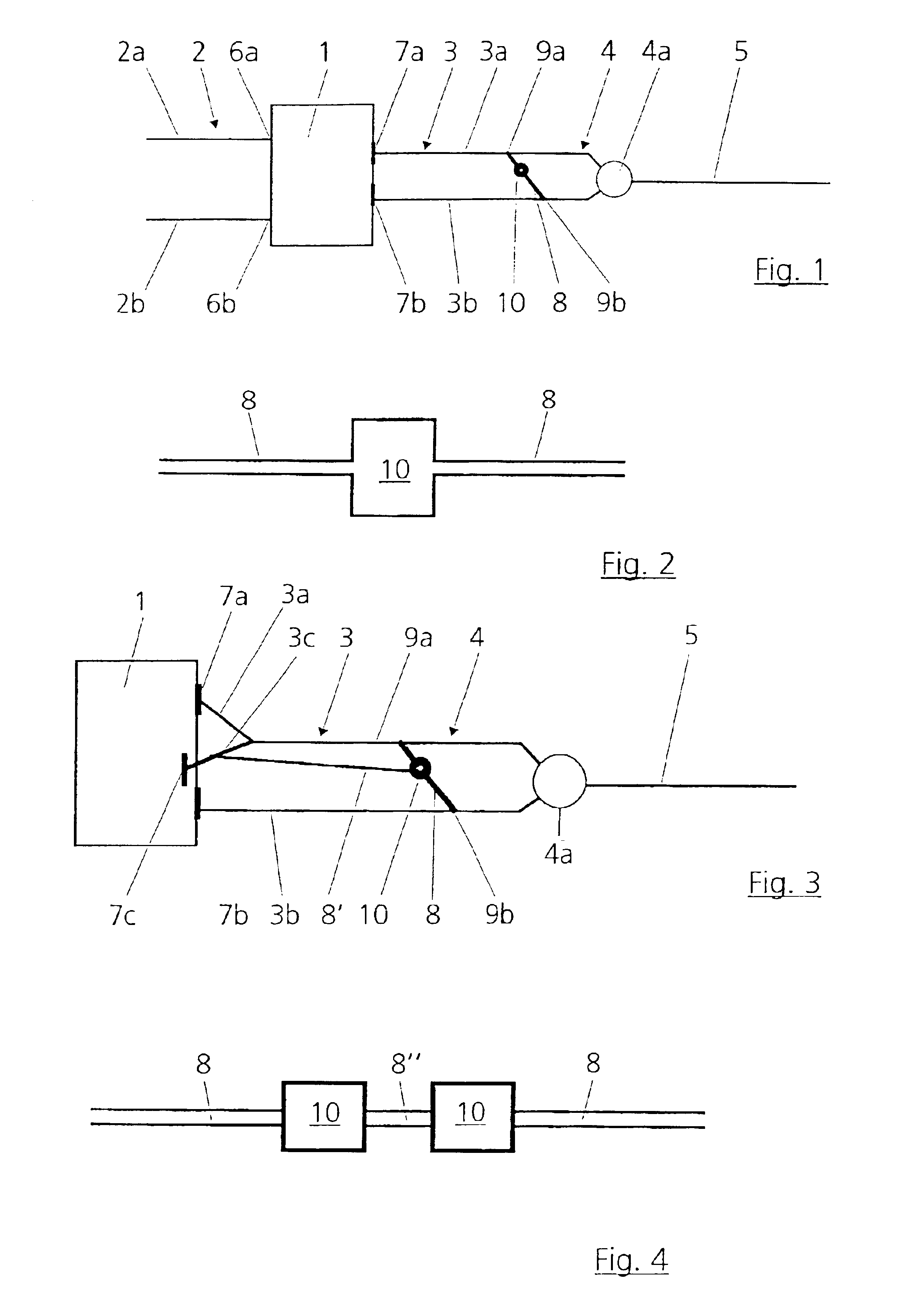

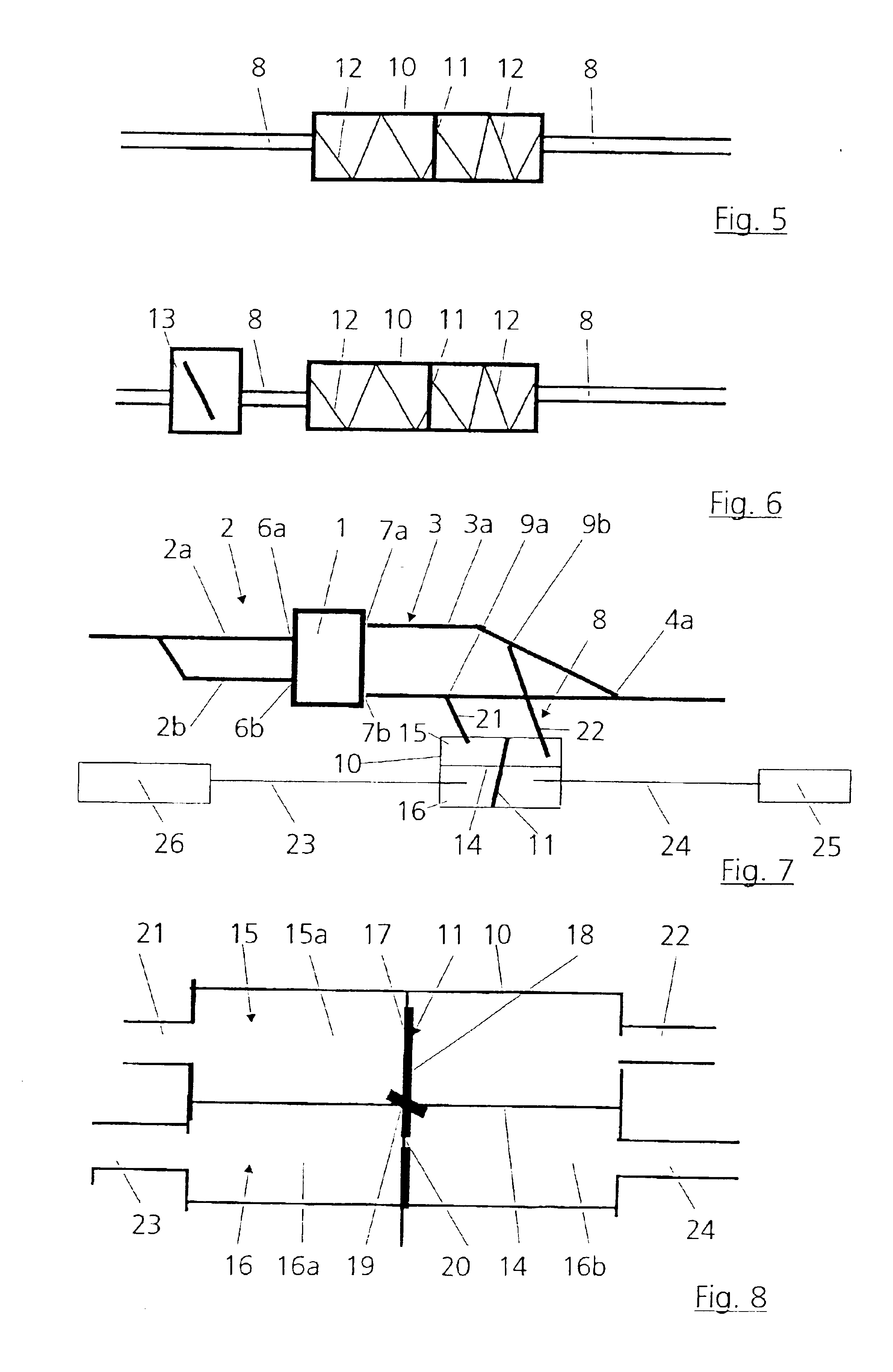

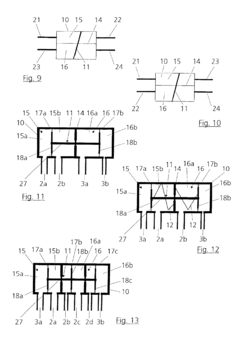

Device for noise structuring in a motor vehicle

PatentInactiveUS6932189B2

Innovation

- Acoustically linking gas-carrying lines of the internal combustion engine to vary intake and exhaust noise by amplifying or eliminating specific sound frequencies, using connecting lines and hollow bodies to create desired sound characteristics without exceeding permitted sound pressure levels.

Environmental Impact of Acoustic Materials

The environmental impact of acoustic materials used in LS engine compartments is a critical consideration in the advancement of acoustic damping technologies. These materials play a crucial role in reducing noise pollution and improving vehicle performance, but their production, use, and disposal can have significant environmental implications.

Traditional acoustic damping materials often contain petroleum-based components, which contribute to carbon emissions and resource depletion. However, recent advancements have led to the development of more sustainable alternatives. Bio-based acoustic materials, derived from renewable resources such as plant fibers and recycled materials, are gaining traction in the automotive industry. These eco-friendly options not only reduce the carbon footprint of vehicle production but also offer comparable or even superior acoustic performance.

The lifecycle assessment of acoustic materials reveals varying environmental impacts at different stages. During production, energy consumption and emissions associated with material synthesis and manufacturing processes are key factors. The use phase generally has minimal direct environmental impact, as acoustic materials are passive components. However, their influence on vehicle weight can affect fuel efficiency and, consequently, emissions over the vehicle's lifespan.

End-of-life considerations for acoustic materials are increasingly important. Traditional materials often end up in landfills, contributing to waste accumulation. In contrast, newer biodegradable or recyclable acoustic solutions offer more sustainable disposal options. Some advanced materials are designed for easy disassembly and recycling, aligning with circular economy principles and reducing overall environmental impact.

The durability and longevity of acoustic materials also play a role in their environmental footprint. Materials that maintain their acoustic properties over extended periods reduce the need for replacement, minimizing waste generation and resource consumption. Innovations in material science are focusing on enhancing the durability of eco-friendly acoustic solutions to match or exceed the lifespan of conventional options.

Water usage and pollution are additional environmental concerns in the production of acoustic materials. Some manufacturing processes require significant water inputs and may generate pollutants. Advanced water treatment and recycling systems in production facilities are being implemented to mitigate these impacts. Moreover, research is ongoing to develop acoustic materials with water-repellent properties, which can reduce maintenance needs and extend the material's effective lifespan.

As regulations on vehicle emissions and environmental standards become more stringent, the demand for environmentally friendly acoustic solutions is expected to grow. This trend is driving innovation in material science and manufacturing processes, aiming to create acoustic damping solutions that offer optimal performance while minimizing environmental impact throughout their lifecycle.

Traditional acoustic damping materials often contain petroleum-based components, which contribute to carbon emissions and resource depletion. However, recent advancements have led to the development of more sustainable alternatives. Bio-based acoustic materials, derived from renewable resources such as plant fibers and recycled materials, are gaining traction in the automotive industry. These eco-friendly options not only reduce the carbon footprint of vehicle production but also offer comparable or even superior acoustic performance.

The lifecycle assessment of acoustic materials reveals varying environmental impacts at different stages. During production, energy consumption and emissions associated with material synthesis and manufacturing processes are key factors. The use phase generally has minimal direct environmental impact, as acoustic materials are passive components. However, their influence on vehicle weight can affect fuel efficiency and, consequently, emissions over the vehicle's lifespan.

End-of-life considerations for acoustic materials are increasingly important. Traditional materials often end up in landfills, contributing to waste accumulation. In contrast, newer biodegradable or recyclable acoustic solutions offer more sustainable disposal options. Some advanced materials are designed for easy disassembly and recycling, aligning with circular economy principles and reducing overall environmental impact.

The durability and longevity of acoustic materials also play a role in their environmental footprint. Materials that maintain their acoustic properties over extended periods reduce the need for replacement, minimizing waste generation and resource consumption. Innovations in material science are focusing on enhancing the durability of eco-friendly acoustic solutions to match or exceed the lifespan of conventional options.

Water usage and pollution are additional environmental concerns in the production of acoustic materials. Some manufacturing processes require significant water inputs and may generate pollutants. Advanced water treatment and recycling systems in production facilities are being implemented to mitigate these impacts. Moreover, research is ongoing to develop acoustic materials with water-repellent properties, which can reduce maintenance needs and extend the material's effective lifespan.

As regulations on vehicle emissions and environmental standards become more stringent, the demand for environmentally friendly acoustic solutions is expected to grow. This trend is driving innovation in material science and manufacturing processes, aiming to create acoustic damping solutions that offer optimal performance while minimizing environmental impact throughout their lifecycle.

Cost-Benefit Analysis of Advanced Damping Solutions

The cost-benefit analysis of advanced damping solutions for LS engine compartments reveals a complex interplay between financial investment and performance gains. Initial implementation costs for cutting-edge acoustic damping technologies can be substantial, often ranging from $500 to $2,000 per vehicle, depending on the sophistication of the solution. These costs encompass materials, redesign efforts, and potential manufacturing process adjustments.

However, the benefits of advanced damping solutions extend beyond mere noise reduction. Enhanced acoustic comfort contributes significantly to perceived vehicle quality, potentially increasing customer satisfaction and brand loyalty. Studies indicate that vehicles with superior noise, vibration, and harshness (NVH) characteristics command price premiums of 2-5% in the luxury segment, translating to thousands of dollars per unit.

From a long-term perspective, the implementation of advanced damping solutions can lead to reduced warranty claims related to noise issues, estimated at savings of $100-$300 per vehicle over its lifetime. Additionally, improved acoustic performance may result in weight reduction compared to traditional damping methods, contributing to fuel efficiency gains of 0.5-1% – a modest but meaningful improvement in the context of stringent emissions regulations.

The return on investment (ROI) for these solutions varies depending on vehicle segment and production volume. In high-volume mainstream models, the break-even point typically occurs within 2-3 years of implementation. For luxury vehicles, where acoustic performance is a key differentiator, the ROI can be realized within the first year of production.

It's crucial to consider the scalability of advanced damping solutions. While initial costs may be high, economies of scale and learning curve effects can reduce per-unit costs by 15-25% over a 3-5 year period. This improvement in cost efficiency enhances the long-term value proposition of investing in acoustic damping technologies.

Lastly, the indirect benefits of advanced damping solutions should not be overlooked. These include potential improvements in structural integrity, thermal management, and overall vehicle dynamics. While challenging to quantify precisely, these ancillary benefits contribute to the holistic value of implementing advanced acoustic damping in LS engine compartments.

However, the benefits of advanced damping solutions extend beyond mere noise reduction. Enhanced acoustic comfort contributes significantly to perceived vehicle quality, potentially increasing customer satisfaction and brand loyalty. Studies indicate that vehicles with superior noise, vibration, and harshness (NVH) characteristics command price premiums of 2-5% in the luxury segment, translating to thousands of dollars per unit.

From a long-term perspective, the implementation of advanced damping solutions can lead to reduced warranty claims related to noise issues, estimated at savings of $100-$300 per vehicle over its lifetime. Additionally, improved acoustic performance may result in weight reduction compared to traditional damping methods, contributing to fuel efficiency gains of 0.5-1% – a modest but meaningful improvement in the context of stringent emissions regulations.

The return on investment (ROI) for these solutions varies depending on vehicle segment and production volume. In high-volume mainstream models, the break-even point typically occurs within 2-3 years of implementation. For luxury vehicles, where acoustic performance is a key differentiator, the ROI can be realized within the first year of production.

It's crucial to consider the scalability of advanced damping solutions. While initial costs may be high, economies of scale and learning curve effects can reduce per-unit costs by 15-25% over a 3-5 year period. This improvement in cost efficiency enhances the long-term value proposition of investing in acoustic damping technologies.

Lastly, the indirect benefits of advanced damping solutions should not be overlooked. These include potential improvements in structural integrity, thermal management, and overall vehicle dynamics. While challenging to quantify precisely, these ancillary benefits contribute to the holistic value of implementing advanced acoustic damping in LS engine compartments.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!