The Relationship Between Engine Downsizing and LS Engine Output

AUG 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Engine Downsizing and LS Output Background

Engine downsizing and LS (Luxury Sport) engine output have been at the forefront of automotive engineering discussions for the past few decades. This technological evolution stems from the increasing demand for fuel-efficient vehicles without compromising performance. The concept of engine downsizing involves reducing the engine's displacement while maintaining or even improving power output through advanced technologies.

The background of this relationship dates back to the 1970s when the oil crisis prompted automakers to seek more fuel-efficient solutions. However, it wasn't until the late 1990s and early 2000s that significant advancements in turbocharging, direct fuel injection, and variable valve timing allowed for effective engine downsizing without sacrificing performance.

LS engines, originally developed by General Motors, have played a crucial role in this technological progression. Introduced in 1997, the LS series represented a paradigm shift in V8 engine design, offering a compact, lightweight, and highly efficient platform. These engines became renowned for their ability to produce substantial power from relatively small displacements, aligning perfectly with the principles of engine downsizing.

The relationship between engine downsizing and LS engine output is characterized by a continuous push for higher specific output – the amount of power produced per liter of engine displacement. This drive has led to the development of advanced materials, improved combustion processes, and sophisticated engine management systems.

As environmental regulations became more stringent in the 21st century, the focus on engine downsizing intensified. Automakers began implementing technologies such as twin-scroll turbochargers, gasoline direct injection, and variable geometry turbochargers to extract maximum performance from smaller engines. The LS engine architecture proved to be highly adaptable to these technologies, allowing for significant power increases without substantial increases in displacement.

The evolution of this relationship has not been without challenges. Engineers have had to address issues such as turbo lag, thermal management, and durability concerns associated with highly stressed smaller engines. However, continuous advancements in materials science, computational fluid dynamics, and electronic control systems have helped overcome many of these obstacles.

Today, the relationship between engine downsizing and LS engine output continues to drive innovation in the automotive industry. Modern LS-based engines demonstrate remarkable efficiency and power density, often outperforming larger naturally aspirated engines while consuming less fuel. This trend is expected to continue as automakers strive to meet increasingly stringent emissions standards while satisfying consumer demands for performance and efficiency.

The background of this relationship dates back to the 1970s when the oil crisis prompted automakers to seek more fuel-efficient solutions. However, it wasn't until the late 1990s and early 2000s that significant advancements in turbocharging, direct fuel injection, and variable valve timing allowed for effective engine downsizing without sacrificing performance.

LS engines, originally developed by General Motors, have played a crucial role in this technological progression. Introduced in 1997, the LS series represented a paradigm shift in V8 engine design, offering a compact, lightweight, and highly efficient platform. These engines became renowned for their ability to produce substantial power from relatively small displacements, aligning perfectly with the principles of engine downsizing.

The relationship between engine downsizing and LS engine output is characterized by a continuous push for higher specific output – the amount of power produced per liter of engine displacement. This drive has led to the development of advanced materials, improved combustion processes, and sophisticated engine management systems.

As environmental regulations became more stringent in the 21st century, the focus on engine downsizing intensified. Automakers began implementing technologies such as twin-scroll turbochargers, gasoline direct injection, and variable geometry turbochargers to extract maximum performance from smaller engines. The LS engine architecture proved to be highly adaptable to these technologies, allowing for significant power increases without substantial increases in displacement.

The evolution of this relationship has not been without challenges. Engineers have had to address issues such as turbo lag, thermal management, and durability concerns associated with highly stressed smaller engines. However, continuous advancements in materials science, computational fluid dynamics, and electronic control systems have helped overcome many of these obstacles.

Today, the relationship between engine downsizing and LS engine output continues to drive innovation in the automotive industry. Modern LS-based engines demonstrate remarkable efficiency and power density, often outperforming larger naturally aspirated engines while consuming less fuel. This trend is expected to continue as automakers strive to meet increasingly stringent emissions standards while satisfying consumer demands for performance and efficiency.

Market Trends in Engine Efficiency

The automotive industry has been witnessing a significant shift towards engine downsizing and increased efficiency in recent years. This trend is driven by several factors, including stringent emissions regulations, consumer demand for fuel-efficient vehicles, and the need to reduce overall vehicle weight. As a result, manufacturers are increasingly focusing on developing smaller, more efficient engines that can deliver comparable or even superior performance to their larger counterparts.

One of the key market trends in engine efficiency is the widespread adoption of turbocharging technology. Turbochargers allow smaller engines to produce power outputs similar to larger naturally aspirated engines, while consuming less fuel and producing fewer emissions. This has led to a proliferation of small-displacement turbocharged engines across various vehicle segments, from compact cars to luxury vehicles.

Another notable trend is the integration of advanced materials and manufacturing techniques in engine design. Lightweight materials such as aluminum and carbon fiber are being used more extensively in engine components, reducing overall weight and improving efficiency. Additionally, precision manufacturing techniques like 3D printing are enabling the production of complex engine parts with optimized designs for better performance and fuel economy.

The market has also seen a growing interest in hybrid powertrains, which combine downsized internal combustion engines with electric motors. This approach allows for further reductions in engine size while maintaining or even improving overall vehicle performance. Mild hybrid systems, in particular, have gained traction as a cost-effective way to boost efficiency without the complexity of full hybrid powertrains.

In the context of LS engines, which are known for their large displacement and high power output, the market trends towards efficiency have led to interesting developments. While traditional LS engines are not typically associated with downsizing, manufacturers have been exploring ways to improve their efficiency without sacrificing performance. This includes the implementation of cylinder deactivation technology, which allows the engine to operate on fewer cylinders under light load conditions, thereby improving fuel economy.

Furthermore, the market has seen an increased focus on optimizing engine management systems and improving combustion efficiency. Advanced fuel injection systems, variable valve timing, and sophisticated engine control units are being employed to extract maximum performance and efficiency from engines of all sizes, including larger displacement units like the LS series.

The trend towards engine downsizing has also influenced the aftermarket and performance sectors. Enthusiasts and tuners are increasingly turning to forced induction solutions to boost the output of smaller engines, rather than relying solely on large displacement naturally aspirated engines. This shift has led to a growing market for aftermarket turbochargers, superchargers, and associated components designed to enhance the performance of downsized engines.

One of the key market trends in engine efficiency is the widespread adoption of turbocharging technology. Turbochargers allow smaller engines to produce power outputs similar to larger naturally aspirated engines, while consuming less fuel and producing fewer emissions. This has led to a proliferation of small-displacement turbocharged engines across various vehicle segments, from compact cars to luxury vehicles.

Another notable trend is the integration of advanced materials and manufacturing techniques in engine design. Lightweight materials such as aluminum and carbon fiber are being used more extensively in engine components, reducing overall weight and improving efficiency. Additionally, precision manufacturing techniques like 3D printing are enabling the production of complex engine parts with optimized designs for better performance and fuel economy.

The market has also seen a growing interest in hybrid powertrains, which combine downsized internal combustion engines with electric motors. This approach allows for further reductions in engine size while maintaining or even improving overall vehicle performance. Mild hybrid systems, in particular, have gained traction as a cost-effective way to boost efficiency without the complexity of full hybrid powertrains.

In the context of LS engines, which are known for their large displacement and high power output, the market trends towards efficiency have led to interesting developments. While traditional LS engines are not typically associated with downsizing, manufacturers have been exploring ways to improve their efficiency without sacrificing performance. This includes the implementation of cylinder deactivation technology, which allows the engine to operate on fewer cylinders under light load conditions, thereby improving fuel economy.

Furthermore, the market has seen an increased focus on optimizing engine management systems and improving combustion efficiency. Advanced fuel injection systems, variable valve timing, and sophisticated engine control units are being employed to extract maximum performance and efficiency from engines of all sizes, including larger displacement units like the LS series.

The trend towards engine downsizing has also influenced the aftermarket and performance sectors. Enthusiasts and tuners are increasingly turning to forced induction solutions to boost the output of smaller engines, rather than relying solely on large displacement naturally aspirated engines. This shift has led to a growing market for aftermarket turbochargers, superchargers, and associated components designed to enhance the performance of downsized engines.

Current Challenges in Engine Downsizing

Engine downsizing has become a prominent trend in automotive engineering, driven by the need for improved fuel efficiency and reduced emissions. However, this approach faces several significant challenges that engineers and manufacturers must overcome to maintain performance and reliability.

One of the primary challenges in engine downsizing is maintaining power output while reducing engine displacement. As engines become smaller, they typically produce less power, which can negatively impact vehicle performance. To compensate, manufacturers often employ forced induction systems, such as turbochargers or superchargers. While these systems can effectively boost power, they introduce additional complexity and potential reliability issues.

Thermal management presents another critical challenge in downsized engines. Smaller engines tend to generate more heat per unit of displacement, which can lead to increased wear, reduced efficiency, and potential component failure. Engineers must develop advanced cooling systems and materials to mitigate these thermal issues without significantly increasing engine weight or complexity.

Noise, vibration, and harshness (NVH) characteristics are also affected by engine downsizing. Smaller engines often operate at higher speeds to produce equivalent power, which can result in increased vibration and noise. This challenge requires innovative solutions in engine mounting, sound insulation, and powertrain design to maintain the level of comfort expected by consumers.

Durability and longevity concerns arise as downsized engines are pushed to their limits to match the performance of larger counterparts. Higher specific power outputs can lead to increased stress on engine components, potentially reducing engine life or requiring more frequent maintenance. Manufacturers must invest in advanced materials and manufacturing techniques to ensure long-term reliability.

The cost-effectiveness of engine downsizing technologies is another significant challenge. While smaller engines can offer fuel savings, the additional technologies required to maintain performance often increase production costs. Balancing these costs against potential fuel economy benefits is crucial for manufacturers to remain competitive in the market.

Emissions control in downsized engines presents unique challenges, particularly in real-world driving conditions. The frequent use of turbocharging can lead to increased particulate emissions during certain operating conditions. Meeting stringent emissions regulations while maintaining performance and efficiency requires sophisticated engine management systems and aftertreatment technologies.

One of the primary challenges in engine downsizing is maintaining power output while reducing engine displacement. As engines become smaller, they typically produce less power, which can negatively impact vehicle performance. To compensate, manufacturers often employ forced induction systems, such as turbochargers or superchargers. While these systems can effectively boost power, they introduce additional complexity and potential reliability issues.

Thermal management presents another critical challenge in downsized engines. Smaller engines tend to generate more heat per unit of displacement, which can lead to increased wear, reduced efficiency, and potential component failure. Engineers must develop advanced cooling systems and materials to mitigate these thermal issues without significantly increasing engine weight or complexity.

Noise, vibration, and harshness (NVH) characteristics are also affected by engine downsizing. Smaller engines often operate at higher speeds to produce equivalent power, which can result in increased vibration and noise. This challenge requires innovative solutions in engine mounting, sound insulation, and powertrain design to maintain the level of comfort expected by consumers.

Durability and longevity concerns arise as downsized engines are pushed to their limits to match the performance of larger counterparts. Higher specific power outputs can lead to increased stress on engine components, potentially reducing engine life or requiring more frequent maintenance. Manufacturers must invest in advanced materials and manufacturing techniques to ensure long-term reliability.

The cost-effectiveness of engine downsizing technologies is another significant challenge. While smaller engines can offer fuel savings, the additional technologies required to maintain performance often increase production costs. Balancing these costs against potential fuel economy benefits is crucial for manufacturers to remain competitive in the market.

Emissions control in downsized engines presents unique challenges, particularly in real-world driving conditions. The frequent use of turbocharging can lead to increased particulate emissions during certain operating conditions. Meeting stringent emissions regulations while maintaining performance and efficiency requires sophisticated engine management systems and aftertreatment technologies.

Downsizing Strategies for LS Engines

01 Engine control and optimization

LS engines employ advanced control systems to optimize performance and efficiency. This includes electronic throttle control, variable valve timing, and fuel injection management. These systems work together to adjust engine parameters in real-time, maximizing output while maintaining fuel efficiency and emissions compliance.- Engine performance optimization: LS engines can be optimized for improved output through various methods, including advanced fuel injection systems, turbocharging, and electronic control units. These technologies allow for precise control over fuel delivery, air intake, and combustion timing, resulting in increased power and efficiency.

- Exhaust system enhancements: Modifications to the exhaust system can significantly impact LS engine output. This includes the use of high-flow catalytic converters, performance mufflers, and optimized exhaust manifolds. These improvements reduce back pressure and allow the engine to expel exhaust gases more efficiently, leading to increased horsepower and torque.

- Intake system improvements: Enhancing the intake system of LS engines can boost output by increasing airflow. This may involve installing cold air intakes, high-flow air filters, and ported intake manifolds. These modifications allow the engine to draw in more air, resulting in improved combustion and increased power output.

- Engine management and tuning: Advanced engine management systems and tuning techniques play a crucial role in maximizing LS engine output. This includes custom ECU programming, adjusting fuel maps, and optimizing ignition timing. These strategies allow for fine-tuning of engine parameters to extract maximum performance while maintaining reliability.

- Internal engine modifications: Internal modifications to LS engines can significantly increase output. This may include installing high-performance camshafts, forged pistons, stronger connecting rods, and ported cylinder heads. These upgrades allow the engine to handle higher RPMs and increased cylinder pressures, resulting in greater power output.

02 Turbocharging and supercharging

Forced induction systems, such as turbochargers and superchargers, are used to increase the power output of LS engines. These systems compress the intake air, allowing more fuel to be burned and resulting in higher horsepower and torque. Advanced designs incorporate intercoolers and variable geometry turbos for improved efficiency across the RPM range.Expand Specific Solutions03 Cylinder deactivation technology

Some LS engines feature cylinder deactivation technology, which allows the engine to shut down a portion of its cylinders under light load conditions. This improves fuel efficiency without sacrificing the ability to produce high power output when needed. The system seamlessly transitions between full and partial cylinder operation based on driving conditions.Expand Specific Solutions04 Advanced materials and manufacturing

LS engines utilize lightweight, high-strength materials and advanced manufacturing techniques to improve performance and efficiency. This includes the use of aluminum alloys for engine blocks and heads, as well as precision machining and assembly processes. These advancements contribute to increased power output while reducing overall engine weight.Expand Specific Solutions05 Exhaust system optimization

LS engines benefit from optimized exhaust systems designed to improve power output and efficiency. This includes the use of high-flow catalytic converters, tuned exhaust manifolds, and variable exhaust systems. These components work together to reduce back pressure, improve scavenging, and enhance overall engine performance across the RPM range.Expand Specific Solutions

Key Players in Engine Manufacturing

The relationship between engine downsizing and LS engine output is at a mature stage in the automotive industry, with a significant market size driven by fuel efficiency demands and emissions regulations. The technology has evolved from experimental to widespread adoption, with major players like Honda Motor Co., Ltd., Toyota Motor Corp., and GM Global Technology Operations LLC leading the way. These companies have invested heavily in research and development, resulting in advanced downsized engines that maintain or even improve performance while reducing fuel consumption. The competitive landscape is intense, with other manufacturers like Volkswagen AG and BMW AG also making significant strides in this area, pushing the boundaries of engine efficiency and power output.

Toyota Motor Corp.

Technical Solution: Toyota's approach to engine downsizing is exemplified by its Dynamic Force Engine series. The 2.0L Dynamic Force Engine uses high-speed combustion technology, a variable control system, and a high compression ratio to achieve thermal efficiency of up to 40% in conventional vehicles and 41% in hybrid applications. This engine produces 169 horsepower and 151 lb-ft of torque, comparable to older, larger engines. Toyota also employs D-4S (Direct injection 4-stroke gasoline engine Superior version) technology, which combines direct and port fuel injection for optimal performance and efficiency across all operating conditions[9][10]. The company's hybrid systems further complement engine downsizing by allowing smaller engines to operate more frequently in their most efficient range.

Strengths: High thermal efficiency, successful integration with hybrid systems. Weaknesses: Conservative approach may result in less dramatic downsizing compared to some competitors.

GM Global Technology Operations LLC

Technical Solution: GM has developed a range of downsized engines, including the 2.7L Turbo engine for full-size trucks. This engine utilizes advanced technologies such as Active Fuel Management, continuously variable valve timing, and a high-pressure direct injection system. The engine delivers 310 horsepower and 348 lb-ft of torque, matching the output of larger V6 engines while improving fuel efficiency[1][2]. GM's approach focuses on combining turbocharging with advanced combustion techniques to maintain performance while reducing engine size and weight.

Strengths: Excellent power-to-displacement ratio, improved fuel efficiency, and reduced emissions. Weaknesses: Potential for increased complexity and higher production costs compared to naturally aspirated engines.

Innovative LS Engine Design Solutions

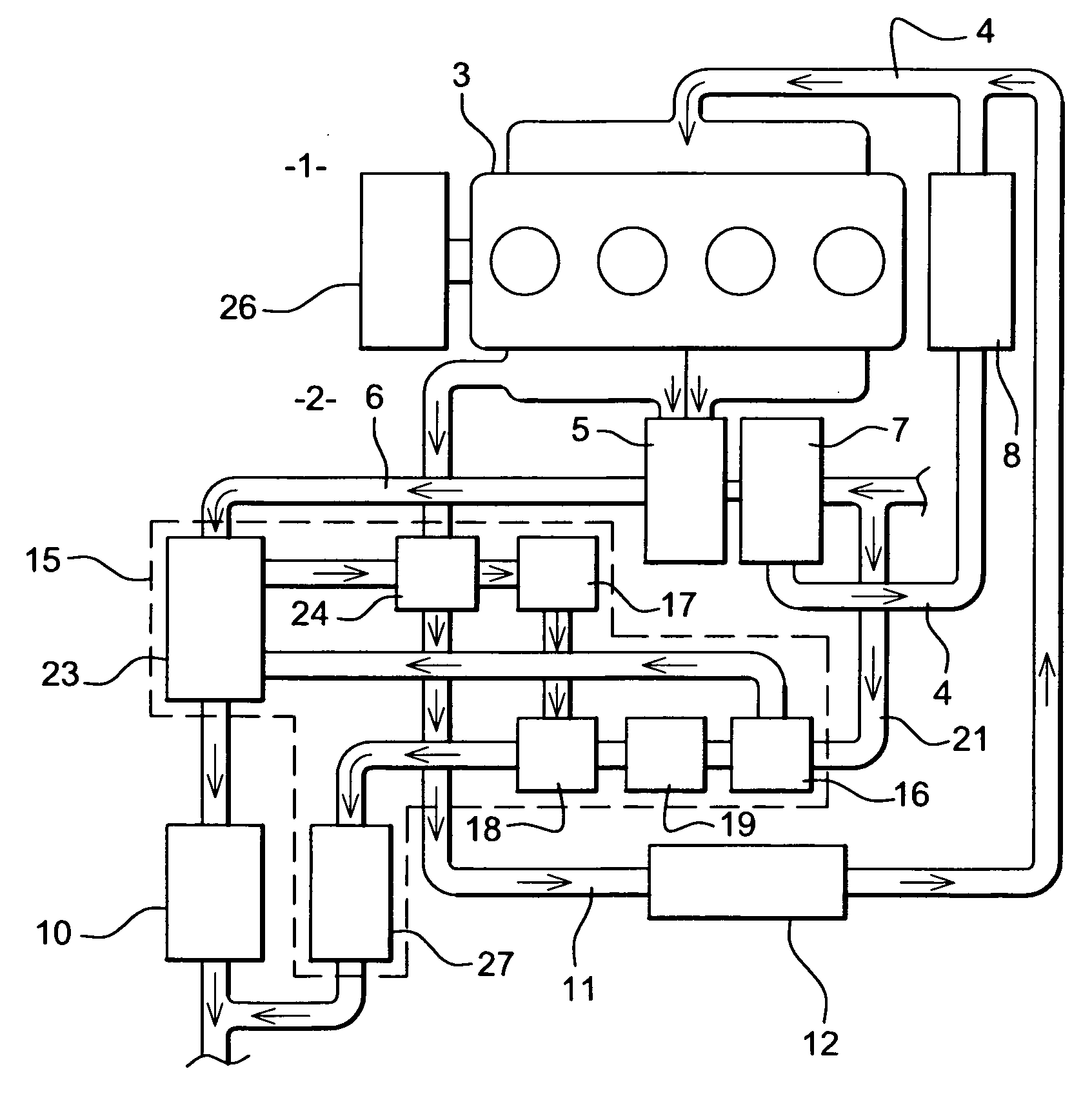

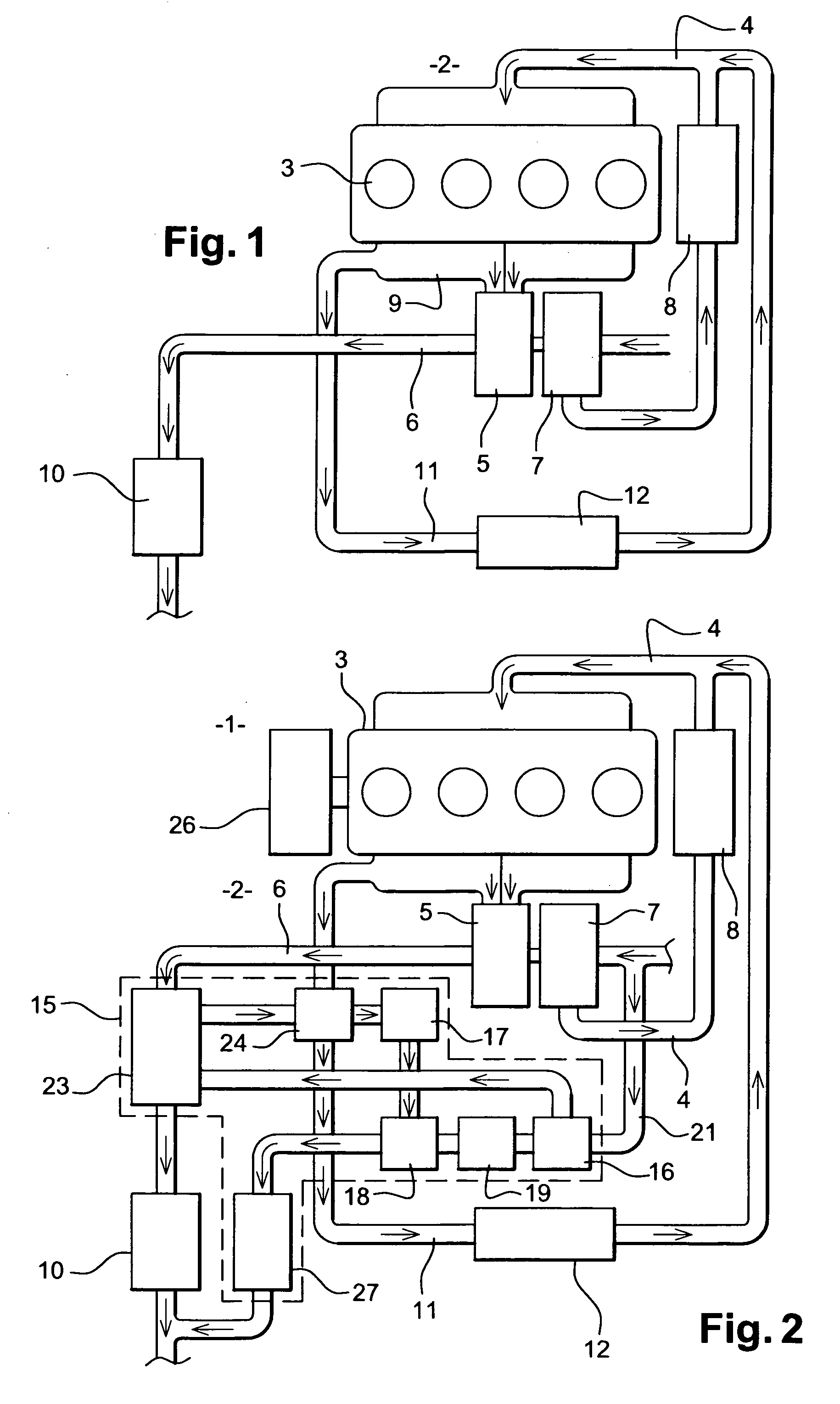

Power assembly, especially for an automotive vehicle

PatentActiveUS20110239643A1

Innovation

- Integration of a Brayton cycle system with a main internal combustion engine, utilizing a gas compressor, fuel burning heater, and turbine to provide additional power, where air is pressurized, heated, and expanded to extract work, efficiently utilizing waste heat without requiring additional cooling capacity.

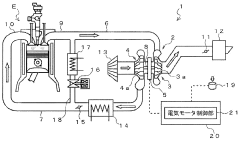

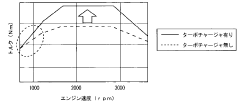

Turbocharge system

PatentWO2012057190A1

Innovation

- A turbocharger system incorporating a turbine in the exhaust and intake passages with an electric motor assisting the compressor, driven by an electric motor control unit to anticipate and mitigate shock loads by pre-rotating the turbocharger, ensuring sufficient air supply and torque generation.

Emissions Regulations Impact

Emissions regulations have played a significant role in shaping the relationship between engine downsizing and LS engine output. As governments worldwide have implemented increasingly stringent emissions standards, automotive manufacturers have been compelled to develop innovative solutions to meet these requirements while maintaining or improving engine performance.

The trend towards engine downsizing has been largely driven by the need to reduce fuel consumption and emissions. Smaller engines typically consume less fuel and produce fewer emissions due to their reduced displacement and weight. However, this presents a challenge for manufacturers seeking to maintain or increase power output, particularly in the case of LS (Luxury Sport) engines, which are known for their high performance capabilities.

To address this challenge, manufacturers have employed various technologies to enhance the efficiency and power output of downsized engines. Turbocharging and supercharging have become widespread, allowing smaller engines to produce power levels comparable to larger naturally aspirated engines. These forced induction systems compress the incoming air, enabling more fuel to be burned and thus increasing power output.

Direct fuel injection technology has also been instrumental in improving the efficiency and performance of downsized engines. By precisely controlling fuel delivery, direct injection systems optimize combustion, resulting in improved fuel economy and reduced emissions while maintaining or even increasing power output.

Variable valve timing and lift systems have further contributed to the ability of downsized engines to meet emissions regulations while delivering high performance. These systems allow for optimized engine breathing across a wide range of operating conditions, improving both efficiency and power output.

The impact of emissions regulations on engine downsizing and LS engine output has also led to the development of hybrid and mild hybrid systems. These technologies allow manufacturers to supplement the power output of downsized engines with electric motors, providing additional performance when needed while still meeting stringent emissions standards.

As emissions regulations continue to evolve, the relationship between engine downsizing and LS engine output is likely to become even more complex. Manufacturers will need to continue innovating to meet increasingly strict standards while satisfying consumer demand for high-performance vehicles. This may lead to further advancements in engine technology, as well as a potential shift towards alternative powertrains such as fully electric or hydrogen fuel cell systems in the luxury sport segment.

The trend towards engine downsizing has been largely driven by the need to reduce fuel consumption and emissions. Smaller engines typically consume less fuel and produce fewer emissions due to their reduced displacement and weight. However, this presents a challenge for manufacturers seeking to maintain or increase power output, particularly in the case of LS (Luxury Sport) engines, which are known for their high performance capabilities.

To address this challenge, manufacturers have employed various technologies to enhance the efficiency and power output of downsized engines. Turbocharging and supercharging have become widespread, allowing smaller engines to produce power levels comparable to larger naturally aspirated engines. These forced induction systems compress the incoming air, enabling more fuel to be burned and thus increasing power output.

Direct fuel injection technology has also been instrumental in improving the efficiency and performance of downsized engines. By precisely controlling fuel delivery, direct injection systems optimize combustion, resulting in improved fuel economy and reduced emissions while maintaining or even increasing power output.

Variable valve timing and lift systems have further contributed to the ability of downsized engines to meet emissions regulations while delivering high performance. These systems allow for optimized engine breathing across a wide range of operating conditions, improving both efficiency and power output.

The impact of emissions regulations on engine downsizing and LS engine output has also led to the development of hybrid and mild hybrid systems. These technologies allow manufacturers to supplement the power output of downsized engines with electric motors, providing additional performance when needed while still meeting stringent emissions standards.

As emissions regulations continue to evolve, the relationship between engine downsizing and LS engine output is likely to become even more complex. Manufacturers will need to continue innovating to meet increasingly strict standards while satisfying consumer demand for high-performance vehicles. This may lead to further advancements in engine technology, as well as a potential shift towards alternative powertrains such as fully electric or hydrogen fuel cell systems in the luxury sport segment.

Performance vs Efficiency Trade-offs

Engine downsizing and LS engine output present a complex relationship that highlights the trade-offs between performance and efficiency in modern automotive engineering. As manufacturers strive to meet increasingly stringent emissions regulations and fuel economy standards, the trend towards smaller, more efficient engines has gained momentum. However, this shift often comes at the expense of raw power output, particularly when compared to larger displacement engines like the LS series.

The primary advantage of engine downsizing lies in its potential for improved fuel efficiency and reduced emissions. Smaller engines typically have lower internal friction, decreased pumping losses, and reduced overall weight, all of which contribute to better fuel economy. Additionally, technologies such as turbocharging and direct fuel injection allow these compact powerplants to achieve power outputs that were once the domain of larger naturally aspirated engines.

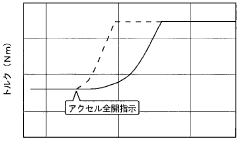

On the other hand, LS engines, known for their robust design and high power output, represent the traditional approach to achieving performance through displacement. These engines excel in delivering high torque across a wide RPM range, providing the kind of immediate throttle response and power delivery that enthusiasts often prefer. The simplicity of their pushrod design also contributes to their reliability and ease of maintenance.

The performance vs. efficiency trade-off becomes evident when comparing these two approaches. Downsized engines often struggle to match the low-end torque and linear power delivery of larger displacement engines like the LS series. While turbocharging can help bridge this gap, it introduces complexities such as turbo lag and heat management issues. Furthermore, highly stressed small engines may face durability concerns when pushed to produce power levels comparable to their larger counterparts.

Conversely, LS engines, while capable of impressive power outputs, generally lag behind in fuel efficiency, especially under partial load conditions. Their larger displacement and increased weight can also negatively impact vehicle dynamics and overall efficiency. However, recent advancements in cylinder deactivation and variable valve timing have helped mitigate some of these drawbacks, allowing LS engines to remain competitive in certain applications.

Ultimately, the choice between engine downsizing and LS-style engines depends on the specific requirements of the vehicle and its intended use. Performance-oriented vehicles may still favor the characteristics of larger displacement engines, while those prioritizing efficiency lean towards downsized options. As technology continues to evolve, the gap between these two approaches may narrow, potentially leading to solutions that combine the best aspects of both philosophies.

The primary advantage of engine downsizing lies in its potential for improved fuel efficiency and reduced emissions. Smaller engines typically have lower internal friction, decreased pumping losses, and reduced overall weight, all of which contribute to better fuel economy. Additionally, technologies such as turbocharging and direct fuel injection allow these compact powerplants to achieve power outputs that were once the domain of larger naturally aspirated engines.

On the other hand, LS engines, known for their robust design and high power output, represent the traditional approach to achieving performance through displacement. These engines excel in delivering high torque across a wide RPM range, providing the kind of immediate throttle response and power delivery that enthusiasts often prefer. The simplicity of their pushrod design also contributes to their reliability and ease of maintenance.

The performance vs. efficiency trade-off becomes evident when comparing these two approaches. Downsized engines often struggle to match the low-end torque and linear power delivery of larger displacement engines like the LS series. While turbocharging can help bridge this gap, it introduces complexities such as turbo lag and heat management issues. Furthermore, highly stressed small engines may face durability concerns when pushed to produce power levels comparable to their larger counterparts.

Conversely, LS engines, while capable of impressive power outputs, generally lag behind in fuel efficiency, especially under partial load conditions. Their larger displacement and increased weight can also negatively impact vehicle dynamics and overall efficiency. However, recent advancements in cylinder deactivation and variable valve timing have helped mitigate some of these drawbacks, allowing LS engines to remain competitive in certain applications.

Ultimately, the choice between engine downsizing and LS-style engines depends on the specific requirements of the vehicle and its intended use. Performance-oriented vehicles may still favor the characteristics of larger displacement engines, while those prioritizing efficiency lean towards downsized options. As technology continues to evolve, the gap between these two approaches may narrow, potentially leading to solutions that combine the best aspects of both philosophies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!