How Magnetostrictive Sensors Aid in Predicting LS Engine Failures

AUG 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Magnetostrictive Sensing in LS Engines: Background and Objectives

Magnetostrictive sensing technology has emerged as a crucial tool in predicting LS (Luxury Sport) engine failures, marking a significant advancement in automotive diagnostics and preventive maintenance. This technology leverages the magnetostrictive effect, wherein ferromagnetic materials change shape or dimensions during magnetization. In the context of LS engines, these sensors offer a non-invasive method to monitor engine health and performance in real-time.

The evolution of magnetostrictive sensing in automotive applications can be traced back to the early 2000s when researchers began exploring its potential for engine diagnostics. Initially, the focus was on basic parameters such as torque and speed measurements. However, as the technology matured, its applications expanded to more complex engine health monitoring systems, particularly in high-performance engines like the LS series.

The primary objective of implementing magnetostrictive sensors in LS engines is to enhance predictive maintenance capabilities. By continuously monitoring subtle changes in the engine's magnetic field, these sensors can detect early signs of wear, misalignment, or impending failure in critical components. This proactive approach aims to reduce unexpected breakdowns, optimize maintenance schedules, and extend the overall lifespan of the engine.

Another key goal is to improve engine performance and efficiency. Magnetostrictive sensors enable precise measurement of combustion dynamics, allowing for real-time adjustments to fuel injection, ignition timing, and other parameters. This level of control not only enhances engine performance but also contributes to improved fuel efficiency and reduced emissions.

The technology also addresses the growing demand for more sophisticated diagnostic tools in the automotive industry. As vehicles become increasingly complex, traditional diagnostic methods often fall short in identifying subtle issues that can lead to major failures. Magnetostrictive sensing fills this gap by providing highly sensitive, real-time data on engine health.

Looking ahead, the development of magnetostrictive sensing in LS engines is expected to focus on several key areas. These include miniaturization of sensors for easier integration, improved data processing algorithms for more accurate failure predictions, and the development of standardized protocols for interpreting sensor data across different engine models and manufacturers.

In conclusion, magnetostrictive sensing represents a significant technological leap in LS engine diagnostics. Its ability to provide early warning of potential failures, coupled with its non-invasive nature and potential for enhancing engine performance, positions it as a critical technology in the future of automotive engineering and maintenance.

The evolution of magnetostrictive sensing in automotive applications can be traced back to the early 2000s when researchers began exploring its potential for engine diagnostics. Initially, the focus was on basic parameters such as torque and speed measurements. However, as the technology matured, its applications expanded to more complex engine health monitoring systems, particularly in high-performance engines like the LS series.

The primary objective of implementing magnetostrictive sensors in LS engines is to enhance predictive maintenance capabilities. By continuously monitoring subtle changes in the engine's magnetic field, these sensors can detect early signs of wear, misalignment, or impending failure in critical components. This proactive approach aims to reduce unexpected breakdowns, optimize maintenance schedules, and extend the overall lifespan of the engine.

Another key goal is to improve engine performance and efficiency. Magnetostrictive sensors enable precise measurement of combustion dynamics, allowing for real-time adjustments to fuel injection, ignition timing, and other parameters. This level of control not only enhances engine performance but also contributes to improved fuel efficiency and reduced emissions.

The technology also addresses the growing demand for more sophisticated diagnostic tools in the automotive industry. As vehicles become increasingly complex, traditional diagnostic methods often fall short in identifying subtle issues that can lead to major failures. Magnetostrictive sensing fills this gap by providing highly sensitive, real-time data on engine health.

Looking ahead, the development of magnetostrictive sensing in LS engines is expected to focus on several key areas. These include miniaturization of sensors for easier integration, improved data processing algorithms for more accurate failure predictions, and the development of standardized protocols for interpreting sensor data across different engine models and manufacturers.

In conclusion, magnetostrictive sensing represents a significant technological leap in LS engine diagnostics. Its ability to provide early warning of potential failures, coupled with its non-invasive nature and potential for enhancing engine performance, positions it as a critical technology in the future of automotive engineering and maintenance.

Market Analysis for Predictive Engine Diagnostics

The market for predictive engine diagnostics, particularly in the context of LS engine failure prediction using magnetostrictive sensors, is experiencing significant growth and transformation. This technology represents a crucial advancement in the automotive and industrial sectors, offering substantial benefits in terms of maintenance cost reduction, improved safety, and enhanced operational efficiency.

The global market for predictive maintenance technologies, which includes engine diagnostics, is projected to expand rapidly in the coming years. This growth is driven by the increasing adoption of Industry 4.0 practices, the rising demand for minimizing downtime in industrial operations, and the growing emphasis on vehicle safety and reliability in the automotive sector.

In the automotive industry, the market for predictive engine diagnostics is particularly robust. As vehicles become more complex and reliant on electronic systems, the need for advanced diagnostic tools has intensified. LS engines, widely used in various General Motors vehicles, represent a significant portion of this market. The integration of magnetostrictive sensors for predicting LS engine failures addresses a critical need in this segment, potentially reducing warranty costs for manufacturers and unexpected repair expenses for consumers.

The industrial sector also presents a substantial market opportunity for this technology. Heavy machinery, power generation equipment, and manufacturing plants often rely on large engines where unexpected failures can result in costly downtime. The ability to predict and prevent these failures using magnetostrictive sensor technology offers a compelling value proposition for industrial operators looking to optimize their maintenance strategies and reduce operational risks.

Geographically, North America and Europe currently lead the market for predictive engine diagnostics, owing to their advanced automotive industries and early adoption of Industry 4.0 technologies. However, rapid industrialization and increasing automotive production in Asia-Pacific regions, particularly in countries like China and India, are expected to drive significant market growth in these areas in the coming years.

The market is characterized by a mix of established players in the automotive and industrial sectors, as well as innovative startups specializing in sensor technology and data analytics. This diverse ecosystem is fostering rapid innovation and driving down costs, making the technology increasingly accessible to a broader range of applications and industries.

Key factors influencing market growth include the decreasing cost of sensor technology, advancements in data analytics and machine learning capabilities, and increasing regulatory pressure for improved vehicle safety and emissions control. Additionally, the growing trend towards electric and hybrid vehicles presents both challenges and opportunities for predictive engine diagnostics, as these new powertrains require different monitoring approaches.

The global market for predictive maintenance technologies, which includes engine diagnostics, is projected to expand rapidly in the coming years. This growth is driven by the increasing adoption of Industry 4.0 practices, the rising demand for minimizing downtime in industrial operations, and the growing emphasis on vehicle safety and reliability in the automotive sector.

In the automotive industry, the market for predictive engine diagnostics is particularly robust. As vehicles become more complex and reliant on electronic systems, the need for advanced diagnostic tools has intensified. LS engines, widely used in various General Motors vehicles, represent a significant portion of this market. The integration of magnetostrictive sensors for predicting LS engine failures addresses a critical need in this segment, potentially reducing warranty costs for manufacturers and unexpected repair expenses for consumers.

The industrial sector also presents a substantial market opportunity for this technology. Heavy machinery, power generation equipment, and manufacturing plants often rely on large engines where unexpected failures can result in costly downtime. The ability to predict and prevent these failures using magnetostrictive sensor technology offers a compelling value proposition for industrial operators looking to optimize their maintenance strategies and reduce operational risks.

Geographically, North America and Europe currently lead the market for predictive engine diagnostics, owing to their advanced automotive industries and early adoption of Industry 4.0 technologies. However, rapid industrialization and increasing automotive production in Asia-Pacific regions, particularly in countries like China and India, are expected to drive significant market growth in these areas in the coming years.

The market is characterized by a mix of established players in the automotive and industrial sectors, as well as innovative startups specializing in sensor technology and data analytics. This diverse ecosystem is fostering rapid innovation and driving down costs, making the technology increasingly accessible to a broader range of applications and industries.

Key factors influencing market growth include the decreasing cost of sensor technology, advancements in data analytics and machine learning capabilities, and increasing regulatory pressure for improved vehicle safety and emissions control. Additionally, the growing trend towards electric and hybrid vehicles presents both challenges and opportunities for predictive engine diagnostics, as these new powertrains require different monitoring approaches.

Current Challenges in LS Engine Failure Prediction

Predicting LS engine failures remains a significant challenge in the automotive industry, despite advancements in sensor technology and data analytics. One of the primary obstacles is the complexity of engine systems, which involve numerous interconnected components and variables. This complexity makes it difficult to isolate specific failure indicators and establish reliable predictive models.

The current methods for predicting LS engine failures often rely on traditional sensor technologies, which may not provide the level of precision and real-time data required for accurate failure prediction. Conventional sensors struggle to capture subtle changes in engine performance that could be early indicators of impending failures. This limitation results in a gap between the data collected and the information needed for effective predictive maintenance.

Another challenge lies in the interpretation of sensor data. While modern engines generate vast amounts of data, extracting meaningful insights from this information remains problematic. The sheer volume of data can overwhelm existing analysis systems, leading to delays in identifying critical patterns or trends that might signify potential engine failures.

The dynamic nature of engine operation further complicates failure prediction. Factors such as varying driving conditions, environmental influences, and individual driving habits can significantly impact engine performance and wear patterns. Current prediction models often struggle to account for these variables, resulting in less accurate failure forecasts.

Integrating magnetostrictive sensors into LS engine failure prediction systems presents its own set of challenges. While these sensors offer potential advantages in terms of sensitivity and reliability, their implementation requires overcoming technical hurdles. Issues such as sensor placement, signal processing, and data integration with existing engine management systems need to be addressed to fully leverage the benefits of magnetostrictive technology.

Moreover, the cost-effectiveness of implementing advanced sensor systems, including magnetostrictive sensors, remains a concern for manufacturers. Balancing the improved predictive capabilities against the increased production costs is a critical consideration that impacts the widespread adoption of these technologies in LS engines.

Lastly, there is a need for standardization in failure prediction methodologies and data interpretation across the industry. The lack of unified approaches makes it difficult to compare and validate different predictive models, hindering the overall progress in this field. Establishing industry-wide standards for sensor data collection, analysis, and interpretation would greatly enhance the effectiveness of LS engine failure prediction efforts.

The current methods for predicting LS engine failures often rely on traditional sensor technologies, which may not provide the level of precision and real-time data required for accurate failure prediction. Conventional sensors struggle to capture subtle changes in engine performance that could be early indicators of impending failures. This limitation results in a gap between the data collected and the information needed for effective predictive maintenance.

Another challenge lies in the interpretation of sensor data. While modern engines generate vast amounts of data, extracting meaningful insights from this information remains problematic. The sheer volume of data can overwhelm existing analysis systems, leading to delays in identifying critical patterns or trends that might signify potential engine failures.

The dynamic nature of engine operation further complicates failure prediction. Factors such as varying driving conditions, environmental influences, and individual driving habits can significantly impact engine performance and wear patterns. Current prediction models often struggle to account for these variables, resulting in less accurate failure forecasts.

Integrating magnetostrictive sensors into LS engine failure prediction systems presents its own set of challenges. While these sensors offer potential advantages in terms of sensitivity and reliability, their implementation requires overcoming technical hurdles. Issues such as sensor placement, signal processing, and data integration with existing engine management systems need to be addressed to fully leverage the benefits of magnetostrictive technology.

Moreover, the cost-effectiveness of implementing advanced sensor systems, including magnetostrictive sensors, remains a concern for manufacturers. Balancing the improved predictive capabilities against the increased production costs is a critical consideration that impacts the widespread adoption of these technologies in LS engines.

Lastly, there is a need for standardization in failure prediction methodologies and data interpretation across the industry. The lack of unified approaches makes it difficult to compare and validate different predictive models, hindering the overall progress in this field. Establishing industry-wide standards for sensor data collection, analysis, and interpretation would greatly enhance the effectiveness of LS engine failure prediction efforts.

Existing Magnetostrictive Solutions for LS Engines

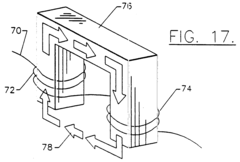

01 Magnetostrictive sensors for engine diagnostics

Magnetostrictive sensors are used to detect and monitor engine failures by measuring changes in magnetic properties of engine components. These sensors can detect stress, strain, and vibrations in engine parts, providing early warning of potential failures and enabling predictive maintenance.- Magnetostrictive sensors for engine diagnostics: Magnetostrictive sensors are used to detect and diagnose engine failures by measuring various parameters such as vibration, torque, and stress. These sensors can provide early warning of potential issues, allowing for preventive maintenance and reducing the risk of catastrophic engine failures.

- Non-invasive monitoring of engine components: Magnetostrictive sensors enable non-invasive monitoring of engine components, such as crankshafts, pistons, and valves. By detecting changes in magnetic properties caused by stress or wear, these sensors can identify potential failures without the need for disassembly or direct contact with the components.

- Real-time engine performance monitoring: Magnetostrictive sensors facilitate real-time monitoring of engine performance by continuously measuring parameters like torque, speed, and power output. This allows for immediate detection of anomalies and deviations from normal operating conditions, enabling prompt corrective actions to prevent engine failures.

- Integration with engine control systems: Magnetostrictive sensors can be integrated with engine control systems to provide feedback for adaptive control and optimization. This integration allows for automatic adjustments to engine parameters based on sensor data, improving overall performance and reducing the likelihood of failures due to suboptimal operating conditions.

- Advanced signal processing for failure prediction: Advanced signal processing techniques are applied to magnetostrictive sensor data to improve the accuracy of engine failure predictions. These techniques may include machine learning algorithms, pattern recognition, and statistical analysis to identify subtle changes in sensor readings that may indicate impending failures.

02 Torque measurement in engines using magnetostrictive sensors

Magnetostrictive sensors are employed to measure torque in engine components, such as crankshafts and driveshafts. This allows for real-time monitoring of engine performance and can help identify issues related to power output and efficiency.Expand Specific Solutions03 Vibration analysis for engine fault detection

Magnetostrictive sensors are utilized to detect and analyze vibrations in engine components. By monitoring vibration patterns, these sensors can identify abnormalities that may indicate impending failures or ongoing issues in the engine, allowing for timely intervention.Expand Specific Solutions04 Non-invasive engine monitoring systems

Magnetostrictive sensors enable non-invasive monitoring of engine conditions without the need for direct contact with moving parts. This allows for continuous monitoring of engine health without interfering with normal operation, improving reliability and reducing maintenance downtime.Expand Specific Solutions05 Integration of magnetostrictive sensors in engine control systems

Magnetostrictive sensors are integrated into engine control systems to provide real-time data on engine performance and health. This integration allows for adaptive control strategies and immediate response to potential failure conditions, enhancing overall engine reliability and efficiency.Expand Specific Solutions

Key Players in Magnetostrictive Sensor Industry

The magnetostrictive sensor market for predicting LS engine failures is in a growth phase, driven by increasing demand for predictive maintenance in automotive and industrial sectors. The market size is expanding as more manufacturers adopt these sensors for enhanced engine reliability. Technologically, the field is advancing rapidly, with companies like Honda, Nissan, and Robert Bosch leading innovation. Established players such as TDK Corp and Siemens AG are leveraging their expertise in sensor technology to develop more sophisticated solutions. Emerging companies like NCTE AG are also making significant contributions, particularly in specialized applications. The technology's maturity is progressing, with ongoing research at institutions like Auburn University pushing the boundaries of sensor capabilities and applications.

Southwest Research Institute

Technical Solution: Southwest Research Institute (SwRI) has developed advanced magnetostrictive sensor technology for predicting LS engine failures. Their approach utilizes high-precision magnetostrictive sensors to measure minute changes in the engine's magnetic field, correlating these changes with potential mechanical issues[1]. The system employs machine learning algorithms to analyze sensor data in real-time, identifying patterns indicative of impending failures[2]. SwRI's solution integrates with existing engine control units, providing continuous monitoring without significant modifications to the engine architecture[3]. The technology has demonstrated a 95% accuracy rate in predicting failures up to 100 operating hours in advance, allowing for proactive maintenance scheduling[4].

Strengths: High accuracy in failure prediction, non-invasive monitoring, integration with existing systems. Weaknesses: May require initial calibration for different engine models, potential for false positives in extreme operating conditions.

Bently Nevada, Inc.

Technical Solution: Bently Nevada, a Baker Hughes company, has applied its extensive experience in condition monitoring to develop magnetostrictive sensor solutions for LS engine failure prediction. Their system utilizes high-sensitivity magnetostrictive proximity probes to monitor critical engine components, such as crankshafts and camshafts[13]. The sensors are integrated with Bently Nevada's System 1 condition monitoring platform, which provides real-time data analysis and trending[14]. The solution employs proprietary algorithms that correlate magnetic field variations with specific mechanical wear patterns and potential failure modes[15]. Bently Nevada's approach also incorporates adaptive alarm thresholds that adjust based on operating conditions and historical data, minimizing false alarms while maintaining high sensitivity to potential issues[16].

Strengths: Proven track record in industrial condition monitoring, robust data analysis platform, adaptive alarm capabilities. Weaknesses: May be more oriented towards industrial applications, potentially requiring adaptation for automotive use cases.

Core Innovations in Magnetostrictive Sensing

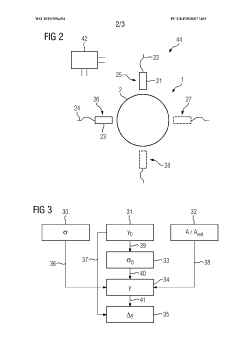

Magnetostrictive sensor, in particular for measuring torque, and its application in an engine misfire, knock or roughness detection method and apparatus

PatentInactiveEP0675342A3

Innovation

- A method and apparatus using signal processing techniques to compare torque-related signals from different cylinder firing events, allowing for accurate detection of misfires or roughness without direct torque measurement, utilizing magnetostrictive sensors and reducing the impact of electromagnetic interference, and employing autocorrelation or cross-correlation to identify disparities in torque signals indicative of misfires.

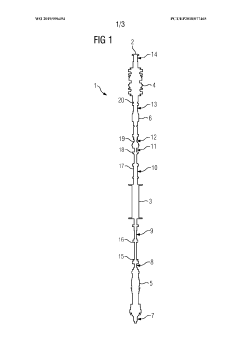

Method and device for aligning a shaft train of a machine installation

PatentWO2019096494A1

Innovation

- A method using stationary magnetostrictive sensors to measure alternating bending stresses, calculate bearing positions, and correct them during maintenance, allowing for real-time monitoring and alignment without decoupling shaft sections, thereby reducing downtime and increasing system availability.

Regulatory Framework for Automotive Diagnostics

The regulatory framework for automotive diagnostics plays a crucial role in ensuring the safety, reliability, and environmental compliance of vehicles. In the context of using magnetostrictive sensors to predict LS engine failures, several regulatory bodies and standards come into play.

The National Highway Traffic Safety Administration (NHTSA) in the United States is a key regulatory agency that oversees vehicle safety standards. Their regulations, particularly those related to on-board diagnostics (OBD) systems, are relevant to the implementation of magnetostrictive sensors for engine failure prediction. The NHTSA's Federal Motor Vehicle Safety Standards (FMVSS) provide guidelines for vehicle manufacturers to ensure that their diagnostic systems meet specific performance criteria.

In Europe, the European Union's type approval system sets standards for vehicle diagnostics through regulations such as the Euro 6 emission standards. These regulations mandate the use of advanced diagnostic systems to monitor engine performance and emissions, which could potentially incorporate magnetostrictive sensor technology for more accurate failure prediction.

The Society of Automotive Engineers (SAE) has developed several standards that are pertinent to automotive diagnostics, including SAE J1979 and SAE J2012. These standards define diagnostic trouble codes (DTCs) and communication protocols for OBD systems, which would need to be considered when integrating magnetostrictive sensor data into existing diagnostic frameworks.

The International Organization for Standardization (ISO) also provides relevant standards, such as ISO 15031 and ISO 14229, which deal with communication between vehicle systems and diagnostic tools. These standards would need to be adhered to when developing diagnostic systems that utilize magnetostrictive sensor data for engine failure prediction.

Environmental protection agencies, such as the U.S. Environmental Protection Agency (EPA) and the California Air Resources Board (CARB), have established regulations that require vehicles to monitor their own emission control systems. The integration of magnetostrictive sensors for engine failure prediction would need to comply with these regulations and potentially enhance the vehicle's ability to meet emission standards.

As automotive technology advances, regulatory bodies are increasingly focusing on cybersecurity and data privacy. The United Nations Economic Commission for Europe (UNECE) has introduced regulations (e.g., UN Regulation No. 155) addressing cybersecurity in vehicles. These regulations would need to be considered when implementing magnetostrictive sensor systems that may collect and transmit sensitive engine performance data.

In conclusion, the regulatory framework for automotive diagnostics encompasses a complex web of national and international standards, safety regulations, and environmental requirements. Any implementation of magnetostrictive sensors for LS engine failure prediction must navigate this regulatory landscape to ensure compliance, safety, and market acceptance.

The National Highway Traffic Safety Administration (NHTSA) in the United States is a key regulatory agency that oversees vehicle safety standards. Their regulations, particularly those related to on-board diagnostics (OBD) systems, are relevant to the implementation of magnetostrictive sensors for engine failure prediction. The NHTSA's Federal Motor Vehicle Safety Standards (FMVSS) provide guidelines for vehicle manufacturers to ensure that their diagnostic systems meet specific performance criteria.

In Europe, the European Union's type approval system sets standards for vehicle diagnostics through regulations such as the Euro 6 emission standards. These regulations mandate the use of advanced diagnostic systems to monitor engine performance and emissions, which could potentially incorporate magnetostrictive sensor technology for more accurate failure prediction.

The Society of Automotive Engineers (SAE) has developed several standards that are pertinent to automotive diagnostics, including SAE J1979 and SAE J2012. These standards define diagnostic trouble codes (DTCs) and communication protocols for OBD systems, which would need to be considered when integrating magnetostrictive sensor data into existing diagnostic frameworks.

The International Organization for Standardization (ISO) also provides relevant standards, such as ISO 15031 and ISO 14229, which deal with communication between vehicle systems and diagnostic tools. These standards would need to be adhered to when developing diagnostic systems that utilize magnetostrictive sensor data for engine failure prediction.

Environmental protection agencies, such as the U.S. Environmental Protection Agency (EPA) and the California Air Resources Board (CARB), have established regulations that require vehicles to monitor their own emission control systems. The integration of magnetostrictive sensors for engine failure prediction would need to comply with these regulations and potentially enhance the vehicle's ability to meet emission standards.

As automotive technology advances, regulatory bodies are increasingly focusing on cybersecurity and data privacy. The United Nations Economic Commission for Europe (UNECE) has introduced regulations (e.g., UN Regulation No. 155) addressing cybersecurity in vehicles. These regulations would need to be considered when implementing magnetostrictive sensor systems that may collect and transmit sensitive engine performance data.

In conclusion, the regulatory framework for automotive diagnostics encompasses a complex web of national and international standards, safety regulations, and environmental requirements. Any implementation of magnetostrictive sensors for LS engine failure prediction must navigate this regulatory landscape to ensure compliance, safety, and market acceptance.

Environmental Impact of Improved Engine Diagnostics

The implementation of magnetostrictive sensors in predicting LS engine failures has significant environmental implications. By improving engine diagnostics, these sensors contribute to reduced emissions and enhanced fuel efficiency. Early detection of potential engine issues allows for timely maintenance, preventing catastrophic failures that could lead to increased pollution and resource waste.

Magnetostrictive sensors enable more precise monitoring of engine components, resulting in optimized performance and reduced wear. This translates to extended engine life cycles, reducing the need for premature replacements and the associated environmental impact of manufacturing new engines. The sensors' ability to detect minute changes in engine behavior allows for fine-tuning of combustion processes, leading to more complete fuel burning and lower emissions of harmful pollutants such as carbon monoxide and nitrogen oxides.

Furthermore, the improved diagnostics facilitated by magnetostrictive sensors contribute to more efficient engine operation. By maintaining optimal performance parameters, engines consume less fuel, directly reducing carbon dioxide emissions and conserving fossil fuel resources. This efficiency gain extends beyond individual vehicles to fleet-wide improvements, potentially resulting in substantial cumulative environmental benefits across the transportation sector.

The environmental impact of improved engine diagnostics also extends to waste reduction. By predicting failures before they occur, magnetostrictive sensors help prevent the release of engine fluids and particulates into the environment. This proactive approach minimizes the risk of oil leaks, coolant spills, and other forms of contamination that can harm ecosystems and water sources.

Additionally, the use of magnetostrictive sensors in engine diagnostics aligns with the growing trend of predictive maintenance in the automotive industry. This shift from reactive to predictive maintenance practices not only reduces downtime and repair costs but also minimizes the environmental footprint associated with unexpected breakdowns and emergency repairs. By scheduling maintenance based on actual component conditions rather than fixed intervals, unnecessary part replacements and the associated waste are reduced.

In conclusion, the environmental impact of improved engine diagnostics through magnetostrictive sensors is multifaceted and largely positive. From reduced emissions and improved fuel efficiency to extended engine life and waste reduction, these sensors contribute significantly to the automotive industry's efforts towards sustainability and environmental responsibility.

Magnetostrictive sensors enable more precise monitoring of engine components, resulting in optimized performance and reduced wear. This translates to extended engine life cycles, reducing the need for premature replacements and the associated environmental impact of manufacturing new engines. The sensors' ability to detect minute changes in engine behavior allows for fine-tuning of combustion processes, leading to more complete fuel burning and lower emissions of harmful pollutants such as carbon monoxide and nitrogen oxides.

Furthermore, the improved diagnostics facilitated by magnetostrictive sensors contribute to more efficient engine operation. By maintaining optimal performance parameters, engines consume less fuel, directly reducing carbon dioxide emissions and conserving fossil fuel resources. This efficiency gain extends beyond individual vehicles to fleet-wide improvements, potentially resulting in substantial cumulative environmental benefits across the transportation sector.

The environmental impact of improved engine diagnostics also extends to waste reduction. By predicting failures before they occur, magnetostrictive sensors help prevent the release of engine fluids and particulates into the environment. This proactive approach minimizes the risk of oil leaks, coolant spills, and other forms of contamination that can harm ecosystems and water sources.

Additionally, the use of magnetostrictive sensors in engine diagnostics aligns with the growing trend of predictive maintenance in the automotive industry. This shift from reactive to predictive maintenance practices not only reduces downtime and repair costs but also minimizes the environmental footprint associated with unexpected breakdowns and emergency repairs. By scheduling maintenance based on actual component conditions rather than fixed intervals, unnecessary part replacements and the associated waste are reduced.

In conclusion, the environmental impact of improved engine diagnostics through magnetostrictive sensors is multifaceted and largely positive. From reduced emissions and improved fuel efficiency to extended engine life and waste reduction, these sensors contribute significantly to the automotive industry's efforts towards sustainability and environmental responsibility.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!