Methods of Reducing Thermodynamic Losses in LS Engine Operation

AUG 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LS Engine Efficiency Goals

The LS (Luxury Sport) engine, a staple in high-performance vehicles, has been a focus of continuous improvement efforts aimed at enhancing efficiency and reducing thermodynamic losses. The primary goal is to maximize the conversion of fuel energy into mechanical power while minimizing waste heat and friction losses. This objective aligns with broader industry trends towards increased fuel economy and reduced emissions without compromising performance.

One of the key efficiency goals for LS engines is to improve thermal efficiency, which typically ranges from 25% to 35% in conventional gasoline engines. Engineers aim to push this boundary closer to 40% or higher, a challenging target that requires addressing multiple aspects of engine design and operation. This includes optimizing combustion processes, reducing pumping losses, and enhancing heat management strategies.

Another critical objective is to minimize mechanical friction within the engine. Friction accounts for a significant portion of energy losses, particularly at lower engine speeds. Reducing friction not only improves overall efficiency but also contributes to increased engine longevity and reduced wear. Targets for friction reduction often focus on decreasing the friction mean effective pressure (FMEP) by a substantial percentage, typically aiming for a 10-20% reduction compared to previous generation engines.

Improving volumetric efficiency is another vital goal in LS engine development. By enhancing the engine's ability to draw in and expel gases, engineers seek to increase power output and efficiency across a wider range of operating conditions. This often involves refining intake and exhaust systems, valve timing, and cylinder head designs to achieve volumetric efficiencies exceeding 100% under certain operating conditions.

Heat management and recovery represent another frontier in LS engine efficiency goals. Efforts are directed towards more effectively capturing and utilizing waste heat, potentially through technologies like thermoelectric generators or advanced cooling systems. The aim is to recover a significant portion of waste heat, with some ambitious targets seeking to convert up to 10% of waste heat back into usable energy.

Lastly, LS engine efficiency goals extend to part-load operation, where engines spend a significant portion of their operating time. Improving efficiency under these conditions is crucial for real-world fuel economy. Strategies such as cylinder deactivation and variable valve timing are being refined to achieve substantial improvements in part-load efficiency, with goals often set to reduce fuel consumption by 5-10% under these conditions.

One of the key efficiency goals for LS engines is to improve thermal efficiency, which typically ranges from 25% to 35% in conventional gasoline engines. Engineers aim to push this boundary closer to 40% or higher, a challenging target that requires addressing multiple aspects of engine design and operation. This includes optimizing combustion processes, reducing pumping losses, and enhancing heat management strategies.

Another critical objective is to minimize mechanical friction within the engine. Friction accounts for a significant portion of energy losses, particularly at lower engine speeds. Reducing friction not only improves overall efficiency but also contributes to increased engine longevity and reduced wear. Targets for friction reduction often focus on decreasing the friction mean effective pressure (FMEP) by a substantial percentage, typically aiming for a 10-20% reduction compared to previous generation engines.

Improving volumetric efficiency is another vital goal in LS engine development. By enhancing the engine's ability to draw in and expel gases, engineers seek to increase power output and efficiency across a wider range of operating conditions. This often involves refining intake and exhaust systems, valve timing, and cylinder head designs to achieve volumetric efficiencies exceeding 100% under certain operating conditions.

Heat management and recovery represent another frontier in LS engine efficiency goals. Efforts are directed towards more effectively capturing and utilizing waste heat, potentially through technologies like thermoelectric generators or advanced cooling systems. The aim is to recover a significant portion of waste heat, with some ambitious targets seeking to convert up to 10% of waste heat back into usable energy.

Lastly, LS engine efficiency goals extend to part-load operation, where engines spend a significant portion of their operating time. Improving efficiency under these conditions is crucial for real-world fuel economy. Strategies such as cylinder deactivation and variable valve timing are being refined to achieve substantial improvements in part-load efficiency, with goals often set to reduce fuel consumption by 5-10% under these conditions.

Market Demand Analysis

The market demand for methods to reduce thermodynamic losses in LS engine operation has been steadily increasing in recent years, driven by several key factors. Stringent environmental regulations and the push for improved fuel efficiency have placed significant pressure on automotive manufacturers to enhance engine performance while reducing emissions. This has led to a growing interest in technologies that can optimize the thermodynamic efficiency of LS engines.

The global automotive engine market, which includes LS engines, is projected to reach a substantial value in the coming years, with a notable portion attributed to performance enhancement technologies. The demand for high-performance engines in both consumer and commercial vehicles continues to rise, creating a fertile ground for innovations in thermodynamic loss reduction.

In the passenger vehicle segment, there is a clear trend towards downsized engines that maintain or improve power output while reducing fuel consumption. This has created a significant market opportunity for technologies that can mitigate thermodynamic losses, as they directly contribute to achieving these seemingly contradictory goals. The commercial vehicle sector also shows strong demand, particularly in long-haul trucking, where even marginal improvements in fuel efficiency can translate to substantial cost savings over time.

The aftermarket sector presents another substantial market opportunity. Performance enthusiasts and racing teams are constantly seeking ways to extract maximum power and efficiency from LS engines, driving demand for advanced thermodynamic loss reduction solutions. This niche market often serves as a testing ground for innovative technologies that may later be adopted in mainstream production.

Geographically, North America remains a key market for LS engine technologies, given the popularity of V8 engines in the region. However, emerging markets in Asia-Pacific and Europe are showing increased interest in high-performance engine technologies, expanding the global market potential for thermodynamic loss reduction methods.

The market is also being shaped by the broader trend towards electrification in the automotive industry. While this might seem counterintuitive, it has actually intensified the focus on maximizing the efficiency of internal combustion engines during the transition period. Manufacturers are investing in technologies that can extend the viability and competitiveness of traditional engines, creating a window of opportunity for advanced thermodynamic solutions.

Looking ahead, the market demand for methods to reduce thermodynamic losses in LS engines is expected to remain strong in the medium term. However, the long-term outlook will likely be influenced by the pace of electric vehicle adoption and potential shifts in regulatory landscapes. This underscores the importance of developing flexible and adaptable technologies that can potentially be applied to other engine types or even alternative powertrain systems.

The global automotive engine market, which includes LS engines, is projected to reach a substantial value in the coming years, with a notable portion attributed to performance enhancement technologies. The demand for high-performance engines in both consumer and commercial vehicles continues to rise, creating a fertile ground for innovations in thermodynamic loss reduction.

In the passenger vehicle segment, there is a clear trend towards downsized engines that maintain or improve power output while reducing fuel consumption. This has created a significant market opportunity for technologies that can mitigate thermodynamic losses, as they directly contribute to achieving these seemingly contradictory goals. The commercial vehicle sector also shows strong demand, particularly in long-haul trucking, where even marginal improvements in fuel efficiency can translate to substantial cost savings over time.

The aftermarket sector presents another substantial market opportunity. Performance enthusiasts and racing teams are constantly seeking ways to extract maximum power and efficiency from LS engines, driving demand for advanced thermodynamic loss reduction solutions. This niche market often serves as a testing ground for innovative technologies that may later be adopted in mainstream production.

Geographically, North America remains a key market for LS engine technologies, given the popularity of V8 engines in the region. However, emerging markets in Asia-Pacific and Europe are showing increased interest in high-performance engine technologies, expanding the global market potential for thermodynamic loss reduction methods.

The market is also being shaped by the broader trend towards electrification in the automotive industry. While this might seem counterintuitive, it has actually intensified the focus on maximizing the efficiency of internal combustion engines during the transition period. Manufacturers are investing in technologies that can extend the viability and competitiveness of traditional engines, creating a window of opportunity for advanced thermodynamic solutions.

Looking ahead, the market demand for methods to reduce thermodynamic losses in LS engines is expected to remain strong in the medium term. However, the long-term outlook will likely be influenced by the pace of electric vehicle adoption and potential shifts in regulatory landscapes. This underscores the importance of developing flexible and adaptable technologies that can potentially be applied to other engine types or even alternative powertrain systems.

Current Challenges

The current challenges in reducing thermodynamic losses in LS engine operation are multifaceted and complex. One of the primary obstacles is the inherent inefficiency of the internal combustion process itself. Despite decades of refinement, modern LS engines still convert only about 30-35% of fuel energy into useful mechanical work, with the majority lost as heat.

Friction remains a significant source of energy loss, particularly in high-load conditions. The piston assembly, bearings, and valve train components contribute to mechanical friction, which can account for up to 15% of total engine losses. Developing advanced materials and surface treatments to reduce friction without compromising durability is an ongoing challenge.

Heat transfer from the combustion chamber to the cooling system represents another major area of thermodynamic loss. While some heat transfer is necessary to maintain engine integrity, excessive cooling robs the engine of potential work output. Balancing the need for adequate cooling with the desire to retain more thermal energy for conversion to mechanical work is a delicate engineering task.

Pumping losses, caused by the work required to move air and exhaust gases in and out of the cylinders, continue to be a significant challenge. These losses are particularly pronounced at partial load conditions, which are common in real-world driving scenarios. Developing more efficient variable valve timing and lift systems to optimize gas exchange processes across a wide range of operating conditions is an area of active research.

The combustion process itself presents challenges in terms of achieving complete and efficient fuel burning. Factors such as mixture homogeneity, turbulence, and flame propagation all affect combustion efficiency. Enhancing in-cylinder fluid dynamics and optimizing injection strategies to promote more complete combustion without increasing NOx emissions remains a complex balancing act.

Exhaust energy recovery is another frontier in reducing thermodynamic losses. A significant portion of energy leaves the engine as hot exhaust gases. While turbocharging has been widely adopted to reclaim some of this energy, more advanced technologies such as thermoelectric generators and Rankine cycle systems are still in the early stages of development for automotive applications.

Lastly, the pursuit of higher thermal efficiency must be balanced with increasingly stringent emissions regulations. Technologies that improve efficiency, such as higher compression ratios or leaner combustion, often lead to increased NOx formation. Developing strategies to simultaneously reduce emissions and improve efficiency without resorting to overly complex and costly aftertreatment systems is a paramount challenge for engine designers.

Friction remains a significant source of energy loss, particularly in high-load conditions. The piston assembly, bearings, and valve train components contribute to mechanical friction, which can account for up to 15% of total engine losses. Developing advanced materials and surface treatments to reduce friction without compromising durability is an ongoing challenge.

Heat transfer from the combustion chamber to the cooling system represents another major area of thermodynamic loss. While some heat transfer is necessary to maintain engine integrity, excessive cooling robs the engine of potential work output. Balancing the need for adequate cooling with the desire to retain more thermal energy for conversion to mechanical work is a delicate engineering task.

Pumping losses, caused by the work required to move air and exhaust gases in and out of the cylinders, continue to be a significant challenge. These losses are particularly pronounced at partial load conditions, which are common in real-world driving scenarios. Developing more efficient variable valve timing and lift systems to optimize gas exchange processes across a wide range of operating conditions is an area of active research.

The combustion process itself presents challenges in terms of achieving complete and efficient fuel burning. Factors such as mixture homogeneity, turbulence, and flame propagation all affect combustion efficiency. Enhancing in-cylinder fluid dynamics and optimizing injection strategies to promote more complete combustion without increasing NOx emissions remains a complex balancing act.

Exhaust energy recovery is another frontier in reducing thermodynamic losses. A significant portion of energy leaves the engine as hot exhaust gases. While turbocharging has been widely adopted to reclaim some of this energy, more advanced technologies such as thermoelectric generators and Rankine cycle systems are still in the early stages of development for automotive applications.

Lastly, the pursuit of higher thermal efficiency must be balanced with increasingly stringent emissions regulations. Technologies that improve efficiency, such as higher compression ratios or leaner combustion, often lead to increased NOx formation. Developing strategies to simultaneously reduce emissions and improve efficiency without resorting to overly complex and costly aftertreatment systems is a paramount challenge for engine designers.

Existing Loss Reduction

01 Thermal management systems for LS engines

Advanced thermal management systems are employed in LS engines to reduce thermodynamic losses. These systems include improved cooling strategies, heat recovery mechanisms, and thermal insulation techniques to optimize engine efficiency and performance.- Thermal management systems for LS engines: Advanced thermal management systems are employed in LS engines to reduce thermodynamic losses. These systems include improved cooling strategies, heat recovery mechanisms, and thermal insulation techniques to optimize engine efficiency and performance.

- Combustion optimization in LS engines: Techniques for optimizing combustion processes in LS engines are implemented to minimize thermodynamic losses. These include advanced fuel injection systems, improved air-fuel mixture control, and combustion chamber design enhancements to increase thermal efficiency.

- Waste heat recovery systems for LS engines: Innovative waste heat recovery systems are integrated into LS engines to capture and utilize thermal energy that would otherwise be lost. These systems may include thermoelectric generators, Rankine cycle systems, or other heat-to-power conversion technologies to improve overall engine efficiency.

- Friction reduction in LS engine components: Advanced materials, coatings, and designs are employed to reduce friction between moving parts in LS engines. This includes improvements in piston rings, bearings, and other critical components to minimize mechanical losses and enhance overall engine efficiency.

- Advanced control systems for LS engine efficiency: Sophisticated control systems and algorithms are developed to optimize LS engine operation in real-time. These systems monitor and adjust various engine parameters to minimize thermodynamic losses across different operating conditions, improving overall efficiency and performance.

02 Combustion optimization in LS engines

Techniques for optimizing combustion processes in LS engines are implemented to minimize thermodynamic losses. These include advanced fuel injection systems, improved air-fuel mixture control, and combustion chamber designs that enhance thermal efficiency and reduce energy waste.Expand Specific Solutions03 Waste heat recovery systems for LS engines

Innovative waste heat recovery systems are integrated into LS engines to capture and utilize thermal energy that would otherwise be lost. These systems may include thermoelectric generators, Rankine cycle systems, or other heat-to-power conversion technologies to improve overall engine efficiency.Expand Specific Solutions04 Friction reduction in LS engine components

Advanced materials, coatings, and designs are employed to reduce friction between moving parts in LS engines. This includes improvements in piston rings, bearings, and other critical components to minimize mechanical losses and enhance overall engine efficiency.Expand Specific Solutions05 Advanced control systems for LS engine efficiency

Sophisticated control systems and algorithms are developed to optimize LS engine operation in real-time. These systems monitor and adjust various engine parameters to minimize thermodynamic losses across different operating conditions, improving overall efficiency and performance.Expand Specific Solutions

Key Industry Players

The competition landscape for reducing thermodynamic losses in LS engine operation is characterized by a mature market with established players and ongoing innovation. Major automotive manufacturers like GM, Toyota, Ford, and Hyundai are actively involved, alongside specialized engine technology companies such as Robert Bosch and ExxonMobil. The market is substantial, driven by the global demand for more efficient internal combustion engines. Technological maturity varies, with companies like Rolls-Royce Solutions and Wärtsilä Finland demonstrating advanced capabilities in engine efficiency. Research institutions like Tianjin University and Port & Airport Research Institute contribute to the field's academic advancement, while tier-1 suppliers such as Aisin and Valeo Thermal Systems focus on component-level innovations to address thermodynamic losses.

Robert Bosch GmbH

Technical Solution: Bosch has developed advanced engine management systems to reduce thermodynamic losses in LS (Large Size) engines. Their approach includes optimized fuel injection strategies, variable valve timing, and intelligent thermal management. The company's direct injection technology allows for precise fuel delivery, reducing wall wetting and improving combustion efficiency[1]. Bosch's variable valve timing system adapts to different engine loads, minimizing pumping losses and optimizing gas exchange[2]. Additionally, their smart thermal management system rapidly brings the engine to optimal operating temperature, reducing friction losses during cold starts[3]. These technologies work in synergy to significantly reduce overall thermodynamic losses in LS engine operation.

Strengths: Comprehensive approach addressing multiple sources of losses, proven expertise in engine management systems. Weaknesses: May require complex integration with existing engine designs, potentially higher initial costs for implementation.

GM Global Technology Operations LLC

Technical Solution: GM has focused on reducing thermodynamic losses in LS engines through their Dynamic Fuel Management (DFM) system and advanced materials technology. The DFM system enables cylinder deactivation on a per-cylinder, per-combustion-event basis, allowing the engine to operate in a variety of cylinder patterns to optimize efficiency[4]. This reduces pumping losses and improves thermal efficiency across a wide range of operating conditions. GM has also implemented low-friction coatings and advanced thermal barrier coatings to reduce heat transfer losses to the cylinder walls and piston[5]. Their LS engines utilize lightweight materials and optimized cooling systems to manage thermal loads more effectively, further reducing thermodynamic losses[6].

Strengths: Innovative cylinder deactivation technology, integration of advanced materials for thermal management. Weaknesses: Complexity of DFM system may impact long-term reliability, potential for increased manufacturing costs.

Core Innovations

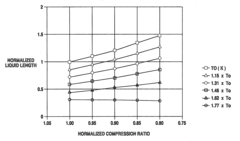

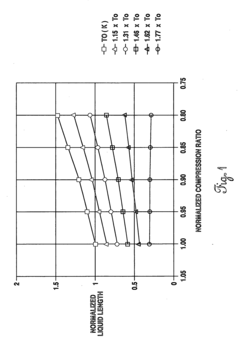

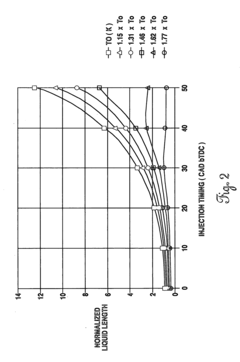

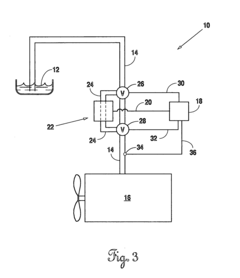

Method and apparatus for controlling liquid-phase fuel penetration distance in a direct-fuel injected engine

PatentInactiveUS20040255900A1

Innovation

- Controllably heating the liquid fuel prior to injection based on real-time engine operating parameters such as fuel composition, injector geometry, and thermodynamic conditions to manage the transition from liquid-phase to vapor-phase, thereby regulating the penetration distance.

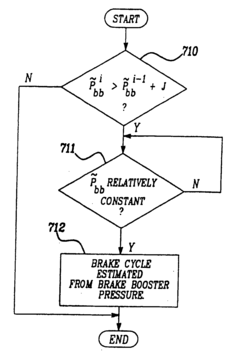

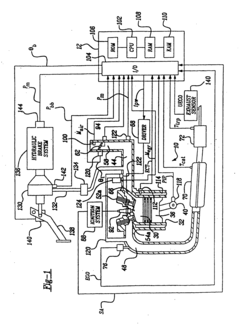

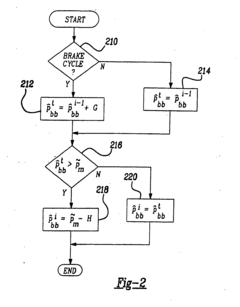

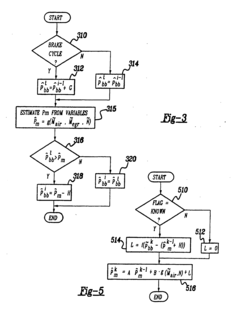

System and method for detection of degradation of vacuum brake booster sensor

PatentInactiveUS20040162652A1

Innovation

- A method to determine sensor degradation in a vacuum brake booster system by measuring engine and vehicle operating parameters, utilizing system redundancy and vehicle information to accurately assess sensor operability and detect in-range sensor issues, such as by comparing brake booster pressure to manifold pressure and analyzing changes during braking cycles.

Emissions Regulations

Emissions regulations play a crucial role in shaping the development of engine technologies, including methods for reducing thermodynamic losses in LS engine operation. These regulations have become increasingly stringent over the years, driving manufacturers to innovate and implement more efficient engine designs.

The primary focus of emissions regulations is to reduce harmful pollutants such as carbon monoxide (CO), nitrogen oxides (NOx), and particulate matter (PM). In the context of LS engines, these regulations have led to the adoption of various technologies and strategies to improve fuel efficiency and reduce emissions simultaneously.

One of the key areas affected by emissions regulations is the combustion process. Manufacturers have been compelled to optimize fuel injection systems, improve air-fuel mixture formation, and enhance combustion chamber designs to ensure more complete combustion. These improvements not only reduce emissions but also contribute to minimizing thermodynamic losses.

Exhaust gas recirculation (EGR) systems have become a standard feature in modern LS engines, largely due to emissions regulations. EGR helps reduce NOx emissions by lowering combustion temperatures, but it also presents challenges in terms of thermodynamic efficiency. Engineers must carefully balance EGR rates to meet emissions standards while minimizing negative impacts on engine performance.

Catalytic converters, mandated by emissions regulations, have undergone significant advancements to cope with stricter standards. While these devices are essential for reducing harmful emissions, they can introduce additional back pressure in the exhaust system, potentially increasing pumping losses. As a result, engineers must develop innovative exhaust system designs to mitigate these losses while maintaining emissions compliance.

The introduction of on-board diagnostics (OBD) systems, required by emissions regulations, has indirectly contributed to reducing thermodynamic losses. These systems continuously monitor engine performance and emissions, allowing for early detection of malfunctions that could lead to increased fuel consumption and emissions. This proactive approach helps maintain optimal engine efficiency throughout the vehicle's lifecycle.

Emissions regulations have also driven the development of advanced engine control strategies. Modern engine control units (ECUs) utilize sophisticated algorithms to optimize combustion timing, fuel injection parameters, and valve timing across various operating conditions. These strategies not only ensure compliance with emissions standards but also contribute to reducing thermodynamic losses by maximizing engine efficiency.

As emissions regulations continue to evolve, manufacturers are exploring new technologies such as low-temperature combustion (LTC) and homogeneous charge compression ignition (HCCI). These advanced combustion strategies aim to simultaneously reduce emissions and improve thermodynamic efficiency, aligning with the dual goals of regulatory compliance and enhanced engine performance.

The primary focus of emissions regulations is to reduce harmful pollutants such as carbon monoxide (CO), nitrogen oxides (NOx), and particulate matter (PM). In the context of LS engines, these regulations have led to the adoption of various technologies and strategies to improve fuel efficiency and reduce emissions simultaneously.

One of the key areas affected by emissions regulations is the combustion process. Manufacturers have been compelled to optimize fuel injection systems, improve air-fuel mixture formation, and enhance combustion chamber designs to ensure more complete combustion. These improvements not only reduce emissions but also contribute to minimizing thermodynamic losses.

Exhaust gas recirculation (EGR) systems have become a standard feature in modern LS engines, largely due to emissions regulations. EGR helps reduce NOx emissions by lowering combustion temperatures, but it also presents challenges in terms of thermodynamic efficiency. Engineers must carefully balance EGR rates to meet emissions standards while minimizing negative impacts on engine performance.

Catalytic converters, mandated by emissions regulations, have undergone significant advancements to cope with stricter standards. While these devices are essential for reducing harmful emissions, they can introduce additional back pressure in the exhaust system, potentially increasing pumping losses. As a result, engineers must develop innovative exhaust system designs to mitigate these losses while maintaining emissions compliance.

The introduction of on-board diagnostics (OBD) systems, required by emissions regulations, has indirectly contributed to reducing thermodynamic losses. These systems continuously monitor engine performance and emissions, allowing for early detection of malfunctions that could lead to increased fuel consumption and emissions. This proactive approach helps maintain optimal engine efficiency throughout the vehicle's lifecycle.

Emissions regulations have also driven the development of advanced engine control strategies. Modern engine control units (ECUs) utilize sophisticated algorithms to optimize combustion timing, fuel injection parameters, and valve timing across various operating conditions. These strategies not only ensure compliance with emissions standards but also contribute to reducing thermodynamic losses by maximizing engine efficiency.

As emissions regulations continue to evolve, manufacturers are exploring new technologies such as low-temperature combustion (LTC) and homogeneous charge compression ignition (HCCI). These advanced combustion strategies aim to simultaneously reduce emissions and improve thermodynamic efficiency, aligning with the dual goals of regulatory compliance and enhanced engine performance.

Cost-Benefit Analysis

The cost-benefit analysis of implementing methods to reduce thermodynamic losses in LS engine operation requires a comprehensive evaluation of both financial and performance aspects. Initial investments in research, development, and implementation of advanced technologies can be substantial. These costs may include upgrading engine components, integrating sophisticated control systems, and potentially redesigning certain aspects of the engine architecture. However, the long-term benefits can outweigh these upfront expenses.

One of the primary advantages is improved fuel efficiency, which translates to reduced operating costs for end-users. Even marginal improvements in thermodynamic efficiency can lead to significant fuel savings over the lifespan of an engine, especially in high-usage scenarios such as commercial transportation or industrial applications. This not only benefits the consumer but also aligns with increasingly stringent environmental regulations and corporate sustainability goals.

Enhanced engine performance is another key benefit. By minimizing thermodynamic losses, engines can deliver more power output for the same fuel input, potentially increasing horsepower and torque. This improvement in power-to-weight ratio can be particularly valuable in automotive and aerospace applications, where performance is a critical selling point.

From a manufacturing perspective, the implementation of these methods may lead to a competitive advantage. Engines with superior efficiency and performance characteristics can command premium pricing and attract environmentally conscious consumers. This can result in increased market share and brand value, offsetting the initial investment costs.

However, it's crucial to consider the potential drawbacks. The complexity added by advanced thermodynamic loss reduction systems may increase maintenance requirements and costs. Additionally, the reliability and durability of these systems must be thoroughly tested to ensure they do not compromise the engine's overall lifespan or increase the frequency of repairs.

The return on investment (ROI) timeline is another critical factor. While long-term benefits are clear, the payback period for implementing these technologies can vary widely depending on the specific application and market conditions. For consumer vehicles, the ROI may be realized over several years, while in industrial or commercial settings, the payback could be more rapid due to higher usage rates.

Lastly, the analysis must account for the broader economic context, including fuel prices, regulatory environments, and consumer preferences. As global emphasis on reducing carbon emissions intensifies, the value proposition of thermodynamic loss reduction technologies is likely to strengthen, potentially accelerating their adoption across various engine applications.

One of the primary advantages is improved fuel efficiency, which translates to reduced operating costs for end-users. Even marginal improvements in thermodynamic efficiency can lead to significant fuel savings over the lifespan of an engine, especially in high-usage scenarios such as commercial transportation or industrial applications. This not only benefits the consumer but also aligns with increasingly stringent environmental regulations and corporate sustainability goals.

Enhanced engine performance is another key benefit. By minimizing thermodynamic losses, engines can deliver more power output for the same fuel input, potentially increasing horsepower and torque. This improvement in power-to-weight ratio can be particularly valuable in automotive and aerospace applications, where performance is a critical selling point.

From a manufacturing perspective, the implementation of these methods may lead to a competitive advantage. Engines with superior efficiency and performance characteristics can command premium pricing and attract environmentally conscious consumers. This can result in increased market share and brand value, offsetting the initial investment costs.

However, it's crucial to consider the potential drawbacks. The complexity added by advanced thermodynamic loss reduction systems may increase maintenance requirements and costs. Additionally, the reliability and durability of these systems must be thoroughly tested to ensure they do not compromise the engine's overall lifespan or increase the frequency of repairs.

The return on investment (ROI) timeline is another critical factor. While long-term benefits are clear, the payback period for implementing these technologies can vary widely depending on the specific application and market conditions. For consumer vehicles, the ROI may be realized over several years, while in industrial or commercial settings, the payback could be more rapid due to higher usage rates.

Lastly, the analysis must account for the broader economic context, including fuel prices, regulatory environments, and consumer preferences. As global emphasis on reducing carbon emissions intensifies, the value proposition of thermodynamic loss reduction technologies is likely to strengthen, potentially accelerating their adoption across various engine applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!