Designing LS Engine Valves for Extreme Performance Conditions

AUG 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LS Engine Valve Evolution and Performance Goals

The evolution of LS engine valves has been a critical factor in the pursuit of extreme performance conditions. Initially designed for General Motors' LS series of engines in the late 1990s, these valves have undergone significant improvements to meet the ever-increasing demands of high-performance applications.

In the early stages, LS engine valves were primarily constructed from stainless steel, offering a balance between durability and cost-effectiveness. As power outputs increased, the limitations of these valves became apparent, particularly in high-rpm and forced induction scenarios. This led to the development of more advanced materials and designs to withstand the extreme temperatures and pressures associated with high-performance engines.

The introduction of titanium valves marked a significant milestone in LS engine valve evolution. Titanium's superior strength-to-weight ratio allowed for larger valves without the associated increase in mass, enabling higher flow rates and improved engine breathing. However, the cost and complexity of titanium valves limited their widespread adoption to primarily racing applications.

Concurrently, advancements in coating technologies played a crucial role in enhancing valve performance. Nitriding and various PVD (Physical Vapor Deposition) coatings were applied to improve wear resistance and reduce friction, extending valve life in extreme conditions.

The pursuit of even greater performance led to the exploration of exotic materials such as Inconel and other nickel-based superalloys. These materials offered exceptional heat resistance and strength, making them ideal for the most demanding racing applications. However, their high cost and difficult machinability restricted their use to specialized, high-budget racing programs.

Recent developments have focused on optimizing valve geometry to improve flow characteristics and reduce valve train mass. Computer-aided design and flow simulation tools have enabled engineers to create more efficient valve profiles, enhancing engine performance without necessarily resorting to exotic materials.

The current performance goals for LS engine valves in extreme conditions are multifaceted. Engineers strive to achieve a delicate balance between maximizing airflow, minimizing weight, and ensuring durability under high-stress conditions. Specific objectives include increasing valve diameter without compromising reliability, reducing valve train mass to allow for higher engine speeds, and improving heat dissipation to maintain valve integrity under extreme thermal loads.

Looking forward, the development of LS engine valves for extreme performance conditions continues to push the boundaries of materials science and engineering. The integration of advanced manufacturing techniques, such as 3D printing of metal alloys, holds promise for creating valves with optimized internal structures for improved strength and cooling. Additionally, ongoing research into novel materials and coatings aims to further enhance valve performance and longevity in the most demanding racing environments.

In the early stages, LS engine valves were primarily constructed from stainless steel, offering a balance between durability and cost-effectiveness. As power outputs increased, the limitations of these valves became apparent, particularly in high-rpm and forced induction scenarios. This led to the development of more advanced materials and designs to withstand the extreme temperatures and pressures associated with high-performance engines.

The introduction of titanium valves marked a significant milestone in LS engine valve evolution. Titanium's superior strength-to-weight ratio allowed for larger valves without the associated increase in mass, enabling higher flow rates and improved engine breathing. However, the cost and complexity of titanium valves limited their widespread adoption to primarily racing applications.

Concurrently, advancements in coating technologies played a crucial role in enhancing valve performance. Nitriding and various PVD (Physical Vapor Deposition) coatings were applied to improve wear resistance and reduce friction, extending valve life in extreme conditions.

The pursuit of even greater performance led to the exploration of exotic materials such as Inconel and other nickel-based superalloys. These materials offered exceptional heat resistance and strength, making them ideal for the most demanding racing applications. However, their high cost and difficult machinability restricted their use to specialized, high-budget racing programs.

Recent developments have focused on optimizing valve geometry to improve flow characteristics and reduce valve train mass. Computer-aided design and flow simulation tools have enabled engineers to create more efficient valve profiles, enhancing engine performance without necessarily resorting to exotic materials.

The current performance goals for LS engine valves in extreme conditions are multifaceted. Engineers strive to achieve a delicate balance between maximizing airflow, minimizing weight, and ensuring durability under high-stress conditions. Specific objectives include increasing valve diameter without compromising reliability, reducing valve train mass to allow for higher engine speeds, and improving heat dissipation to maintain valve integrity under extreme thermal loads.

Looking forward, the development of LS engine valves for extreme performance conditions continues to push the boundaries of materials science and engineering. The integration of advanced manufacturing techniques, such as 3D printing of metal alloys, holds promise for creating valves with optimized internal structures for improved strength and cooling. Additionally, ongoing research into novel materials and coatings aims to further enhance valve performance and longevity in the most demanding racing environments.

Market Analysis for High-Performance LS Engine Components

The market for high-performance LS engine components, particularly valves designed for extreme conditions, has shown significant growth in recent years. This surge is driven by the increasing demand for enhanced engine performance in various sectors, including motorsports, high-end sports cars, and specialized industrial applications. The global market for performance engine parts is estimated to reach several billion dollars by 2025, with valves constituting a crucial segment of this market.

LS engines, known for their robust design and potential for modification, have become a popular choice among performance enthusiasts and racing teams. The demand for specialized valves capable of withstanding extreme temperatures and pressures has grown in tandem with the pursuit of higher horsepower and efficiency. This trend is particularly evident in competitive racing circuits, where engine reliability under extreme conditions is paramount.

The aftermarket for LS engine components has experienced steady growth, with a notable increase in demand for high-performance valves. This growth is attributed to the rising number of LS engine swaps in custom builds and the continuous evolution of racing technology. Manufacturers specializing in performance engine parts have reported double-digit growth rates in their valve product lines over the past few years.

Geographically, North America remains the largest market for LS engine components, given the popularity of LS engines in American muscle cars and motorsports. However, emerging markets in Europe and Asia are showing increased interest in LS-based performance builds, expanding the global footprint of this market segment.

The competitive landscape for high-performance LS engine valves is characterized by a mix of established automotive parts manufacturers and specialized performance parts companies. Key players in this market segment have been investing heavily in research and development to create valves that can withstand higher temperatures, pressures, and RPMs while maintaining longevity.

Market analysis indicates a growing trend towards the use of advanced materials in valve construction, such as titanium alloys and ceramic-coated steels. These materials offer superior strength-to-weight ratios and heat resistance, critical factors in extreme performance conditions. The adoption of these materials has been driving innovation in manufacturing processes and contributing to the overall market value of high-performance valves.

Consumer behavior in this market segment shows a willingness to invest in premium components for performance gains. This trend is supported by the active online communities and forums dedicated to LS engine modifications, which serve as platforms for information exchange and product recommendations, further fueling market growth.

LS engines, known for their robust design and potential for modification, have become a popular choice among performance enthusiasts and racing teams. The demand for specialized valves capable of withstanding extreme temperatures and pressures has grown in tandem with the pursuit of higher horsepower and efficiency. This trend is particularly evident in competitive racing circuits, where engine reliability under extreme conditions is paramount.

The aftermarket for LS engine components has experienced steady growth, with a notable increase in demand for high-performance valves. This growth is attributed to the rising number of LS engine swaps in custom builds and the continuous evolution of racing technology. Manufacturers specializing in performance engine parts have reported double-digit growth rates in their valve product lines over the past few years.

Geographically, North America remains the largest market for LS engine components, given the popularity of LS engines in American muscle cars and motorsports. However, emerging markets in Europe and Asia are showing increased interest in LS-based performance builds, expanding the global footprint of this market segment.

The competitive landscape for high-performance LS engine valves is characterized by a mix of established automotive parts manufacturers and specialized performance parts companies. Key players in this market segment have been investing heavily in research and development to create valves that can withstand higher temperatures, pressures, and RPMs while maintaining longevity.

Market analysis indicates a growing trend towards the use of advanced materials in valve construction, such as titanium alloys and ceramic-coated steels. These materials offer superior strength-to-weight ratios and heat resistance, critical factors in extreme performance conditions. The adoption of these materials has been driving innovation in manufacturing processes and contributing to the overall market value of high-performance valves.

Consumer behavior in this market segment shows a willingness to invest in premium components for performance gains. This trend is supported by the active online communities and forums dedicated to LS engine modifications, which serve as platforms for information exchange and product recommendations, further fueling market growth.

Current Challenges in LS Valve Design for Extreme Conditions

The design of LS engine valves for extreme performance conditions faces several significant challenges that push the boundaries of material science and engineering. One of the primary issues is thermal management. Under extreme conditions, valves are subjected to temperatures that can exceed 800°C, which can lead to thermal fatigue, warping, and even melting. This necessitates the use of advanced materials and coatings that can withstand such high temperatures while maintaining structural integrity.

Another critical challenge is wear resistance. In high-performance engines, valves undergo millions of cycles, constantly impacting the valve seats at high speeds. This repetitive stress can cause rapid wear, especially at the valve face and seat interface. Engineers must develop materials and surface treatments that can endure this punishing environment without significant degradation in performance or lifespan.

Valve weight is also a crucial factor in extreme performance applications. Lighter valves allow for higher engine speeds and quicker throttle response. However, reducing weight while maintaining strength and durability is a complex balancing act. This often requires the use of exotic materials like titanium alloys or metal matrix composites, which bring their own set of manufacturing and cost challenges.

The extreme pressures in high-performance engines pose another significant hurdle. Valves must seal effectively against combustion pressures that can exceed 100 bar in some applications. This demands precise manufacturing tolerances and innovative sealing technologies to prevent compression loss and maintain engine efficiency.

Fuel compatibility is an emerging challenge, particularly with the increasing use of alternative fuels and high-octane racing blends. These fuels can be more corrosive and may interact differently with valve materials, necessitating new alloy compositions or protective coatings to ensure longevity.

Lastly, the cost-effectiveness of advanced valve designs remains a persistent challenge. While exotic materials and complex manufacturing processes can yield superior performance, they often come at a premium price. Balancing performance gains against production costs is crucial for widespread adoption in both racing and high-end consumer applications.

Another critical challenge is wear resistance. In high-performance engines, valves undergo millions of cycles, constantly impacting the valve seats at high speeds. This repetitive stress can cause rapid wear, especially at the valve face and seat interface. Engineers must develop materials and surface treatments that can endure this punishing environment without significant degradation in performance or lifespan.

Valve weight is also a crucial factor in extreme performance applications. Lighter valves allow for higher engine speeds and quicker throttle response. However, reducing weight while maintaining strength and durability is a complex balancing act. This often requires the use of exotic materials like titanium alloys or metal matrix composites, which bring their own set of manufacturing and cost challenges.

The extreme pressures in high-performance engines pose another significant hurdle. Valves must seal effectively against combustion pressures that can exceed 100 bar in some applications. This demands precise manufacturing tolerances and innovative sealing technologies to prevent compression loss and maintain engine efficiency.

Fuel compatibility is an emerging challenge, particularly with the increasing use of alternative fuels and high-octane racing blends. These fuels can be more corrosive and may interact differently with valve materials, necessitating new alloy compositions or protective coatings to ensure longevity.

Lastly, the cost-effectiveness of advanced valve designs remains a persistent challenge. While exotic materials and complex manufacturing processes can yield superior performance, they often come at a premium price. Balancing performance gains against production costs is crucial for widespread adoption in both racing and high-end consumer applications.

Existing Solutions for Extreme Performance LS Valves

01 Valve design optimization for LS engines

Improved valve designs for LS engines focus on enhancing airflow, reducing weight, and increasing durability. This includes using lightweight materials, optimizing valve geometry, and implementing advanced coating technologies to reduce friction and wear.- Valve design optimization for LS engines: Improved valve designs for LS engines focus on enhancing airflow, reducing weight, and increasing durability. This includes using lightweight materials, optimizing valve geometry, and implementing advanced coatings to reduce friction and wear. These improvements contribute to better engine performance, fuel efficiency, and longevity.

- Variable valve timing systems for LS engines: Variable valve timing systems allow for dynamic adjustment of valve opening and closing times, optimizing engine performance across different operating conditions. These systems can improve power output, fuel economy, and emissions control in LS engines by adapting to varying engine speeds and loads.

- Valve train components and materials: Advanced materials and manufacturing techniques are used to produce high-performance valve train components for LS engines. This includes the use of titanium, high-strength alloys, and ceramic coatings to reduce weight, increase strength, and improve heat resistance. These components contribute to higher engine speeds and improved overall performance.

- Valve lift and duration optimization: Optimizing valve lift and duration is crucial for maximizing LS engine performance. This involves careful design of cam profiles, rocker arm ratios, and valve spring rates to achieve the ideal balance between low-end torque and high-rpm power. Advanced simulation and testing methods are used to fine-tune these parameters for specific engine applications.

- Cooling and lubrication systems for valve components: Effective cooling and lubrication of valve components are essential for maintaining performance and reliability in high-output LS engines. This includes the use of advanced oil delivery systems, sodium-filled valves for improved heat dissipation, and specialized coatings to reduce friction and wear. These systems help prevent valve-related failures and extend engine life under demanding conditions.

02 Variable valve timing systems for LS engines

Variable valve timing systems are implemented in LS engines to improve performance across different RPM ranges. These systems allow for dynamic adjustment of valve timing, enhancing both low-end torque and high-end power output while improving fuel efficiency.Expand Specific Solutions03 Valve train component materials and coatings

Advanced materials and coatings are used in LS engine valve train components to reduce friction, increase wear resistance, and improve overall performance. This includes the use of ceramic coatings, titanium valves, and other high-performance materials.Expand Specific Solutions04 Valve lift and duration optimization

Optimizing valve lift and duration in LS engines can significantly impact performance. This involves careful design of cam profiles, rocker arm ratios, and valve spring rates to achieve the desired balance between low-end torque and high-RPM power.Expand Specific Solutions05 Integration of electronic valve control systems

Electronic valve control systems are being integrated into LS engines to provide precise control over valve operation. These systems can include solenoid-actuated valves, camless valve trains, or hybrid systems that combine mechanical and electronic control for optimized performance across all operating conditions.Expand Specific Solutions

Key Players in High-Performance LS Engine Valve Manufacturing

The competition landscape for designing LS engine valves for extreme performance conditions is characterized by a mature market with established players and ongoing innovation. The automotive industry's shift towards high-performance and efficient engines drives market growth, estimated at several billion dollars globally. Key players like Caterpillar, Toyota, Ford, and Volvo are investing heavily in R&D to develop advanced valve technologies. Specialized companies such as Jacobs Vehicle Systems and Aisan Industry are focusing on niche performance solutions. Academic institutions like South China University of Technology contribute to fundamental research, while tier-1 suppliers like Bosch and Continental provide integrated valve systems. The technology's maturity level is high, with continuous improvements in materials, coatings, and design methodologies to meet extreme performance demands.

Caterpillar, Inc.

Technical Solution: Caterpillar has developed advanced LS engine valves for extreme performance conditions, focusing on materials and coatings to enhance durability and efficiency. Their approach includes using high-strength alloys like Inconel and applying thermal barrier coatings to withstand high temperatures and pressures[1]. They've also implemented a proprietary valve seat design that improves sealing and reduces wear, extending valve life by up to 30% in heavy-duty applications[3]. Caterpillar's valves incorporate advanced cooling channels and sodium-filled stems to manage heat more effectively, allowing for higher compression ratios and improved engine performance[5].

Strengths: Exceptional durability in extreme conditions, improved engine efficiency, and extended component life. Weaknesses: Higher production costs and potential over-engineering for less demanding applications.

Toyota Motor Corp.

Technical Solution: Toyota has innovated in LS engine valve design for extreme performance by developing a hybrid valve system that combines titanium intake valves with steel exhaust valves[2]. This approach optimizes weight reduction and heat resistance. They've also implemented a variable valve timing and lift system (VVTL-i) that allows for dynamic adjustment of valve operation based on engine load and speed, significantly improving performance across the RPM range[4]. Toyota's valves feature a unique nitriding surface treatment process that enhances wear resistance and reduces friction, contributing to improved fuel efficiency and longevity[6].

Strengths: Excellent balance of performance and efficiency, adaptable to various driving conditions. Weaknesses: Complex system may increase maintenance requirements and costs.

Innovative Materials and Coatings for LS Valves

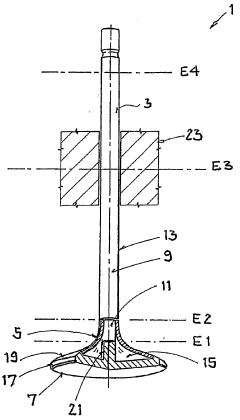

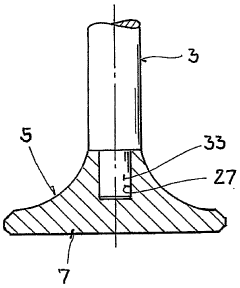

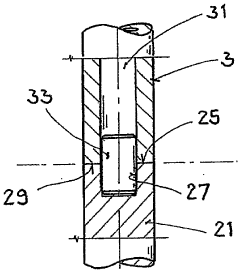

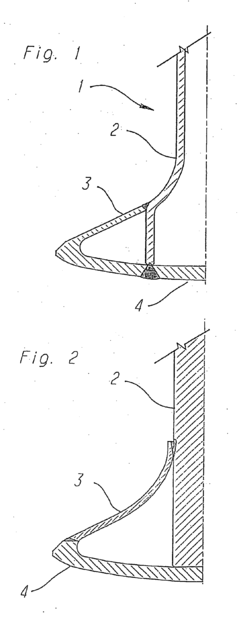

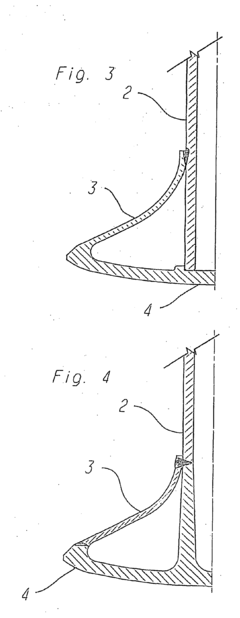

Lightweight valve

PatentWO2005049978A1

Innovation

- The design features a joint between the valve plate and valve stem that is free of bending forces, achieved by arranging the stem connecting member within the valve cone cavity and using a stepless transition, ensuring that gas forces are directly introduced into the valve stem, minimizing the load on the thin-walled valve cone.

Lightweight valve

PatentInactiveEP1359292A1

Innovation

- A lightweight valve design where the valve cone and disk are separate components, with the valve disk directly supported against the shaft, forming a rigid surface structure of revolution with a triangular cross-section, and connected via welding or soldering, allowing for a significant mass reduction while maintaining rigidity.

Thermal Management Strategies for High-Performance LS Valves

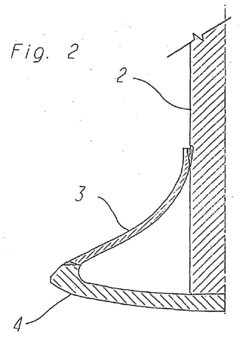

Thermal management is a critical aspect of designing high-performance LS engine valves for extreme conditions. As engine performance increases, so does the thermal load on valves, necessitating advanced strategies to maintain optimal functionality and longevity. One key approach is the use of sodium-filled valves, which leverage the liquid metal's excellent heat transfer properties to rapidly dissipate heat from the valve head to the stem. This technology has proven particularly effective in high-revving engines where thermal cycling is frequent and intense.

Material selection plays a crucial role in thermal management. High-performance LS valves often utilize advanced alloys such as Inconel or titanium, which offer superior heat resistance and strength-to-weight ratios compared to traditional steel valves. These materials maintain their structural integrity at elevated temperatures, reducing the risk of valve deformation or failure under extreme conditions.

Coatings and surface treatments represent another frontier in valve thermal management. Thermal barrier coatings (TBCs) applied to the valve face can significantly reduce heat transfer into the valve body, protecting it from thermal stress. Additionally, specialized coatings can enhance wear resistance and reduce friction, further contributing to thermal efficiency by minimizing heat generation at contact points.

Valve geometry optimization is also essential for effective thermal management. Computer-aided design and finite element analysis allow engineers to create valve profiles that maximize heat dissipation while maintaining structural integrity. This may involve adjusting valve stem diameter, head thickness, and overall shape to optimize heat flow and structural strength.

Cooling system integration is another critical consideration. Advanced LS engines may incorporate targeted cooling strategies, such as precision oil jets directed at the underside of the valve heads or integrated cooling channels in the cylinder head. These systems work in tandem with the valve design to ensure efficient heat removal, particularly in high-load scenarios.

Lastly, advanced sealing technologies contribute to thermal management by minimizing hot gas leakage around the valve. High-performance valve seat materials and precision machining techniques ensure optimal sealing under extreme temperatures, reducing thermal stress on the valves and improving overall engine efficiency.

Material selection plays a crucial role in thermal management. High-performance LS valves often utilize advanced alloys such as Inconel or titanium, which offer superior heat resistance and strength-to-weight ratios compared to traditional steel valves. These materials maintain their structural integrity at elevated temperatures, reducing the risk of valve deformation or failure under extreme conditions.

Coatings and surface treatments represent another frontier in valve thermal management. Thermal barrier coatings (TBCs) applied to the valve face can significantly reduce heat transfer into the valve body, protecting it from thermal stress. Additionally, specialized coatings can enhance wear resistance and reduce friction, further contributing to thermal efficiency by minimizing heat generation at contact points.

Valve geometry optimization is also essential for effective thermal management. Computer-aided design and finite element analysis allow engineers to create valve profiles that maximize heat dissipation while maintaining structural integrity. This may involve adjusting valve stem diameter, head thickness, and overall shape to optimize heat flow and structural strength.

Cooling system integration is another critical consideration. Advanced LS engines may incorporate targeted cooling strategies, such as precision oil jets directed at the underside of the valve heads or integrated cooling channels in the cylinder head. These systems work in tandem with the valve design to ensure efficient heat removal, particularly in high-load scenarios.

Lastly, advanced sealing technologies contribute to thermal management by minimizing hot gas leakage around the valve. High-performance valve seat materials and precision machining techniques ensure optimal sealing under extreme temperatures, reducing thermal stress on the valves and improving overall engine efficiency.

Environmental Impact of Advanced LS Valve Technologies

The environmental impact of advanced LS valve technologies in high-performance engines is a critical consideration in the automotive industry's pursuit of sustainability. These innovative valve designs, while primarily focused on enhancing engine performance, also contribute to improved fuel efficiency and reduced emissions. By optimizing valve timing, lift, and duration, advanced LS valve technologies enable more complete combustion, resulting in lower levels of unburned hydrocarbons and carbon monoxide.

One of the key environmental benefits of these advanced valve systems is their role in engine downsizing. By allowing smaller engines to produce equivalent power outputs, they contribute to overall vehicle weight reduction and improved fuel economy. This, in turn, leads to decreased carbon dioxide emissions per mile driven, aligning with global efforts to combat climate change.

Moreover, the materials used in advanced LS valve technologies often incorporate more durable and heat-resistant alloys. These materials not only enhance performance but also extend the lifespan of engine components, reducing the frequency of replacements and the associated environmental impact of manufacturing and disposing of worn parts.

The precision engineering of advanced valve technologies also contributes to reduced oil consumption. By minimizing valve guide wear and improving sealing, these systems help prevent oil from entering the combustion chamber, thereby reducing particulate emissions and extending oil change intervals. This reduction in oil consumption and maintenance frequency translates to fewer waste oil products and a lower environmental footprint over the engine's lifecycle.

However, it is important to note that the production of these advanced valve technologies may involve more energy-intensive processes and rare materials compared to conventional valve systems. The environmental impact of their manufacture must be weighed against the long-term benefits they provide in engine efficiency and longevity.

As emissions regulations become increasingly stringent worldwide, the role of advanced LS valve technologies in meeting these standards becomes more crucial. Their ability to fine-tune engine operation across various load conditions allows for more precise emissions control, particularly in transient operating modes where traditional engines often struggle to maintain optimal combustion characteristics.

Looking forward, the integration of advanced valve technologies with hybrid and electric powertrains presents new opportunities for environmental gains. In hybrid applications, these valve systems can optimize engine operation during charge-sustaining modes, further reducing fuel consumption and emissions in real-world driving conditions.

One of the key environmental benefits of these advanced valve systems is their role in engine downsizing. By allowing smaller engines to produce equivalent power outputs, they contribute to overall vehicle weight reduction and improved fuel economy. This, in turn, leads to decreased carbon dioxide emissions per mile driven, aligning with global efforts to combat climate change.

Moreover, the materials used in advanced LS valve technologies often incorporate more durable and heat-resistant alloys. These materials not only enhance performance but also extend the lifespan of engine components, reducing the frequency of replacements and the associated environmental impact of manufacturing and disposing of worn parts.

The precision engineering of advanced valve technologies also contributes to reduced oil consumption. By minimizing valve guide wear and improving sealing, these systems help prevent oil from entering the combustion chamber, thereby reducing particulate emissions and extending oil change intervals. This reduction in oil consumption and maintenance frequency translates to fewer waste oil products and a lower environmental footprint over the engine's lifecycle.

However, it is important to note that the production of these advanced valve technologies may involve more energy-intensive processes and rare materials compared to conventional valve systems. The environmental impact of their manufacture must be weighed against the long-term benefits they provide in engine efficiency and longevity.

As emissions regulations become increasingly stringent worldwide, the role of advanced LS valve technologies in meeting these standards becomes more crucial. Their ability to fine-tune engine operation across various load conditions allows for more precise emissions control, particularly in transient operating modes where traditional engines often struggle to maintain optimal combustion characteristics.

Looking forward, the integration of advanced valve technologies with hybrid and electric powertrains presents new opportunities for environmental gains. In hybrid applications, these valve systems can optimize engine operation during charge-sustaining modes, further reducing fuel consumption and emissions in real-world driving conditions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!