Nanotechnology Applications to Reduce LS Engine Emissions

AUG 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Nanotechnology in LS Engine Emission Control: Background and Objectives

Nanotechnology has emerged as a promising frontier in addressing the environmental challenges posed by internal combustion engines, particularly in reducing emissions from LS (Luxury Sport) engines. The development of nanotechnology applications in this field represents a convergence of materials science, chemistry, and automotive engineering, aimed at enhancing engine efficiency and minimizing harmful exhaust emissions.

The evolution of emission control technologies for LS engines has been driven by increasingly stringent environmental regulations and a growing global awareness of the need for sustainable transportation solutions. Traditional approaches to emission reduction, such as catalytic converters and particulate filters, while effective, have reached a plateau in terms of performance improvements. This has necessitated the exploration of novel technologies, with nanotechnology offering unprecedented opportunities for innovation.

Nanotechnology's potential in emission control stems from its ability to manipulate materials at the atomic and molecular scale, creating structures with unique properties that can significantly enhance catalytic efficiency, improve fuel combustion, and capture pollutants more effectively. The primary objective of applying nanotechnology to LS engine emission control is to develop advanced materials and systems that can dramatically reduce the release of harmful substances such as carbon monoxide, nitrogen oxides, and particulate matter.

Key areas of focus include the development of nano-engineered catalysts that can operate at lower temperatures and with higher efficiency, nanostructured materials for improved filtration of exhaust gases, and nano-additives for fuels to enhance combustion processes. These advancements aim not only to meet current emission standards but also to anticipate and exceed future regulatory requirements.

The technological trajectory in this field is characterized by a shift from macro-scale to nano-scale solutions, with researchers and engineers exploring the vast potential of materials like graphene, carbon nanotubes, and metal nanoparticles. This transition represents a paradigm shift in emission control strategies, moving from passive treatment of exhaust gases to active intervention in the combustion process itself.

As the automotive industry faces increasing pressure to reduce its environmental footprint, the integration of nanotechnology into LS engine emission control systems offers a pathway to achieving significant reductions in pollutant emissions without compromising engine performance or fuel efficiency. This aligns with broader industry goals of developing cleaner, more sustainable transportation technologies while maintaining the high performance expected from luxury sport vehicles.

The pursuit of nanotechnology applications in this domain is not without challenges, including issues of scalability, cost-effectiveness, and long-term durability of nano-engineered components in the harsh environment of an engine. However, the potential benefits in terms of emission reduction and improved air quality make this an area of intense research and development, with implications that extend far beyond the automotive sector.

The evolution of emission control technologies for LS engines has been driven by increasingly stringent environmental regulations and a growing global awareness of the need for sustainable transportation solutions. Traditional approaches to emission reduction, such as catalytic converters and particulate filters, while effective, have reached a plateau in terms of performance improvements. This has necessitated the exploration of novel technologies, with nanotechnology offering unprecedented opportunities for innovation.

Nanotechnology's potential in emission control stems from its ability to manipulate materials at the atomic and molecular scale, creating structures with unique properties that can significantly enhance catalytic efficiency, improve fuel combustion, and capture pollutants more effectively. The primary objective of applying nanotechnology to LS engine emission control is to develop advanced materials and systems that can dramatically reduce the release of harmful substances such as carbon monoxide, nitrogen oxides, and particulate matter.

Key areas of focus include the development of nano-engineered catalysts that can operate at lower temperatures and with higher efficiency, nanostructured materials for improved filtration of exhaust gases, and nano-additives for fuels to enhance combustion processes. These advancements aim not only to meet current emission standards but also to anticipate and exceed future regulatory requirements.

The technological trajectory in this field is characterized by a shift from macro-scale to nano-scale solutions, with researchers and engineers exploring the vast potential of materials like graphene, carbon nanotubes, and metal nanoparticles. This transition represents a paradigm shift in emission control strategies, moving from passive treatment of exhaust gases to active intervention in the combustion process itself.

As the automotive industry faces increasing pressure to reduce its environmental footprint, the integration of nanotechnology into LS engine emission control systems offers a pathway to achieving significant reductions in pollutant emissions without compromising engine performance or fuel efficiency. This aligns with broader industry goals of developing cleaner, more sustainable transportation technologies while maintaining the high performance expected from luxury sport vehicles.

The pursuit of nanotechnology applications in this domain is not without challenges, including issues of scalability, cost-effectiveness, and long-term durability of nano-engineered components in the harsh environment of an engine. However, the potential benefits in terms of emission reduction and improved air quality make this an area of intense research and development, with implications that extend far beyond the automotive sector.

Market Demand for Low-Emission LS Engines

The market demand for low-emission LS engines has been steadily increasing in recent years, driven by stringent environmental regulations, growing consumer awareness, and the automotive industry's shift towards more sustainable technologies. As governments worldwide implement stricter emission standards, such as Euro 6 in Europe and Tier 3 in the United States, automakers are under pressure to develop cleaner engine technologies.

The LS engine, known for its performance and reliability, has been a popular choice in various vehicle segments. However, its traditional design faces challenges in meeting modern emission requirements. This has created a significant market opportunity for low-emission variants that can maintain the LS engine's desirable characteristics while reducing harmful emissions.

Consumer preferences have also shifted towards more environmentally friendly vehicles, with many buyers willing to pay a premium for cleaner technologies. This trend is particularly evident in developed markets, where environmental consciousness is high, and governments offer incentives for low-emission vehicles.

The commercial vehicle sector represents another substantial market for low-emission LS engines. Fleet operators are increasingly seeking ways to reduce their carbon footprint and comply with urban emission zones, making cleaner LS engine options highly attractive.

Automotive manufacturers are investing heavily in research and development to meet this demand. The integration of nanotechnology in emission reduction systems for LS engines has emerged as a promising solution. Nanotech applications can potentially enhance catalytic converter efficiency, improve fuel combustion, and reduce particulate matter emissions without compromising engine performance.

The aftermarket sector also presents a significant opportunity, as owners of existing LS-powered vehicles seek upgrades to improve emissions performance. This has led to the development of retrofit solutions incorporating nanotechnology, further expanding the market for low-emission LS engine technologies.

Market analysts project substantial growth in the low-emission engine segment over the next decade. The global push towards carbon neutrality and the implementation of more stringent emission standards in emerging markets are expected to further drive demand for cleaner LS engine variants.

The LS engine, known for its performance and reliability, has been a popular choice in various vehicle segments. However, its traditional design faces challenges in meeting modern emission requirements. This has created a significant market opportunity for low-emission variants that can maintain the LS engine's desirable characteristics while reducing harmful emissions.

Consumer preferences have also shifted towards more environmentally friendly vehicles, with many buyers willing to pay a premium for cleaner technologies. This trend is particularly evident in developed markets, where environmental consciousness is high, and governments offer incentives for low-emission vehicles.

The commercial vehicle sector represents another substantial market for low-emission LS engines. Fleet operators are increasingly seeking ways to reduce their carbon footprint and comply with urban emission zones, making cleaner LS engine options highly attractive.

Automotive manufacturers are investing heavily in research and development to meet this demand. The integration of nanotechnology in emission reduction systems for LS engines has emerged as a promising solution. Nanotech applications can potentially enhance catalytic converter efficiency, improve fuel combustion, and reduce particulate matter emissions without compromising engine performance.

The aftermarket sector also presents a significant opportunity, as owners of existing LS-powered vehicles seek upgrades to improve emissions performance. This has led to the development of retrofit solutions incorporating nanotechnology, further expanding the market for low-emission LS engine technologies.

Market analysts project substantial growth in the low-emission engine segment over the next decade. The global push towards carbon neutrality and the implementation of more stringent emission standards in emerging markets are expected to further drive demand for cleaner LS engine variants.

Current Challenges in LS Engine Emission Reduction

Despite significant advancements in engine technology, Large-Scale (LS) engines continue to face substantial challenges in emission reduction. One of the primary obstacles is the inherent trade-off between engine performance and emissions control. As engines are optimized for power and efficiency, they often produce higher levels of pollutants, particularly nitrogen oxides (NOx) and particulate matter (PM).

The complexity of combustion processes in LS engines presents another major challenge. The large cylinder volumes and high compression ratios characteristic of these engines create conditions that are difficult to control precisely, leading to incomplete combustion and increased emissions. This is exacerbated by the variability in fuel quality and operating conditions, which can significantly impact emission levels.

Aftertreatment systems, while effective, face limitations in their ability to handle the high exhaust volumes and temperatures produced by LS engines. Current catalytic converters and particulate filters struggle to maintain efficiency over the wide range of operating conditions experienced by these engines, particularly during cold starts and low-load operations.

The durability and longevity of emission control systems pose another significant challenge. LS engines often operate in demanding environments and for extended periods, putting considerable stress on emission reduction components. Ensuring these systems maintain their effectiveness over the engine's entire lifecycle without frequent maintenance or replacement is a critical concern.

Cost considerations also play a crucial role in the challenges faced by LS engine emission reduction efforts. Implementing advanced emission control technologies can significantly increase the overall cost of the engine, making it less competitive in price-sensitive markets. This economic factor often leads to a reluctance in adopting cutting-edge emission reduction solutions.

Regulatory compliance adds another layer of complexity to the emission reduction challenge. As environmental regulations become increasingly stringent, LS engine manufacturers must continually innovate to meet new standards. This often requires substantial investments in research and development, as well as redesigns of existing engine architectures.

The integration of emission reduction technologies with engine control systems presents its own set of challenges. Optimizing the interaction between combustion parameters, fuel injection strategies, and aftertreatment systems requires sophisticated control algorithms and sensors, adding to the complexity and potential points of failure in the engine system.

The complexity of combustion processes in LS engines presents another major challenge. The large cylinder volumes and high compression ratios characteristic of these engines create conditions that are difficult to control precisely, leading to incomplete combustion and increased emissions. This is exacerbated by the variability in fuel quality and operating conditions, which can significantly impact emission levels.

Aftertreatment systems, while effective, face limitations in their ability to handle the high exhaust volumes and temperatures produced by LS engines. Current catalytic converters and particulate filters struggle to maintain efficiency over the wide range of operating conditions experienced by these engines, particularly during cold starts and low-load operations.

The durability and longevity of emission control systems pose another significant challenge. LS engines often operate in demanding environments and for extended periods, putting considerable stress on emission reduction components. Ensuring these systems maintain their effectiveness over the engine's entire lifecycle without frequent maintenance or replacement is a critical concern.

Cost considerations also play a crucial role in the challenges faced by LS engine emission reduction efforts. Implementing advanced emission control technologies can significantly increase the overall cost of the engine, making it less competitive in price-sensitive markets. This economic factor often leads to a reluctance in adopting cutting-edge emission reduction solutions.

Regulatory compliance adds another layer of complexity to the emission reduction challenge. As environmental regulations become increasingly stringent, LS engine manufacturers must continually innovate to meet new standards. This often requires substantial investments in research and development, as well as redesigns of existing engine architectures.

The integration of emission reduction technologies with engine control systems presents its own set of challenges. Optimizing the interaction between combustion parameters, fuel injection strategies, and aftertreatment systems requires sophisticated control algorithms and sensors, adding to the complexity and potential points of failure in the engine system.

Existing Nanomaterial Solutions for LS Engine Emissions

01 Nanoparticle emission control in manufacturing processes

This category focuses on methods and systems for controlling and reducing nanoparticle emissions during various manufacturing processes. It includes techniques for capturing, filtering, and monitoring nanoparticles to minimize their release into the environment and protect worker health.- Nanoparticle emission control in manufacturing processes: This category focuses on methods and systems for controlling nanoparticle emissions during various manufacturing processes. It includes techniques for capturing, filtering, and monitoring nanoparticles to minimize their release into the environment and protect worker health.

- Nanotechnology-based air purification systems: This point covers the development of air purification systems that utilize nanotechnology to remove pollutants and harmful particles from the air. These systems may incorporate nanomaterials or nanostructures to enhance filtration efficiency and reduce emissions in various settings.

- Nanocoatings for emission reduction in industrial applications: This category involves the use of nanocoatings and nanomaterials to reduce emissions in industrial processes. These coatings can be applied to surfaces or equipment to catalyze reactions, trap pollutants, or improve energy efficiency, thereby reducing overall emissions.

- Nanosensors for emission detection and monitoring: This point focuses on the development and application of nanosensors for detecting and monitoring emissions at the nanoscale. These sensors can provide real-time data on nanoparticle concentrations and help in implementing effective emission control strategies.

- Environmental impact assessment of nanotechnology emissions: This category covers research and methodologies for assessing the environmental impact of nanotechnology emissions. It includes studies on the fate and behavior of nanoparticles in different ecosystems, their potential risks, and the development of guidelines for safe handling and disposal of nanomaterials.

02 Nanotechnology-based air purification systems

This point covers the development of air purification systems that utilize nanotechnology to remove pollutants and harmful particles from the air. These systems may incorporate nanomaterials or nanostructures to enhance filtration efficiency and reduce emissions in various settings.Expand Specific Solutions03 Nanocoatings for emission reduction in automotive applications

This category explores the use of nanocoatings and nanomaterials in automotive applications to reduce emissions. It includes innovations in catalytic converters, exhaust systems, and engine components that leverage nanotechnology to improve fuel efficiency and minimize harmful emissions.Expand Specific Solutions04 Nanosensors for emission detection and monitoring

This point focuses on the development and application of nanosensors for detecting and monitoring various types of emissions. These sensors utilize nanomaterials or nanostructures to achieve high sensitivity and selectivity in measuring pollutants and potentially harmful nanoparticle emissions.Expand Specific Solutions05 Environmental impact assessment of nanoparticle emissions

This category addresses methods and systems for assessing the environmental impact of nanoparticle emissions. It includes techniques for measuring, analyzing, and modeling the behavior of nanoparticles in various ecosystems to better understand their potential risks and develop appropriate mitigation strategies.Expand Specific Solutions

Key Players in Automotive Nanotechnology and Emission Control

The nanotechnology applications for reducing LS engine emissions are in an early development stage, with significant potential for growth. The market size is expanding as automotive manufacturers seek innovative solutions to meet stringent emission standards. While the technology is still maturing, several key players are actively involved in research and development. Companies like Ford Global Technologies LLC, GM Global Technology Operations LLC, and Toyota Motor Corp. are leading the charge, leveraging their extensive automotive expertise. Research institutions such as Southwest Research Institute and King Abdullah University of Science & Technology are contributing to advancements in this field. The competitive landscape is dynamic, with both established automotive giants and specialized nanotechnology firms vying for market share and technological breakthroughs.

Ford Global Technologies LLC

Technical Solution: Ford has implemented a multi-pronged nanotechnology strategy to address LS engine emissions. Their approach includes the development of nano-structured catalytic converters that utilize precisely controlled arrangements of noble metal nanoparticles to maximize catalytic efficiency while minimizing precious metal usage[10]. Ford has also pioneered the use of carbon nanotube-reinforced polymers in engine components, reducing weight and improving thermal management. Additionally, they have developed nano-engineered surface treatments for cylinder walls that significantly reduce friction and oil consumption, leading to improved fuel efficiency and reduced emissions[11]. Ford's research extends to nano-sensors integrated into the exhaust system for real-time emissions monitoring and engine control optimization[12].

Strengths: Integrated approach combining materials science and sensor technology. Potential for significant emission reductions without major engine redesigns. Weaknesses: Some technologies may have high initial costs and require specialized manufacturing processes.

GM Global Technology Operations LLC

Technical Solution: GM has developed a nanotechnology-based catalytic converter system for LS engines that utilizes advanced nanomaterials to enhance catalytic efficiency. The system employs nanoparticles of precious metals like platinum and palladium, which are dispersed on a high-surface-area nanoporous support structure. This nano-engineered catalyst significantly increases the active surface area, leading to improved conversion of harmful emissions. GM's approach also incorporates smart nano-sensors that continuously monitor exhaust composition, allowing for real-time adjustments to engine parameters and catalytic performance[1][3]. Additionally, GM has integrated nano-scale thermal management materials to optimize catalyst temperature, ensuring peak efficiency across a wider range of operating conditions[5].

Strengths: Highly efficient emission reduction, improved catalyst durability, and adaptive performance. Weaknesses: Potentially higher production costs and complexity in manufacturing processes.

Innovative Nanotech Approaches for Emission Reduction

Combatting air pollution

PatentInactiveEP1049529B1

Innovation

- The method involves contacting exhaust gas with ozone at temperatures from ambient to 250°C in the absence of platinum, selectively oxidizing NO to NO2 while minimizing SO2 conversion to SO3, using an ozone generator to inject ozone into the exhaust gas, and subsequently reducing NO2 to N2.

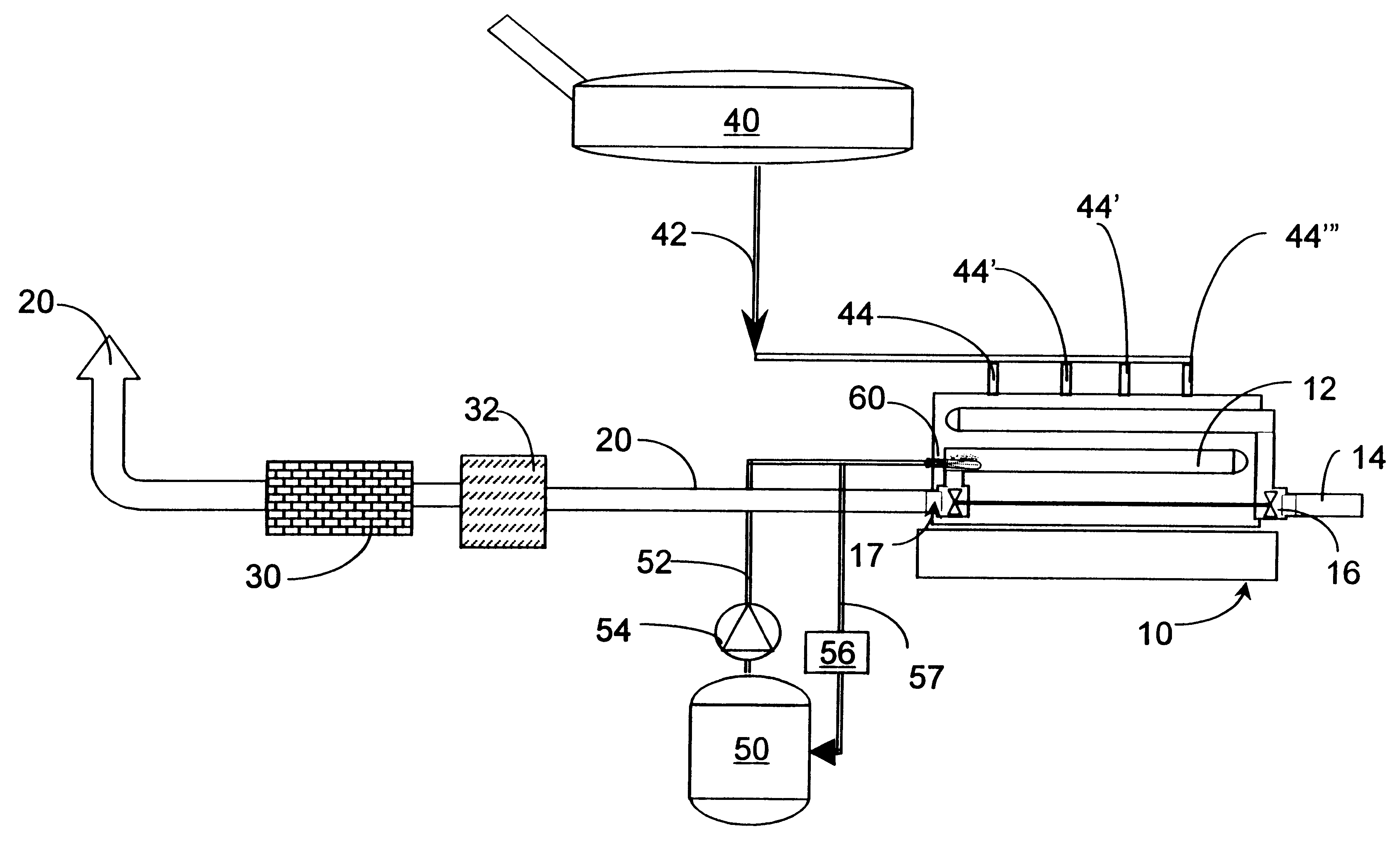

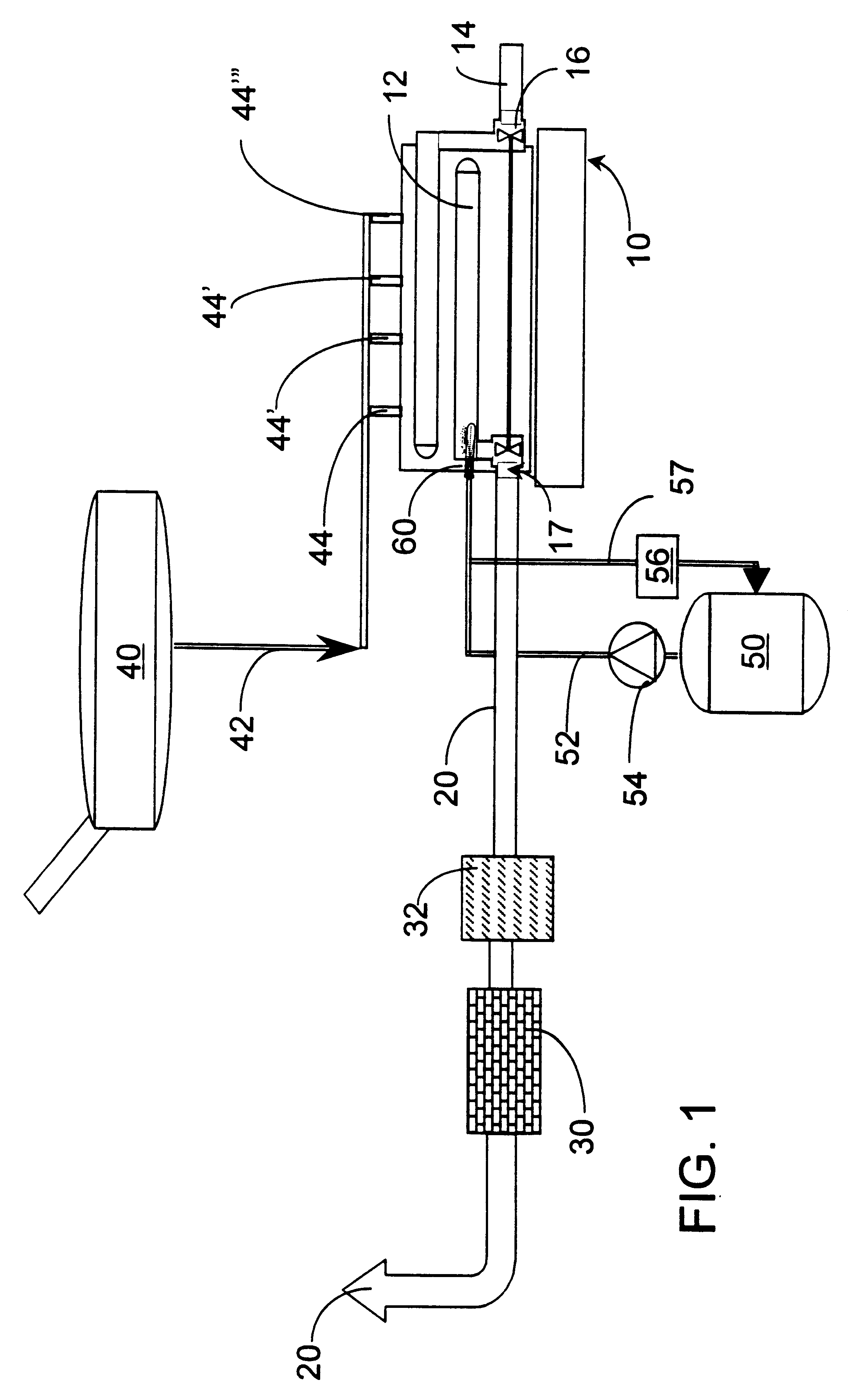

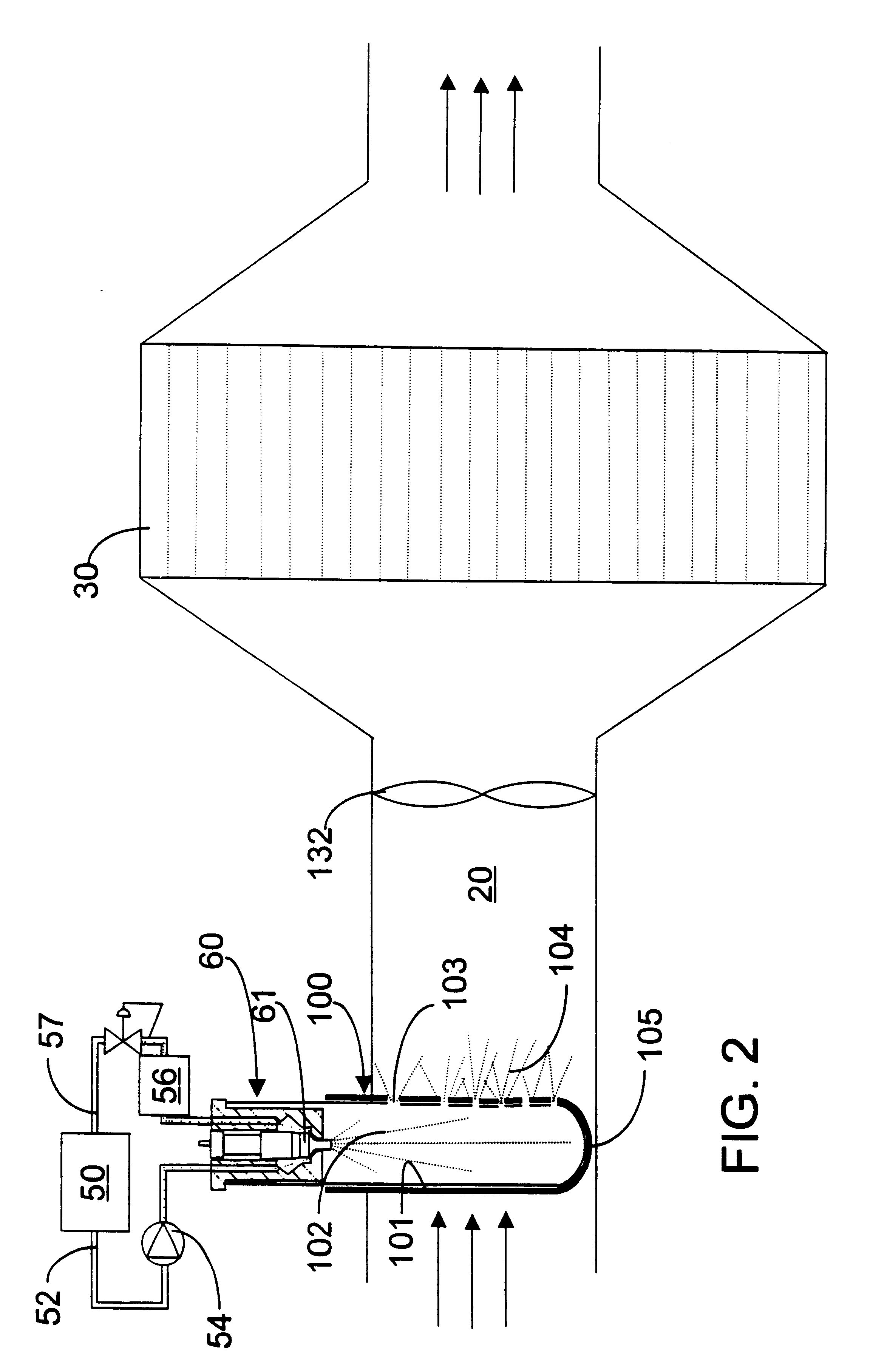

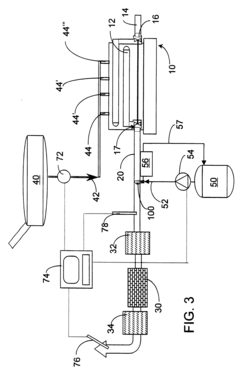

Urea pyrolysis chamber and process for reducing lean-burn engine NOx emissions by selective catalytic reduction

PatentInactiveUS6203770B1

Innovation

- A process and apparatus that involves spraying an aqueous urea solution onto heated surfaces in a pyrolysis chamber to evaporate water and pyrolyze urea, generating gaseous products which are then introduced into the exhaust gases and contacted with an SCR reactor for selective catalytic reduction, allowing for close coupling of reagent injection and catalyst, eliminating the need for ammonia and reducing fouling risks.

Environmental Impact Assessment of Nanotech Solutions

The application of nanotechnology to reduce LS engine emissions presents both potential benefits and environmental concerns that require careful assessment. Nanoparticles used in catalytic converters and fuel additives can significantly enhance emission reduction efficiency, potentially lowering harmful pollutants such as carbon monoxide, nitrogen oxides, and particulate matter. However, the environmental impact of these nanotech solutions must be thoroughly evaluated.

One primary consideration is the potential release of engineered nanoparticles into the environment. As catalytic converters degrade over time, there is a risk of nanoparticles being emitted along with exhaust gases. These particles may have unforeseen effects on air quality, soil composition, and aquatic ecosystems. Long-term studies are needed to understand the fate and behavior of these nanoparticles in various environmental compartments.

The production and disposal of nanotech-enhanced components also raise environmental concerns. Manufacturing processes for nanomaterials often require significant energy inputs and may involve hazardous chemicals. Proper disposal and recycling methods for nanoparticle-containing automotive parts must be developed to prevent environmental contamination and potential health risks.

Lifecycle assessment (LCA) studies are crucial to evaluate the overall environmental impact of nanotech solutions in LS engines. These assessments should compare the environmental footprint of conventional emission reduction technologies with nanotech-enhanced alternatives, considering factors such as resource consumption, energy use, and emissions throughout the product lifecycle.

Potential ecological impacts on flora and fauna must also be investigated. Nanoparticles may interact with biological systems in ways that are not yet fully understood. Research is needed to assess potential bioaccumulation, toxicity, and long-term effects on ecosystems exposed to nanoparticles from automotive emissions.

Regulatory frameworks and standardization efforts are essential to ensure the safe development and implementation of nanotech solutions for LS engine emissions. Environmental monitoring protocols specific to engineered nanoparticles should be established to track their presence and behavior in the environment. This data will be crucial for ongoing impact assessments and the refinement of nanotech applications in automotive emission control.

One primary consideration is the potential release of engineered nanoparticles into the environment. As catalytic converters degrade over time, there is a risk of nanoparticles being emitted along with exhaust gases. These particles may have unforeseen effects on air quality, soil composition, and aquatic ecosystems. Long-term studies are needed to understand the fate and behavior of these nanoparticles in various environmental compartments.

The production and disposal of nanotech-enhanced components also raise environmental concerns. Manufacturing processes for nanomaterials often require significant energy inputs and may involve hazardous chemicals. Proper disposal and recycling methods for nanoparticle-containing automotive parts must be developed to prevent environmental contamination and potential health risks.

Lifecycle assessment (LCA) studies are crucial to evaluate the overall environmental impact of nanotech solutions in LS engines. These assessments should compare the environmental footprint of conventional emission reduction technologies with nanotech-enhanced alternatives, considering factors such as resource consumption, energy use, and emissions throughout the product lifecycle.

Potential ecological impacts on flora and fauna must also be investigated. Nanoparticles may interact with biological systems in ways that are not yet fully understood. Research is needed to assess potential bioaccumulation, toxicity, and long-term effects on ecosystems exposed to nanoparticles from automotive emissions.

Regulatory frameworks and standardization efforts are essential to ensure the safe development and implementation of nanotech solutions for LS engine emissions. Environmental monitoring protocols specific to engineered nanoparticles should be established to track their presence and behavior in the environment. This data will be crucial for ongoing impact assessments and the refinement of nanotech applications in automotive emission control.

Regulatory Framework for Automotive Nanotechnology Applications

The regulatory framework for automotive nanotechnology applications is a complex and evolving landscape that plays a crucial role in shaping the development and implementation of nanotechnology solutions for reducing LS engine emissions. As governments and regulatory bodies worldwide recognize the potential of nanotechnology in addressing environmental concerns, they are working to establish comprehensive guidelines and standards to ensure the safe and effective use of these innovative technologies.

At the forefront of this regulatory framework is the Environmental Protection Agency (EPA) in the United States, which has been actively developing policies and regulations specific to nanomaterials in automotive applications. The EPA's approach focuses on assessing the potential risks and benefits of nanotechnology-based solutions, with particular emphasis on their impact on air quality and human health. This includes stringent testing requirements for nanomaterials used in catalytic converters, particulate filters, and other emission control devices.

In the European Union, the European Chemicals Agency (ECHA) has implemented the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation, which encompasses nanomaterials used in automotive applications. REACH mandates that manufacturers and importers provide detailed information on the properties and potential risks of nanomaterials, ensuring a high level of protection for human health and the environment.

Japan's Ministry of Economy, Trade, and Industry (METI) has also established guidelines for the safe handling and use of nanomaterials in various industries, including automotive. These guidelines emphasize the importance of risk assessment and management throughout the lifecycle of nanotechnology-based products, from research and development to disposal.

International organizations such as the Organization for Economic Co-operation and Development (OECD) and the International Organization for Standardization (ISO) are working to harmonize global standards for nanotechnology applications. The OECD's Working Party on Manufactured Nanomaterials (WPMN) has developed a series of test guidelines specifically for nanomaterials, which are being adopted by regulatory agencies worldwide.

As the field of nanotechnology continues to advance, regulatory frameworks are expected to evolve to address emerging challenges and opportunities. This includes the development of more sophisticated testing methods to assess the long-term environmental impact of nanomaterials used in automotive applications, as well as the establishment of clear labeling and reporting requirements for manufacturers.

The regulatory landscape also encompasses intellectual property considerations, with patent offices worldwide adapting their processes to accommodate the unique aspects of nanotechnology inventions. This includes addressing issues related to the patentability of nanoscale structures and their applications in emission reduction technologies.

At the forefront of this regulatory framework is the Environmental Protection Agency (EPA) in the United States, which has been actively developing policies and regulations specific to nanomaterials in automotive applications. The EPA's approach focuses on assessing the potential risks and benefits of nanotechnology-based solutions, with particular emphasis on their impact on air quality and human health. This includes stringent testing requirements for nanomaterials used in catalytic converters, particulate filters, and other emission control devices.

In the European Union, the European Chemicals Agency (ECHA) has implemented the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation, which encompasses nanomaterials used in automotive applications. REACH mandates that manufacturers and importers provide detailed information on the properties and potential risks of nanomaterials, ensuring a high level of protection for human health and the environment.

Japan's Ministry of Economy, Trade, and Industry (METI) has also established guidelines for the safe handling and use of nanomaterials in various industries, including automotive. These guidelines emphasize the importance of risk assessment and management throughout the lifecycle of nanotechnology-based products, from research and development to disposal.

International organizations such as the Organization for Economic Co-operation and Development (OECD) and the International Organization for Standardization (ISO) are working to harmonize global standards for nanotechnology applications. The OECD's Working Party on Manufactured Nanomaterials (WPMN) has developed a series of test guidelines specifically for nanomaterials, which are being adopted by regulatory agencies worldwide.

As the field of nanotechnology continues to advance, regulatory frameworks are expected to evolve to address emerging challenges and opportunities. This includes the development of more sophisticated testing methods to assess the long-term environmental impact of nanomaterials used in automotive applications, as well as the establishment of clear labeling and reporting requirements for manufacturers.

The regulatory landscape also encompasses intellectual property considerations, with patent offices worldwide adapting their processes to accommodate the unique aspects of nanotechnology inventions. This includes addressing issues related to the patentability of nanoscale structures and their applications in emission reduction technologies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!