Analyzing LSA Engine Variable Valve timing Systems

SEP 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LSA Engine VVT Technology Background and Objectives

Variable Valve Timing (VVT) technology represents a significant advancement in internal combustion engine design, with the LSA Engine's implementation marking a notable milestone in automotive engineering. The evolution of VVT systems began in the 1980s with rudimentary mechanical systems, progressing through the 1990s with hydraulic actuation, and reaching sophisticated electronic control systems in modern applications. The LSA Engine, a supercharged 6.2L V8 developed by General Motors, incorporates advanced VVT technology to optimize performance across varying operating conditions.

The primary objective of VVT implementation in LSA engines is to enhance volumetric efficiency by precisely controlling valve timing relative to piston position. This optimization allows for improved power output, fuel economy, and emissions reduction - a critical triad of performance metrics in contemporary engine design. The LSA Engine's VVT system specifically aims to deliver responsive low-end torque while maintaining high-RPM power, addressing the traditional compromise between these performance characteristics.

Historical data indicates that VVT technology has evolved through three distinct generations, with the LSA Engine's system representing the third generation that features continuous and independent control of intake and exhaust valve timing. This technological progression has been driven by increasingly stringent emissions regulations worldwide, particularly Euro 6 and EPA Tier 3 standards, which demand unprecedented levels of combustion efficiency.

The LSA Engine's VVT system utilizes cam phasing technology that allows for up to 62 degrees of camshaft rotation relative to the crankshaft. This range enables significant overlap control between intake and exhaust valve events, facilitating internal exhaust gas recirculation (EGR) at specific operating points to reduce NOx emissions while maintaining combustion stability.

Technical objectives for the LSA Engine's VVT system include achieving response times under 300 milliseconds for camshaft phase adjustments, maintaining phase accuracy within ±2 degrees across the operating range, and ensuring system durability for the engine's service life (typically 150,000+ miles). These parameters are critical for meeting both performance expectations and regulatory requirements.

The integration of VVT with the LSA's supercharging system presents unique engineering challenges, as the forced induction alters the optimal valve timing maps compared to naturally aspirated engines. Engineers have developed specialized control algorithms that account for boost pressure when determining ideal valve timing, representing a significant advancement in engine management technology.

Looking forward, the technical trajectory for LSA Engine VVT systems points toward fully electronic valve actuation, eliminating mechanical camshafts entirely. This evolution aims to provide infinite variability in valve timing and lift, potentially unlocking further efficiency gains of 8-12% according to recent research publications from automotive engineering consortiums.

The primary objective of VVT implementation in LSA engines is to enhance volumetric efficiency by precisely controlling valve timing relative to piston position. This optimization allows for improved power output, fuel economy, and emissions reduction - a critical triad of performance metrics in contemporary engine design. The LSA Engine's VVT system specifically aims to deliver responsive low-end torque while maintaining high-RPM power, addressing the traditional compromise between these performance characteristics.

Historical data indicates that VVT technology has evolved through three distinct generations, with the LSA Engine's system representing the third generation that features continuous and independent control of intake and exhaust valve timing. This technological progression has been driven by increasingly stringent emissions regulations worldwide, particularly Euro 6 and EPA Tier 3 standards, which demand unprecedented levels of combustion efficiency.

The LSA Engine's VVT system utilizes cam phasing technology that allows for up to 62 degrees of camshaft rotation relative to the crankshaft. This range enables significant overlap control between intake and exhaust valve events, facilitating internal exhaust gas recirculation (EGR) at specific operating points to reduce NOx emissions while maintaining combustion stability.

Technical objectives for the LSA Engine's VVT system include achieving response times under 300 milliseconds for camshaft phase adjustments, maintaining phase accuracy within ±2 degrees across the operating range, and ensuring system durability for the engine's service life (typically 150,000+ miles). These parameters are critical for meeting both performance expectations and regulatory requirements.

The integration of VVT with the LSA's supercharging system presents unique engineering challenges, as the forced induction alters the optimal valve timing maps compared to naturally aspirated engines. Engineers have developed specialized control algorithms that account for boost pressure when determining ideal valve timing, representing a significant advancement in engine management technology.

Looking forward, the technical trajectory for LSA Engine VVT systems points toward fully electronic valve actuation, eliminating mechanical camshafts entirely. This evolution aims to provide infinite variability in valve timing and lift, potentially unlocking further efficiency gains of 8-12% according to recent research publications from automotive engineering consortiums.

Market Analysis for Variable Valve Timing Systems

The variable valve timing (VVT) system market has experienced substantial growth over the past decade, driven primarily by stringent emission regulations and increasing consumer demand for fuel-efficient vehicles. The global market for VVT systems was valued at approximately $32.5 billion in 2022 and is projected to reach $45.7 billion by 2028, representing a compound annual growth rate (CAGR) of 5.8% during the forecast period.

The passenger vehicle segment dominates the market share, accounting for over 70% of the total VVT system installations. This dominance is attributed to the higher production volume of passenger vehicles compared to commercial vehicles and the increasing adoption of advanced engine technologies in mid-range and premium passenger cars. Within this segment, continuous variable valve timing (CVVT) systems have gained significant traction due to their superior performance in optimizing engine efficiency across various operating conditions.

Regional analysis reveals that Asia-Pacific currently leads the market, with China and Japan being the major contributors. The region's dominance is fueled by the presence of major automotive manufacturers, increasing vehicle production, and growing consumer preference for fuel-efficient vehicles. North America and Europe follow closely, with their markets primarily driven by stringent emission norms and the high adoption rate of advanced automotive technologies.

The commercial vehicle segment, although smaller in market share, is witnessing faster growth at a CAGR of approximately 6.5%. This growth is primarily attributed to the implementation of stringent emission regulations for commercial vehicles in developed regions and the increasing focus on reducing operating costs through improved fuel efficiency.

Market penetration analysis indicates that approximately 65% of new vehicles globally are equipped with some form of VVT system, with the percentage significantly higher in developed markets (85-90%) compared to emerging markets (40-45%). This disparity presents substantial growth opportunities in developing regions as emission standards become more stringent and consumer awareness regarding fuel efficiency increases.

The aftermarket segment for VVT systems is also gaining momentum, valued at approximately $5.3 billion in 2022. This growth is driven by the increasing average age of vehicles in operation and the growing awareness among vehicle owners about the benefits of upgrading to more efficient engine components.

The passenger vehicle segment dominates the market share, accounting for over 70% of the total VVT system installations. This dominance is attributed to the higher production volume of passenger vehicles compared to commercial vehicles and the increasing adoption of advanced engine technologies in mid-range and premium passenger cars. Within this segment, continuous variable valve timing (CVVT) systems have gained significant traction due to their superior performance in optimizing engine efficiency across various operating conditions.

Regional analysis reveals that Asia-Pacific currently leads the market, with China and Japan being the major contributors. The region's dominance is fueled by the presence of major automotive manufacturers, increasing vehicle production, and growing consumer preference for fuel-efficient vehicles. North America and Europe follow closely, with their markets primarily driven by stringent emission norms and the high adoption rate of advanced automotive technologies.

The commercial vehicle segment, although smaller in market share, is witnessing faster growth at a CAGR of approximately 6.5%. This growth is primarily attributed to the implementation of stringent emission regulations for commercial vehicles in developed regions and the increasing focus on reducing operating costs through improved fuel efficiency.

Market penetration analysis indicates that approximately 65% of new vehicles globally are equipped with some form of VVT system, with the percentage significantly higher in developed markets (85-90%) compared to emerging markets (40-45%). This disparity presents substantial growth opportunities in developing regions as emission standards become more stringent and consumer awareness regarding fuel efficiency increases.

The aftermarket segment for VVT systems is also gaining momentum, valued at approximately $5.3 billion in 2022. This growth is driven by the increasing average age of vehicles in operation and the growing awareness among vehicle owners about the benefits of upgrading to more efficient engine components.

Current VVT Technology Landscape and Challenges

Variable Valve Timing (VVT) technology in LSA engines has evolved significantly over the past decade, with current systems representing a complex interplay of mechanical, hydraulic, and electronic components. The landscape is dominated by cam-phasing systems that adjust valve timing by rotating the camshaft relative to its drive gear, optimizing engine performance across various operating conditions.

The predominant VVT technologies in today's market include hydraulic cam phasers, electric cam phasers, and more advanced systems incorporating both intake and exhaust timing control. Hydraulic systems remain the most widely implemented due to their reliability and cost-effectiveness, utilizing engine oil pressure controlled by solenoid valves to adjust camshaft position. Electric systems, though less common, offer faster response times and more precise control, particularly at low engine speeds where oil pressure may be insufficient.

Current challenges in LSA engine VVT systems center around several key areas. Response time limitations remain significant, with hydraulic systems typically requiring 0.2-0.5 seconds to fully adjust timing—too slow for optimal transient operation. System complexity presents another hurdle, as more sophisticated control strategies demand additional sensors, actuators, and computational resources, increasing both cost and potential failure points.

Durability concerns persist, particularly in high-performance applications where thermal stress and mechanical wear accelerate component degradation. The oil-dependent nature of hydraulic systems introduces vulnerability to oil quality and temperature variations, potentially compromising system performance under extreme conditions.

Energy efficiency represents another challenge, as conventional VVT systems consume engine power for operation, partially offsetting the efficiency gains they provide. This parasitic loss becomes increasingly significant as manufacturers pursue marginal improvements in fuel economy and emissions reduction.

Integration with other engine technologies presents additional complexity, as VVT systems must work harmoniously with direct injection, turbocharging, and cylinder deactivation technologies. The control algorithms governing these interactions require sophisticated calibration to maximize benefits while avoiding operational conflicts.

Emissions compliance drives continuous refinement of VVT technology, with increasingly stringent regulations demanding more precise combustion control across all operating conditions. Cold-start emissions remain particularly challenging, requiring specialized VVT strategies to rapidly achieve optimal combustion temperatures while minimizing pollutant formation.

Cost pressures continue to shape the technology landscape, with manufacturers seeking to deliver advanced functionality while maintaining competitive pricing. This economic reality often necessitates compromises between performance, durability, and manufacturing complexity.

The predominant VVT technologies in today's market include hydraulic cam phasers, electric cam phasers, and more advanced systems incorporating both intake and exhaust timing control. Hydraulic systems remain the most widely implemented due to their reliability and cost-effectiveness, utilizing engine oil pressure controlled by solenoid valves to adjust camshaft position. Electric systems, though less common, offer faster response times and more precise control, particularly at low engine speeds where oil pressure may be insufficient.

Current challenges in LSA engine VVT systems center around several key areas. Response time limitations remain significant, with hydraulic systems typically requiring 0.2-0.5 seconds to fully adjust timing—too slow for optimal transient operation. System complexity presents another hurdle, as more sophisticated control strategies demand additional sensors, actuators, and computational resources, increasing both cost and potential failure points.

Durability concerns persist, particularly in high-performance applications where thermal stress and mechanical wear accelerate component degradation. The oil-dependent nature of hydraulic systems introduces vulnerability to oil quality and temperature variations, potentially compromising system performance under extreme conditions.

Energy efficiency represents another challenge, as conventional VVT systems consume engine power for operation, partially offsetting the efficiency gains they provide. This parasitic loss becomes increasingly significant as manufacturers pursue marginal improvements in fuel economy and emissions reduction.

Integration with other engine technologies presents additional complexity, as VVT systems must work harmoniously with direct injection, turbocharging, and cylinder deactivation technologies. The control algorithms governing these interactions require sophisticated calibration to maximize benefits while avoiding operational conflicts.

Emissions compliance drives continuous refinement of VVT technology, with increasingly stringent regulations demanding more precise combustion control across all operating conditions. Cold-start emissions remain particularly challenging, requiring specialized VVT strategies to rapidly achieve optimal combustion temperatures while minimizing pollutant formation.

Cost pressures continue to shape the technology landscape, with manufacturers seeking to deliver advanced functionality while maintaining competitive pricing. This economic reality often necessitates compromises between performance, durability, and manufacturing complexity.

Current LSA Engine VVT Implementation Strategies

01 Hydraulic Variable Valve Timing Systems

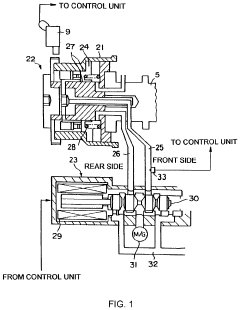

Hydraulic systems use oil pressure to adjust the timing of valve operations in internal combustion engines. These systems typically include hydraulic actuators, control valves, and oil flow passages that allow for precise control of camshaft phasing relative to the crankshaft. The hydraulic pressure can be regulated to advance or retard valve timing based on engine operating conditions, improving performance, fuel efficiency, and emissions control.- Hydraulic Variable Valve Timing Systems: Hydraulic systems use oil pressure to adjust the timing of valve operations in internal combustion engines. These systems typically include hydraulic actuators that can advance or retard the camshaft position relative to the crankshaft. The hydraulic pressure is controlled by solenoid valves that regulate oil flow to the actuator chambers, allowing for precise control of valve timing based on engine operating conditions.

- Electronic Control Strategies for Variable Valve Timing: Advanced electronic control units (ECUs) manage variable valve timing systems by processing data from various engine sensors to determine optimal valve timing. These control strategies include adaptive algorithms that adjust timing based on factors such as engine load, speed, temperature, and driver demand. The electronic systems can implement different timing maps for various operating conditions, improving engine performance, fuel efficiency, and emissions control across the entire operating range.

- Cam Phasing Mechanisms for Variable Valve Timing: Cam phasing mechanisms allow for the rotation of the camshaft relative to its drive sprocket or gear, changing the valve timing. These mechanisms include vane-type phasers, where oil pressure acts on vanes to rotate the camshaft, and helical spline systems that convert axial movement into rotational adjustment. Some advanced designs incorporate locking pins to maintain specific timing positions during engine operation or shutdown, ensuring consistent performance and reliable starting.

- Continuous Variable Valve Timing Systems: Continuous variable valve timing systems allow for stepless adjustment of valve timing throughout the engine operating range. Unlike discrete systems that can only switch between fixed positions, continuous systems provide infinite adjustment within their operating range. These systems typically use rotary actuators or cam phasers that can be positioned at any point within their design limits, allowing for optimized engine performance under all conditions and smoother transitions between different operating states.

- Dual Independent Variable Valve Timing: Dual independent variable valve timing systems allow separate control of both intake and exhaust valve timing. By independently adjusting the timing of both camshafts, these systems provide greater flexibility in optimizing engine breathing characteristics. This technology enables advanced combustion strategies such as internal exhaust gas recirculation, Miller cycle operation, and optimized valve overlap for different engine speeds and loads, resulting in improved power output, fuel economy, and emissions performance across a wider operating range.

02 Electronic Control Strategies for VVT Systems

Advanced electronic control units (ECUs) manage variable valve timing systems by processing data from various engine sensors to determine optimal valve timing. These control strategies include algorithms that consider factors such as engine load, speed, temperature, and driver demand to continuously adjust valve timing. The electronic systems can implement different timing maps for various operating conditions, enabling seamless transitions between performance, economy, and emissions-focused operation modes.Expand Specific Solutions03 Cam Phasing Mechanisms and Actuators

Various mechanical designs are employed to achieve variable valve timing, including vane-type phasers, helical spline mechanisms, and eccentric cam systems. These mechanisms physically alter the rotational relationship between the camshaft and crankshaft, allowing for adjustment of valve opening and closing timing. The actuators can be designed for different response rates, phasing ranges, and durability requirements depending on the specific engine application and performance targets.Expand Specific Solutions04 Integration with Engine Management Systems

Variable valve timing systems are integrated with broader engine management systems to coordinate with other engine functions such as fuel injection, ignition timing, and turbocharging. This integration allows for comprehensive optimization of engine performance across the entire operating range. The systems can communicate via CAN bus or other protocols to ensure synchronized operation, with fail-safe mechanisms that default to safe operating parameters if malfunctions are detected.Expand Specific Solutions05 Continuous vs. Discrete Variable Valve Timing

Variable valve timing systems can be designed to operate either continuously or in discrete steps. Continuous systems allow for infinitely variable adjustment within their operating range, providing optimal timing at any engine speed or load. Discrete systems offer simpler implementation with specific timing positions (such as 'normal' and 'advanced') that are selected based on predetermined thresholds. Each approach offers different trade-offs between precision, complexity, cost, and reliability in real-world applications.Expand Specific Solutions

Major Manufacturers and Competitors in VVT Market

Variable valve timing (VVT) systems in LSA engines are evolving rapidly, with the market currently in a growth phase characterized by increasing adoption across automotive platforms. The global market size for VVT systems is expanding significantly, driven by stringent emission regulations and fuel efficiency demands. From a technological maturity perspective, Toyota, BorgWarner, and Denso lead with advanced dual VVT-i and continuous variable valve timing technologies. Hyundai, Nissan, and Ford have established strong competitive positions with their proprietary systems, while emerging players like Chery and Changan are gaining ground with cost-effective solutions. Academic institutions such as Tianjin University are contributing significant research to next-generation valve timing technologies, creating a dynamic competitive landscape balancing innovation with manufacturing scale.

Toyota Motor Corp.

Technical Solution: Toyota has developed advanced Variable Valve Timing with intelligence (VVT-i) systems for their LSA (Linear Solenoid Actuated) engines. Their technology utilizes an oil control valve (OCV) that precisely regulates hydraulic pressure to the camshaft actuator, allowing for continuous and optimal adjustment of valve timing based on engine load and speed. Toyota's latest iteration, Dual VVT-i, independently controls both intake and exhaust valve timing, significantly improving combustion efficiency. The system incorporates sophisticated ECU algorithms that analyze multiple parameters including engine temperature, throttle position, and vehicle speed to determine optimal valve timing in real-time. Toyota has also integrated their VVT-i technology with their D-4S direct injection system, creating a comprehensive approach to engine efficiency that has shown up to 10% improvement in fuel economy while reducing emissions by approximately 20% compared to fixed valve timing systems.

Strengths: Toyota's system offers exceptional reliability with proven durability exceeding 150,000 miles without significant maintenance. Their hydraulic-based actuation provides smooth, precise control with minimal noise. Weaknesses: The hydraulic-based system has inherent response limitations at extreme temperatures and requires more complex oil passages in the cylinder head, increasing manufacturing complexity.

DENSO Corp.

Technical Solution: DENSO has pioneered electromagnetic variable valve timing (VVT) systems for LSA engines that utilize direct electromagnetic actuation rather than traditional hydraulic mechanisms. Their technology employs high-response linear solenoid actuators that directly control valve movement with millisecond precision. This electromagnetic approach eliminates the hydraulic delay inherent in conventional systems, allowing for more precise valve timing control across all engine operating conditions. DENSO's system incorporates advanced position sensors that provide real-time feedback on valve position, enabling closed-loop control that can compensate for wear and thermal expansion. The company has also developed specialized power management circuits that optimize the electrical energy required for actuation, reducing the overall power consumption of the system by approximately 30% compared to earlier electromagnetic designs. Their latest innovation includes predictive control algorithms that anticipate required valve timing changes based on driver behavior patterns, further enhancing responsiveness and efficiency.

Strengths: DENSO's electromagnetic system provides extremely fast response times (under 5ms) and precise control independent of oil temperature or pressure. The system allows for more aggressive valve timing strategies that can significantly boost performance. Weaknesses: Higher cost compared to hydraulic systems, increased electrical power requirements, and greater complexity in control electronics that may impact long-term reliability.

Key Patents and Technical Innovations in VVT Systems

Variable valve timing system and method for controlling the same

PatentInactiveEP2057363A2

Innovation

- A variable valve timing system utilizing an electric motor as an actuator, with a stop-time phase control unit that includes a mode changeover condition setting unit and a mode changeover determination unit to switch between high-speed and feedback control modes based on rotational speed and deviation from target valve timing, ensuring accurate valve timing setting when the engine is stopped.

Method for diagnosing variable valve timing system

PatentInactiveUS10626820B2

Innovation

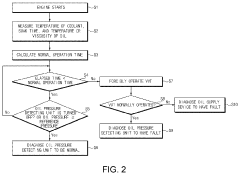

- A method that determines the normal operation time of the oil pressure detecting device based on engine coolant temperature, soak time, and oil viscosity, and uses a forcible operation command signal to diagnose faults in the VVT system, identifying issues with the oil pressure detecting device or oil supply system.

Emissions Regulations Impact on VVT Development

The evolution of emissions regulations has been a primary driver for Variable Valve Timing (VVT) technology development in LSA (Luxury Sport Automobile) engines. Since the introduction of the first comprehensive emissions standards in the 1970s, regulatory frameworks have progressively tightened, compelling automotive manufacturers to innovate valve timing mechanisms to meet increasingly stringent requirements.

The European Union's Euro standards have been particularly influential, with each iteration from Euro 1 to the current Euro 6d imposing more demanding limits on nitrogen oxides (NOx), carbon monoxide (CO), and particulate matter. Similarly, the United States EPA Tier 3 standards and California's CARB regulations have established challenging benchmarks that directly impact VVT design parameters.

These regulations have necessitated sophisticated VVT solutions capable of optimizing combustion efficiency across varying engine loads and speeds. The requirement to reduce cold-start emissions—a period when traditional engines produce their highest pollutants—has driven the development of more responsive VVT systems with wider adjustment ranges and faster actuation times.

Carbon dioxide (CO2) emission targets, particularly in Europe where fleet-average CO2 limits are enforced with substantial penalties, have further accelerated VVT innovation. Manufacturers have responded by implementing dual independent cam phasing and continuously variable valve lift technologies that can precisely adjust valve events to minimize fuel consumption while maintaining performance.

Real Driving Emissions (RDE) testing, introduced in Europe in 2017, represents another regulatory shift impacting VVT development. This testing methodology evaluates emissions performance under actual driving conditions rather than laboratory settings, requiring VVT systems to maintain optimal combustion characteristics across a broader operating envelope.

The global trend toward harmonization of emissions standards, exemplified by the Worldwide Harmonized Light Vehicles Test Procedure (WLTP), has compelled manufacturers to develop VVT technologies with universal applicability. This has led to more sophisticated control algorithms that can adapt to different regulatory requirements across markets.

Looking forward, upcoming regulations such as Euro 7 and equivalent standards in other regions will likely demand even greater emissions reductions, potentially driving the next generation of VVT innovations. These may include electrified VVT actuators with millisecond response times and predictive control systems leveraging artificial intelligence to anticipate optimal valve timing based on driving conditions and environmental factors.

The European Union's Euro standards have been particularly influential, with each iteration from Euro 1 to the current Euro 6d imposing more demanding limits on nitrogen oxides (NOx), carbon monoxide (CO), and particulate matter. Similarly, the United States EPA Tier 3 standards and California's CARB regulations have established challenging benchmarks that directly impact VVT design parameters.

These regulations have necessitated sophisticated VVT solutions capable of optimizing combustion efficiency across varying engine loads and speeds. The requirement to reduce cold-start emissions—a period when traditional engines produce their highest pollutants—has driven the development of more responsive VVT systems with wider adjustment ranges and faster actuation times.

Carbon dioxide (CO2) emission targets, particularly in Europe where fleet-average CO2 limits are enforced with substantial penalties, have further accelerated VVT innovation. Manufacturers have responded by implementing dual independent cam phasing and continuously variable valve lift technologies that can precisely adjust valve events to minimize fuel consumption while maintaining performance.

Real Driving Emissions (RDE) testing, introduced in Europe in 2017, represents another regulatory shift impacting VVT development. This testing methodology evaluates emissions performance under actual driving conditions rather than laboratory settings, requiring VVT systems to maintain optimal combustion characteristics across a broader operating envelope.

The global trend toward harmonization of emissions standards, exemplified by the Worldwide Harmonized Light Vehicles Test Procedure (WLTP), has compelled manufacturers to develop VVT technologies with universal applicability. This has led to more sophisticated control algorithms that can adapt to different regulatory requirements across markets.

Looking forward, upcoming regulations such as Euro 7 and equivalent standards in other regions will likely demand even greater emissions reductions, potentially driving the next generation of VVT innovations. These may include electrified VVT actuators with millisecond response times and predictive control systems leveraging artificial intelligence to anticipate optimal valve timing based on driving conditions and environmental factors.

Performance Benchmarking Methodologies for VVT Systems

Performance benchmarking methodologies for Variable Valve Timing (VVT) systems in LSA engines require systematic approaches to evaluate efficiency, responsiveness, and overall impact on engine performance. These methodologies typically begin with establishing baseline measurements under controlled conditions, including dynamometer testing at various engine speeds and loads to capture the full operational spectrum.

Comparative analysis forms the cornerstone of effective VVT benchmarking, where the system under evaluation is measured against both fixed valve timing configurations and competing VVT technologies. Key performance indicators include volumetric efficiency improvements, torque curve enhancement, fuel economy gains, and emissions reduction percentages across different operating conditions.

Real-time data acquisition systems with high sampling rates are essential for capturing the precise timing of valve events and corresponding engine parameters. Modern benchmarking setups employ in-cylinder pressure transducers, crankshaft position sensors, and exhaust gas analyzers working in concert to provide comprehensive performance profiles. The correlation between valve timing adjustments and combustion characteristics requires particular attention to measurement precision.

Standardized test cycles play a crucial role in ensuring reproducibility and comparability of results. Industry-recognized cycles such as the FTP-75, WLTP, and NEDC provide frameworks for evaluating VVT performance under various driving conditions. Supplementary custom test protocols often focus on transient response characteristics, which are particularly relevant for evaluating the adaptability of VVT systems to rapidly changing demands.

Thermal condition variation testing represents another critical dimension of VVT benchmarking. Performance evaluation across cold-start, warm-up, and fully warmed operating states helps identify potential weaknesses in system design and control algorithms. This approach is particularly valuable for camshaft phasing systems in LSA engines, where oil viscosity changes can significantly impact actuation speed.

Advanced benchmarking methodologies increasingly incorporate model-based testing approaches, where experimental results validate computational fluid dynamics (CFD) and 1D engine simulation models. This hybrid approach enables more comprehensive exploration of the design space and facilitates optimization of control strategies without exhaustive physical testing of all possible configurations.

Durability and reliability assessments extend traditional performance benchmarking by subjecting VVT systems to accelerated aging protocols. These tests evaluate long-term performance stability and identify potential failure modes through extended operation under high-stress conditions, providing critical insights for production engineering decisions.

Comparative analysis forms the cornerstone of effective VVT benchmarking, where the system under evaluation is measured against both fixed valve timing configurations and competing VVT technologies. Key performance indicators include volumetric efficiency improvements, torque curve enhancement, fuel economy gains, and emissions reduction percentages across different operating conditions.

Real-time data acquisition systems with high sampling rates are essential for capturing the precise timing of valve events and corresponding engine parameters. Modern benchmarking setups employ in-cylinder pressure transducers, crankshaft position sensors, and exhaust gas analyzers working in concert to provide comprehensive performance profiles. The correlation between valve timing adjustments and combustion characteristics requires particular attention to measurement precision.

Standardized test cycles play a crucial role in ensuring reproducibility and comparability of results. Industry-recognized cycles such as the FTP-75, WLTP, and NEDC provide frameworks for evaluating VVT performance under various driving conditions. Supplementary custom test protocols often focus on transient response characteristics, which are particularly relevant for evaluating the adaptability of VVT systems to rapidly changing demands.

Thermal condition variation testing represents another critical dimension of VVT benchmarking. Performance evaluation across cold-start, warm-up, and fully warmed operating states helps identify potential weaknesses in system design and control algorithms. This approach is particularly valuable for camshaft phasing systems in LSA engines, where oil viscosity changes can significantly impact actuation speed.

Advanced benchmarking methodologies increasingly incorporate model-based testing approaches, where experimental results validate computational fluid dynamics (CFD) and 1D engine simulation models. This hybrid approach enables more comprehensive exploration of the design space and facilitates optimization of control strategies without exhaustive physical testing of all possible configurations.

Durability and reliability assessments extend traditional performance benchmarking by subjecting VVT systems to accelerated aging protocols. These tests evaluate long-term performance stability and identify potential failure modes through extended operation under high-stress conditions, providing critical insights for production engineering decisions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!