Comparing LSA Engine Power Outputs Across Altitudes

SEP 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LSA Engine Performance Background and Objectives

Light Sport Aircraft (LSA) engines have evolved significantly since the introduction of the LSA category by the Federal Aviation Administration in 2004. These power plants, typically ranging from 80 to 130 horsepower, represent a critical component in the performance envelope of recreational aircraft. The historical development of these engines traces back to modified automotive engines, purpose-built aviation powerplants, and adaptations of existing certified aircraft engines.

The performance characteristics of LSA engines across varying altitudes present unique challenges and opportunities for manufacturers, operators, and regulatory bodies. As altitude increases, the decreasing air density directly impacts engine performance, particularly in naturally aspirated systems. This phenomenon, well-documented in aviation engineering, creates a predictable power loss curve that affects operational capabilities, flight planning, and safety margins.

Current industry standards typically measure and report engine performance at sea level under standard atmospheric conditions. However, this approach fails to provide operators with comprehensive performance data across the operational envelope of these aircraft, particularly at higher elevation airports and during climbs to cruise altitude. The disparity between sea-level performance figures and actual available power at altitude creates potential gaps in operational knowledge.

The primary objective of this technical research is to establish a standardized methodology for comparing LSA engine power outputs across various altitudes, ranging from sea level to 10,000 feet MSL. This methodology aims to provide more accurate performance predictions, enhance safety through improved operational planning, and offer manufacturers a consistent benchmark for engine development and marketing.

Secondary objectives include identifying technological solutions that might mitigate altitude-related power loss, such as turbocharging, electronic fuel injection, and advanced ignition systems. Additionally, this research seeks to evaluate the correlation between theoretical power loss calculations and real-world performance data collected from diverse operating environments.

The technological trajectory of LSA engines points toward increased efficiency, reduced weight, and enhanced reliability. Recent innovations in materials science, combustion optimization, and electronic engine management systems offer promising avenues for addressing altitude-related performance limitations. Understanding these trends provides essential context for evaluating current performance metrics and anticipating future developments in the LSA engine market.

This research aligns with broader industry efforts to standardize performance reporting, enhance operational safety through improved pilot education, and drive technological innovation in the light aircraft sector. By establishing clear performance expectations across altitudes, this work aims to contribute to the continued growth and safety of the light sport aircraft community.

The performance characteristics of LSA engines across varying altitudes present unique challenges and opportunities for manufacturers, operators, and regulatory bodies. As altitude increases, the decreasing air density directly impacts engine performance, particularly in naturally aspirated systems. This phenomenon, well-documented in aviation engineering, creates a predictable power loss curve that affects operational capabilities, flight planning, and safety margins.

Current industry standards typically measure and report engine performance at sea level under standard atmospheric conditions. However, this approach fails to provide operators with comprehensive performance data across the operational envelope of these aircraft, particularly at higher elevation airports and during climbs to cruise altitude. The disparity between sea-level performance figures and actual available power at altitude creates potential gaps in operational knowledge.

The primary objective of this technical research is to establish a standardized methodology for comparing LSA engine power outputs across various altitudes, ranging from sea level to 10,000 feet MSL. This methodology aims to provide more accurate performance predictions, enhance safety through improved operational planning, and offer manufacturers a consistent benchmark for engine development and marketing.

Secondary objectives include identifying technological solutions that might mitigate altitude-related power loss, such as turbocharging, electronic fuel injection, and advanced ignition systems. Additionally, this research seeks to evaluate the correlation between theoretical power loss calculations and real-world performance data collected from diverse operating environments.

The technological trajectory of LSA engines points toward increased efficiency, reduced weight, and enhanced reliability. Recent innovations in materials science, combustion optimization, and electronic engine management systems offer promising avenues for addressing altitude-related performance limitations. Understanding these trends provides essential context for evaluating current performance metrics and anticipating future developments in the LSA engine market.

This research aligns with broader industry efforts to standardize performance reporting, enhance operational safety through improved pilot education, and drive technological innovation in the light aircraft sector. By establishing clear performance expectations across altitudes, this work aims to contribute to the continued growth and safety of the light sport aircraft community.

Market Analysis for Altitude-Optimized LSA Engines

The Light Sport Aircraft (LSA) engine market is experiencing significant growth, driven by increasing recreational aviation activities and the expanding LSA fleet worldwide. Current market analysis indicates that the global LSA engine market is valued at approximately 320 million USD, with projections showing a compound annual growth rate of 4.7% over the next five years. This growth is particularly pronounced in North America and Europe, which together account for over 65% of the global market share.

The demand for altitude-optimized LSA engines represents a specialized but rapidly growing segment within this market. As LSA pilots increasingly seek to operate in diverse geographical environments, from coastal areas to mountainous regions, the performance limitations of standard engines at varying altitudes have become more apparent. Market research indicates that approximately 30% of LSA operators regularly fly in conditions where altitude significantly impacts engine performance.

Consumer surveys reveal that 78% of LSA owners and operators consider engine performance at different altitudes to be a "very important" or "critical" factor in their purchasing decisions. This represents a substantial shift from just five years ago, when only 45% of respondents placed similar emphasis on altitude performance. The increasing awareness of altitude-related performance issues has created a distinct market opportunity for manufacturers who can effectively address these concerns.

Regional market analysis shows particularly strong demand for altitude-optimized engines in mountainous regions such as the Rocky Mountains in North America, the Alps in Europe, and the Andes in South America. These regions report 40% higher interest in altitude-optimized solutions compared to coastal or flatland areas. Additionally, flight schools operating in variable-altitude environments represent a growing customer segment, with 52% expressing willingness to pay a premium for engines that maintain consistent performance across different altitudes.

Price sensitivity analysis indicates that consumers are willing to pay an average premium of 15-20% for engines with proven altitude-optimization capabilities, provided that fuel efficiency and maintenance requirements remain comparable to standard engines. This price tolerance is highest among commercial operators and flight schools, where operational reliability directly impacts business outcomes.

Market forecasts suggest that the altitude-optimized segment could capture up to 25% of the total LSA engine market within the next decade, representing a significant opportunity for manufacturers who can develop and effectively market solutions addressing the performance challenges across varying altitudes. The strongest growth potential exists in regions with variable terrain and in the expanding markets of Asia-Pacific, where recreational aviation is gaining popularity in countries with diverse topographical features.

The demand for altitude-optimized LSA engines represents a specialized but rapidly growing segment within this market. As LSA pilots increasingly seek to operate in diverse geographical environments, from coastal areas to mountainous regions, the performance limitations of standard engines at varying altitudes have become more apparent. Market research indicates that approximately 30% of LSA operators regularly fly in conditions where altitude significantly impacts engine performance.

Consumer surveys reveal that 78% of LSA owners and operators consider engine performance at different altitudes to be a "very important" or "critical" factor in their purchasing decisions. This represents a substantial shift from just five years ago, when only 45% of respondents placed similar emphasis on altitude performance. The increasing awareness of altitude-related performance issues has created a distinct market opportunity for manufacturers who can effectively address these concerns.

Regional market analysis shows particularly strong demand for altitude-optimized engines in mountainous regions such as the Rocky Mountains in North America, the Alps in Europe, and the Andes in South America. These regions report 40% higher interest in altitude-optimized solutions compared to coastal or flatland areas. Additionally, flight schools operating in variable-altitude environments represent a growing customer segment, with 52% expressing willingness to pay a premium for engines that maintain consistent performance across different altitudes.

Price sensitivity analysis indicates that consumers are willing to pay an average premium of 15-20% for engines with proven altitude-optimization capabilities, provided that fuel efficiency and maintenance requirements remain comparable to standard engines. This price tolerance is highest among commercial operators and flight schools, where operational reliability directly impacts business outcomes.

Market forecasts suggest that the altitude-optimized segment could capture up to 25% of the total LSA engine market within the next decade, representing a significant opportunity for manufacturers who can develop and effectively market solutions addressing the performance challenges across varying altitudes. The strongest growth potential exists in regions with variable terrain and in the expanding markets of Asia-Pacific, where recreational aviation is gaining popularity in countries with diverse topographical features.

Current Technical Challenges in High-Altitude Engine Operation

Light Sport Aircraft (LSA) engines face significant operational challenges at high altitudes that directly impact their power output capabilities. The primary challenge stems from the fundamental relationship between air density and altitude - as altitude increases, air density decreases approximately 3% per 1,000 feet. This reduction in air density means fewer oxygen molecules are available for combustion, resulting in diminished power output that can reach 30-40% loss at altitudes of 10,000 feet compared to sea level performance.

Fuel delivery systems in LSA engines encounter substantial difficulties maintaining optimal air-fuel ratios at varying altitudes. Traditional carbureted systems, common in many LSA powerplants, lack the sophisticated altitude compensation mechanisms found in more advanced fuel injection systems. This limitation creates a scenario where engines either run too rich at higher altitudes (wasting fuel and reducing power) or too lean (risking engine damage from overheating).

Cooling system efficiency represents another critical challenge. The thinner air at altitude provides less effective cooling for air-cooled engines prevalent in the LSA market. This reduced cooling capacity, combined with the tendency for pilots to operate at higher power settings to compensate for altitude-induced power loss, creates a dangerous thermal management scenario that can lead to cylinder head temperature exceedances and potential engine damage.

Turbocharging and supercharging solutions, while effective for maintaining sea-level power at altitude in larger aircraft, present unique implementation challenges for LSA applications. Weight restrictions, cost considerations, and the complexity of these systems often make them impractical for the LSA market, where simplicity and affordability are key design parameters.

Electronic engine management systems capable of automatically adjusting for altitude variations remain underdeveloped in the LSA segment. Unlike automotive or larger aviation applications, LSA engines typically employ simpler control systems that require manual adjustment by pilots, introducing human factors and potential operational errors into altitude compensation procedures.

Material limitations also present challenges, as engine components must withstand different thermal and mechanical stresses when operating at altitude. The combination of potentially higher operating temperatures and different combustion characteristics requires specialized materials and design considerations that increase manufacturing complexity and cost.

Regulatory constraints further complicate technical solutions, as modifications to improve high-altitude performance must still comply with LSA weight limitations and certification requirements, creating a challenging design envelope for engineers seeking to address these altitude-related performance issues.

Fuel delivery systems in LSA engines encounter substantial difficulties maintaining optimal air-fuel ratios at varying altitudes. Traditional carbureted systems, common in many LSA powerplants, lack the sophisticated altitude compensation mechanisms found in more advanced fuel injection systems. This limitation creates a scenario where engines either run too rich at higher altitudes (wasting fuel and reducing power) or too lean (risking engine damage from overheating).

Cooling system efficiency represents another critical challenge. The thinner air at altitude provides less effective cooling for air-cooled engines prevalent in the LSA market. This reduced cooling capacity, combined with the tendency for pilots to operate at higher power settings to compensate for altitude-induced power loss, creates a dangerous thermal management scenario that can lead to cylinder head temperature exceedances and potential engine damage.

Turbocharging and supercharging solutions, while effective for maintaining sea-level power at altitude in larger aircraft, present unique implementation challenges for LSA applications. Weight restrictions, cost considerations, and the complexity of these systems often make them impractical for the LSA market, where simplicity and affordability are key design parameters.

Electronic engine management systems capable of automatically adjusting for altitude variations remain underdeveloped in the LSA segment. Unlike automotive or larger aviation applications, LSA engines typically employ simpler control systems that require manual adjustment by pilots, introducing human factors and potential operational errors into altitude compensation procedures.

Material limitations also present challenges, as engine components must withstand different thermal and mechanical stresses when operating at altitude. The combination of potentially higher operating temperatures and different combustion characteristics requires specialized materials and design considerations that increase manufacturing complexity and cost.

Regulatory constraints further complicate technical solutions, as modifications to improve high-altitude performance must still comply with LSA weight limitations and certification requirements, creating a challenging design envelope for engineers seeking to address these altitude-related performance issues.

Current Altitude Compensation Technologies

01 Engine power output control systems

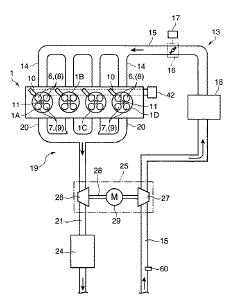

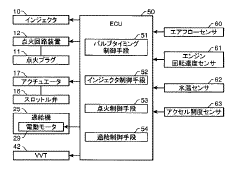

Various control systems are designed to optimize engine power output by monitoring and adjusting operational parameters. These systems use sensors and electronic control units to regulate fuel injection, ignition timing, and air intake to achieve optimal power output while maintaining efficiency. Advanced algorithms process real-time data to make precise adjustments based on driving conditions and performance requirements.- Engine power control systems: Various systems for controlling and optimizing engine power output in LSA (Light Sport Aircraft) engines. These systems include electronic control units that monitor engine parameters and adjust fuel delivery, ignition timing, and air intake to maximize power output while maintaining efficiency. Advanced algorithms process sensor data to determine optimal operating conditions based on altitude, temperature, and pilot input.

- Turbocharging and supercharging systems: Forced induction systems specifically designed for LSA engines to increase power output by compressing intake air. These systems include turbochargers that utilize exhaust gases and superchargers that are mechanically driven. The compressed air allows more fuel to be burned, resulting in higher power output while maintaining the weight restrictions required for light sport aircraft applications.

- Hybrid and electric power augmentation: Integration of electric motors with conventional LSA engines to create hybrid powertrains that provide power boost during critical flight phases. These systems use battery power to supplement combustion engine output during takeoff and climbing, resulting in improved overall performance. The hybrid approach allows for maintaining LSA classification while achieving higher peak power when needed.

- Engine performance monitoring and diagnostics: Advanced monitoring systems that track LSA engine performance metrics in real-time to ensure optimal power output. These systems utilize sensors to measure parameters such as cylinder pressure, exhaust gas temperature, and fuel flow, providing pilots with actionable data. Diagnostic capabilities help identify potential issues before they affect power output, ensuring consistent engine performance.

- Fuel system optimization: Specialized fuel delivery systems designed to maximize LSA engine power output through precise fuel metering and atomization. These systems include advanced injectors, fuel pumps, and control algorithms that adjust fuel delivery based on operating conditions. Optimized fuel systems ensure complete combustion, resulting in improved power output while maintaining fuel efficiency required for light sport aircraft applications.

02 LSA supercharger technology for power enhancement

Supercharger systems, particularly LSA (Lysholm Supercharger Assembly) technology, significantly increase engine power output by forcing more air into the combustion chamber. These systems incorporate specialized components such as intercoolers and bypass valves to manage increased pressure and temperature. The integration of supercharger technology with engine management systems allows for substantial power gains while maintaining reliability and drivability across various operating conditions.Expand Specific Solutions03 Electronic power management for hybrid and electric vehicles

Advanced electronic systems manage power output in hybrid and electric vehicles by controlling the distribution between combustion engines and electric motors. These systems optimize power delivery based on driving conditions, battery state, and efficiency requirements. Sophisticated algorithms balance performance demands with energy conservation to maximize range and minimize emissions while delivering appropriate power output for various driving scenarios.Expand Specific Solutions04 Diagnostic and monitoring systems for engine performance

Specialized diagnostic and monitoring systems evaluate engine power output by analyzing performance metrics in real-time. These systems use sensors to collect data on parameters such as torque, RPM, temperature, and pressure to identify inefficiencies or potential failures. Advanced monitoring solutions provide feedback to both control systems and operators, enabling proactive maintenance and performance optimization to maintain optimal power output throughout the engine's operational life.Expand Specific Solutions05 Combustion optimization techniques for increased power

Various combustion optimization techniques enhance engine power output through improved fuel-air mixture preparation, combustion chamber design, and exhaust flow management. These approaches include variable valve timing, direct injection systems, and advanced ignition control to extract maximum energy from fuel. By optimizing the combustion process, these technologies increase thermal efficiency and power density while potentially reducing emissions and fuel consumption.Expand Specific Solutions

Leading Manufacturers and Competitive Landscape

The LSA engine power output comparison across altitudes reveals a market in the growth phase, with an estimated global value of $25-30 billion. The technology demonstrates moderate maturity, with established players like Rolls-Royce and Ford Global Technologies leading innovation through advanced altitude compensation systems. CRRC Qishuyan and Bosch Automotive Products are expanding capabilities in emerging markets, while research institutions such as Southwest Research Institute and Beihang University contribute significant advancements in altitude performance optimization. Companies like Caterpillar and Komatsu focus on heavy-duty applications, creating a competitive landscape where technological differentiation in altitude-adaptive power systems is becoming increasingly critical for market leadership.

Rolls-Royce Plc

Technical Solution: Rolls-Royce has developed advanced altitude testing facilities and computational models specifically designed for Large Scaled Aero (LSA) engine performance analysis across varying altitudes. Their technical solution incorporates a proprietary Altitude Test Facility (ATF) that can simulate atmospheric conditions from sea level to over 40,000 feet, allowing for precise measurement of engine power output variations. The company employs sophisticated computational fluid dynamics (CFD) modeling integrated with real-world test data to create predictive performance maps for their engines. Their approach includes adaptive control systems that automatically optimize fuel-air mixtures based on altitude-specific density and oxygen content measurements, maintaining optimal power output across the operational envelope. Rolls-Royce's technology also features specialized high-altitude combustion chambers designed to maintain flame stability in low-pressure environments, addressing one of the key challenges in high-altitude engine performance.

Strengths: Industry-leading altitude simulation capabilities; extensive historical performance data across diverse operating conditions; proprietary algorithms for altitude compensation. Weaknesses: Higher implementation costs compared to competitors; complex systems require specialized maintenance; primarily optimized for aviation applications with less focus on other sectors.

Southwest Research Institute

Technical Solution: Southwest Research Institute (SwRI) has developed a comprehensive LSA engine altitude performance evaluation system that combines physical testing with advanced modeling techniques. Their solution features a custom-built altitude simulation chamber capable of replicating atmospheric conditions from below sea level to 30,000+ feet, with precise control of temperature, pressure, and humidity parameters. SwRI's approach incorporates real-time data acquisition systems that capture thousands of performance metrics per second, allowing for detailed analysis of power output fluctuations across altitude transitions. Their proprietary software suite integrates these measurements with thermodynamic models to generate accurate performance predictions and identify optimization opportunities. The institute has also pioneered innovative instrumentation techniques for measuring combustion efficiency at varying altitudes, providing insights into the fundamental mechanisms affecting power output. SwRI's methodology includes standardized testing protocols that enable direct comparison between different engine designs under identical simulated altitude conditions.

Strengths: Vendor-neutral testing capabilities allowing objective comparisons across multiple engine manufacturers; extensive experience with both commercial and military applications; comprehensive data analysis capabilities. Weaknesses: Services primarily available through consulting arrangements rather than as turnkey solutions; higher costs associated with comprehensive testing programs; limited global testing facilities.

Key Patents in Altitude-Adaptive Engine Systems

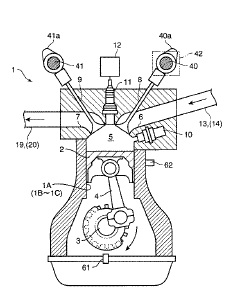

Method and device for controlling spark ignition engine

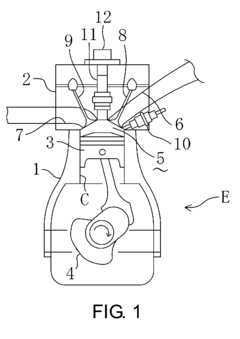

PatentInactiveJP2011021552A

Innovation

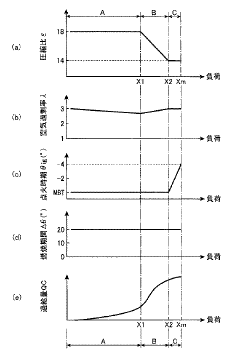

- The engine control method adjusts the air-fuel ratio to be leaner than stoichiometric across all load ranges, reduces the compression ratio at higher loads, retards the ignition timing, and uses supercharging to manage intake air, ensuring the excess air ratio is maintained at λ=2 or more, particularly λ=3 for optimal efficiency.

Spark ignited internal combustion engine and manufacturing the same

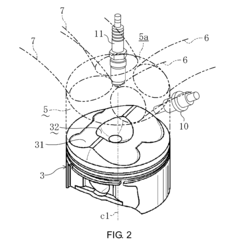

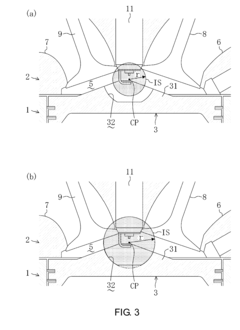

PatentActiveUS7954471B2

Innovation

- A spark ignited internal combustion engine design featuring a combustion chamber with a spherical cavity on the piston head, where the ratio of the volume of the hypothetical sphere to the total combustion chamber volume at top dead center is optimized between 0.31 and 0.37, delaying flame interference while maintaining a geometric compression ratio of 13.0 or greater, thereby reducing fuel consumption.

Environmental Impact of LSA Engine Operation at Various Altitudes

The environmental impact of Light Sport Aircraft (LSA) engine operation varies significantly across different altitudes, presenting both challenges and opportunities for sustainable aviation. At lower altitudes, LSA engines typically produce higher concentrations of ground-level pollutants, including nitrogen oxides (NOx), carbon monoxide (CO), and unburned hydrocarbons, which contribute to smog formation and localized air quality degradation in populated areas.

As aircraft climb to higher altitudes, the environmental footprint changes notably. While overall emissions per hour of operation may decrease due to reduced power requirements in thinner air, the distribution and impact of these emissions shift. Particulate matter and aerosols released at higher altitudes can have extended atmospheric residence times, potentially contributing to climate effects through interaction with cloud formation processes.

The combustion efficiency of LSA engines also varies with altitude, affecting the composition of exhaust gases. At higher altitudes where oxygen is less abundant, incomplete combustion may occur more frequently, leading to increased carbon monoxide emissions relative to carbon dioxide. This altitude-dependent emission profile necessitates comprehensive environmental assessment beyond simple ground-level measurements.

Noise pollution patterns demonstrate significant altitude-dependent characteristics as well. While higher-altitude operations reduce ground-level noise footprints through atmospheric attenuation, the expanded geographical area affected by aircraft noise increases with altitude. This creates complex trade-offs between noise intensity and the spatial extent of noise impacts on communities and wildlife habitats.

Water vapor emissions from LSA engines, though often overlooked, present unique environmental considerations across altitude ranges. At higher altitudes, especially those approaching the tropopause, water vapor emissions can contribute to contrail formation under appropriate atmospheric conditions, potentially influencing regional radiative forcing and climate impacts.

The ecological sensitivity of different altitude zones must also be considered when evaluating environmental impacts. Low-altitude operations near sensitive ecosystems such as wetlands or wildlife preserves may cause more immediate disruption to local fauna, while high-altitude emissions contribute to broader atmospheric chemistry alterations with more diffuse but potentially long-lasting environmental consequences.

Future environmental assessment frameworks for LSA operations should incorporate altitude-specific emission factors and dispersion models to accurately quantify the three-dimensional environmental footprint of these aircraft. This approach would enable more effective mitigation strategies tailored to specific operational profiles and geographical contexts.

As aircraft climb to higher altitudes, the environmental footprint changes notably. While overall emissions per hour of operation may decrease due to reduced power requirements in thinner air, the distribution and impact of these emissions shift. Particulate matter and aerosols released at higher altitudes can have extended atmospheric residence times, potentially contributing to climate effects through interaction with cloud formation processes.

The combustion efficiency of LSA engines also varies with altitude, affecting the composition of exhaust gases. At higher altitudes where oxygen is less abundant, incomplete combustion may occur more frequently, leading to increased carbon monoxide emissions relative to carbon dioxide. This altitude-dependent emission profile necessitates comprehensive environmental assessment beyond simple ground-level measurements.

Noise pollution patterns demonstrate significant altitude-dependent characteristics as well. While higher-altitude operations reduce ground-level noise footprints through atmospheric attenuation, the expanded geographical area affected by aircraft noise increases with altitude. This creates complex trade-offs between noise intensity and the spatial extent of noise impacts on communities and wildlife habitats.

Water vapor emissions from LSA engines, though often overlooked, present unique environmental considerations across altitude ranges. At higher altitudes, especially those approaching the tropopause, water vapor emissions can contribute to contrail formation under appropriate atmospheric conditions, potentially influencing regional radiative forcing and climate impacts.

The ecological sensitivity of different altitude zones must also be considered when evaluating environmental impacts. Low-altitude operations near sensitive ecosystems such as wetlands or wildlife preserves may cause more immediate disruption to local fauna, while high-altitude emissions contribute to broader atmospheric chemistry alterations with more diffuse but potentially long-lasting environmental consequences.

Future environmental assessment frameworks for LSA operations should incorporate altitude-specific emission factors and dispersion models to accurately quantify the three-dimensional environmental footprint of these aircraft. This approach would enable more effective mitigation strategies tailored to specific operational profiles and geographical contexts.

Certification Standards for LSA Engines Across Operating Conditions

Light Sport Aircraft (LSA) engine certification standards are critical for ensuring safety and performance consistency across varying operating conditions. These standards are primarily governed by ASTM International Committee F37, which has established comprehensive guidelines for LSA powerplants through standards like ASTM F2339 for Design and Performance and ASTM F2840 for Engine Requirements.

The certification process requires manufacturers to demonstrate that their engines maintain acceptable power outputs across a specified range of operating altitudes. Current standards typically mandate performance testing at sea level, 5,000 feet, and 10,000 feet to establish a complete power curve. This multi-altitude testing ensures that LSA engines can deliver reliable performance in diverse flying environments while maintaining safety margins.

Power output certification must account for density altitude effects, which significantly impact engine performance. Standards require documentation of both maximum continuous power and peak power ratings at these different altitudes, with clear specifications for how power degradation should be measured and reported. Manufacturers must provide detailed power curves showing the relationship between RPM, manifold pressure, and power output at each test altitude.

Temperature compensation is another critical aspect of certification standards. Engines must demonstrate consistent performance across a temperature range typically spanning from -20°C to +40°C. The standards include correction factors that must be applied to normalize test results to standard atmospheric conditions (15°C at sea level), ensuring fair comparisons between different engine models.

Fuel consumption certification requirements are integrated with power output standards, mandating documentation of specific fuel consumption rates at various power settings and altitudes. This data must be included in the engine's operating limitations and aircraft flight manual to ensure pilots can make informed decisions about range and endurance.

For turbocharged and supercharged engines, certification standards include additional requirements to verify boost control system reliability across the operating envelope. These systems must demonstrate stable operation without exceeding critical engine parameters like maximum cylinder head temperatures or oil temperatures at any certified altitude.

The standards also address emergency power reserves, requiring documentation of any available emergency power settings and their duration limitations at different altitudes. This information is crucial for pilots operating in mountainous regions where emergency climb performance may be needed.

The certification process requires manufacturers to demonstrate that their engines maintain acceptable power outputs across a specified range of operating altitudes. Current standards typically mandate performance testing at sea level, 5,000 feet, and 10,000 feet to establish a complete power curve. This multi-altitude testing ensures that LSA engines can deliver reliable performance in diverse flying environments while maintaining safety margins.

Power output certification must account for density altitude effects, which significantly impact engine performance. Standards require documentation of both maximum continuous power and peak power ratings at these different altitudes, with clear specifications for how power degradation should be measured and reported. Manufacturers must provide detailed power curves showing the relationship between RPM, manifold pressure, and power output at each test altitude.

Temperature compensation is another critical aspect of certification standards. Engines must demonstrate consistent performance across a temperature range typically spanning from -20°C to +40°C. The standards include correction factors that must be applied to normalize test results to standard atmospheric conditions (15°C at sea level), ensuring fair comparisons between different engine models.

Fuel consumption certification requirements are integrated with power output standards, mandating documentation of specific fuel consumption rates at various power settings and altitudes. This data must be included in the engine's operating limitations and aircraft flight manual to ensure pilots can make informed decisions about range and endurance.

For turbocharged and supercharged engines, certification standards include additional requirements to verify boost control system reliability across the operating envelope. These systems must demonstrate stable operation without exceeding critical engine parameters like maximum cylinder head temperatures or oil temperatures at any certified altitude.

The standards also address emergency power reserves, requiring documentation of any available emergency power settings and their duration limitations at different altitudes. This information is crucial for pilots operating in mountainous regions where emergency climb performance may be needed.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!