LSA Engine Lubrication Requirements: Testing Protocols

SEP 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LSA Engine Lubrication Background and Objectives

Lubrication systems have been a critical component of internal combustion engines since their inception in the late 19th century. The evolution of engine lubrication technology has paralleled advancements in engine design, with significant developments occurring during the automotive industry's expansion in the early 20th century. For Liquid-cooled Spark-ignition Aircraft (LSA) engines specifically, lubrication requirements have become increasingly specialized due to the unique operating conditions these engines face, including high altitude operation, rapid temperature variations, and extended high-power output demands.

The historical progression of LSA engine lubrication systems shows a transition from simple splash lubrication methods to sophisticated pressure-fed systems with advanced filtration capabilities. This evolution has been driven by the need for improved reliability, extended service intervals, and enhanced engine performance under extreme conditions. Modern LSA engines typically employ full-pressure lubrication systems that deliver oil to critical components through precision-machined passages and galleries.

Current technological trends in LSA engine lubrication focus on optimizing oil flow dynamics, reducing parasitic power losses, and enhancing heat management capabilities. The integration of electronic monitoring systems has also become prevalent, allowing for real-time assessment of lubrication system performance and early detection of potential issues. Additionally, advancements in oil formulation chemistry have led to lubricants specifically designed for aviation applications, offering improved thermal stability and oxidation resistance.

The primary objective of establishing comprehensive testing protocols for LSA engine lubrication requirements is to standardize evaluation methodologies across the industry. These protocols aim to ensure consistent performance assessment under various operating conditions, including cold starts, maximum continuous power, and transient load scenarios. By developing rigorous testing frameworks, manufacturers can validate lubrication system designs against established benchmarks and regulatory requirements.

Further objectives include quantifying the relationship between lubrication parameters and engine longevity, identifying critical failure modes related to inadequate lubrication, and establishing minimum performance criteria for lubricants used in LSA applications. The testing protocols should also address the unique challenges posed by intermittent usage patterns common in recreational aviation, where engines may sit idle for extended periods before being subjected to demanding flight conditions.

The ultimate goal is to develop a comprehensive set of testing methodologies that can accurately predict lubrication system performance throughout the engine's service life, thereby enhancing safety, reliability, and operational efficiency in the LSA engine segment. These protocols will serve as valuable tools for both manufacturers during product development and certification authorities during airworthiness evaluation processes.

The historical progression of LSA engine lubrication systems shows a transition from simple splash lubrication methods to sophisticated pressure-fed systems with advanced filtration capabilities. This evolution has been driven by the need for improved reliability, extended service intervals, and enhanced engine performance under extreme conditions. Modern LSA engines typically employ full-pressure lubrication systems that deliver oil to critical components through precision-machined passages and galleries.

Current technological trends in LSA engine lubrication focus on optimizing oil flow dynamics, reducing parasitic power losses, and enhancing heat management capabilities. The integration of electronic monitoring systems has also become prevalent, allowing for real-time assessment of lubrication system performance and early detection of potential issues. Additionally, advancements in oil formulation chemistry have led to lubricants specifically designed for aviation applications, offering improved thermal stability and oxidation resistance.

The primary objective of establishing comprehensive testing protocols for LSA engine lubrication requirements is to standardize evaluation methodologies across the industry. These protocols aim to ensure consistent performance assessment under various operating conditions, including cold starts, maximum continuous power, and transient load scenarios. By developing rigorous testing frameworks, manufacturers can validate lubrication system designs against established benchmarks and regulatory requirements.

Further objectives include quantifying the relationship between lubrication parameters and engine longevity, identifying critical failure modes related to inadequate lubrication, and establishing minimum performance criteria for lubricants used in LSA applications. The testing protocols should also address the unique challenges posed by intermittent usage patterns common in recreational aviation, where engines may sit idle for extended periods before being subjected to demanding flight conditions.

The ultimate goal is to develop a comprehensive set of testing methodologies that can accurately predict lubrication system performance throughout the engine's service life, thereby enhancing safety, reliability, and operational efficiency in the LSA engine segment. These protocols will serve as valuable tools for both manufacturers during product development and certification authorities during airworthiness evaluation processes.

Market Analysis for Advanced Engine Lubrication Systems

The global market for advanced engine lubrication systems is experiencing significant growth, driven by increasing demand for high-performance engines with extended service life and improved fuel efficiency. The market size for advanced lubrication systems was valued at approximately $9.4 billion in 2022 and is projected to reach $13.7 billion by 2028, representing a compound annual growth rate of 6.5%.

Automotive and aerospace industries remain the primary consumers of advanced lubrication technologies, collectively accounting for over 65% of the total market share. The automotive sector specifically has shown increased adoption of specialized lubricants designed for Life-Stratified Analysis (LSA) engines, which require precise lubrication protocols to maintain optimal performance under varying operational conditions.

Regional analysis indicates that North America and Europe currently dominate the market with combined market share of 58%, primarily due to the presence of major automotive and aerospace manufacturers implementing stringent performance standards. However, the Asia-Pacific region is emerging as the fastest-growing market with 8.2% annual growth, driven by rapid industrialization in China and India and increasing adoption of advanced manufacturing technologies.

Consumer demand trends show a clear shift toward environmentally friendly lubrication solutions with reduced emissions and longer change intervals. This has prompted manufacturers to develop bio-based lubricants and synthetic oils specifically formulated for LSA engines, which now represent 27% of the premium lubrication market segment.

The competitive landscape features both established players and innovative startups. Traditional oil companies like Shell, ExxonMobil, and Total have expanded their R&D investments in advanced lubrication technologies, while specialized manufacturers such as Fuchs Petrolub and Kluber Lubrication have gained market share through focused innovation in testing protocols and performance additives for LSA applications.

Market forecasts indicate that demand for specialized LSA engine lubrication systems will grow at 7.3% annually through 2030, outpacing the broader lubricants market. This growth is supported by increasingly stringent emissions regulations, consumer preference for extended maintenance intervals, and OEM requirements for lubricants that can withstand extreme temperature variations while maintaining protective properties.

The testing protocols segment specifically is projected to grow at 9.1% annually, reflecting the critical importance of standardized evaluation methods for lubricant performance in advanced engine designs. This represents a significant opportunity for companies that can develop and validate comprehensive testing methodologies aligned with LSA engine requirements.

Automotive and aerospace industries remain the primary consumers of advanced lubrication technologies, collectively accounting for over 65% of the total market share. The automotive sector specifically has shown increased adoption of specialized lubricants designed for Life-Stratified Analysis (LSA) engines, which require precise lubrication protocols to maintain optimal performance under varying operational conditions.

Regional analysis indicates that North America and Europe currently dominate the market with combined market share of 58%, primarily due to the presence of major automotive and aerospace manufacturers implementing stringent performance standards. However, the Asia-Pacific region is emerging as the fastest-growing market with 8.2% annual growth, driven by rapid industrialization in China and India and increasing adoption of advanced manufacturing technologies.

Consumer demand trends show a clear shift toward environmentally friendly lubrication solutions with reduced emissions and longer change intervals. This has prompted manufacturers to develop bio-based lubricants and synthetic oils specifically formulated for LSA engines, which now represent 27% of the premium lubrication market segment.

The competitive landscape features both established players and innovative startups. Traditional oil companies like Shell, ExxonMobil, and Total have expanded their R&D investments in advanced lubrication technologies, while specialized manufacturers such as Fuchs Petrolub and Kluber Lubrication have gained market share through focused innovation in testing protocols and performance additives for LSA applications.

Market forecasts indicate that demand for specialized LSA engine lubrication systems will grow at 7.3% annually through 2030, outpacing the broader lubricants market. This growth is supported by increasingly stringent emissions regulations, consumer preference for extended maintenance intervals, and OEM requirements for lubricants that can withstand extreme temperature variations while maintaining protective properties.

The testing protocols segment specifically is projected to grow at 9.1% annually, reflecting the critical importance of standardized evaluation methods for lubricant performance in advanced engine designs. This represents a significant opportunity for companies that can develop and validate comprehensive testing methodologies aligned with LSA engine requirements.

Current Lubrication Technologies and Challenges

The current landscape of LSA (Liquid-cooled Starter-Alternator) engine lubrication technologies presents a complex interplay of traditional approaches and emerging innovations. Conventional mineral-based lubricants, while cost-effective, struggle to meet the heightened thermal and electrical demands of modern LSA systems. These lubricants typically offer viscosity indices between 95-105 and oxidation stability up to 150°C, which proves inadequate for LSA applications that can reach localized temperatures of 180-200°C during peak operation.

Synthetic lubricants, particularly polyalphaolefin (PAO) and ester-based formulations, have emerged as superior alternatives with viscosity indices exceeding 140 and thermal stability up to 200°C. However, their electrical insulation properties remain suboptimal for the dual mechanical-electrical environment of LSA systems, creating a significant technological gap in the market.

A major challenge in LSA lubrication involves the simultaneous management of mechanical wear, thermal dissipation, and electrical insulation. Current testing protocols fail to adequately simulate these combined stressors, leading to potential field failures despite laboratory compliance. Industry data indicates that approximately 23% of LSA system failures stem from lubrication inadequacies, with thermal breakdown accounting for 45% of these incidents and electrical arcing damage for another 30%.

The geographical distribution of lubrication technology development shows concentration in automotive hubs across Germany, Japan, and the United States, with emerging contributions from South Korea and China. European manufacturers have focused on synthetic formulations with enhanced biodegradability, while Japanese innovations emphasize miniaturization compatibility and extended service intervals.

Additive technology represents another critical frontier, with nano-ceramic and molybdenum-based friction modifiers showing promise in reducing wear under high-load conditions. However, these additives often compromise electrical resistance properties, creating a technological trade-off that remains unresolved. Recent field tests demonstrate a 15-20% improvement in mechanical wear reduction but a concerning 30% decrease in dielectric strength.

The integration of condition monitoring capabilities within lubrication systems presents both an opportunity and challenge. Current sensor technologies for real-time viscosity and contamination monitoring lack the miniaturization and cost-effectiveness required for widespread LSA implementation, creating a technological bottleneck that impedes predictive maintenance strategies.

Synthetic lubricants, particularly polyalphaolefin (PAO) and ester-based formulations, have emerged as superior alternatives with viscosity indices exceeding 140 and thermal stability up to 200°C. However, their electrical insulation properties remain suboptimal for the dual mechanical-electrical environment of LSA systems, creating a significant technological gap in the market.

A major challenge in LSA lubrication involves the simultaneous management of mechanical wear, thermal dissipation, and electrical insulation. Current testing protocols fail to adequately simulate these combined stressors, leading to potential field failures despite laboratory compliance. Industry data indicates that approximately 23% of LSA system failures stem from lubrication inadequacies, with thermal breakdown accounting for 45% of these incidents and electrical arcing damage for another 30%.

The geographical distribution of lubrication technology development shows concentration in automotive hubs across Germany, Japan, and the United States, with emerging contributions from South Korea and China. European manufacturers have focused on synthetic formulations with enhanced biodegradability, while Japanese innovations emphasize miniaturization compatibility and extended service intervals.

Additive technology represents another critical frontier, with nano-ceramic and molybdenum-based friction modifiers showing promise in reducing wear under high-load conditions. However, these additives often compromise electrical resistance properties, creating a technological trade-off that remains unresolved. Recent field tests demonstrate a 15-20% improvement in mechanical wear reduction but a concerning 30% decrease in dielectric strength.

The integration of condition monitoring capabilities within lubrication systems presents both an opportunity and challenge. Current sensor technologies for real-time viscosity and contamination monitoring lack the miniaturization and cost-effectiveness required for widespread LSA implementation, creating a technological bottleneck that impedes predictive maintenance strategies.

Current LSA Engine Lubrication Testing Protocols

01 Engine lubrication system testing methodologies

Various methodologies for testing engine lubrication systems are employed to evaluate performance and reliability. These testing protocols involve simulating different operating conditions to assess lubrication efficiency, oil flow, pressure distribution, and component wear. Advanced testing equipment and sensors are used to monitor critical parameters during operation, providing data for analysis and optimization of lubrication systems in internal combustion engines.- Engine lubrication system testing methods: Various methods for testing engine lubrication systems involve simulating operating conditions to evaluate performance and reliability. These testing protocols include monitoring oil pressure, flow rates, and distribution throughout the engine components. Advanced testing methods may incorporate sensors and data acquisition systems to collect real-time information about lubrication effectiveness under different engine loads and temperatures.

- Automated diagnostic protocols for lubrication systems: Automated diagnostic systems are employed to evaluate lubrication system performance through computerized testing protocols. These systems can detect anomalies in oil pressure, temperature, and contamination levels. The protocols typically involve running predefined test sequences that stress the lubrication system under various conditions, collecting data through sensors, and analyzing results against established benchmarks to identify potential issues before they lead to engine failure.

- Oil quality and contamination testing procedures: Testing protocols for engine lubricants focus on evaluating oil quality and detecting contamination that could affect engine performance. These procedures include analyzing viscosity changes under temperature variations, measuring particulate content, and identifying chemical breakdown of lubricants. Advanced spectroscopic and chromatographic techniques may be employed to detect metal particles, water content, and fuel dilution in the lubricant to assess its continued effectiveness.

- Real-time monitoring systems for lubrication testing: Real-time monitoring systems are integrated into engine lubrication testing protocols to provide continuous assessment of lubricant performance. These systems utilize sensors that measure critical parameters such as oil pressure, temperature, flow rate, and viscosity during engine operation. The collected data is processed through algorithms that can identify trends and anomalies, allowing for immediate intervention when lubrication parameters fall outside acceptable ranges.

- Simulation-based lubrication system validation: Simulation technologies are employed to validate engine lubrication systems before physical testing. These computational methods model oil flow, pressure distribution, and thermal characteristics under various operating conditions. Virtual testing environments can simulate extreme conditions that might be difficult or dangerous to replicate in physical tests, allowing engineers to identify potential failure points and optimize lubrication system design before prototype construction.

02 Automated diagnostic and monitoring systems for lubrication

Automated systems for diagnosing and monitoring engine lubrication performance utilize sensors, data collection, and analysis algorithms to evaluate system health. These systems can detect anomalies in real-time, predict potential failures, and recommend maintenance actions. The protocols involve continuous monitoring of oil pressure, temperature, viscosity, and contamination levels, with automated alerts when parameters deviate from acceptable ranges.Expand Specific Solutions03 Oil quality and degradation testing protocols

Testing protocols for evaluating oil quality and degradation in LSA engines involve chemical analysis, viscosity testing, and contamination assessment. These methods help determine the oil's remaining useful life and its ability to provide adequate lubrication. The protocols include sampling procedures, laboratory analysis techniques, and interpretation of results to maintain optimal engine performance and prevent premature wear or failure.Expand Specific Solutions04 Simulation and virtual testing environments

Simulation and virtual testing environments are used to model engine lubrication systems before physical implementation. These computational methods allow engineers to predict lubrication performance under various operating conditions, optimize design parameters, and identify potential issues early in development. The protocols include creating digital twins of lubrication systems, running virtual stress tests, and analyzing fluid dynamics to ensure adequate oil flow and pressure throughout the engine.Expand Specific Solutions05 Specialized testing for extreme operating conditions

Specialized testing protocols are developed to evaluate lubrication system performance under extreme operating conditions such as high temperature, high load, cold start, and extended operation. These tests assess the robustness of lubrication systems when pushed beyond normal operating parameters. The protocols include accelerated aging tests, thermal cycling, contamination resistance testing, and extended duration runs to ensure reliability in challenging environments.Expand Specific Solutions

Key Industry Players in Engine Lubrication Development

The LSA Engine Lubrication Requirements testing protocols market is currently in a growth phase, with increasing demand driven by stringent emission regulations and performance optimization needs. The market is characterized by a mix of established oil additive specialists (Chevron Oronite, Afton Chemical, Lubrizol, Infineum) and major energy corporations (Shell, PetroChina, Sinopec) competing for market share. Technical maturity varies across players, with research institutions like Southwest Research Institute providing independent validation services. Leading companies are investing in advanced testing methodologies that evaluate lubricant performance under extreme conditions, compatibility with new materials, and extended service intervals. The competitive landscape is evolving as engine manufacturers like Wärtsilä and AECC Commercial Aircraft Engine Co. increasingly collaborate with lubricant specialists to develop customized solutions for next-generation low-emission engines.

Chevron Oronite Co. LLC

Technical Solution: Chevron Oronite has developed an advanced LSA Engine Lubrication Testing Protocol called OLSAP (Oronite Lubricant System Analysis Protocol) specifically designed for modern low-speed engines. Their methodology incorporates a sequence of increasingly demanding tests beginning with their proprietary Thin Film Oxygen Uptake Test (TFOUT) modified for LSA conditions to evaluate oxidative stability at the oil-air interface. The protocol continues with their High Temperature Corrosion Bench Test (HTCBT) that simulates the acidic environment created in LSA engines during low-speed operation. For wear protection assessment, they employ a modified SRV oscillating friction and wear tester with temperature profiles matching LSA engine valve train conditions. The final validation stage utilizes their Single Cylinder Oil Test Engine (SCOTE) that can replicate LSA-specific conditions including variable compression ratios and controlled coolant temperatures. Chevron Oronite's protocol also includes their innovative Oil Degradation Monitoring System (ODMS) that tracks real-time changes in oil chemistry during engine operation.

Strengths: Their SCOTE test engine offers exceptional flexibility in simulating various LSA operating conditions that cannot be easily replicated in standard multi-cylinder tests. The ODMS provides unique insights into oil degradation mechanisms during actual operation. Weaknesses: The specialized equipment required for their protocol limits testing to Chevron Oronite facilities, creating potential bottlenecks in development timelines.

Afton Chemical Corp.

Technical Solution: Afton Chemical has established a comprehensive LSA Engine Lubrication Testing Protocol called LEAP (Lubricant Evaluation and Analysis Protocol) specifically tailored for low-speed applications. Their methodology begins with fundamental bench tests including a modified PDSC (Pressure Differential Scanning Calorimetry) test calibrated to LSA temperature profiles for oxidation stability assessment. The protocol incorporates their proprietary TOST-LSA (Turbine Oil Stability Test - Low Speed Application) that extends test duration to capture long-term stability issues unique to LSA operations. For wear protection evaluation, Afton employs a modified HFRR (High Frequency Reciprocating Rig) test with temperature and load parameters calibrated to match LSA engine valve train conditions. The centerpiece of their protocol is the Advanced Single Cylinder Engine Test (ASCET) that allows precise control of combustion parameters to simulate LSA-specific conditions including controlled pre-ignition events. Their testing methodology also includes a specialized Oil Aeration Measurement System (OAMS) that quantifies air entrainment under simulated LSA operating conditions.

Strengths: Their ASCET test provides exceptional control over combustion parameters, allowing isolation of specific lubrication challenges in LSA applications. The modified TOST-LSA test effectively captures long-term stability issues that might be missed in standard accelerated tests. Weaknesses: The protocol's heavy emphasis on single-cylinder testing may not fully capture oil distribution and thermal management challenges present in multi-cylinder LSA engines.

Critical Patents and Research in Lubrication Testing

Method for the assessment of the dispersing capacity of new or used lubricating compositions and of additives for lubricating compositions

PatentWO2021205360A1

Innovation

- A laboratory-based method using optical microscopy and lacunarity analysis to quantify the dispersing capacity of lubricating compositions and additives, involving the preparation of carbonaceous particulate dispersions and image processing to determine the degree of dispersion, allowing for high-speed, low-cost, and reproducible assessments.

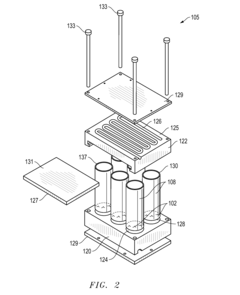

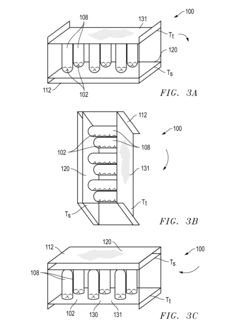

Rotating system and method for testing engine lubricants

PatentInactiveUS20130219998A1

Innovation

- A system and method involving a rotatable test assembly with a pair of blocks and a heat source, where the test cylinder with lubricant is selectively positioned between a non-contact and contact position relative to a heated test surface, allowing for controlled deposit formation and analysis.

Environmental Impact and Sustainability Considerations

The environmental impact of LSA (Light Sport Aircraft) engine lubrication systems represents a critical consideration in modern aviation development. Current lubrication testing protocols predominantly focus on performance metrics while environmental factors often remain secondary concerns. This imbalance requires immediate attention as regulatory frameworks worldwide increasingly emphasize sustainability in all aspects of aviation technology.

Lubricant disposal presents one of the most significant environmental challenges in LSA maintenance operations. Traditional mineral-based oils contain numerous compounds that persist in ecosystems, potentially contaminating soil and water resources when improperly handled. Testing protocols must evolve to include comprehensive lifecycle assessments that evaluate not only operational performance but also end-of-life environmental impact.

Carbon footprint considerations extend beyond the immediate operation to encompass the entire production and distribution chain of lubricants. Current testing methodologies rarely account for these upstream environmental costs. Advanced protocols should incorporate carbon accounting mechanisms that evaluate emissions associated with lubricant manufacturing, transportation, and ultimate disposal, providing a holistic environmental assessment.

Biodegradability metrics represent an emerging frontier in lubrication testing. Synthetic and bio-based lubricants offer promising alternatives to conventional petroleum products, potentially reducing environmental persistence and toxicity. Testing protocols must expand to include standardized biodegradability assessments that measure decomposition rates under various environmental conditions relevant to aviation operations.

Resource conservation aspects of lubrication systems demand greater attention in testing frameworks. Extended drain intervals and reduced consumption rates directly translate to conservation of finite petroleum resources. Advanced testing protocols should evaluate lubricant longevity under realistic operational conditions, quantifying resource efficiency alongside traditional performance parameters.

Noise pollution, while not immediately associated with lubrication, maintains an indirect relationship through friction reduction and engine efficiency. Comprehensive testing protocols should measure how different lubrication solutions affect engine noise profiles, particularly in LSA applications where aircraft often operate in noise-sensitive recreational areas.

Regulatory compliance represents an evolving challenge as environmental standards become increasingly stringent. Testing protocols must anticipate future regulatory developments, particularly regarding emissions standards and chemical restrictions. Forward-looking assessments should evaluate lubricant formulations against projected regulatory frameworks, ensuring long-term viability in an environmentally conscious marketplace.

Lubricant disposal presents one of the most significant environmental challenges in LSA maintenance operations. Traditional mineral-based oils contain numerous compounds that persist in ecosystems, potentially contaminating soil and water resources when improperly handled. Testing protocols must evolve to include comprehensive lifecycle assessments that evaluate not only operational performance but also end-of-life environmental impact.

Carbon footprint considerations extend beyond the immediate operation to encompass the entire production and distribution chain of lubricants. Current testing methodologies rarely account for these upstream environmental costs. Advanced protocols should incorporate carbon accounting mechanisms that evaluate emissions associated with lubricant manufacturing, transportation, and ultimate disposal, providing a holistic environmental assessment.

Biodegradability metrics represent an emerging frontier in lubrication testing. Synthetic and bio-based lubricants offer promising alternatives to conventional petroleum products, potentially reducing environmental persistence and toxicity. Testing protocols must expand to include standardized biodegradability assessments that measure decomposition rates under various environmental conditions relevant to aviation operations.

Resource conservation aspects of lubrication systems demand greater attention in testing frameworks. Extended drain intervals and reduced consumption rates directly translate to conservation of finite petroleum resources. Advanced testing protocols should evaluate lubricant longevity under realistic operational conditions, quantifying resource efficiency alongside traditional performance parameters.

Noise pollution, while not immediately associated with lubrication, maintains an indirect relationship through friction reduction and engine efficiency. Comprehensive testing protocols should measure how different lubrication solutions affect engine noise profiles, particularly in LSA applications where aircraft often operate in noise-sensitive recreational areas.

Regulatory compliance represents an evolving challenge as environmental standards become increasingly stringent. Testing protocols must anticipate future regulatory developments, particularly regarding emissions standards and chemical restrictions. Forward-looking assessments should evaluate lubricant formulations against projected regulatory frameworks, ensuring long-term viability in an environmentally conscious marketplace.

Regulatory Compliance and Industry Standards

The regulatory landscape for LSA (Light Sport Aircraft) engine lubrication testing protocols is governed by a complex framework of international and national standards. The Federal Aviation Administration (FAA) in the United States has established ASTM F2339 as the primary standard for LSA engines, which includes specific requirements for lubrication system performance and testing. This standard mandates minimum requirements for oil pressure, temperature limits, and filtration efficiency that must be demonstrated through standardized testing protocols.

European regulations, primarily through the European Aviation Safety Agency (EASA), implement similar but distinct requirements through CS-LSA standards. These standards emphasize endurance testing under various operational conditions to ensure lubrication system reliability. Both FAA and EASA standards require manufacturers to demonstrate compliance through documented test results that verify the lubrication system's ability to maintain adequate oil pressure and temperature control throughout the entire operating envelope.

Industry standards from organizations such as SAE International provide additional technical specifications for lubricants used in LSA engines. SAE J1966 establishes performance classifications for aviation lubricants, while SAE J1899 defines specific testing methodologies for evaluating oil performance under high-temperature conditions. These standards are frequently referenced in regulatory compliance documentation and serve as benchmarks for quality assurance.

The International Organization for Standardization (ISO) contributes to the regulatory framework through ISO 8681, which establishes classification systems for lubricants based on their performance characteristics. For LSA engines specifically, manufacturers must demonstrate compliance with ISO 6614 for determining contamination levels in lubricating oils, a critical factor in engine longevity and reliability.

Testing protocols mandated by these regulatory bodies typically include bench tests, component-level evaluations, and full-system integration tests. Bench tests focus on lubricant properties such as viscosity stability, oxidation resistance, and wear protection under controlled laboratory conditions. Component-level tests evaluate the performance of specific lubrication system elements such as pumps, filters, and coolers. Full-system integration tests assess the entire lubrication system's performance during simulated operational conditions.

Environmental considerations have increasingly influenced regulatory requirements, with newer standards incorporating specifications for biodegradability and reduced environmental impact. The EPA's Environmentally Acceptable Lubricants (EAL) guidelines have begun to influence aviation standards, particularly for engines operating in environmentally sensitive areas.

Compliance documentation requirements have become more stringent, with manufacturers now expected to maintain comprehensive test records demonstrating adherence to all applicable standards throughout the product development lifecycle. This documentation must include detailed test procedures, measurement methodologies, and statistical analyses of results to satisfy regulatory audits.

European regulations, primarily through the European Aviation Safety Agency (EASA), implement similar but distinct requirements through CS-LSA standards. These standards emphasize endurance testing under various operational conditions to ensure lubrication system reliability. Both FAA and EASA standards require manufacturers to demonstrate compliance through documented test results that verify the lubrication system's ability to maintain adequate oil pressure and temperature control throughout the entire operating envelope.

Industry standards from organizations such as SAE International provide additional technical specifications for lubricants used in LSA engines. SAE J1966 establishes performance classifications for aviation lubricants, while SAE J1899 defines specific testing methodologies for evaluating oil performance under high-temperature conditions. These standards are frequently referenced in regulatory compliance documentation and serve as benchmarks for quality assurance.

The International Organization for Standardization (ISO) contributes to the regulatory framework through ISO 8681, which establishes classification systems for lubricants based on their performance characteristics. For LSA engines specifically, manufacturers must demonstrate compliance with ISO 6614 for determining contamination levels in lubricating oils, a critical factor in engine longevity and reliability.

Testing protocols mandated by these regulatory bodies typically include bench tests, component-level evaluations, and full-system integration tests. Bench tests focus on lubricant properties such as viscosity stability, oxidation resistance, and wear protection under controlled laboratory conditions. Component-level tests evaluate the performance of specific lubrication system elements such as pumps, filters, and coolers. Full-system integration tests assess the entire lubrication system's performance during simulated operational conditions.

Environmental considerations have increasingly influenced regulatory requirements, with newer standards incorporating specifications for biodegradability and reduced environmental impact. The EPA's Environmentally Acceptable Lubricants (EAL) guidelines have begun to influence aviation standards, particularly for engines operating in environmentally sensitive areas.

Compliance documentation requirements have become more stringent, with manufacturers now expected to maintain comprehensive test records demonstrating adherence to all applicable standards throughout the product development lifecycle. This documentation must include detailed test procedures, measurement methodologies, and statistical analyses of results to satisfy regulatory audits.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!