LSA Engine vs Diesel Engines: Emission Impact

SEP 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LSA Engine Technology Background and Objectives

The LSA (Lean Stratified-charge Aspirated) engine represents a significant evolution in internal combustion engine technology, emerging as a response to increasingly stringent emission regulations and the global push toward more environmentally friendly transportation solutions. Developed over the past two decades, LSA engines combine the principles of lean-burn combustion with stratified charge technology to optimize fuel efficiency while minimizing harmful emissions.

The historical development of LSA technology can be traced back to early experiments with lean combustion in the 1990s, which demonstrated potential for reduced nitrogen oxide (NOx) and carbon dioxide (CO2) emissions. However, these early attempts faced challenges with combustion stability and power output. The breakthrough came with the integration of direct injection systems and advanced electronic control units in the early 2000s, enabling precise fuel delivery and combustion management.

LSA engines operate on the principle of creating a stratified fuel-air mixture, where the richest mixture is concentrated around the spark plug while the remainder of the combustion chamber contains a much leaner mixture. This approach allows for overall leaner operation compared to conventional gasoline engines, while maintaining reliable ignition and combustion stability.

The primary technical objectives of LSA engine development focus on achieving substantial emission reductions compared to traditional diesel engines without compromising performance or reliability. Specifically, LSA technology aims to reduce particulate matter (PM) emissions by 80-90% and nitrogen oxides (NOx) by 60-70% compared to conventional diesel engines, while maintaining or improving fuel efficiency.

Current research in LSA technology is exploring several avenues for further improvement, including advanced combustion control algorithms, innovative chamber designs, and integration with mild hybrid systems. These developments are driven by increasingly stringent emission standards worldwide, particularly Euro 7 in Europe, China 7 in Asia, and Tier 3 in North America.

The technology evolution trajectory suggests that LSA engines represent an important transitional technology in the automotive industry's path toward decarbonization. While full electrification remains the long-term goal for many manufacturers, LSA engines offer a medium-term solution that can significantly reduce emissions from the existing and near-future internal combustion engine fleet, particularly in market segments where electrification faces challenges related to infrastructure, cost, or specific use cases.

The technical challenges that continue to drive LSA engine development include optimizing cold-start emissions, improving transient response, and ensuring durability under lean-burn conditions, all while maintaining competitive manufacturing costs compared to conventional engines.

The historical development of LSA technology can be traced back to early experiments with lean combustion in the 1990s, which demonstrated potential for reduced nitrogen oxide (NOx) and carbon dioxide (CO2) emissions. However, these early attempts faced challenges with combustion stability and power output. The breakthrough came with the integration of direct injection systems and advanced electronic control units in the early 2000s, enabling precise fuel delivery and combustion management.

LSA engines operate on the principle of creating a stratified fuel-air mixture, where the richest mixture is concentrated around the spark plug while the remainder of the combustion chamber contains a much leaner mixture. This approach allows for overall leaner operation compared to conventional gasoline engines, while maintaining reliable ignition and combustion stability.

The primary technical objectives of LSA engine development focus on achieving substantial emission reductions compared to traditional diesel engines without compromising performance or reliability. Specifically, LSA technology aims to reduce particulate matter (PM) emissions by 80-90% and nitrogen oxides (NOx) by 60-70% compared to conventional diesel engines, while maintaining or improving fuel efficiency.

Current research in LSA technology is exploring several avenues for further improvement, including advanced combustion control algorithms, innovative chamber designs, and integration with mild hybrid systems. These developments are driven by increasingly stringent emission standards worldwide, particularly Euro 7 in Europe, China 7 in Asia, and Tier 3 in North America.

The technology evolution trajectory suggests that LSA engines represent an important transitional technology in the automotive industry's path toward decarbonization. While full electrification remains the long-term goal for many manufacturers, LSA engines offer a medium-term solution that can significantly reduce emissions from the existing and near-future internal combustion engine fleet, particularly in market segments where electrification faces challenges related to infrastructure, cost, or specific use cases.

The technical challenges that continue to drive LSA engine development include optimizing cold-start emissions, improving transient response, and ensuring durability under lean-burn conditions, all while maintaining competitive manufacturing costs compared to conventional engines.

Market Demand Analysis for Low-Emission Engines

The global market for low-emission engines has experienced significant growth over the past decade, driven primarily by increasingly stringent environmental regulations and growing consumer awareness about climate change. The demand for cleaner alternatives to traditional diesel engines has created a substantial market opportunity for technologies like LSA (Low Swirl Advanced) engines, which promise comparable performance with reduced environmental impact.

Current market analysis indicates that the commercial transportation sector represents the largest potential market for low-emission engine technologies, with an estimated annual growth rate exceeding 8% through 2030. Fleet operators face mounting pressure from both regulatory bodies and corporate sustainability initiatives to reduce their carbon footprint, creating strong pull factors for adoption of cleaner engine technologies.

Regional market variations show Europe leading in adoption rates of low-emission technologies, followed by North America and rapidly developing Asian markets. China, in particular, has implemented aggressive policies to combat urban air pollution, creating substantial demand for cleaner engine alternatives in both public transportation and commercial logistics sectors.

Consumer sentiment research reveals a growing willingness to pay premium prices for vehicles with demonstrably lower environmental impact, though this trend is more pronounced in passenger vehicles than commercial applications. For commercial applications, the total cost of ownership remains the primary decision factor, necessitating that low-emission alternatives demonstrate comparable operational costs to traditional diesel engines.

Market segmentation analysis shows varying adoption potential across different vehicle categories. Urban delivery fleets show the highest immediate adoption potential due to their operation in emission-controlled zones and predictable route patterns that simplify refueling infrastructure requirements. Long-haul transportation presents greater challenges due to range requirements and infrastructure limitations.

Industry forecasts project that by 2028, low-emission engines could capture up to 40% of new commercial vehicle sales in developed markets, representing a substantial shift from current market penetration levels. This transition is expected to accelerate as technology costs decrease and supporting infrastructure expands.

Key market drivers include tightening emission standards worldwide, government incentives for clean technology adoption, corporate sustainability commitments, and increasing fuel price volatility. Barriers to more rapid market penetration include higher initial acquisition costs, concerns about technology reliability, and infrastructure limitations for alternative fuel options.

Current market analysis indicates that the commercial transportation sector represents the largest potential market for low-emission engine technologies, with an estimated annual growth rate exceeding 8% through 2030. Fleet operators face mounting pressure from both regulatory bodies and corporate sustainability initiatives to reduce their carbon footprint, creating strong pull factors for adoption of cleaner engine technologies.

Regional market variations show Europe leading in adoption rates of low-emission technologies, followed by North America and rapidly developing Asian markets. China, in particular, has implemented aggressive policies to combat urban air pollution, creating substantial demand for cleaner engine alternatives in both public transportation and commercial logistics sectors.

Consumer sentiment research reveals a growing willingness to pay premium prices for vehicles with demonstrably lower environmental impact, though this trend is more pronounced in passenger vehicles than commercial applications. For commercial applications, the total cost of ownership remains the primary decision factor, necessitating that low-emission alternatives demonstrate comparable operational costs to traditional diesel engines.

Market segmentation analysis shows varying adoption potential across different vehicle categories. Urban delivery fleets show the highest immediate adoption potential due to their operation in emission-controlled zones and predictable route patterns that simplify refueling infrastructure requirements. Long-haul transportation presents greater challenges due to range requirements and infrastructure limitations.

Industry forecasts project that by 2028, low-emission engines could capture up to 40% of new commercial vehicle sales in developed markets, representing a substantial shift from current market penetration levels. This transition is expected to accelerate as technology costs decrease and supporting infrastructure expands.

Key market drivers include tightening emission standards worldwide, government incentives for clean technology adoption, corporate sustainability commitments, and increasing fuel price volatility. Barriers to more rapid market penetration include higher initial acquisition costs, concerns about technology reliability, and infrastructure limitations for alternative fuel options.

Current State and Challenges in Engine Emission Reduction

The global engine industry is currently at a critical juncture in emission reduction efforts. Both LSA (Lean Stratified Architecture) and diesel engines face increasingly stringent regulatory standards worldwide, with the European Union's Euro 7, the United States' EPA Tier 3, and China's National VI standards representing the most challenging compliance frameworks to date. These regulations have progressively reduced allowable NOx, particulate matter, and CO2 emissions to near-zero levels, creating significant technical hurdles for manufacturers.

Diesel engines, despite efficiency improvements, continue to struggle with inherent emission challenges. Current diesel technology employs complex after-treatment systems including Selective Catalytic Reduction (SCR), Diesel Particulate Filters (DPF), and Diesel Oxidation Catalysts (DOC). While effective, these systems add considerable cost, weight, and complexity to vehicles, with the latest data showing after-treatment systems now representing 15-20% of total powertrain costs.

LSA engines have emerged as a promising alternative, offering reduced emissions through precise fuel stratification and lean combustion. Recent advancements in direct injection technology and electronic control systems have enabled LSA engines to achieve up to 15% lower CO2 emissions compared to conventional gasoline engines. However, LSA technology faces challenges in NOx formation during lean operation and cold-start emissions performance.

A significant technical barrier for both engine types is the "real-world versus laboratory" emission gap. Studies from the International Council on Clean Transportation reveal that real-world NOx emissions from diesel vehicles can exceed regulatory limits by 4-7 times under normal driving conditions. Similarly, LSA engines show performance variability depending on ambient conditions and driving patterns, with efficiency benefits diminishing under high-load operations.

Material constraints present another challenge, particularly for high-temperature components in both engine types. Advanced ceramics and heat-resistant alloys are required but face supply chain limitations and cost barriers. The industry is also confronting catalyst material scarcity, with platinum group metals becoming increasingly expensive and subject to geopolitical supply risks.

Geographically, emission reduction technology development remains concentrated in specific regions. European manufacturers lead in diesel emission control technologies, while Japanese and American companies have made significant advances in LSA engine development. Chinese manufacturers are rapidly closing the technology gap through substantial R&D investments, particularly in electrification integration strategies.

The integration of emission reduction technologies with hybridization represents both a challenge and opportunity. Current hybrid systems must be optimized differently for LSA versus diesel powertrains, with energy management strategies becoming increasingly complex as manufacturers seek to balance performance, efficiency, and emissions across multiple operating modes.

Diesel engines, despite efficiency improvements, continue to struggle with inherent emission challenges. Current diesel technology employs complex after-treatment systems including Selective Catalytic Reduction (SCR), Diesel Particulate Filters (DPF), and Diesel Oxidation Catalysts (DOC). While effective, these systems add considerable cost, weight, and complexity to vehicles, with the latest data showing after-treatment systems now representing 15-20% of total powertrain costs.

LSA engines have emerged as a promising alternative, offering reduced emissions through precise fuel stratification and lean combustion. Recent advancements in direct injection technology and electronic control systems have enabled LSA engines to achieve up to 15% lower CO2 emissions compared to conventional gasoline engines. However, LSA technology faces challenges in NOx formation during lean operation and cold-start emissions performance.

A significant technical barrier for both engine types is the "real-world versus laboratory" emission gap. Studies from the International Council on Clean Transportation reveal that real-world NOx emissions from diesel vehicles can exceed regulatory limits by 4-7 times under normal driving conditions. Similarly, LSA engines show performance variability depending on ambient conditions and driving patterns, with efficiency benefits diminishing under high-load operations.

Material constraints present another challenge, particularly for high-temperature components in both engine types. Advanced ceramics and heat-resistant alloys are required but face supply chain limitations and cost barriers. The industry is also confronting catalyst material scarcity, with platinum group metals becoming increasingly expensive and subject to geopolitical supply risks.

Geographically, emission reduction technology development remains concentrated in specific regions. European manufacturers lead in diesel emission control technologies, while Japanese and American companies have made significant advances in LSA engine development. Chinese manufacturers are rapidly closing the technology gap through substantial R&D investments, particularly in electrification integration strategies.

The integration of emission reduction technologies with hybridization represents both a challenge and opportunity. Current hybrid systems must be optimized differently for LSA versus diesel powertrains, with energy management strategies becoming increasingly complex as manufacturers seek to balance performance, efficiency, and emissions across multiple operating modes.

Current Technical Solutions for Emission Reduction

01 Exhaust gas treatment systems for diesel engines

Various exhaust gas treatment systems are designed to reduce emissions from diesel engines. These systems include catalytic converters, particulate filters, and selective catalytic reduction (SCR) systems that work to remove harmful pollutants such as nitrogen oxides (NOx), particulate matter, and carbon monoxide from exhaust gases before they are released into the atmosphere. These technologies help diesel engines meet increasingly stringent emission standards while maintaining performance.- Emission control systems for diesel engines: Various emission control systems are designed specifically for diesel engines to reduce harmful pollutants. These systems include selective catalytic reduction (SCR), diesel particulate filters (DPF), and exhaust gas recirculation (EGR) technologies. These technologies work together or independently to reduce nitrogen oxides (NOx), particulate matter, and other harmful emissions from diesel engines, helping to meet increasingly stringent environmental regulations.

- Fuel composition modifications for emission reduction: Modifications to diesel fuel compositions can significantly impact engine emissions. Additives and alternative fuel formulations can reduce soot formation, improve combustion efficiency, and lower emissions of sulfur compounds and particulate matter. These fuel modifications can include biodiesel blends, low-sulfur diesel formulations, and specific chemical additives designed to enhance combustion characteristics while reducing harmful exhaust components.

- Engine design and combustion optimization: Innovations in engine design and combustion chamber configurations can significantly reduce emissions from both LSA and diesel engines. These include advanced fuel injection timing, improved air-fuel mixing, variable valve timing, and optimized combustion chamber geometry. By enhancing the combustion process, these design improvements lead to more complete fuel burning, reduced formation of pollutants, and overall lower emission levels while maintaining or improving engine performance.

- Exhaust aftertreatment technologies: Aftertreatment systems are crucial for treating exhaust gases after combustion to reduce emissions before they are released into the atmosphere. These technologies include catalytic converters specifically designed for diesel applications, NOx traps, oxidation catalysts, and integrated systems that combine multiple treatment methods. Advanced sensors and control systems monitor and adjust these aftertreatment processes in real-time to maximize emission reduction efficiency across various operating conditions.

- Electronic control and monitoring systems: Sophisticated electronic control units (ECUs) and monitoring systems play a vital role in managing engine parameters to minimize emissions. These systems use real-time data from multiple sensors to optimize fuel injection, air intake, exhaust gas recirculation, and aftertreatment processes. Advanced algorithms and machine learning techniques enable adaptive control strategies that can balance emission reduction with performance requirements across different operating conditions and throughout the engine's lifecycle.

02 Fuel composition modifications for emission reduction

Specialized fuel compositions and additives can significantly reduce emissions from both LSA and diesel engines. These formulations may include oxygenated compounds, detergents, cetane improvers, and other additives that promote more complete combustion, reduce particulate formation, and lower NOx emissions. Modified fuel compositions can be an effective approach to emissions reduction without requiring major engine hardware modifications.Expand Specific Solutions03 Engine control systems and strategies for emission reduction

Advanced engine control systems utilize sensors, electronic control units (ECUs), and sophisticated algorithms to optimize combustion parameters in real-time. These systems can adjust fuel injection timing, pressure, duration, air-fuel ratios, and exhaust gas recirculation (EGR) rates to minimize emissions while maintaining performance. Adaptive control strategies can respond to changing operating conditions and driver demands to ensure optimal emission control across various driving scenarios.Expand Specific Solutions04 Alternative combustion technologies for cleaner emissions

Novel combustion approaches such as homogeneous charge compression ignition (HCCI), low temperature combustion (LTC), and premixed charge compression ignition (PCCI) can significantly reduce emissions from diesel and LSA engines. These technologies aim to achieve more uniform combustion with lower peak temperatures, which naturally produces fewer pollutants, particularly NOx and particulate matter. Implementation often requires specialized hardware modifications and precise control strategies.Expand Specific Solutions05 Hybrid and dual-fuel systems for emission reduction

Hybrid powertrains that combine conventional engines with electric motors can significantly reduce overall emissions by operating the engine in its most efficient range and recovering energy through regenerative braking. Dual-fuel systems that allow engines to run on combinations of diesel and cleaner alternative fuels like natural gas can also achieve substantial emission reductions while maintaining the power and efficiency advantages of compression ignition engines.Expand Specific Solutions

Major Players in Clean Engine Technology Development

The LSA Engine vs Diesel Engines emission impact landscape is currently in a transformative phase, with the market growing rapidly as environmental regulations tighten globally. The technology is approaching maturity, with key players driving innovation across different segments. Cummins leads in commercial applications with significant R&D investments in emission reduction technologies, while Johnson Matthey provides critical catalyst solutions. Major OEMs including PACCAR, Ford, and Caterpillar are integrating LSA technologies into their product lines. Academic institutions like Tianjin University and Zhejiang University contribute fundamental research, while specialized entities such as Southwest Research Institute bridge the gap between research and commercial implementation. The competitive dynamics are intensifying as companies position themselves for increasingly stringent emission standards worldwide.

Cummins, Inc.

Technical Solution: Cummins has developed advanced Low Swirl Atomization (LSA) engine technology that significantly reduces emissions compared to conventional diesel engines. Their LSA system utilizes innovative air-fuel mixing techniques that create a more homogeneous charge, resulting in more complete combustion and lower particulate matter (PM) formation. The technology incorporates a specialized injection system with optimized spray patterns that promote low-temperature combustion while maintaining high thermal efficiency. Cummins' LSA engines feature sophisticated exhaust gas recirculation (EGR) systems working in conjunction with selective catalytic reduction (SCR) technology, achieving near-zero NOx emissions while meeting stringent EPA and Euro emissions standards. Their integrated approach combines hardware innovations with advanced control algorithms that continuously optimize combustion parameters based on operating conditions, load demands, and environmental factors.

Strengths: Superior NOx and PM reduction capabilities without significant fuel economy penalties; robust performance across varying operating conditions; proven durability in commercial applications. Weaknesses: Higher initial system complexity and cost; requires more sophisticated control systems; potential challenges in cold-start conditions.

Johnson Matthey Plc

Technical Solution: Johnson Matthey has pioneered advanced catalyst technologies specifically designed to work with LSA engines to further reduce emissions compared to traditional diesel systems. Their integrated emission control systems combine innovative substrate designs with proprietary catalyst formulations that effectively convert nitrogen oxides, carbon monoxide, and hydrocarbons into harmless compounds. The company's dual-layer catalyst technology features a specialized washcoat that enhances low-temperature catalytic activity, particularly beneficial for LSA engines that typically operate at lower exhaust temperatures than conventional diesel engines. Johnson Matthey's systems incorporate advanced selective catalytic reduction (SCR) technology with enhanced urea injection strategies tailored specifically for the exhaust profile of LSA engines. Their catalyst systems are designed to maintain high conversion efficiency throughout the engine's lifetime, with special attention to thermal stability and resistance to catalyst poisoning from fuel and lubricant additives.

Strengths: Industry-leading catalyst efficiency at lower exhaust temperatures; extensive experience in emissions control systems; comprehensive integration capabilities with engine management systems. Weaknesses: Premium pricing compared to standard catalyst systems; requires precise calibration with specific engine parameters; potential dependency on rare earth materials.

Key Innovations in LSA vs Diesel Emission Control

Method for operating an internal combustion engine and internal combustion engine

PatentInactiveEP2976521A1

Innovation

- A method that determines the type of spark (surface or air) based on burning duration, using an ignition device and engine control unit to adjust combustion conditions, thereby reducing the frequency of surface sparks and optimizing ignition timing and fuel injection to maintain efficient and smooth engine operation.

Improvements in emission control

PatentWO2009106849A1

Innovation

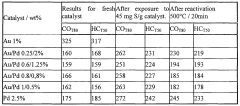

- Locating an oxidation catalyst comprising a combination of palladium and gold, preferably as an alloy, between the engine and the turbocharger to expose it to higher exhaust gas temperatures, enhancing methane oxidation efficiency and resistance to sulphation, while potentially combining with downstream catalysts for improved performance.

Environmental Impact Assessment of Engine Technologies

The environmental impact of engine technologies represents a critical dimension in the comparative analysis of LSA (Lean Stratified Atmosphere) engines versus traditional diesel engines. LSA technology has emerged as a promising alternative that potentially addresses several environmental concerns associated with conventional diesel combustion systems.

When examining emissions profiles, LSA engines demonstrate significant reductions in particulate matter (PM) emissions, with studies indicating decreases of 40-60% compared to conventional diesel engines operating under similar conditions. This reduction stems from the lean combustion process that enables more complete fuel oxidation, minimizing carbon residue formation.

Nitrogen oxide (NOx) emissions present a more complex picture. While diesel engines typically produce higher NOx levels due to their high-temperature combustion characteristics, LSA engines can achieve 30-45% lower NOx emissions through controlled stratification of the air-fuel mixture and precise timing of the combustion process. This advantage becomes particularly pronounced in urban driving cycles where traditional diesel engines struggle with emission control during frequent acceleration events.

Carbon dioxide (CO2) emissions, directly linked to fuel efficiency, show modest improvements with LSA technology. The enhanced thermal efficiency of LSA engines typically yields 5-15% reduction in CO2 emissions compared to conventional diesel counterparts, contributing to reduced greenhouse gas impacts. This improvement becomes more significant when considering lifecycle emissions across the entire fuel production and consumption chain.

Hydrocarbon and carbon monoxide emissions also demonstrate favorable patterns in LSA engines, with reductions of approximately 25-35% compared to diesel engines. The more complete combustion process in LSA technology minimizes these pollutants, which are particularly harmful in urban environments and contribute to photochemical smog formation.

Water resource impacts differ significantly between the two technologies. Diesel engines typically require more extensive exhaust aftertreatment systems that consume water for regeneration processes, while LSA engines can operate with simplified emission control systems, reducing water consumption and contamination risks during operation and maintenance.

Land use considerations and ecosystem impacts also favor LSA technology, as the reduced emission profile translates to lower deposition of acidifying compounds and particulates on surrounding ecosystems. This advantage becomes particularly relevant in environmentally sensitive areas or densely populated regions where cumulative environmental impacts are of heightened concern.

When examining emissions profiles, LSA engines demonstrate significant reductions in particulate matter (PM) emissions, with studies indicating decreases of 40-60% compared to conventional diesel engines operating under similar conditions. This reduction stems from the lean combustion process that enables more complete fuel oxidation, minimizing carbon residue formation.

Nitrogen oxide (NOx) emissions present a more complex picture. While diesel engines typically produce higher NOx levels due to their high-temperature combustion characteristics, LSA engines can achieve 30-45% lower NOx emissions through controlled stratification of the air-fuel mixture and precise timing of the combustion process. This advantage becomes particularly pronounced in urban driving cycles where traditional diesel engines struggle with emission control during frequent acceleration events.

Carbon dioxide (CO2) emissions, directly linked to fuel efficiency, show modest improvements with LSA technology. The enhanced thermal efficiency of LSA engines typically yields 5-15% reduction in CO2 emissions compared to conventional diesel counterparts, contributing to reduced greenhouse gas impacts. This improvement becomes more significant when considering lifecycle emissions across the entire fuel production and consumption chain.

Hydrocarbon and carbon monoxide emissions also demonstrate favorable patterns in LSA engines, with reductions of approximately 25-35% compared to diesel engines. The more complete combustion process in LSA technology minimizes these pollutants, which are particularly harmful in urban environments and contribute to photochemical smog formation.

Water resource impacts differ significantly between the two technologies. Diesel engines typically require more extensive exhaust aftertreatment systems that consume water for regeneration processes, while LSA engines can operate with simplified emission control systems, reducing water consumption and contamination risks during operation and maintenance.

Land use considerations and ecosystem impacts also favor LSA technology, as the reduced emission profile translates to lower deposition of acidifying compounds and particulates on surrounding ecosystems. This advantage becomes particularly relevant in environmentally sensitive areas or densely populated regions where cumulative environmental impacts are of heightened concern.

Regulatory Compliance Framework for Engine Emissions

The global regulatory landscape for engine emissions has evolved significantly over the past decades, creating a complex framework that manufacturers must navigate. For LSA (Light Sport Aircraft) engines and diesel engines, these regulations vary considerably across regions but share common objectives of reducing harmful emissions and environmental impact.

In the United States, the Environmental Protection Agency (EPA) establishes emission standards under the Clean Air Act, with specific provisions for non-road engines including those used in light aircraft. The EPA's Tier 4 standards represent the current benchmark for diesel engines, requiring substantial reductions in particulate matter (PM) and nitrogen oxides (NOx). For LSA engines, the Federal Aviation Administration (FAA) coordinates with the EPA to establish appropriate standards that balance performance requirements with environmental considerations.

The European Union implements the Euro standards (currently Euro 6/VI) for diesel engines, which are among the most stringent globally. The European Aviation Safety Agency (EASA) has developed parallel frameworks for aircraft engines, including those used in light sport applications. These regulations emphasize reductions in carbon dioxide (CO2), NOx, and unburned hydrocarbons.

Compliance verification processes differ significantly between engine types. Diesel engines typically undergo standardized test cycles such as the World Harmonized Test Cycle (WHTC) and World Harmonized Stationary Cycle (WHSC). LSA engines face different testing protocols focused on their specific operational profiles, often with greater emphasis on cruise performance rather than transient operations.

Enforcement mechanisms include certification requirements, in-use testing programs, and penalties for non-compliance. Manufacturers must obtain type approval before marketing engines, with ongoing conformity of production checks ensuring continued compliance. Recent regulatory trends show increasing focus on real-world emissions rather than laboratory test results, particularly following diesel emissions scandals.

The regulatory timeline for implementation presents different challenges for each engine type. Diesel engine manufacturers have faced progressively tightening standards with established phase-in periods. LSA engine regulations have evolved more gradually, often with longer implementation timeframes reflecting the smaller market size and specialized applications.

Carbon pricing mechanisms and emissions trading schemes increasingly affect both engine types, though diesel engines face more immediate economic impacts due to their wider commercial applications. These market-based instruments complement traditional command-and-control regulations, creating economic incentives for emissions reduction beyond minimum compliance levels.

Future regulatory developments point toward lifecycle emissions assessment, incorporating manufacturing and end-of-life considerations alongside operational emissions. This holistic approach will likely reshape compliance strategies for both diesel and LSA engine manufacturers in the coming decade.

In the United States, the Environmental Protection Agency (EPA) establishes emission standards under the Clean Air Act, with specific provisions for non-road engines including those used in light aircraft. The EPA's Tier 4 standards represent the current benchmark for diesel engines, requiring substantial reductions in particulate matter (PM) and nitrogen oxides (NOx). For LSA engines, the Federal Aviation Administration (FAA) coordinates with the EPA to establish appropriate standards that balance performance requirements with environmental considerations.

The European Union implements the Euro standards (currently Euro 6/VI) for diesel engines, which are among the most stringent globally. The European Aviation Safety Agency (EASA) has developed parallel frameworks for aircraft engines, including those used in light sport applications. These regulations emphasize reductions in carbon dioxide (CO2), NOx, and unburned hydrocarbons.

Compliance verification processes differ significantly between engine types. Diesel engines typically undergo standardized test cycles such as the World Harmonized Test Cycle (WHTC) and World Harmonized Stationary Cycle (WHSC). LSA engines face different testing protocols focused on their specific operational profiles, often with greater emphasis on cruise performance rather than transient operations.

Enforcement mechanisms include certification requirements, in-use testing programs, and penalties for non-compliance. Manufacturers must obtain type approval before marketing engines, with ongoing conformity of production checks ensuring continued compliance. Recent regulatory trends show increasing focus on real-world emissions rather than laboratory test results, particularly following diesel emissions scandals.

The regulatory timeline for implementation presents different challenges for each engine type. Diesel engine manufacturers have faced progressively tightening standards with established phase-in periods. LSA engine regulations have evolved more gradually, often with longer implementation timeframes reflecting the smaller market size and specialized applications.

Carbon pricing mechanisms and emissions trading schemes increasingly affect both engine types, though diesel engines face more immediate economic impacts due to their wider commercial applications. These market-based instruments complement traditional command-and-control regulations, creating economic incentives for emissions reduction beyond minimum compliance levels.

Future regulatory developments point toward lifecycle emissions assessment, incorporating manufacturing and end-of-life considerations alongside operational emissions. This holistic approach will likely reshape compliance strategies for both diesel and LSA engine manufacturers in the coming decade.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!