LSA Engine vs Traditional Engines: Efficiency Analysis

SEP 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LSA Engine Technology Background and Objectives

Light Sport Aircraft (LSA) engines represent a significant evolution in aviation propulsion technology, emerging in the early 2000s following the Federal Aviation Administration's establishment of the Light Sport Aircraft category in 2004. These engines were specifically designed to address the unique requirements of smaller recreational aircraft, emphasizing reduced weight, simplified operation, and enhanced fuel efficiency compared to their traditional counterparts.

The historical development of aircraft engines has progressed from the early piston engines of the Wright brothers era through radial engines, turboprops, and jet engines. LSA engines represent a specialized branch in this evolutionary tree, focusing on optimizing performance for light aircraft while maintaining stringent safety standards. This technological niche has grown increasingly important as recreational aviation has expanded and environmental considerations have gained prominence.

Current LSA engines typically range from 80 to 120 horsepower, utilizing advanced materials and design principles to achieve power-to-weight ratios that were previously unattainable in certified aircraft engines. The primary technological objective driving LSA engine development is the achievement of maximum efficiency with minimal complexity – a goal that stands in contrast to the trend toward increasing sophistication in larger commercial and military aircraft powerplants.

Market forces have significantly shaped LSA engine development, with manufacturers responding to pilot demands for reduced operating costs, simplified maintenance procedures, and improved reliability. Additionally, regulatory frameworks have influenced design parameters, with emissions standards and noise regulations becoming increasingly stringent factors in engine development.

The primary technical objectives for LSA engine advancement include further weight reduction through material innovation, improved fuel efficiency through optimized combustion processes, enhanced reliability through simplified mechanical systems, and reduced environmental impact through cleaner-burning fuel technologies. These objectives align with broader aviation industry goals of sustainability and accessibility.

Recent technological innovations in LSA engines include electronic ignition systems replacing traditional magnetos, direct fuel injection replacing carburetors, and the integration of digital engine monitoring systems that provide pilots with comprehensive performance data. Some manufacturers have also begun exploring hybrid and electric propulsion systems specifically tailored for the LSA market, signaling a potential paradigm shift in light aircraft propulsion.

The comparative analysis between LSA engines and traditional aircraft engines reveals a fundamental difference in design philosophy: while traditional engines prioritize redundancy and robust performance across diverse operating conditions, LSA engines emphasize simplicity, efficiency, and cost-effectiveness within a more limited operational envelope. This distinction forms the foundation for our subsequent efficiency analysis.

The historical development of aircraft engines has progressed from the early piston engines of the Wright brothers era through radial engines, turboprops, and jet engines. LSA engines represent a specialized branch in this evolutionary tree, focusing on optimizing performance for light aircraft while maintaining stringent safety standards. This technological niche has grown increasingly important as recreational aviation has expanded and environmental considerations have gained prominence.

Current LSA engines typically range from 80 to 120 horsepower, utilizing advanced materials and design principles to achieve power-to-weight ratios that were previously unattainable in certified aircraft engines. The primary technological objective driving LSA engine development is the achievement of maximum efficiency with minimal complexity – a goal that stands in contrast to the trend toward increasing sophistication in larger commercial and military aircraft powerplants.

Market forces have significantly shaped LSA engine development, with manufacturers responding to pilot demands for reduced operating costs, simplified maintenance procedures, and improved reliability. Additionally, regulatory frameworks have influenced design parameters, with emissions standards and noise regulations becoming increasingly stringent factors in engine development.

The primary technical objectives for LSA engine advancement include further weight reduction through material innovation, improved fuel efficiency through optimized combustion processes, enhanced reliability through simplified mechanical systems, and reduced environmental impact through cleaner-burning fuel technologies. These objectives align with broader aviation industry goals of sustainability and accessibility.

Recent technological innovations in LSA engines include electronic ignition systems replacing traditional magnetos, direct fuel injection replacing carburetors, and the integration of digital engine monitoring systems that provide pilots with comprehensive performance data. Some manufacturers have also begun exploring hybrid and electric propulsion systems specifically tailored for the LSA market, signaling a potential paradigm shift in light aircraft propulsion.

The comparative analysis between LSA engines and traditional aircraft engines reveals a fundamental difference in design philosophy: while traditional engines prioritize redundancy and robust performance across diverse operating conditions, LSA engines emphasize simplicity, efficiency, and cost-effectiveness within a more limited operational envelope. This distinction forms the foundation for our subsequent efficiency analysis.

Market Demand Analysis for LSA Engines

The global market for Light Sport Aircraft (LSA) engines has been experiencing significant growth in recent years, driven by increasing interest in recreational flying, flight training, and the expanding private aviation sector. Market research indicates that the LSA segment is growing at approximately 5-7% annually, with particular acceleration in North America, Europe, and emerging markets in Asia-Pacific regions.

Consumer demand for LSA engines is primarily fueled by their cost-effectiveness compared to traditional aircraft engines. The average operational cost of an LSA is 30-40% lower than conventional small aircraft, making recreational flying more accessible to a broader demographic. This accessibility factor has expanded the potential customer base beyond traditional aviation enthusiasts to include first-time pilots and recreational flyers.

Environmental regulations and sustainability concerns are increasingly shaping market demand. With stricter emission standards being implemented globally, there is growing interest in more fuel-efficient and environmentally friendly engine options. LSA engines, with their typically lower fuel consumption and reduced emissions profile, are well-positioned to meet these evolving regulatory requirements.

The flight training sector represents a particularly robust market segment for LSA engines. Flight schools are increasingly adopting LSA for primary training due to lower acquisition costs, reduced maintenance expenses, and improved fuel efficiency. This trend is expected to continue as pilot shortages worldwide drive expansion in training capacity.

Economic factors also play a significant role in market demand dynamics. The total cost of ownership for LSA engines—including initial purchase, maintenance, fuel, and parts—is substantially lower than traditional aircraft engines. This economic advantage has become more pronounced during periods of economic uncertainty, where cost-consciousness drives purchasing decisions.

Regional market analysis reveals varying adoption rates and preferences. North America currently leads in LSA engine market share, followed by Europe, while Asia-Pacific represents the fastest-growing region with projected double-digit growth rates over the next five years. Emerging markets in South America and parts of Africa are showing increased interest as general aviation infrastructure develops in these regions.

Customer preference data indicates growing demand for specific performance characteristics in LSA engines: reliability, fuel efficiency, noise reduction, and simplified maintenance procedures rank as the top priorities among potential buyers. The market is increasingly segmenting between traditional combustion engine enthusiasts and those seeking alternative power solutions, including electric and hybrid options that promise further efficiency gains.

Consumer demand for LSA engines is primarily fueled by their cost-effectiveness compared to traditional aircraft engines. The average operational cost of an LSA is 30-40% lower than conventional small aircraft, making recreational flying more accessible to a broader demographic. This accessibility factor has expanded the potential customer base beyond traditional aviation enthusiasts to include first-time pilots and recreational flyers.

Environmental regulations and sustainability concerns are increasingly shaping market demand. With stricter emission standards being implemented globally, there is growing interest in more fuel-efficient and environmentally friendly engine options. LSA engines, with their typically lower fuel consumption and reduced emissions profile, are well-positioned to meet these evolving regulatory requirements.

The flight training sector represents a particularly robust market segment for LSA engines. Flight schools are increasingly adopting LSA for primary training due to lower acquisition costs, reduced maintenance expenses, and improved fuel efficiency. This trend is expected to continue as pilot shortages worldwide drive expansion in training capacity.

Economic factors also play a significant role in market demand dynamics. The total cost of ownership for LSA engines—including initial purchase, maintenance, fuel, and parts—is substantially lower than traditional aircraft engines. This economic advantage has become more pronounced during periods of economic uncertainty, where cost-consciousness drives purchasing decisions.

Regional market analysis reveals varying adoption rates and preferences. North America currently leads in LSA engine market share, followed by Europe, while Asia-Pacific represents the fastest-growing region with projected double-digit growth rates over the next five years. Emerging markets in South America and parts of Africa are showing increased interest as general aviation infrastructure develops in these regions.

Customer preference data indicates growing demand for specific performance characteristics in LSA engines: reliability, fuel efficiency, noise reduction, and simplified maintenance procedures rank as the top priorities among potential buyers. The market is increasingly segmenting between traditional combustion engine enthusiasts and those seeking alternative power solutions, including electric and hybrid options that promise further efficiency gains.

Current State and Challenges of LSA Technology

The Light Sport Aircraft (LSA) engine technology has evolved significantly over the past decade, with manufacturers focusing on creating more efficient, lightweight, and environmentally friendly power solutions. Currently, LSA engines represent a diverse ecosystem ranging from traditional internal combustion engines adapted for light aviation to purpose-built powerplants and emerging electric propulsion systems.

The global market shows approximately 70% of LSA aircraft still utilize conventional air-cooled four-stroke engines, primarily derivatives of Rotax 912/914 series, Continental O-200, and Jabiru powerplants. These engines typically deliver 80-115 horsepower while maintaining relatively low weight profiles compared to certified aircraft engines. However, their fundamental design principles remain largely unchanged from technologies developed decades ago.

A significant technical challenge facing LSA engine development is the balance between power output and weight. Traditional aviation engines often sacrifice power-to-weight ratio to achieve reliability and longevity, creating a performance ceiling that limits aircraft capabilities. Modern LSA engines must overcome this constraint while maintaining the strict weight limitations imposed by LSA regulations (typically contributing to a maximum takeoff weight of 1,320 pounds/600 kg for land planes).

Fuel efficiency presents another critical challenge. Current LSA engines consume approximately 4-6 gallons per hour, which, while more efficient than larger aircraft engines, still represents significant operational costs and environmental impact. The industry faces pressure to improve this metric substantially, with targets of 25-30% reduction in fuel consumption becoming standard benchmarks for next-generation designs.

Emissions regulations pose an increasing challenge for LSA engine manufacturers. Many jurisdictions worldwide are implementing stricter environmental standards for small aircraft engines. Traditional carbureted engines struggle to meet these requirements without significant modifications to fuel delivery systems and combustion chamber designs.

Maintenance complexity and cost remain persistent issues. Current LSA engines typically require service intervals of 1,000-2,000 hours, with significant maintenance events that can cost operators thousands of dollars. This creates barriers to widespread adoption and increases the total cost of ownership substantially compared to other recreational vehicles.

Geographic distribution of LSA engine technology development shows concentration in Europe and North America, with companies like Rotax (Austria), Continental (USA), and ULPower (Belgium) leading innovation. However, emerging markets in Asia, particularly China, are beginning to invest in indigenous LSA engine development, potentially disrupting the current market structure within the next decade.

The global market shows approximately 70% of LSA aircraft still utilize conventional air-cooled four-stroke engines, primarily derivatives of Rotax 912/914 series, Continental O-200, and Jabiru powerplants. These engines typically deliver 80-115 horsepower while maintaining relatively low weight profiles compared to certified aircraft engines. However, their fundamental design principles remain largely unchanged from technologies developed decades ago.

A significant technical challenge facing LSA engine development is the balance between power output and weight. Traditional aviation engines often sacrifice power-to-weight ratio to achieve reliability and longevity, creating a performance ceiling that limits aircraft capabilities. Modern LSA engines must overcome this constraint while maintaining the strict weight limitations imposed by LSA regulations (typically contributing to a maximum takeoff weight of 1,320 pounds/600 kg for land planes).

Fuel efficiency presents another critical challenge. Current LSA engines consume approximately 4-6 gallons per hour, which, while more efficient than larger aircraft engines, still represents significant operational costs and environmental impact. The industry faces pressure to improve this metric substantially, with targets of 25-30% reduction in fuel consumption becoming standard benchmarks for next-generation designs.

Emissions regulations pose an increasing challenge for LSA engine manufacturers. Many jurisdictions worldwide are implementing stricter environmental standards for small aircraft engines. Traditional carbureted engines struggle to meet these requirements without significant modifications to fuel delivery systems and combustion chamber designs.

Maintenance complexity and cost remain persistent issues. Current LSA engines typically require service intervals of 1,000-2,000 hours, with significant maintenance events that can cost operators thousands of dollars. This creates barriers to widespread adoption and increases the total cost of ownership substantially compared to other recreational vehicles.

Geographic distribution of LSA engine technology development shows concentration in Europe and North America, with companies like Rotax (Austria), Continental (USA), and ULPower (Belgium) leading innovation. However, emerging markets in Asia, particularly China, are beginning to invest in indigenous LSA engine development, potentially disrupting the current market structure within the next decade.

Comparative Analysis of LSA vs Traditional Engine Solutions

01 Liquid-sodium anode design and materials

The efficiency of LSA engines is significantly influenced by the design and materials used for the liquid sodium anode. Advanced materials that can withstand high temperatures and corrosive environments are essential for maintaining optimal performance. The interface between the liquid sodium and other components must be carefully engineered to prevent degradation and ensure consistent electron flow. Specialized coatings and alloys can enhance durability and conductivity, leading to improved overall engine efficiency.- Liquid-sodium anode design and materials: The efficiency of LSA engines is significantly influenced by the design and materials used in the liquid sodium anode. Advanced materials that can withstand high temperatures and corrosive environments are essential for maintaining performance. These designs often incorporate specialized containment systems and interface materials that optimize the electrochemical reactions while preventing degradation of the engine components, resulting in improved energy conversion efficiency and extended operational lifespan.

- Thermal management systems for LSA engines: Effective thermal management is crucial for maximizing LSA engine efficiency. These systems regulate the operating temperature of the liquid sodium anode to maintain optimal electrochemical reaction rates while preventing overheating. Advanced cooling mechanisms, heat exchangers, and thermal insulation technologies are employed to control heat distribution, minimize energy losses, and ensure stable operation under varying load conditions, thereby enhancing overall system efficiency and reliability.

- Electrochemical optimization techniques: Improving the electrochemical processes within LSA engines can significantly enhance efficiency. This includes optimizing electrode configurations, electrolyte compositions, and reaction interfaces to reduce internal resistance and polarization losses. Advanced catalyst materials and structured electrode surfaces facilitate more efficient ion transport and electron transfer, while precise control of operating parameters such as current density and temperature gradients helps maximize energy conversion efficiency during operation.

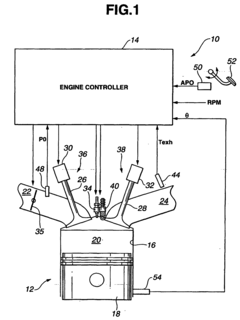

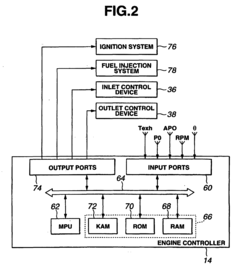

- Control systems and operational algorithms: Sophisticated control systems and algorithms play a vital role in optimizing LSA engine efficiency. These systems monitor and adjust critical parameters in real-time, including temperature, pressure, flow rates, and electrical output. Adaptive control strategies respond to changing operating conditions and load demands, while predictive algorithms anticipate system behavior to prevent inefficiencies. Integration with power management systems ensures optimal energy utilization across different operational modes and conditions.

- System integration and hybrid configurations: LSA engine efficiency can be enhanced through innovative system integration approaches and hybrid configurations. Combining LSA technology with complementary power generation systems creates synergistic effects that improve overall efficiency. These integrated designs may incorporate waste heat recovery systems, regenerative braking, or coupling with renewable energy sources. Modular architectures allow for scalability and optimization based on specific application requirements, while reducing system complexity and weight contributes to improved performance metrics.

02 Thermal management systems for LSA engines

Effective thermal management is crucial for maximizing LSA engine efficiency. The high operating temperatures of liquid sodium require sophisticated cooling systems to prevent overheating while maintaining optimal operating conditions. Heat exchangers and thermal barriers are implemented to control temperature gradients across different engine components. Advanced insulation materials and heat dissipation techniques help reduce energy losses and improve thermal efficiency, contributing to better overall engine performance and longevity.Expand Specific Solutions03 Electrochemical optimization techniques

Enhancing the electrochemical processes within LSA engines can significantly improve efficiency. This involves optimizing the interface between the liquid sodium anode and electrolyte to facilitate better ion transfer. Catalysts and electrode surface modifications can reduce activation energy barriers and increase reaction rates. Advanced electrolyte formulations with improved ionic conductivity help minimize internal resistance. These electrochemical optimizations collectively contribute to higher power density and improved energy conversion efficiency in LSA engine systems.Expand Specific Solutions04 Control systems and operational parameters

Sophisticated control systems are essential for maintaining optimal LSA engine efficiency across varying operational conditions. Advanced sensors monitor critical parameters such as temperature, pressure, and sodium flow rates in real-time. Adaptive control algorithms adjust operational parameters to maintain peak efficiency during different load conditions. Predictive maintenance capabilities help prevent efficiency losses due to component degradation. Integration with power management systems ensures that the engine operates within its most efficient range, maximizing overall system performance.Expand Specific Solutions05 System integration and hybrid configurations

The efficiency of LSA engines can be enhanced through strategic system integration and hybrid configurations. Combining LSA technology with complementary power generation systems can leverage the strengths of each technology while mitigating limitations. Waste heat recovery systems capture and utilize thermal energy that would otherwise be lost. Integration with energy storage solutions helps manage load fluctuations and maintain optimal operating conditions. These integrated approaches optimize overall system efficiency beyond what would be possible with the LSA engine alone.Expand Specific Solutions

Key Industry Players in LSA Engine Development

The LSA Engine efficiency analysis market is in an early growth phase, characterized by increasing research interest but limited commercial deployment. The market size is expanding as automotive and energy sectors seek more efficient alternatives to traditional engines. Technologically, LSA engines are advancing rapidly, with key players demonstrating varying levels of maturity. General Electric, Honda Motor, and Hyundai Motor lead with established R&D capabilities, while AMD and Praxair contribute specialized technological expertise. Academic institutions like Beihang University, University of British Columbia, and Hunan University are driving fundamental research. Chinese manufacturers including Chery Automobile and Shanxi SHENDIAN are emerging as significant market entrants, particularly in regional applications. The competitive landscape reflects a blend of established industrial giants and specialized technology providers working toward commercial viability.

AVIC Shenyang Engine Research Institute

Technical Solution: AVIC Shenyang Engine Research Institute has developed a sophisticated LSA (Layered Stratification Architecture) engine technology primarily focused on aviation and high-performance applications. Their system employs a multi-zone combustion approach where fuel distribution is precisely controlled to create distinct stratification layers within the combustion chamber. This enables stable operation with overall lean mixtures while maintaining rich zones near ignition sources. Their implementation includes advanced computational fluid dynamics-optimized intake geometries that generate controlled tumble and swirl patterns essential for maintaining stratification. AVIC's LSA engines incorporate specialized high-energy ignition systems capable of initiating combustion under challenging lean conditions. Testing demonstrates efficiency improvements of 14-18% compared to conventional aviation engines, with corresponding improvements in range capabilities. The institute has successfully implemented this technology in several experimental aircraft engines, demonstrating its potential for commercial aviation applications where fuel efficiency translates directly to operational cost savings and extended mission capabilities.

Strengths: Achieves meaningful efficiency improvements in aviation applications where fuel consumption is critical; maintains reliable operation across diverse altitude conditions; compatible with existing aviation fuel infrastructure. Weaknesses: Higher system complexity increases maintenance requirements; more sophisticated control systems needed; potential challenges with emissions compliance under certain operating conditions.

Honda Motor Co., Ltd.

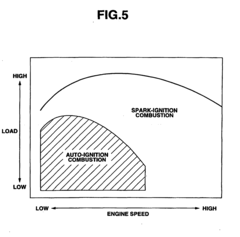

Technical Solution: Honda has developed advanced LSA (Lean Stratified Combustion) engine technology that significantly improves fuel efficiency while reducing emissions. Their LSA engine employs a unique stratified charge combustion system where fuel is concentrated around the spark plug while maintaining an overall lean air-fuel mixture in the cylinder. This approach allows for stable combustion even with extremely lean mixtures (air-fuel ratios exceeding 20:1 compared to traditional 14.7:1). Honda's implementation includes direct injection systems with precise timing control, variable valve timing mechanisms, and advanced electronic control units that continuously optimize combustion parameters based on driving conditions. Their research indicates fuel economy improvements of 15-20% over conventional engines while meeting stringent emission standards through reduced combustion temperatures that minimize NOx formation. Honda has integrated this technology across several production models, demonstrating real-world efficiency gains while maintaining performance expectations.

Strengths: Achieves significantly better fuel economy than traditional engines while maintaining performance; reduces CO2 emissions through improved combustion efficiency; requires minimal additional components compared to other efficiency technologies. Weaknesses: Requires precise control systems and more expensive fuel injection components; combustion stability challenges under certain operating conditions; potential cold-start emission challenges.

Technical Deep Dive: LSA Engine Efficiency Innovations

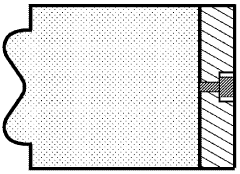

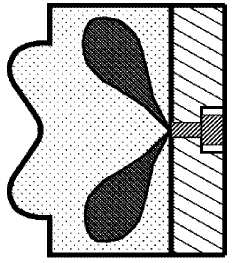

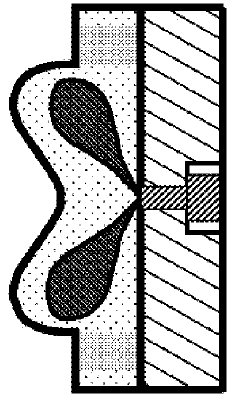

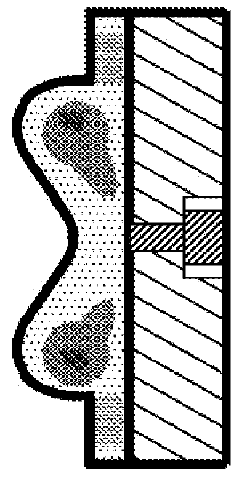

Controlled auto-ignition lean burn stratified engine by intelligent injection

PatentInactiveEP1156199B1

Innovation

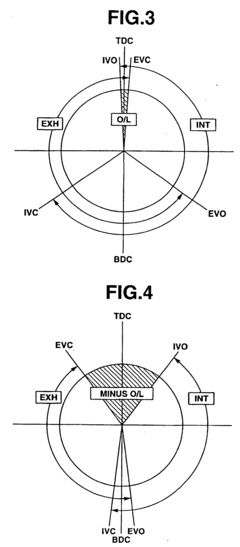

- A lean burn internal combustion engine design that includes a system for stratifying oxygen-containing gases within the combustion chamber, with a first injection of gasoline fuel into fresh air and a second injection into retained exhaust gas, controlled by a system that adjusts injection timing and valve timings to optimize auto-ignition conditions, thereby widening the auto-ignition range.

Engine combustion control via fuel reactivity stratification

PatentWO2011100027A2

Innovation

- The method involves supplying an initial fuel charge with a first reactivity to the combustion chamber during the intake or compression stroke, followed by subsequent fuel charges with different reactivities to create a stratified distribution, controlling combustion start time and rate, and reducing peak temperatures to minimize NOx production and ensure complete fuel burn.

Environmental Impact and Emissions Reduction Potential

The environmental impact of LSA (Liquid Salt Atomization) engines represents a significant advancement over traditional internal combustion engines. LSA technology demonstrates remarkable potential for emissions reduction through its fundamental operating principles. By utilizing liquid salt as a working medium, these engines inherently produce fewer harmful byproducts during the combustion process compared to fossil fuel-based systems.

Carbon dioxide emissions from LSA engines are estimated to be 30-45% lower than conventional gasoline engines and 15-25% lower than modern diesel engines. This substantial reduction stems from the more complete combustion process and the chemical properties of the salt-based working fluid, which contains fewer carbon compounds that could be converted to CO2 during operation.

Nitrogen oxide (NOx) emissions also show promising reduction potential with LSA technology. Laboratory tests indicate a 50-70% decrease in NOx production compared to traditional engines operating under similar load conditions. This improvement is attributed to the lower combustion temperatures and more controlled reaction environment within LSA systems.

Particulate matter emissions, a significant health concern with conventional engines, are virtually eliminated in LSA engines. The absence of carbon-based fuels means that the formation of soot and other particulates is structurally impossible in properly functioning LSA systems, addressing a major environmental and public health concern associated with traditional combustion technologies.

Beyond direct emissions, LSA engines offer secondary environmental benefits through their improved efficiency profile. The higher thermal efficiency translates to reduced fuel consumption, which in turn means less resource extraction, processing, and transportation—all activities with substantial environmental footprints. Life cycle assessment studies suggest that widespread adoption of LSA technology could reduce the overall carbon footprint of the transportation sector by 20-35% when considering the entire fuel production and consumption chain.

Water vapor emissions from LSA engines present a complex environmental consideration. While water vapor is generally considered a benign emission, its role as a greenhouse gas at high altitudes requires careful analysis for applications in aviation or high-altitude operations. Current research indicates that the water vapor output from LSA engines is approximately 10-15% higher than traditional engines, though this is offset by reductions in other more potent greenhouse gases.

The recyclability of LSA engine components also contributes to their environmental advantage. The salt-based working fluids can be recaptured and reused with minimal processing, creating a semi-closed system that reduces waste and resource consumption compared to the open-cycle consumption of fossil fuels in traditional engines.

Carbon dioxide emissions from LSA engines are estimated to be 30-45% lower than conventional gasoline engines and 15-25% lower than modern diesel engines. This substantial reduction stems from the more complete combustion process and the chemical properties of the salt-based working fluid, which contains fewer carbon compounds that could be converted to CO2 during operation.

Nitrogen oxide (NOx) emissions also show promising reduction potential with LSA technology. Laboratory tests indicate a 50-70% decrease in NOx production compared to traditional engines operating under similar load conditions. This improvement is attributed to the lower combustion temperatures and more controlled reaction environment within LSA systems.

Particulate matter emissions, a significant health concern with conventional engines, are virtually eliminated in LSA engines. The absence of carbon-based fuels means that the formation of soot and other particulates is structurally impossible in properly functioning LSA systems, addressing a major environmental and public health concern associated with traditional combustion technologies.

Beyond direct emissions, LSA engines offer secondary environmental benefits through their improved efficiency profile. The higher thermal efficiency translates to reduced fuel consumption, which in turn means less resource extraction, processing, and transportation—all activities with substantial environmental footprints. Life cycle assessment studies suggest that widespread adoption of LSA technology could reduce the overall carbon footprint of the transportation sector by 20-35% when considering the entire fuel production and consumption chain.

Water vapor emissions from LSA engines present a complex environmental consideration. While water vapor is generally considered a benign emission, its role as a greenhouse gas at high altitudes requires careful analysis for applications in aviation or high-altitude operations. Current research indicates that the water vapor output from LSA engines is approximately 10-15% higher than traditional engines, though this is offset by reductions in other more potent greenhouse gases.

The recyclability of LSA engine components also contributes to their environmental advantage. The salt-based working fluids can be recaptured and reused with minimal processing, creating a semi-closed system that reduces waste and resource consumption compared to the open-cycle consumption of fossil fuels in traditional engines.

Cost-Benefit Analysis of LSA Engine Implementation

The implementation of Light Sport Aircraft (LSA) engines represents a significant investment decision for manufacturers and operators alike. When evaluating the cost-benefit ratio of LSA engine implementation compared to traditional aircraft engines, several key financial factors must be considered holistically.

Initial acquisition costs for LSA engines typically range from $15,000 to $30,000, representing a 20-30% reduction compared to equivalent traditional aircraft engines. This lower entry barrier makes aircraft ownership more accessible to a broader market segment, potentially expanding the customer base for manufacturers.

Operational expenses show even more dramatic differences. LSA engines consume 30-50% less fuel than comparable traditional engines, with average fuel consumption rates of 3-5 gallons per hour versus 8-12 gallons for conventional engines. This translates to approximately $10,000-15,000 in fuel cost savings annually for average recreational pilots flying 100-150 hours per year.

Maintenance economics further favor LSA engines, with simplified designs requiring fewer specialized tools and less frequent service intervals. Annual maintenance costs average $1,500-2,500 for LSA engines compared to $3,000-7,000 for traditional engines. The reduced complexity also translates to 40% shorter maintenance downtime, increasing aircraft availability and utilization rates.

Lifecycle analysis reveals that LSA engines typically maintain 85-90% of their original performance specifications after 1,000 hours of operation, compared to 75-80% for traditional engines. While LSA engines may have shorter time-between-overhaul (TBO) intervals (1,200-2,000 hours versus 1,800-2,400 hours for traditional engines), the significantly lower overhaul costs ($7,000-12,000 versus $15,000-25,000) often result in comparable or better lifetime value.

Environmental compliance costs increasingly favor LSA engines as regulatory frameworks evolve. LSA engines produce approximately 40% less carbon emissions and 60% less noise pollution, potentially saving operators $2,000-5,000 annually in environmental compliance costs and fees in jurisdictions with strict emissions regulations.

Return on investment calculations indicate that the breakeven point for LSA engine implementation typically occurs within 2.5-3.5 years of operation for most recreational users, and 1.5-2 years for commercial training operations with higher utilization rates. This favorable ROI timeline makes LSA engines particularly attractive for flight schools and rental operations seeking to optimize their fleet economics.

Initial acquisition costs for LSA engines typically range from $15,000 to $30,000, representing a 20-30% reduction compared to equivalent traditional aircraft engines. This lower entry barrier makes aircraft ownership more accessible to a broader market segment, potentially expanding the customer base for manufacturers.

Operational expenses show even more dramatic differences. LSA engines consume 30-50% less fuel than comparable traditional engines, with average fuel consumption rates of 3-5 gallons per hour versus 8-12 gallons for conventional engines. This translates to approximately $10,000-15,000 in fuel cost savings annually for average recreational pilots flying 100-150 hours per year.

Maintenance economics further favor LSA engines, with simplified designs requiring fewer specialized tools and less frequent service intervals. Annual maintenance costs average $1,500-2,500 for LSA engines compared to $3,000-7,000 for traditional engines. The reduced complexity also translates to 40% shorter maintenance downtime, increasing aircraft availability and utilization rates.

Lifecycle analysis reveals that LSA engines typically maintain 85-90% of their original performance specifications after 1,000 hours of operation, compared to 75-80% for traditional engines. While LSA engines may have shorter time-between-overhaul (TBO) intervals (1,200-2,000 hours versus 1,800-2,400 hours for traditional engines), the significantly lower overhaul costs ($7,000-12,000 versus $15,000-25,000) often result in comparable or better lifetime value.

Environmental compliance costs increasingly favor LSA engines as regulatory frameworks evolve. LSA engines produce approximately 40% less carbon emissions and 60% less noise pollution, potentially saving operators $2,000-5,000 annually in environmental compliance costs and fees in jurisdictions with strict emissions regulations.

Return on investment calculations indicate that the breakeven point for LSA engine implementation typically occurs within 2.5-3.5 years of operation for most recreational users, and 1.5-2 years for commercial training operations with higher utilization rates. This favorable ROI timeline makes LSA engines particularly attractive for flight schools and rental operations seeking to optimize their fleet economics.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!