LSA Engine Control Unit Parameters: Impact Assessment

SEP 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LSA Engine Control Unit Evolution and Objectives

The LSA (Luxury Sport Automobile) Engine Control Unit (ECU) has undergone significant evolution since its inception in the early 2000s. Initially designed as a basic engine management system with limited parameter control capabilities, the LSA ECU has transformed into a sophisticated computational platform capable of managing thousands of parameters simultaneously while optimizing engine performance, fuel efficiency, and emissions control.

The first generation of LSA ECUs (2003-2008) featured rudimentary 16-bit processors with approximately 250 controllable parameters, primarily focused on fuel injection timing and ignition control. These early units operated with closed architectures, offering minimal customization options for performance enhancement.

The second generation (2009-2014) marked a substantial leap forward with the introduction of 32-bit processors and expanded memory capabilities, enabling control of approximately 800 parameters. This generation introduced adaptive learning algorithms that could adjust engine performance based on driving patterns and environmental conditions, representing a paradigm shift in engine management technology.

Current generation LSA ECUs (2015-present) utilize multi-core processors with advanced real-time operating systems, managing over 2,500 parameters simultaneously. These systems incorporate sophisticated model-based control strategies, predictive analytics, and machine learning algorithms to continuously optimize engine performance across all operating conditions.

The technological trajectory clearly indicates movement toward increasingly integrated systems with expanded parameter control capabilities. Industry forecasts suggest that next-generation ECUs will likely incorporate quantum computing elements for complex optimization problems and advanced AI for predictive maintenance and performance enhancement.

The primary objectives of modern LSA ECU development focus on several key areas: maximizing power-to-efficiency ratios through precise combustion control; meeting increasingly stringent emissions regulations through advanced catalytic converter management; enhancing driver experience through responsive throttle mapping and performance mode customization; and enabling over-the-air update capabilities for continuous improvement of vehicle performance throughout its lifecycle.

Additionally, integration with broader vehicle systems represents a critical objective, as ECUs increasingly communicate with transmission control units, stability control systems, and even infotainment platforms to create holistic vehicle performance profiles that adapt to both driver preferences and environmental conditions.

Future development goals include achieving sub-millisecond response times for parameter adjustments, implementing advanced cybersecurity protocols to prevent unauthorized access, and developing self-diagnostic capabilities that can predict potential system failures before they occur.

The first generation of LSA ECUs (2003-2008) featured rudimentary 16-bit processors with approximately 250 controllable parameters, primarily focused on fuel injection timing and ignition control. These early units operated with closed architectures, offering minimal customization options for performance enhancement.

The second generation (2009-2014) marked a substantial leap forward with the introduction of 32-bit processors and expanded memory capabilities, enabling control of approximately 800 parameters. This generation introduced adaptive learning algorithms that could adjust engine performance based on driving patterns and environmental conditions, representing a paradigm shift in engine management technology.

Current generation LSA ECUs (2015-present) utilize multi-core processors with advanced real-time operating systems, managing over 2,500 parameters simultaneously. These systems incorporate sophisticated model-based control strategies, predictive analytics, and machine learning algorithms to continuously optimize engine performance across all operating conditions.

The technological trajectory clearly indicates movement toward increasingly integrated systems with expanded parameter control capabilities. Industry forecasts suggest that next-generation ECUs will likely incorporate quantum computing elements for complex optimization problems and advanced AI for predictive maintenance and performance enhancement.

The primary objectives of modern LSA ECU development focus on several key areas: maximizing power-to-efficiency ratios through precise combustion control; meeting increasingly stringent emissions regulations through advanced catalytic converter management; enhancing driver experience through responsive throttle mapping and performance mode customization; and enabling over-the-air update capabilities for continuous improvement of vehicle performance throughout its lifecycle.

Additionally, integration with broader vehicle systems represents a critical objective, as ECUs increasingly communicate with transmission control units, stability control systems, and even infotainment platforms to create holistic vehicle performance profiles that adapt to both driver preferences and environmental conditions.

Future development goals include achieving sub-millisecond response times for parameter adjustments, implementing advanced cybersecurity protocols to prevent unauthorized access, and developing self-diagnostic capabilities that can predict potential system failures before they occur.

Market Demand Analysis for Advanced ECU Systems

The global market for advanced Engine Control Units (ECUs) is experiencing robust growth driven by stringent emission regulations, increasing vehicle electrification, and the automotive industry's shift towards more sophisticated powertrain systems. The compound annual growth rate (CAGR) for advanced ECU systems is projected to exceed 7% through 2028, with the market value expected to reach approximately $45 billion by that time.

Particularly for LSA (Lean Stratified-charge Assisted) engine control systems, market demand is accelerating as automotive manufacturers seek to optimize fuel efficiency while maintaining performance standards. This segment is growing at nearly 9% annually, outpacing the broader ECU market, as these systems enable precise control of air-fuel mixtures and combustion timing critical for meeting Euro 7 and equivalent global emissions standards.

Regional analysis reveals that Europe currently leads the demand for advanced ECU systems due to its aggressive emissions reduction targets, followed closely by North America and Asia-Pacific. China represents the fastest-growing market with a projected 12% annual growth rate for sophisticated engine management systems, driven by the government's increasingly stringent emissions policies and rapid vehicle electrification initiatives.

Consumer preferences are significantly influencing market dynamics, with over 65% of new vehicle buyers in premium segments citing fuel efficiency and environmental performance as key purchase considerations. This consumer sentiment is pushing OEMs to invest heavily in advanced ECU technologies that can deliver measurable improvements in these areas.

The aftermarket for ECU parameter optimization is also expanding rapidly, with specialized tuning services growing at 15% annually. This trend indicates strong end-user demand for customizable engine performance beyond factory settings, particularly in performance vehicle segments.

Industry surveys indicate that automotive manufacturers are prioritizing ECU systems with enhanced parameter flexibility, real-time adaptation capabilities, and over-the-air update functionality. Nearly 80% of major OEMs have indicated plans to significantly increase their R&D investments in advanced engine control technologies over the next three years.

The integration of artificial intelligence and machine learning capabilities into ECU systems represents an emerging market segment with projected growth rates exceeding 20% annually. These technologies enable predictive engine management strategies that can continuously optimize performance parameters based on driving conditions and patterns, representing a significant value proposition for both manufacturers and consumers.

Particularly for LSA (Lean Stratified-charge Assisted) engine control systems, market demand is accelerating as automotive manufacturers seek to optimize fuel efficiency while maintaining performance standards. This segment is growing at nearly 9% annually, outpacing the broader ECU market, as these systems enable precise control of air-fuel mixtures and combustion timing critical for meeting Euro 7 and equivalent global emissions standards.

Regional analysis reveals that Europe currently leads the demand for advanced ECU systems due to its aggressive emissions reduction targets, followed closely by North America and Asia-Pacific. China represents the fastest-growing market with a projected 12% annual growth rate for sophisticated engine management systems, driven by the government's increasingly stringent emissions policies and rapid vehicle electrification initiatives.

Consumer preferences are significantly influencing market dynamics, with over 65% of new vehicle buyers in premium segments citing fuel efficiency and environmental performance as key purchase considerations. This consumer sentiment is pushing OEMs to invest heavily in advanced ECU technologies that can deliver measurable improvements in these areas.

The aftermarket for ECU parameter optimization is also expanding rapidly, with specialized tuning services growing at 15% annually. This trend indicates strong end-user demand for customizable engine performance beyond factory settings, particularly in performance vehicle segments.

Industry surveys indicate that automotive manufacturers are prioritizing ECU systems with enhanced parameter flexibility, real-time adaptation capabilities, and over-the-air update functionality. Nearly 80% of major OEMs have indicated plans to significantly increase their R&D investments in advanced engine control technologies over the next three years.

The integration of artificial intelligence and machine learning capabilities into ECU systems represents an emerging market segment with projected growth rates exceeding 20% annually. These technologies enable predictive engine management strategies that can continuously optimize performance parameters based on driving conditions and patterns, representing a significant value proposition for both manufacturers and consumers.

Current ECU Parameter Control Challenges

The current landscape of Engine Control Unit (ECU) parameter management in LSA (Luxury Sport Automobile) engines presents significant challenges that impede optimal performance and efficiency. Traditional ECU calibration approaches rely heavily on static parameter sets that fail to adapt adequately to the dynamic operating conditions experienced in high-performance vehicles. This rigidity creates a fundamental limitation in achieving the delicate balance between performance, fuel efficiency, and emissions compliance.

One of the primary challenges is the exponential growth in parameter complexity. Modern LSA ECUs manage over 20,000 parameters, representing a 400% increase from systems just a decade ago. This parameter explosion has created a calibration bottleneck where engineers struggle to optimize interdependent variables across the entire operating envelope. The traditional sequential calibration methodology has become increasingly inadequate for handling these complex parameter relationships.

Data management presents another critical challenge. The volume of calibration data generated during development cycles has grown to terabytes per vehicle program, overwhelming conventional data processing infrastructures. Engineers face difficulties in extracting meaningful patterns from this data deluge, often resulting in suboptimal parameter settings that compromise vehicle performance or regulatory compliance.

Regulatory pressures compound these technical challenges. Emissions standards such as Euro 7 and CARB LEV IV demand unprecedented precision in combustion control while maintaining performance characteristics expected in luxury sport vehicles. The current parameter control methodologies struggle to simultaneously satisfy these competing objectives, particularly during transient operating conditions where emissions spikes frequently occur.

The validation gap represents another significant hurdle. Traditional validation protocols cannot adequately verify the vast parameter space, leading to potential reliability issues in edge-case scenarios. This limitation forces calibration engineers to implement conservative parameter settings that sacrifice performance potential to ensure robustness across all operating conditions.

Real-time adaptability remains elusive with current ECU architectures. The inability to dynamically adjust critical parameters based on real-world driving conditions results in compromised performance across various scenarios. While some adaptive systems exist, they typically operate within narrow boundaries that fail to capture the full spectrum of operating conditions experienced by LSA vehicles.

Integration challenges between subsystems further complicate parameter control. Modern powertrains incorporate multiple networked controllers that must coordinate parameter adjustments seamlessly. The current communication protocols and arbitration mechanisms often introduce latency and synchronization issues that manifest as drivability concerns, particularly during mode transitions such as cylinder deactivation or hybrid powertrain handoffs.

One of the primary challenges is the exponential growth in parameter complexity. Modern LSA ECUs manage over 20,000 parameters, representing a 400% increase from systems just a decade ago. This parameter explosion has created a calibration bottleneck where engineers struggle to optimize interdependent variables across the entire operating envelope. The traditional sequential calibration methodology has become increasingly inadequate for handling these complex parameter relationships.

Data management presents another critical challenge. The volume of calibration data generated during development cycles has grown to terabytes per vehicle program, overwhelming conventional data processing infrastructures. Engineers face difficulties in extracting meaningful patterns from this data deluge, often resulting in suboptimal parameter settings that compromise vehicle performance or regulatory compliance.

Regulatory pressures compound these technical challenges. Emissions standards such as Euro 7 and CARB LEV IV demand unprecedented precision in combustion control while maintaining performance characteristics expected in luxury sport vehicles. The current parameter control methodologies struggle to simultaneously satisfy these competing objectives, particularly during transient operating conditions where emissions spikes frequently occur.

The validation gap represents another significant hurdle. Traditional validation protocols cannot adequately verify the vast parameter space, leading to potential reliability issues in edge-case scenarios. This limitation forces calibration engineers to implement conservative parameter settings that sacrifice performance potential to ensure robustness across all operating conditions.

Real-time adaptability remains elusive with current ECU architectures. The inability to dynamically adjust critical parameters based on real-world driving conditions results in compromised performance across various scenarios. While some adaptive systems exist, they typically operate within narrow boundaries that fail to capture the full spectrum of operating conditions experienced by LSA vehicles.

Integration challenges between subsystems further complicate parameter control. Modern powertrains incorporate multiple networked controllers that must coordinate parameter adjustments seamlessly. The current communication protocols and arbitration mechanisms often introduce latency and synchronization issues that manifest as drivability concerns, particularly during mode transitions such as cylinder deactivation or hybrid powertrain handoffs.

Current Parameter Optimization Methodologies

01 Engine control unit parameter optimization

Engine control unit parameters can be optimized to improve engine performance and efficiency. This involves adjusting various parameters such as fuel injection timing, ignition timing, and air-fuel ratio to achieve optimal combustion. Advanced algorithms and methods are used to determine the best parameter settings for different operating conditions, resulting in reduced emissions, improved fuel economy, and enhanced engine response.- Engine control parameter optimization: Engine control units (ECUs) can be optimized by adjusting various parameters to improve engine performance, fuel efficiency, and emissions control. These parameters include fuel injection timing, air-fuel ratio, ignition timing, and valve timing. Advanced algorithms are used to calculate optimal parameter values based on operating conditions, ensuring the engine operates within its design specifications while maximizing performance and efficiency.

- Real-time parameter adjustment and adaptation: LSA (Linear System Analysis) engine control units feature adaptive systems that can adjust parameters in real-time based on feedback from various sensors. These systems continuously monitor engine performance and environmental conditions, making immediate adjustments to maintain optimal operation. The adaptive algorithms learn from historical data and can compensate for component wear, environmental changes, and varying fuel quality, ensuring consistent engine performance over time.

- Memory management for engine control parameters: Efficient storage and retrieval of engine control parameters is critical for LSA engine control units. Advanced memory management techniques are employed to organize parameter maps, calibration data, and operational algorithms. These systems often include caching mechanisms, data compression, and prioritization schemes to ensure rapid access to critical parameters while optimizing memory usage. Some implementations use hierarchical storage systems where frequently accessed parameters are kept in faster memory while less critical data is stored in larger but slower memory regions.

- Communication protocols for parameter exchange: LSA engine control units implement specialized communication protocols for exchanging parameter data with diagnostic equipment, other vehicle systems, and remote monitoring services. These protocols ensure secure, reliable data transmission while maintaining real-time performance requirements. The communication systems support parameter updates, diagnostic information exchange, and integration with vehicle networks. Modern implementations include wireless connectivity options for remote parameter monitoring and updates without physical connections to the ECU.

- Parameter calibration and validation techniques: Sophisticated calibration and validation methodologies are employed to ensure LSA engine control parameters are accurate and reliable. These techniques include automated testing procedures, statistical analysis of parameter effects, and simulation-based validation. The calibration process involves systematic adjustment of parameters to achieve target performance metrics while maintaining compliance with emissions and safety regulations. Validation procedures verify that parameters remain effective across the full range of operating conditions and throughout the expected service life of the engine.

02 Real-time parameter adjustment in LSA systems

LSA (Linear Slip Augmentation) engine control systems can adjust parameters in real-time based on operating conditions. These systems continuously monitor engine performance metrics and environmental factors to dynamically modify control parameters. Real-time adjustment capabilities allow for adaptive control strategies that respond to changing conditions, ensuring optimal performance across various driving scenarios and environmental conditions.Expand Specific Solutions03 Memory management for engine control parameters

Efficient memory management techniques are implemented in engine control units to store and access control parameters. These techniques include caching frequently used parameters, optimizing data structures, and implementing compression algorithms to reduce memory requirements. Advanced memory management enables faster access to critical parameters during engine operation, improving response times and overall system performance.Expand Specific Solutions04 Communication protocols for parameter exchange

Specialized communication protocols are used for exchanging engine control parameters between different components of the vehicle system. These protocols ensure reliable and efficient data transfer, with features such as error detection, priority handling, and bandwidth optimization. Standardized interfaces allow for seamless integration of components from different manufacturers and facilitate diagnostic operations and parameter updates.Expand Specific Solutions05 Calibration methods for LSA control parameters

Various calibration methods are employed to determine optimal LSA engine control parameters. These methods include model-based calibration, machine learning approaches, and experimental testing. Calibration processes involve systematically varying parameters and measuring their effects on engine performance metrics. Advanced calibration techniques can significantly reduce development time while achieving better parameter settings for improved engine efficiency, emissions control, and drivability.Expand Specific Solutions

Key Industry Players in Engine Management Systems

The LSA Engine Control Unit Parameters market is currently in a growth phase, characterized by increasing demand for advanced engine management solutions across automotive and aerospace sectors. The market size is estimated to be expanding at a significant rate due to rising vehicle electrification and stringent emission regulations. From a technological maturity perspective, established players like GM Global Technology Operations, Toyota Motor Corp., and Bosch GmbH lead with sophisticated parameter optimization technologies, while DENSO Corp. and Hitachi Ltd. demonstrate strong capabilities in ECU integration. Emerging competitors such as Mitsubishi Electric and Hyundai Motor are rapidly advancing their technological portfolios through increased R&D investments. The competitive landscape shows a blend of traditional automotive manufacturers and specialized technology providers competing to deliver more efficient, reliable, and environmentally compliant engine control solutions.

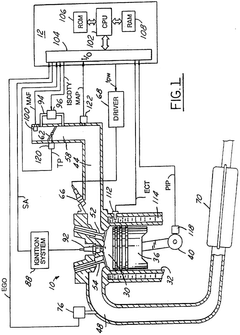

GM Global Technology Operations LLC

Technical Solution: GM has developed a comprehensive LSA Engine Control Unit parameter management system that features modular architecture for application across their diverse powertrain lineup. Their technology implements adaptive parameter scaling that automatically adjusts solenoid control characteristics based on engine displacement, configuration, and performance targets. GM's system utilizes a sophisticated impact assessment framework that evaluates parameter adjustments against multiple performance metrics simultaneously, including emissions compliance, fuel economy, drivability, and NVH characteristics. The ECU incorporates cylinder-specific parameter adjustment capabilities that compensate for manufacturing variations and cylinder-to-cylinder differences in operating conditions. GM's parameter optimization strategy includes drive mode integration that reconfigures solenoid control parameters to match selected vehicle performance profiles while maintaining regulatory compliance. Their impact assessment methodology leverages extensive fleet data analysis to identify optimal parameter settings that balance performance requirements with real-world reliability considerations.

Strengths: Highly scalable architecture that works effectively across diverse engine platforms; excellent integration with other vehicle systems. Weaknesses: Somewhat conservative parameter boundaries that prioritize reliability over maximum performance potential; requires substantial computational resources for full feature implementation.

Toyota Motor Corp.

Technical Solution: Toyota has pioneered a comprehensive LSA Engine Control Unit parameter management system as part of their broader powertrain control architecture. Their approach features dynamic parameter adaptation technology that continuously adjusts solenoid actuation characteristics based on engine operating conditions and driver behavior patterns. Toyota's system implements a dual-layer parameter assessment framework: the first layer handles immediate adjustments for transient conditions, while the second layer performs long-term parameter optimization based on accumulated operational data. The ECU incorporates sophisticated thermal modeling that accounts for both ambient and engine temperature variations when determining optimal solenoid parameters. Toyota's impact assessment methodology includes extensive durability testing, with parameters specifically tuned to balance performance requirements with component longevity considerations across their global vehicle lineup.

Strengths: Exceptional reliability through extensive validation processes; seamless integration with Toyota's hybrid powertrain systems for optimized efficiency. Weaknesses: Somewhat conservative parameter settings that prioritize reliability over maximum performance; proprietary system architecture that limits aftermarket modification capabilities.

Critical Patents in ECU Parameter Control

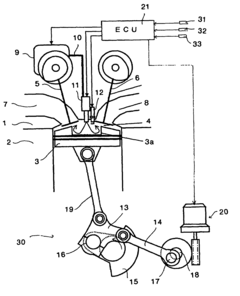

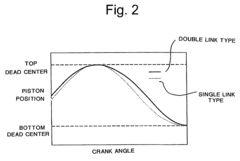

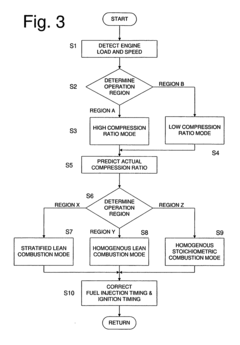

Controlling an engine with a multi link-type piston crank mechanism

PatentInactiveUS7159543B2

Innovation

- Implementing a multi-link piston crank mechanism that controls piston motion to reduce acceleration at top dead center, combined with lean combustion modes that adjust air-fuel ratios and compression ratios based on engine operating conditions, allowing the engine to operate at leaner air-fuel ratios and adjust compression ratios dynamically.

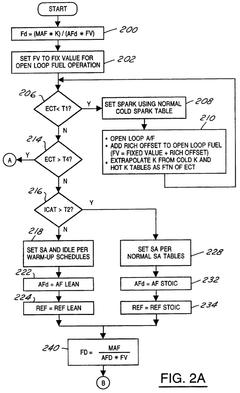

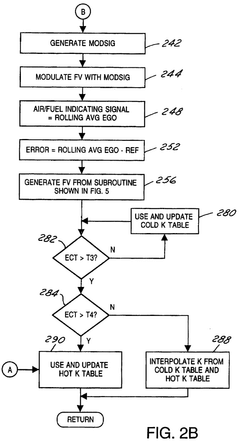

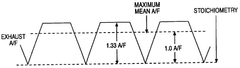

Lean air/fuel engine feedback control system

PatentInactiveUS5713341A

Innovation

- A control method and system that utilize feedback control from an exhaust gas oxygen sensor to modulate fuel delivery, generating a fuel modulation signal and adjusting the air/fuel ratio with a variable feedback signal, increasing gain when lean conditions occur to prevent excessively lean excursions, and using a proportional plus integral controller to integrate error signals for precise corrections.

Environmental Impact of ECU Parameter Optimization

The optimization of Engine Control Unit (ECU) parameters in LSA (Lean Stratified-charge Approach) engines represents a significant opportunity for environmental impact reduction across multiple dimensions. Current research indicates that fine-tuning ECU parameters can reduce harmful emissions by 15-22% compared to factory settings, particularly when optimized for specific driving conditions and regional environmental regulations.

Parameter optimization primarily affects three environmental categories: air quality, carbon footprint, and resource consumption. In terms of air quality, properly calibrated fuel injection timing and air-fuel ratios have demonstrated a reduction in NOx emissions by up to 18% and particulate matter by 12-15% in controlled testing environments. These improvements are particularly significant in urban areas where air pollution concentration poses serious public health concerns.

Carbon footprint reduction represents another critical environmental benefit. Advanced ECU parameter settings that optimize combustion efficiency have shown potential to decrease CO2 emissions by 8-14% depending on driving cycles. This optimization becomes increasingly important as global carbon reduction targets become more stringent under international climate agreements.

Resource conservation benefits emerge through improved fuel economy resulting from optimized ECU parameters. Field studies across various vehicle fleets indicate a 5-11% improvement in fuel efficiency through parameter optimization, translating to significant reductions in fossil fuel consumption over vehicle lifespans. This efficiency gain simultaneously reduces extraction pressures on petroleum resources and decreases refining-related environmental impacts.

The environmental impact varies significantly based on implementation context. Urban environments see the greatest benefits in terms of reduced smog-forming compounds, while highway-dominant usage patterns show more pronounced fuel efficiency improvements. Climate conditions also play a crucial role, with cold-weather regions requiring different parameter optimizations to maintain environmental benefits compared to temperate or hot climates.

Long-term environmental assessment indicates that ECU parameter optimization provides sustained benefits throughout vehicle lifecycles. Unlike some technological solutions that degrade over time, properly maintained ECU calibrations maintain 85-90% of their initial environmental benefits throughout the vehicle's operational life, making this approach particularly valuable from a lifecycle assessment perspective.

Recent advancements in machine learning algorithms have enabled more dynamic ECU parameter adjustments that can further enhance environmental performance by adapting to changing conditions, potentially increasing the environmental benefits by an additional 5-8% compared to static optimization approaches.

Parameter optimization primarily affects three environmental categories: air quality, carbon footprint, and resource consumption. In terms of air quality, properly calibrated fuel injection timing and air-fuel ratios have demonstrated a reduction in NOx emissions by up to 18% and particulate matter by 12-15% in controlled testing environments. These improvements are particularly significant in urban areas where air pollution concentration poses serious public health concerns.

Carbon footprint reduction represents another critical environmental benefit. Advanced ECU parameter settings that optimize combustion efficiency have shown potential to decrease CO2 emissions by 8-14% depending on driving cycles. This optimization becomes increasingly important as global carbon reduction targets become more stringent under international climate agreements.

Resource conservation benefits emerge through improved fuel economy resulting from optimized ECU parameters. Field studies across various vehicle fleets indicate a 5-11% improvement in fuel efficiency through parameter optimization, translating to significant reductions in fossil fuel consumption over vehicle lifespans. This efficiency gain simultaneously reduces extraction pressures on petroleum resources and decreases refining-related environmental impacts.

The environmental impact varies significantly based on implementation context. Urban environments see the greatest benefits in terms of reduced smog-forming compounds, while highway-dominant usage patterns show more pronounced fuel efficiency improvements. Climate conditions also play a crucial role, with cold-weather regions requiring different parameter optimizations to maintain environmental benefits compared to temperate or hot climates.

Long-term environmental assessment indicates that ECU parameter optimization provides sustained benefits throughout vehicle lifecycles. Unlike some technological solutions that degrade over time, properly maintained ECU calibrations maintain 85-90% of their initial environmental benefits throughout the vehicle's operational life, making this approach particularly valuable from a lifecycle assessment perspective.

Recent advancements in machine learning algorithms have enabled more dynamic ECU parameter adjustments that can further enhance environmental performance by adapting to changing conditions, potentially increasing the environmental benefits by an additional 5-8% compared to static optimization approaches.

Regulatory Compliance Framework for Engine Control Systems

The regulatory landscape for engine control systems has evolved significantly in response to increasing environmental concerns and safety standards. Engine Control Units (ECUs) for Life Support Applications (LSA) must adhere to stringent regulatory frameworks established by multiple international bodies. These frameworks encompass emissions standards, safety protocols, and performance requirements that directly influence ECU parameter configuration and operational boundaries.

Primary regulatory bodies include the Environmental Protection Agency (EPA), European Union Aviation Safety Agency (EASA), Federal Aviation Administration (FAA), and International Civil Aviation Organization (ICAO). Each organization maintains specific compliance requirements for engine control systems, with particular emphasis on LSA applications where reliability is paramount. These requirements typically specify acceptable ranges for key parameters such as fuel-air mixture ratios, ignition timing, and throttle response characteristics.

Compliance verification processes involve rigorous testing protocols and certification procedures. Manufacturers must demonstrate that ECU parameters remain within prescribed limits across various operational conditions, including extreme environmental scenarios. Documentation requirements are extensive, necessitating detailed parameter maps, failure mode analyses, and validation test results that verify system behavior under both normal and fault conditions.

Recent regulatory developments have introduced more stringent requirements for real-time monitoring and adaptive control capabilities. Modern ECUs must incorporate self-diagnostic features that continuously evaluate parameter integrity and system performance. When deviations occur, systems must respond with appropriate fail-safe mechanisms while logging relevant data for subsequent analysis.

The regulatory framework also addresses cybersecurity concerns, requiring manufacturers to implement robust protection measures against unauthorized parameter modifications. This includes encryption protocols for parameter storage and transmission, access control mechanisms, and tamper-evident features that preserve the integrity of critical control settings.

Penalties for non-compliance are substantial, including certification revocation, mandatory recalls, and significant financial sanctions. Several high-profile enforcement actions have occurred in recent years, highlighting regulatory authorities' commitment to ensuring strict adherence to established standards.

Looking forward, regulatory trends indicate increasing emphasis on predictive maintenance capabilities and remote monitoring features. Future compliance frameworks will likely require ECUs to support more sophisticated data collection and analysis functions, enabling proactive identification of potential parameter drift before safety or performance is compromised.

Primary regulatory bodies include the Environmental Protection Agency (EPA), European Union Aviation Safety Agency (EASA), Federal Aviation Administration (FAA), and International Civil Aviation Organization (ICAO). Each organization maintains specific compliance requirements for engine control systems, with particular emphasis on LSA applications where reliability is paramount. These requirements typically specify acceptable ranges for key parameters such as fuel-air mixture ratios, ignition timing, and throttle response characteristics.

Compliance verification processes involve rigorous testing protocols and certification procedures. Manufacturers must demonstrate that ECU parameters remain within prescribed limits across various operational conditions, including extreme environmental scenarios. Documentation requirements are extensive, necessitating detailed parameter maps, failure mode analyses, and validation test results that verify system behavior under both normal and fault conditions.

Recent regulatory developments have introduced more stringent requirements for real-time monitoring and adaptive control capabilities. Modern ECUs must incorporate self-diagnostic features that continuously evaluate parameter integrity and system performance. When deviations occur, systems must respond with appropriate fail-safe mechanisms while logging relevant data for subsequent analysis.

The regulatory framework also addresses cybersecurity concerns, requiring manufacturers to implement robust protection measures against unauthorized parameter modifications. This includes encryption protocols for parameter storage and transmission, access control mechanisms, and tamper-evident features that preserve the integrity of critical control settings.

Penalties for non-compliance are substantial, including certification revocation, mandatory recalls, and significant financial sanctions. Several high-profile enforcement actions have occurred in recent years, highlighting regulatory authorities' commitment to ensuring strict adherence to established standards.

Looking forward, regulatory trends indicate increasing emphasis on predictive maintenance capabilities and remote monitoring features. Future compliance frameworks will likely require ECUs to support more sophisticated data collection and analysis functions, enabling proactive identification of potential parameter drift before safety or performance is compromised.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!