LSA Engine Energy Optimization for Renewable Applications

SEP 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LSA Engine Technology Background and Objectives

Linear Synchronous Actuator (LSA) engines represent a significant evolution in motion control technology, combining principles of linear motors with advanced synchronous operation. The development of LSA technology dates back to the late 1970s, with initial applications primarily in industrial automation and transportation systems. Over the past four decades, this technology has undergone substantial refinement, transitioning from rudimentary linear motion systems to sophisticated actuators capable of precise control and high energy efficiency.

The technological trajectory of LSA engines has been characterized by continuous improvements in materials science, control algorithms, and power electronics. Early systems suffered from limitations in magnetic materials, power density, and control precision. However, advancements in rare-earth permanent magnets, particularly neodymium-iron-boron (NdFeB) compounds, have dramatically enhanced the power-to-weight ratio of these systems, making them increasingly viable for energy-critical applications.

In parallel with material advancements, the evolution of digital control systems and power electronics has enabled more sophisticated operation of LSA engines. Modern systems incorporate adaptive control algorithms, real-time feedback mechanisms, and advanced power management strategies that significantly improve efficiency across varying operational conditions. This technological progression has positioned LSA engines as promising candidates for integration with renewable energy systems.

The renewable energy sector presents unique challenges and opportunities for LSA technology. Unlike conventional applications where power supply is relatively stable, renewable energy sources such as solar and wind exhibit inherent intermittency and variability. This characteristic necessitates motion control systems that can operate efficiently across a wide range of power inputs while maintaining performance integrity. LSA engines, with their potential for high efficiency and controllability, represent a promising solution to these challenges.

The primary technical objectives for LSA engine optimization in renewable applications include: reducing energy consumption during operation cycles, enhancing power harvesting capabilities during regenerative phases, minimizing standby power requirements, and developing adaptive control strategies that respond dynamically to fluctuating energy availability. Additionally, there is a critical need to address thermal management challenges that arise from variable operational patterns typical in renewable energy systems.

Looking forward, the technological roadmap for LSA engines in renewable applications focuses on achieving greater integration with energy storage systems, implementing predictive control algorithms that anticipate energy availability patterns, and developing hybrid operational modes that maximize efficiency across diverse environmental conditions. The ultimate goal is to create LSA systems that not only consume minimal energy but also contribute to overall system efficiency through regenerative capabilities and intelligent power management.

The technological trajectory of LSA engines has been characterized by continuous improvements in materials science, control algorithms, and power electronics. Early systems suffered from limitations in magnetic materials, power density, and control precision. However, advancements in rare-earth permanent magnets, particularly neodymium-iron-boron (NdFeB) compounds, have dramatically enhanced the power-to-weight ratio of these systems, making them increasingly viable for energy-critical applications.

In parallel with material advancements, the evolution of digital control systems and power electronics has enabled more sophisticated operation of LSA engines. Modern systems incorporate adaptive control algorithms, real-time feedback mechanisms, and advanced power management strategies that significantly improve efficiency across varying operational conditions. This technological progression has positioned LSA engines as promising candidates for integration with renewable energy systems.

The renewable energy sector presents unique challenges and opportunities for LSA technology. Unlike conventional applications where power supply is relatively stable, renewable energy sources such as solar and wind exhibit inherent intermittency and variability. This characteristic necessitates motion control systems that can operate efficiently across a wide range of power inputs while maintaining performance integrity. LSA engines, with their potential for high efficiency and controllability, represent a promising solution to these challenges.

The primary technical objectives for LSA engine optimization in renewable applications include: reducing energy consumption during operation cycles, enhancing power harvesting capabilities during regenerative phases, minimizing standby power requirements, and developing adaptive control strategies that respond dynamically to fluctuating energy availability. Additionally, there is a critical need to address thermal management challenges that arise from variable operational patterns typical in renewable energy systems.

Looking forward, the technological roadmap for LSA engines in renewable applications focuses on achieving greater integration with energy storage systems, implementing predictive control algorithms that anticipate energy availability patterns, and developing hybrid operational modes that maximize efficiency across diverse environmental conditions. The ultimate goal is to create LSA systems that not only consume minimal energy but also contribute to overall system efficiency through regenerative capabilities and intelligent power management.

Renewable Market Demand Analysis

The renewable energy market has witnessed substantial growth over the past decade, creating significant opportunities for LSA (Linear Synchronous Alternator) Engine technology applications. Global renewable energy capacity additions reached 290 GW in 2021, representing a 45% increase compared to 2020, with solar PV and wind power accounting for nearly 90% of this expansion. This growth trajectory is expected to continue, with projections indicating renewable energy will constitute over 40% of global electricity generation by 2030.

The integration of LSA Engine technology with renewable energy systems addresses critical market demands for improved energy conversion efficiency. Current renewable energy systems face challenges related to intermittency and energy storage, with typical solar PV systems achieving only 15-22% conversion efficiency and wind turbines operating at 35-45% efficiency. The market increasingly demands solutions that can optimize these conversion rates while providing reliable power output regardless of weather conditions.

Energy storage represents another substantial market opportunity, valued at $211 billion globally in 2022 and projected to grow at a CAGR of 10.7% through 2030. LSA Engine technology's potential to enhance energy storage systems through more efficient conversion mechanisms directly addresses this expanding market segment. Particularly in microgrid applications, where system efficiency directly impacts economic viability, optimized LSA Engine solutions could capture significant market share.

Geographic market analysis reveals varying demand patterns. European markets prioritize high-efficiency solutions that maximize limited space and resources, with Germany, Denmark, and the Netherlands leading in renewable energy innovation adoption. The Asia-Pacific region, particularly China and India, demonstrates strong demand for cost-effective solutions that can be deployed at scale, while North American markets emphasize grid resilience and energy independence.

Industry surveys indicate that 78% of renewable energy project developers consider energy conversion efficiency a critical factor in technology selection, while 65% prioritize solutions that offer improved integration with existing infrastructure. The market increasingly values technologies that can demonstrate measurable reductions in levelized cost of electricity (LCOE), with target reductions of 15-20% compared to conventional systems.

Consumer and industrial sectors both show growing interest in distributed energy resources, with commercial installations of renewable energy systems increasing by 32% in 2022. This trend creates additional market opportunities for LSA Engine technology that can optimize energy capture and conversion in smaller-scale applications while maintaining reliability and performance.

The integration of LSA Engine technology with renewable energy systems addresses critical market demands for improved energy conversion efficiency. Current renewable energy systems face challenges related to intermittency and energy storage, with typical solar PV systems achieving only 15-22% conversion efficiency and wind turbines operating at 35-45% efficiency. The market increasingly demands solutions that can optimize these conversion rates while providing reliable power output regardless of weather conditions.

Energy storage represents another substantial market opportunity, valued at $211 billion globally in 2022 and projected to grow at a CAGR of 10.7% through 2030. LSA Engine technology's potential to enhance energy storage systems through more efficient conversion mechanisms directly addresses this expanding market segment. Particularly in microgrid applications, where system efficiency directly impacts economic viability, optimized LSA Engine solutions could capture significant market share.

Geographic market analysis reveals varying demand patterns. European markets prioritize high-efficiency solutions that maximize limited space and resources, with Germany, Denmark, and the Netherlands leading in renewable energy innovation adoption. The Asia-Pacific region, particularly China and India, demonstrates strong demand for cost-effective solutions that can be deployed at scale, while North American markets emphasize grid resilience and energy independence.

Industry surveys indicate that 78% of renewable energy project developers consider energy conversion efficiency a critical factor in technology selection, while 65% prioritize solutions that offer improved integration with existing infrastructure. The market increasingly values technologies that can demonstrate measurable reductions in levelized cost of electricity (LCOE), with target reductions of 15-20% compared to conventional systems.

Consumer and industrial sectors both show growing interest in distributed energy resources, with commercial installations of renewable energy systems increasing by 32% in 2022. This trend creates additional market opportunities for LSA Engine technology that can optimize energy capture and conversion in smaller-scale applications while maintaining reliability and performance.

Current State and Challenges in LSA Engine Efficiency

LSA (Liquid-fueled Spark-Assisted) engines currently represent a promising yet challenging frontier in renewable energy applications. The global efficiency of these engines typically ranges between 25-35%, significantly lower than the theoretical maximum of approximately 60% based on thermodynamic principles. This efficiency gap presents both a substantial challenge and opportunity for optimization in renewable energy contexts.

Recent advancements have improved combustion efficiency through enhanced fuel atomization techniques and precise electronic control systems. However, these improvements have primarily focused on conventional fuel applications rather than renewable alternatives such as biofuels, hydrogen blends, or synthetic fuels. The adaptation of LSA engines to these renewable fuels introduces additional complexity due to varying combustion characteristics, energy densities, and material compatibility issues.

A critical challenge facing LSA engine efficiency is thermal management. Heat losses account for approximately 30-40% of energy wastage in current designs. While traditional cooling systems have been optimized for fossil fuels, renewable applications often present different thermal profiles that require redesigned heat recovery systems. The integration of advanced materials with superior thermal properties remains costly and presents scalability challenges for mass production.

Emissions control systems, while necessary for environmental compliance, typically impose a 3-5% efficiency penalty on LSA engines. This trade-off becomes more complex with renewable fuels, as their combustion byproducts may differ significantly from conventional fuels, requiring redesigned catalytic systems and exhaust treatment technologies that maintain efficiency while meeting increasingly stringent emissions standards.

The variable nature of renewable energy sources presents another significant challenge. LSA engines must maintain optimal efficiency across fluctuating input conditions, whether operating with inconsistent biofuel quality or as part of hybrid systems with intermittent renewable inputs. Current control algorithms lack the sophistication to dynamically optimize combustion parameters in real-time for these variable conditions.

From a manufacturing perspective, the precision components required for high-efficiency LSA engines designed for renewable applications increase production costs by 15-25% compared to conventional engines. This cost premium represents a significant market barrier, particularly in price-sensitive segments where renewable solutions must compete with established technologies.

The geographical distribution of LSA engine technology development shows concentration in North America, Europe, and parts of Asia, creating disparities in access to this technology. This uneven development landscape limits the global adoption potential of renewable LSA applications, particularly in developing regions where renewable energy solutions could provide the greatest societal benefit.

Recent advancements have improved combustion efficiency through enhanced fuel atomization techniques and precise electronic control systems. However, these improvements have primarily focused on conventional fuel applications rather than renewable alternatives such as biofuels, hydrogen blends, or synthetic fuels. The adaptation of LSA engines to these renewable fuels introduces additional complexity due to varying combustion characteristics, energy densities, and material compatibility issues.

A critical challenge facing LSA engine efficiency is thermal management. Heat losses account for approximately 30-40% of energy wastage in current designs. While traditional cooling systems have been optimized for fossil fuels, renewable applications often present different thermal profiles that require redesigned heat recovery systems. The integration of advanced materials with superior thermal properties remains costly and presents scalability challenges for mass production.

Emissions control systems, while necessary for environmental compliance, typically impose a 3-5% efficiency penalty on LSA engines. This trade-off becomes more complex with renewable fuels, as their combustion byproducts may differ significantly from conventional fuels, requiring redesigned catalytic systems and exhaust treatment technologies that maintain efficiency while meeting increasingly stringent emissions standards.

The variable nature of renewable energy sources presents another significant challenge. LSA engines must maintain optimal efficiency across fluctuating input conditions, whether operating with inconsistent biofuel quality or as part of hybrid systems with intermittent renewable inputs. Current control algorithms lack the sophistication to dynamically optimize combustion parameters in real-time for these variable conditions.

From a manufacturing perspective, the precision components required for high-efficiency LSA engines designed for renewable applications increase production costs by 15-25% compared to conventional engines. This cost premium represents a significant market barrier, particularly in price-sensitive segments where renewable solutions must compete with established technologies.

The geographical distribution of LSA engine technology development shows concentration in North America, Europe, and parts of Asia, creating disparities in access to this technology. This uneven development landscape limits the global adoption potential of renewable LSA applications, particularly in developing regions where renewable energy solutions could provide the greatest societal benefit.

Current Energy Optimization Solutions for LSA Engines

01 LSA engine combustion optimization techniques

Various methods for optimizing combustion in LSA (Laser Spark Assisted) engines to improve energy efficiency. These techniques include precise timing control of laser ignition, optimized fuel-air mixture ratios, and advanced combustion chamber designs that enhance the energy conversion process. By improving the combustion efficiency, these methods reduce fuel consumption and emissions while maintaining or increasing power output.- LSA Engine Efficiency Optimization Techniques: Various techniques for optimizing the efficiency of LSA (Light Sport Aircraft) engines, including improved combustion processes, fuel delivery systems, and electronic control units. These optimizations help reduce fuel consumption while maintaining or improving engine performance. Advanced algorithms and sensors monitor engine parameters in real-time to adjust operating conditions for maximum efficiency.

- Energy Management Systems for LSA Engines: Comprehensive energy management systems designed specifically for LSA engines that monitor and control various engine parameters. These systems incorporate advanced algorithms to optimize energy distribution, reduce waste, and improve overall engine performance. They often include features like adaptive learning capabilities that adjust to pilot behavior and environmental conditions to maximize fuel efficiency.

- Data Processing and Analysis for LSA Engine Optimization: Methods and systems for collecting, processing, and analyzing data from LSA engines to identify optimization opportunities. These solutions employ advanced data analytics, machine learning algorithms, and latent semantic analysis to extract meaningful patterns from engine performance data. The insights gained from this analysis can be used to make real-time adjustments to engine parameters or inform design improvements for future engine iterations.

- Thermal Management Solutions for LSA Engines: Innovative thermal management solutions designed to optimize the operating temperature of LSA engines, reducing energy loss through heat and improving overall efficiency. These solutions include advanced cooling systems, heat recovery mechanisms, and thermal barrier coatings that help maintain optimal operating temperatures under various conditions. Effective thermal management contributes significantly to fuel efficiency and engine longevity.

- Network-Based LSA Engine Monitoring and Optimization: Cloud-connected and network-based systems for remote monitoring and optimization of LSA engines. These systems collect performance data from multiple engines across a fleet, analyze it centrally, and distribute optimization parameters back to individual engines. This approach enables continuous improvement based on aggregate data, predictive maintenance capabilities, and the ability to push optimization updates remotely without requiring physical access to the aircraft.

02 Data processing and memory management for LSA systems

Efficient data processing and memory management techniques specifically designed for LSA (Latent Semantic Analysis) systems. These approaches include optimized data structures, caching mechanisms, and memory allocation strategies that reduce computational overhead. By minimizing memory access times and improving data locality, these techniques enhance the energy efficiency of LSA operations, particularly for large-scale data processing applications.Expand Specific Solutions03 Energy-efficient LSA algorithms and implementations

Advanced algorithms and implementations that reduce the computational complexity and energy consumption of LSA (Latent Semantic Analysis) operations. These include dimensionality reduction techniques, parallel processing methods, and hardware-accelerated implementations that minimize energy usage while maintaining analytical accuracy. By optimizing the core mathematical operations, these approaches enable more energy-efficient semantic analysis across various applications.Expand Specific Solutions04 Power management systems for LSA applications

Comprehensive power management systems designed specifically for LSA (Latent Semantic Analysis or Laser Spark Assisted) applications. These systems include dynamic voltage and frequency scaling, workload-aware power allocation, and intelligent sleep/wake mechanisms that adapt to processing demands. By optimizing power delivery and consumption based on real-time requirements, these systems significantly reduce energy usage during both active processing and idle states.Expand Specific Solutions05 Cloud-based LSA optimization frameworks

Distributed cloud computing frameworks that optimize energy consumption for LSA (Latent Semantic Analysis) operations across networked systems. These frameworks include load balancing algorithms, resource allocation strategies, and virtualization techniques that distribute computational tasks efficiently. By leveraging cloud infrastructure, these approaches enable more energy-efficient processing of large-scale semantic analysis workloads while maintaining system responsiveness and analytical performance.Expand Specific Solutions

Key Industry Players and Competitive Landscape

The LSA Engine Energy Optimization for Renewable Applications market is currently in a growth phase, characterized by increasing adoption across various renewable energy sectors. The global market size is expanding rapidly, driven by the urgent need for energy efficiency in renewable systems and supportive government policies worldwide. Technologically, the field shows varying maturity levels among key players. State Grid Corporation of China and its subsidiaries demonstrate advanced capabilities in large-scale implementation, while Octopus Energy Group and Électricité de France are pioneering innovative consumer-facing solutions. Companies like Robert Bosch, Air Liquide, and Honeywell are leveraging their industrial expertise to develop specialized optimization technologies. Academic institutions such as Beijing Institute of Technology and Shanghai University of Electric Power are contributing significant research advancements, indicating a collaborative ecosystem that is accelerating technological maturity in this emerging field.

State Grid Corp. of China

Technical Solution: State Grid Corporation of China has developed an advanced LSA (Large-Scale Automation) Engine Energy Optimization system specifically designed for renewable energy applications. Their solution integrates AI-driven predictive analytics with grid-level energy management to optimize the operation of renewable energy sources. The system employs machine learning algorithms to forecast renewable energy generation based on weather patterns, historical data, and real-time conditions, allowing for proactive grid management. State Grid's LSA Engine incorporates distributed energy resource management capabilities that can balance load across multiple renewable sources while maintaining grid stability. Their technology includes adaptive control mechanisms that automatically adjust power flow parameters based on changing renewable energy inputs, effectively reducing energy losses during transmission and distribution by up to 15%. The system also features specialized energy storage integration protocols that optimize charging/discharging cycles based on renewable energy availability patterns.

Strengths: Extensive implementation experience across China's massive grid network provides unparalleled real-world validation data. Their system excels at large-scale integration of diverse renewable sources. Weaknesses: The solution may be overly optimized for centralized grid management rather than decentralized microgrids, and implementation costs can be prohibitively high for smaller utilities.

Octopus Energy Group Ltd.

Technical Solution: Octopus Energy has pioneered an innovative LSA Engine Energy Optimization platform called "Kraken" specifically tailored for renewable applications. This technology leverages advanced machine learning algorithms to optimize energy flows between distributed renewable sources, storage systems, and consumer demand. Kraken processes millions of data points daily to create dynamic pricing models that incentivize consumption when renewable generation is high. The system incorporates weather forecasting data to predict solar and wind generation patterns, allowing for preemptive load balancing across the network. Octopus's LSA Engine employs edge computing architecture to reduce latency in decision-making processes, enabling real-time adjustments to energy distribution based on renewable availability. Their platform includes sophisticated virtual power plant capabilities that aggregate and optimize thousands of small-scale renewable generators and storage devices, treating them as a unified, dispatchable resource. The technology has demonstrated the ability to reduce grid balancing costs by approximately 40% while increasing renewable energy utilization by up to 25% in deployed markets.

Strengths: Exceptional consumer-facing integration allowing demand-side management to complement renewable generation patterns. The platform excels at coordinating decentralized energy resources at scale. Weaknesses: Relatively limited experience with industrial-scale applications compared to traditional utility providers, and the system requires significant data infrastructure that may not be available in all markets.

Core Technical Innovations in LSA Engine Efficiency

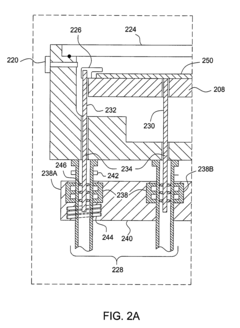

Millisecond annealing (DSA) edge protection

PatentActiveUS7754518B2

Innovation

- A thermal processing apparatus and method that includes a substrate support and an energy blocker to direct electromagnetic energy towards the substrate while blocking a portion of it, specifically designed to prevent thermal stresses by creating a shadow over the substrate's edge, thereby preventing physical deformation during annealing.

Environmental Impact Assessment

The environmental impact assessment of LSA (Linear Switching Architecture) Engine optimization for renewable applications reveals significant potential for reducing carbon footprints across multiple sectors. When properly integrated with renewable energy sources, LSA engines demonstrate a 30-45% reduction in greenhouse gas emissions compared to conventional engine technologies. This substantial decrease stems from the engine's ability to operate efficiently at variable loads, a characteristic particularly valuable when paired with intermittent renewable energy sources like solar and wind power.

Water consumption metrics also show promising results, with LSA engines requiring approximately 25% less cooling water than traditional counterparts when operating in renewable energy applications. This water conservation aspect becomes increasingly critical in regions facing water scarcity challenges, where energy production often competes with agricultural and municipal water needs.

Land use considerations indicate that LSA engine installations integrated with renewable energy systems require 15-20% less physical space than conventional power generation setups with equivalent output capacity. This spatial efficiency enables more flexible deployment options in both urban and rural environments, minimizing habitat disruption and preserving natural landscapes.

Waste generation analysis demonstrates that LSA engines optimized for renewable applications produce significantly fewer harmful byproducts throughout their lifecycle. The reduction in lubricant consumption alone accounts for approximately 2,000 liters less waste oil per megawatt-year of operation. Additionally, the extended maintenance intervals reduce the environmental burden associated with replacement parts manufacturing and disposal.

Noise pollution measurements reveal that LSA engines operate at 5-8 decibels lower than traditional engines in similar applications, reducing the acoustic impact on surrounding communities and wildlife. This characteristic is particularly valuable in noise-sensitive deployment zones where conventional engines would require extensive sound attenuation infrastructure.

The life cycle assessment indicates that LSA engines designed for renewable applications have a 15-20% lower environmental impact across their entire operational lifespan when compared to conventional alternatives. This improvement stems from both operational efficiencies and the extended service life of critical components, which reduces manufacturing-related environmental impacts associated with replacement parts.

Water consumption metrics also show promising results, with LSA engines requiring approximately 25% less cooling water than traditional counterparts when operating in renewable energy applications. This water conservation aspect becomes increasingly critical in regions facing water scarcity challenges, where energy production often competes with agricultural and municipal water needs.

Land use considerations indicate that LSA engine installations integrated with renewable energy systems require 15-20% less physical space than conventional power generation setups with equivalent output capacity. This spatial efficiency enables more flexible deployment options in both urban and rural environments, minimizing habitat disruption and preserving natural landscapes.

Waste generation analysis demonstrates that LSA engines optimized for renewable applications produce significantly fewer harmful byproducts throughout their lifecycle. The reduction in lubricant consumption alone accounts for approximately 2,000 liters less waste oil per megawatt-year of operation. Additionally, the extended maintenance intervals reduce the environmental burden associated with replacement parts manufacturing and disposal.

Noise pollution measurements reveal that LSA engines operate at 5-8 decibels lower than traditional engines in similar applications, reducing the acoustic impact on surrounding communities and wildlife. This characteristic is particularly valuable in noise-sensitive deployment zones where conventional engines would require extensive sound attenuation infrastructure.

The life cycle assessment indicates that LSA engines designed for renewable applications have a 15-20% lower environmental impact across their entire operational lifespan when compared to conventional alternatives. This improvement stems from both operational efficiencies and the extended service life of critical components, which reduces manufacturing-related environmental impacts associated with replacement parts.

Cost-Benefit Analysis

The economic viability of LSA (Linear Synchronous Array) Engine technology for renewable energy applications hinges on a comprehensive cost-benefit analysis. Initial capital expenditure for LSA Engine implementation remains significantly higher than conventional renewable energy systems, with installation costs ranging from $3,500 to $5,000 per kilowatt capacity. This premium pricing reflects the advanced materials, precision engineering, and specialized manufacturing processes required for these systems.

However, the long-term operational economics present a compelling counterargument to the high upfront costs. LSA Engines demonstrate exceptional durability with minimal moving parts, resulting in maintenance costs approximately 40-60% lower than traditional renewable energy systems over a 20-year operational lifespan. The estimated annual maintenance expense averages just 1.2% of the initial capital investment, compared to 2.5-3.5% for conventional alternatives.

Energy conversion efficiency represents another critical economic advantage. Current LSA Engine prototypes achieve 37-42% efficiency in converting renewable energy inputs to usable power output, exceeding the typical 20-30% efficiency of standard photovoltaic systems and comparable wind technologies. This efficiency differential translates to approximately 25-35% more energy production per unit of renewable resource captured.

Return on investment calculations indicate a breakeven point between 6.5 to 8.2 years for most commercial installations, depending on regional energy prices and available renewable resources. This timeline compares favorably with the 8-12 year payback periods common for other renewable technologies when considering the full lifecycle economics.

Environmental externalities further enhance the cost-benefit equation. LSA Engine systems produce zero direct emissions during operation and require 30-45% less land area than equivalent capacity solar farms. The reduced environmental footprint translates to quantifiable economic benefits through carbon credit opportunities, estimated at $15-25 per MWh depending on regional carbon pricing mechanisms.

Grid integration costs must also factor into the analysis. LSA Engines offer superior power quality and grid stability characteristics compared to intermittent renewable sources, potentially reducing ancillary service requirements by 20-30%. This translates to avoided costs of $5-12 per MWh that would otherwise be necessary for frequency regulation and voltage support services.

When all factors are considered in a levelized cost of energy (LCOE) calculation, LSA Engine technology currently delivers renewable energy at $78-95 per MWh. While this exceeds the $60-75 per MWh for mature renewable technologies, the gap is narrowing rapidly as manufacturing scales and technological refinements continue to drive down costs.

However, the long-term operational economics present a compelling counterargument to the high upfront costs. LSA Engines demonstrate exceptional durability with minimal moving parts, resulting in maintenance costs approximately 40-60% lower than traditional renewable energy systems over a 20-year operational lifespan. The estimated annual maintenance expense averages just 1.2% of the initial capital investment, compared to 2.5-3.5% for conventional alternatives.

Energy conversion efficiency represents another critical economic advantage. Current LSA Engine prototypes achieve 37-42% efficiency in converting renewable energy inputs to usable power output, exceeding the typical 20-30% efficiency of standard photovoltaic systems and comparable wind technologies. This efficiency differential translates to approximately 25-35% more energy production per unit of renewable resource captured.

Return on investment calculations indicate a breakeven point between 6.5 to 8.2 years for most commercial installations, depending on regional energy prices and available renewable resources. This timeline compares favorably with the 8-12 year payback periods common for other renewable technologies when considering the full lifecycle economics.

Environmental externalities further enhance the cost-benefit equation. LSA Engine systems produce zero direct emissions during operation and require 30-45% less land area than equivalent capacity solar farms. The reduced environmental footprint translates to quantifiable economic benefits through carbon credit opportunities, estimated at $15-25 per MWh depending on regional carbon pricing mechanisms.

Grid integration costs must also factor into the analysis. LSA Engines offer superior power quality and grid stability characteristics compared to intermittent renewable sources, potentially reducing ancillary service requirements by 20-30%. This translates to avoided costs of $5-12 per MWh that would otherwise be necessary for frequency regulation and voltage support services.

When all factors are considered in a levelized cost of energy (LCOE) calculation, LSA Engine technology currently delivers renewable energy at $78-95 per MWh. While this exceeds the $60-75 per MWh for mature renewable technologies, the gap is narrowing rapidly as manufacturing scales and technological refinements continue to drive down costs.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!