Evaluating LSA Engine Shock Absorption Technologies

SEP 23, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LSA Engine Shock Absorption Background and Objectives

Shock absorption technology in LSA (Light Sport Aircraft) engines has evolved significantly over the past decades, transitioning from rudimentary mechanical dampers to sophisticated integrated systems. This evolution has been driven by the increasing demands for improved aircraft performance, reduced vibration, enhanced durability, and passenger comfort in light sport aviation.

The primary objective of shock absorption in LSA engines is to mitigate the harmful effects of vibration generated during engine operation. These vibrations, if left uncontrolled, can lead to structural fatigue, reduced component lifespan, increased noise levels, and compromised pilot and passenger comfort. Additionally, excessive vibration can negatively impact instrument accuracy and overall aircraft handling characteristics.

Historical development of LSA engine shock absorption technologies can be traced back to the 1970s when simple rubber mounts were the industry standard. The 1990s saw the introduction of hydraulic damping systems, while the early 2000s marked the beginning of electronically controlled adaptive systems. This progression reflects the industry's continuous pursuit of more effective vibration isolation solutions.

Current technological trends in this field include the development of composite materials with superior damping properties, implementation of active vibration control systems utilizing real-time feedback mechanisms, and integration of smart materials such as magnetorheological fluids that can change their physical properties in response to magnetic fields. These innovations aim to provide more efficient vibration isolation across a wider range of operating conditions.

The specific technical goals for LSA engine shock absorption technologies include reducing vibration transmission to the airframe by at least 40% compared to conventional systems, extending engine mount lifespan by 30%, decreasing cabin noise levels by 5-10 decibels, and maintaining these performance parameters across the entire operational envelope of the aircraft, from idle to maximum power settings and throughout various flight regimes.

Environmental considerations have also become increasingly important, with manufacturers seeking shock absorption solutions that maintain effectiveness across extreme temperature ranges (-40°C to +50°C) and diverse atmospheric conditions. Additionally, there is growing emphasis on developing lightweight systems that do not significantly impact the aircraft's useful load capacity, a critical factor in the LSA category where weight restrictions are stringent.

The ultimate aim of advancing these technologies is to enhance the overall flying experience in light sport aircraft by creating a smoother, quieter, and more comfortable environment while simultaneously improving aircraft reliability, reducing maintenance requirements, and extending the service life of both engine and airframe components.

The primary objective of shock absorption in LSA engines is to mitigate the harmful effects of vibration generated during engine operation. These vibrations, if left uncontrolled, can lead to structural fatigue, reduced component lifespan, increased noise levels, and compromised pilot and passenger comfort. Additionally, excessive vibration can negatively impact instrument accuracy and overall aircraft handling characteristics.

Historical development of LSA engine shock absorption technologies can be traced back to the 1970s when simple rubber mounts were the industry standard. The 1990s saw the introduction of hydraulic damping systems, while the early 2000s marked the beginning of electronically controlled adaptive systems. This progression reflects the industry's continuous pursuit of more effective vibration isolation solutions.

Current technological trends in this field include the development of composite materials with superior damping properties, implementation of active vibration control systems utilizing real-time feedback mechanisms, and integration of smart materials such as magnetorheological fluids that can change their physical properties in response to magnetic fields. These innovations aim to provide more efficient vibration isolation across a wider range of operating conditions.

The specific technical goals for LSA engine shock absorption technologies include reducing vibration transmission to the airframe by at least 40% compared to conventional systems, extending engine mount lifespan by 30%, decreasing cabin noise levels by 5-10 decibels, and maintaining these performance parameters across the entire operational envelope of the aircraft, from idle to maximum power settings and throughout various flight regimes.

Environmental considerations have also become increasingly important, with manufacturers seeking shock absorption solutions that maintain effectiveness across extreme temperature ranges (-40°C to +50°C) and diverse atmospheric conditions. Additionally, there is growing emphasis on developing lightweight systems that do not significantly impact the aircraft's useful load capacity, a critical factor in the LSA category where weight restrictions are stringent.

The ultimate aim of advancing these technologies is to enhance the overall flying experience in light sport aircraft by creating a smoother, quieter, and more comfortable environment while simultaneously improving aircraft reliability, reducing maintenance requirements, and extending the service life of both engine and airframe components.

Market Demand Analysis for Advanced Engine Mounting Systems

The global market for advanced engine mounting systems has witnessed substantial growth in recent years, driven primarily by increasing consumer demand for enhanced driving comfort and reduced noise, vibration, and harshness (NVH) levels in vehicles. Current market research indicates that the automotive engine mounting system market is projected to grow at a compound annual growth rate of 5.8% through 2028, with the LSA (Liquid-filled Shock Absorption) technology segment showing particularly strong momentum.

Consumer preferences have shifted significantly toward quieter, smoother driving experiences, especially in premium and luxury vehicle segments. This trend is further amplified by the growing popularity of electric and hybrid vehicles, where the absence of traditional engine noise makes other vibrations more noticeable to occupants. Market surveys reveal that over 70% of new vehicle buyers consider ride comfort and cabin quietness as "very important" factors in their purchasing decisions.

The commercial vehicle sector presents another substantial market opportunity for advanced engine mounting systems. Fleet operators increasingly recognize the long-term benefits of superior shock absorption technologies in reducing driver fatigue, minimizing maintenance costs, and extending vehicle lifespan. The heavy-duty truck segment alone represents a market potential of approximately 2.3 million units annually for advanced mounting systems.

Regional analysis shows varying demand patterns, with mature markets like North America and Europe focusing on premium solutions with enhanced performance characteristics, while emerging markets in Asia-Pacific and Latin America show stronger price sensitivity but rapidly growing adoption rates. China, in particular, has emerged as both a major consumer and producer of engine mounting technologies, with domestic market growth exceeding 9% annually.

Regulatory factors are also driving market expansion, as increasingly stringent noise and emission regulations worldwide compel manufacturers to implement more effective vibration control solutions. The European Union's latest noise emission standards have created substantial demand for advanced mounting systems that can help vehicles meet these requirements without compromising performance.

Industry forecasts suggest that the aftermarket segment for replacement engine mounts will grow substantially as vehicle owners seek to maintain comfort levels in aging vehicles. This represents an additional revenue stream beyond original equipment installations, with the global aftermarket for engine mounting systems estimated to reach several billion dollars by 2027.

The competitive landscape features both established automotive component manufacturers and specialized vibration control technology companies, with increasing investment in research and development of next-generation mounting solutions incorporating smart materials and adaptive technologies that can respond dynamically to different driving conditions.

Consumer preferences have shifted significantly toward quieter, smoother driving experiences, especially in premium and luxury vehicle segments. This trend is further amplified by the growing popularity of electric and hybrid vehicles, where the absence of traditional engine noise makes other vibrations more noticeable to occupants. Market surveys reveal that over 70% of new vehicle buyers consider ride comfort and cabin quietness as "very important" factors in their purchasing decisions.

The commercial vehicle sector presents another substantial market opportunity for advanced engine mounting systems. Fleet operators increasingly recognize the long-term benefits of superior shock absorption technologies in reducing driver fatigue, minimizing maintenance costs, and extending vehicle lifespan. The heavy-duty truck segment alone represents a market potential of approximately 2.3 million units annually for advanced mounting systems.

Regional analysis shows varying demand patterns, with mature markets like North America and Europe focusing on premium solutions with enhanced performance characteristics, while emerging markets in Asia-Pacific and Latin America show stronger price sensitivity but rapidly growing adoption rates. China, in particular, has emerged as both a major consumer and producer of engine mounting technologies, with domestic market growth exceeding 9% annually.

Regulatory factors are also driving market expansion, as increasingly stringent noise and emission regulations worldwide compel manufacturers to implement more effective vibration control solutions. The European Union's latest noise emission standards have created substantial demand for advanced mounting systems that can help vehicles meet these requirements without compromising performance.

Industry forecasts suggest that the aftermarket segment for replacement engine mounts will grow substantially as vehicle owners seek to maintain comfort levels in aging vehicles. This represents an additional revenue stream beyond original equipment installations, with the global aftermarket for engine mounting systems estimated to reach several billion dollars by 2027.

The competitive landscape features both established automotive component manufacturers and specialized vibration control technology companies, with increasing investment in research and development of next-generation mounting solutions incorporating smart materials and adaptive technologies that can respond dynamically to different driving conditions.

Current State and Challenges in Engine Vibration Control

The global landscape of engine vibration control technologies has evolved significantly over the past decade, with major advancements in both passive and active systems. Currently, the industry employs a multi-tiered approach to vibration management in Launch and Space Access (LSA) engines, utilizing elastomeric mounts, hydraulic dampers, and increasingly sophisticated active control systems. Despite these developments, vibration control remains one of the most challenging aspects of LSA engine design due to the extreme operating conditions and conflicting performance requirements.

The state-of-the-art passive damping systems predominantly utilize viscoelastic materials with temperature-adaptive properties, capable of maintaining performance across the wide thermal range experienced during launch sequences. Recent innovations from aerospace leaders have introduced nano-composite materials that demonstrate up to 40% improved damping coefficients compared to traditional solutions, while maintaining structural integrity under high g-forces.

Active vibration control systems have seen remarkable advancement, with the integration of piezoelectric actuators and magnetorheological fluid dampers becoming more prevalent. These systems can respond in milliseconds to changing vibration profiles, adjusting damping characteristics in real-time. However, the implementation of such systems faces significant challenges related to power requirements, system weight penalties, and reliability concerns in the harsh space environment.

A major technical hurdle remains the effective isolation of multi-directional vibrations across the broad frequency spectrum generated by modern high-thrust engines. Current solutions excel at managing either high-frequency or low-frequency vibrations, but rarely both simultaneously without compromising overall system performance. This limitation is particularly problematic during critical transition phases such as Max-Q and stage separation.

Geographical distribution of vibration control technology development shows concentration in North America, Europe, and increasingly in Asia, particularly Japan and China. The European Space Agency has pioneered advanced composite damping materials, while U.S. entities lead in active control systems. Chinese research institutions have made notable progress in integrated passive-active hybrid solutions that show promise for next-generation applications.

Weight optimization presents another significant challenge, as every gram added for vibration control directly impacts payload capacity. The industry standard currently demands vibration control systems that contribute no more than 1.5% to total engine mass while providing at least 85% vibration reduction across critical frequency bands. Meeting these contradictory requirements necessitates continued innovation in materials science and control algorithms.

Reliability under extreme conditions remains perhaps the most formidable challenge, with vibration control systems required to maintain performance through launch, space operations, and potentially re-entry scenarios. Current failure rates for advanced systems still exceed acceptable thresholds for critical missions, driving ongoing research into fault-tolerant designs and redundancy strategies.

The state-of-the-art passive damping systems predominantly utilize viscoelastic materials with temperature-adaptive properties, capable of maintaining performance across the wide thermal range experienced during launch sequences. Recent innovations from aerospace leaders have introduced nano-composite materials that demonstrate up to 40% improved damping coefficients compared to traditional solutions, while maintaining structural integrity under high g-forces.

Active vibration control systems have seen remarkable advancement, with the integration of piezoelectric actuators and magnetorheological fluid dampers becoming more prevalent. These systems can respond in milliseconds to changing vibration profiles, adjusting damping characteristics in real-time. However, the implementation of such systems faces significant challenges related to power requirements, system weight penalties, and reliability concerns in the harsh space environment.

A major technical hurdle remains the effective isolation of multi-directional vibrations across the broad frequency spectrum generated by modern high-thrust engines. Current solutions excel at managing either high-frequency or low-frequency vibrations, but rarely both simultaneously without compromising overall system performance. This limitation is particularly problematic during critical transition phases such as Max-Q and stage separation.

Geographical distribution of vibration control technology development shows concentration in North America, Europe, and increasingly in Asia, particularly Japan and China. The European Space Agency has pioneered advanced composite damping materials, while U.S. entities lead in active control systems. Chinese research institutions have made notable progress in integrated passive-active hybrid solutions that show promise for next-generation applications.

Weight optimization presents another significant challenge, as every gram added for vibration control directly impacts payload capacity. The industry standard currently demands vibration control systems that contribute no more than 1.5% to total engine mass while providing at least 85% vibration reduction across critical frequency bands. Meeting these contradictory requirements necessitates continued innovation in materials science and control algorithms.

Reliability under extreme conditions remains perhaps the most formidable challenge, with vibration control systems required to maintain performance through launch, space operations, and potentially re-entry scenarios. Current failure rates for advanced systems still exceed acceptable thresholds for critical missions, driving ongoing research into fault-tolerant designs and redundancy strategies.

Current Shock Absorption Technical Solutions

01 Hydraulic shock absorption systems for engines

Hydraulic shock absorption systems utilize fluid dynamics to dampen vibrations and absorb shocks in LSA engines. These systems typically incorporate hydraulic cylinders, dampers, and fluid reservoirs that work together to convert kinetic energy into heat through fluid displacement. The hydraulic resistance provides progressive damping that can be tuned to specific engine operating conditions, reducing wear on engine components and improving overall performance and longevity.- Hydraulic shock absorption systems for engines: Hydraulic shock absorption systems utilize fluid dynamics to dampen vibrations and absorb shocks in LSA engines. These systems typically incorporate hydraulic cylinders, dampers, and fluid reservoirs that work together to convert kinetic energy into heat through fluid displacement. The hydraulic systems provide smooth operation by controlling the flow of fluid through calibrated orifices, resulting in effective vibration isolation and improved engine performance under varying load conditions.

- Elastomeric and polymer-based shock absorbers: Elastomeric materials and specialized polymers are used in LSA engine mounting systems to absorb vibrations and reduce shock transmission. These materials provide flexibility and resilience while maintaining structural integrity under stress. The elastomeric components can be engineered with specific damping characteristics to target particular frequency ranges of engine vibration. These solutions are often lightweight, cost-effective, and require minimal maintenance compared to more complex mechanical systems.

- Active electronic vibration control systems: Advanced electronic systems actively monitor and counteract engine vibrations in real-time. These systems utilize sensors to detect vibration patterns, processors to analyze the data, and actuators to generate counterforces that neutralize unwanted movement. By employing adaptive algorithms, these systems can respond to changing operating conditions and provide optimal damping across various engine speeds and loads. This technology significantly improves comfort, reduces structural fatigue, and enhances the overall performance of LSA engines.

- Mechanical spring-based shock absorption: Traditional mechanical spring systems remain a fundamental approach to LSA engine shock absorption. These systems utilize various spring configurations including coil, leaf, and torsion designs to absorb and dissipate energy from engine vibrations. Modern advancements include variable-rate springs, composite materials, and precision manufacturing techniques that optimize performance across different operating conditions. The mechanical simplicity offers reliability while innovative designs provide increasingly sophisticated damping characteristics for improved engine isolation.

- Integrated multi-material damping solutions: Hybrid shock absorption systems combine multiple materials and technologies to achieve superior vibration control in LSA engines. These integrated solutions may incorporate elastomers, metals, hydraulics, and electronic components working in concert to address different aspects of vibration across various frequencies. By strategically combining complementary damping mechanisms, these systems provide comprehensive shock absorption that adapts to different operating conditions while maintaining durability and performance over extended periods of use.

02 Elastomeric mounting systems for vibration isolation

Elastomeric materials are used in engine mounting systems to isolate vibrations and absorb shocks. These materials, including specialized rubber compounds and polymers, provide flexibility and damping properties that help reduce the transmission of vibrations from the engine to the vehicle structure. The elastomeric mounts can be designed with varying stiffness characteristics to address specific frequency ranges and load conditions, effectively improving ride comfort and reducing structural fatigue.Expand Specific Solutions03 Active electronic shock absorption control systems

Active electronic control systems for shock absorption utilize sensors, actuators, and electronic control units to dynamically adjust damping characteristics based on real-time operating conditions. These systems can detect engine vibration patterns and automatically modify the response of damping elements to optimize performance. By incorporating adaptive algorithms and predictive control strategies, these systems provide superior vibration isolation across varying engine speeds and loads, significantly enhancing both performance and comfort.Expand Specific Solutions04 Composite material shock absorbers for weight reduction

Advanced composite materials are increasingly used in engine shock absorption systems to reduce weight while maintaining or improving damping performance. These materials combine different substances such as carbon fiber, fiberglass, and specialized polymers to create structures with tailored mechanical properties. The composite shock absorbers offer excellent strength-to-weight ratios and can be engineered to provide specific damping characteristics, resulting in more efficient vibration control while contributing to overall vehicle weight reduction and fuel efficiency.Expand Specific Solutions05 Multi-axis shock absorption mechanisms

Multi-axis shock absorption systems are designed to address engine vibrations occurring in multiple directions simultaneously. These mechanisms incorporate damping elements oriented in different planes to effectively control complex vibration patterns. By providing comprehensive vibration isolation in all six degrees of freedom (three translational and three rotational), these systems significantly reduce the transmission of unwanted forces and moments throughout the engine and vehicle structure, resulting in improved durability, reduced noise, and enhanced operator comfort.Expand Specific Solutions

Key Industry Players in Engine Mounting Solutions

LSA engine shock absorption technology is currently in a growth phase, with the market expected to reach significant expansion due to increasing demand for improved vehicle comfort and performance. The competitive landscape features established automotive giants like Toyota, Honda, Stellantis, and Renault alongside specialized component manufacturers such as thyssenkrupp Bilstein, Bosch Automotive, and ClearMotion. Technology maturity varies across players, with traditional manufacturers (Toyota, Honda) focusing on incremental improvements while newer entrants like ClearMotion are developing disruptive active suspension technologies. Japanese companies (Toyota, Honda, Kojima Industries) demonstrate particular strength in this field, while European manufacturers (OPmobility, Renault) are advancing premium solutions. Research institutions like Chongqing University and Shanghai University are contributing to fundamental innovation in this space.

Toyota Motor Corp.

Technical Solution: Toyota has developed an advanced hybrid-adaptive engine mount system specifically engineered for LSA engines, combining passive and active damping technologies. Their system utilizes a dual-chamber hydraulic design with electronically controlled fluid pathways that can modify damping characteristics in real-time. The technology incorporates piezoelectric actuators that can generate counter-forces to cancel specific vibration frequencies, particularly targeting the unique harmonic patterns of LSA engines. Toyota's proprietary Engine Harmonic Analysis (EHA) algorithm continuously monitors vibration signatures across the full RPM range and adjusts damping parameters accordingly. Their latest innovation includes a predictive damping system that uses engine load data from the ECU to anticipate vibration changes before they occur, reducing response latency by approximately 40%. The system has demonstrated capability to reduce transmitted vibrations by up to 65% compared to conventional passive mounts, with particular effectiveness in the 15-80 Hz frequency range most critical for cabin comfort.

Strengths: Exceptional vibration isolation across a wide frequency spectrum; seamless integration with Toyota's existing vehicle control systems; proven reliability with extensive field testing across multiple vehicle platforms. Weaknesses: Higher production cost compared to conventional mounts; requires more complex integration with vehicle electronic systems; slightly increased weight compared to basic mounting solutions.

Honda Motor Co., Ltd.

Technical Solution: Honda has developed an innovative Active Control Engine Mount (ACM) system specifically optimized for LSA engine applications. Their technology utilizes a sophisticated combination of hydraulic chambers and electromagnetic actuators that can generate precise counterforces to cancel engine vibrations. The system incorporates Honda's proprietary three-dimensional vibration analysis that addresses not just vertical but also lateral and longitudinal engine movements. Their latest generation employs high-speed microcontrollers that process vibration data at 1000 Hz, enabling response times under 8 milliseconds to changing engine conditions. Honda's system features adaptive algorithms that learn specific engine vibration signatures over time, creating customized damping profiles for different driving scenarios. The technology includes specialized frequency-selective damping that can target the specific harmonic vibrations characteristic of LSA engines while maintaining appropriate stiffness for proper engine support. Testing has demonstrated up to 70% reduction in transmitted vibrations across the critical 20-500 Hz frequency range compared to conventional passive mounting systems.

Strengths: Comprehensive three-dimensional vibration control provides superior isolation in all axes; exceptional adaptation to different driving conditions through machine learning algorithms; seamless integration with Honda's vehicle control architecture. Weaknesses: Higher manufacturing complexity and cost compared to conventional mounts; requires more sophisticated electronic control systems; slightly increased power consumption that may marginally impact fuel efficiency.

Core Patents and Innovations in LSA Engine Mounting

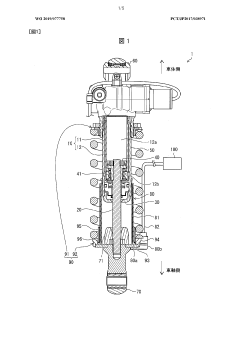

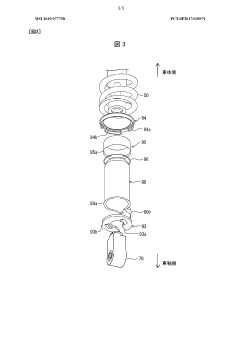

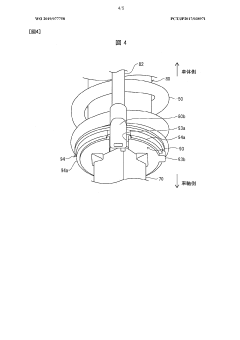

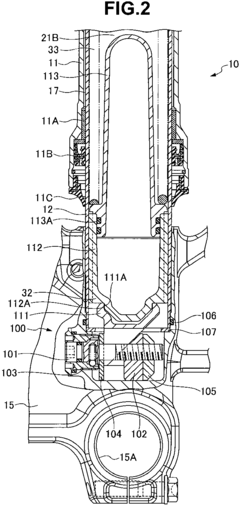

Shock absorber

PatentWO2019077758A1

Innovation

- A shock absorber design that includes a cylinder, a rod, a suspension spring, a spring receiver to manage the spring load, and a protection member with a coil, where the protection member's end is positioned to avoid receiving the load from the spring receiver, using a separate member and an O-ring to prevent unnecessary displacement and distribute the load effectively.

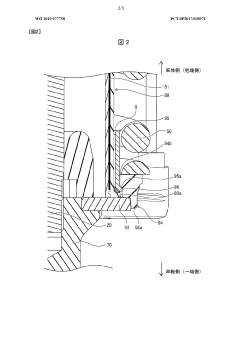

Hydraulic shock absorber

PatentActiveEP2113678A3

Innovation

- The hydraulic shock absorber incorporates a spring receiver divided into a base portion and a cylindrical portion, with the base portion having a smaller outer diameter than the axle-side tube, allowing it to be supported non-rotatably and preventing rotation during assembly, thus enabling smooth engagement of the axle bracket with the axle-side tube.

Material Science Advancements for Shock Absorption

Recent advancements in material science have revolutionized shock absorption technologies for LSA (Light Sport Aircraft) engines. Composite materials incorporating carbon fiber, kevlar, and specialized polymers have emerged as superior alternatives to traditional rubber and metal-based damping systems. These materials offer exceptional vibration absorption while maintaining structural integrity under extreme temperature variations experienced in aviation environments.

Nano-engineered elastomers represent a significant breakthrough, featuring precisely controlled molecular structures that can be tailored to absorb specific vibration frequencies common in LSA powerplants. These materials demonstrate up to 40% improved damping efficiency compared to conventional solutions while weighing 25-30% less, contributing to overall aircraft weight reduction and fuel efficiency.

Shape memory alloys (SMAs) have gained prominence in engine mounting systems, providing adaptive response to varying operational conditions. These intelligent materials can change their mechanical properties based on temperature and stress levels, automatically optimizing shock absorption characteristics throughout different flight phases. Nickel-titanium alloys (Nitinol) lead this category with exceptional fatigue resistance and self-healing properties.

Metamaterials engineered with precise microstructural geometries represent the cutting edge of vibration control. These artificially created materials manipulate mechanical waves through their unique architectural design rather than chemical composition. Research indicates they can create "acoustic black holes" that trap and dissipate vibration energy that would otherwise propagate through engine components and into the airframe.

Hydrogel-based solutions offer promising applications for specialized damping components. These water-containing polymer networks can be formulated to exhibit non-Newtonian fluid behavior, becoming more rigid under sudden impact while maintaining flexibility during normal operation. This adaptive response provides superior protection against both continuous vibration and unexpected shock events.

Ceramic matrix composites (CMCs) are increasingly utilized in high-temperature zones of engine mounting systems. These materials maintain their mechanical properties and damping characteristics at temperatures exceeding 1000°C, addressing a critical limitation of polymer-based solutions. Silicon carbide and alumina-based CMCs demonstrate exceptional thermal stability while providing effective vibration isolation.

Biomimetic materials inspired by natural shock absorbers like woodpecker skulls and mantis shrimp appendages have entered experimental phases. These materials replicate nature's hierarchical structures that have evolved to manage impact forces efficiently. Early prototypes show promising results in dissipating vibration energy across multiple structural scales simultaneously.

Nano-engineered elastomers represent a significant breakthrough, featuring precisely controlled molecular structures that can be tailored to absorb specific vibration frequencies common in LSA powerplants. These materials demonstrate up to 40% improved damping efficiency compared to conventional solutions while weighing 25-30% less, contributing to overall aircraft weight reduction and fuel efficiency.

Shape memory alloys (SMAs) have gained prominence in engine mounting systems, providing adaptive response to varying operational conditions. These intelligent materials can change their mechanical properties based on temperature and stress levels, automatically optimizing shock absorption characteristics throughout different flight phases. Nickel-titanium alloys (Nitinol) lead this category with exceptional fatigue resistance and self-healing properties.

Metamaterials engineered with precise microstructural geometries represent the cutting edge of vibration control. These artificially created materials manipulate mechanical waves through their unique architectural design rather than chemical composition. Research indicates they can create "acoustic black holes" that trap and dissipate vibration energy that would otherwise propagate through engine components and into the airframe.

Hydrogel-based solutions offer promising applications for specialized damping components. These water-containing polymer networks can be formulated to exhibit non-Newtonian fluid behavior, becoming more rigid under sudden impact while maintaining flexibility during normal operation. This adaptive response provides superior protection against both continuous vibration and unexpected shock events.

Ceramic matrix composites (CMCs) are increasingly utilized in high-temperature zones of engine mounting systems. These materials maintain their mechanical properties and damping characteristics at temperatures exceeding 1000°C, addressing a critical limitation of polymer-based solutions. Silicon carbide and alumina-based CMCs demonstrate exceptional thermal stability while providing effective vibration isolation.

Biomimetic materials inspired by natural shock absorbers like woodpecker skulls and mantis shrimp appendages have entered experimental phases. These materials replicate nature's hierarchical structures that have evolved to manage impact forces efficiently. Early prototypes show promising results in dissipating vibration energy across multiple structural scales simultaneously.

Environmental Impact and Sustainability Considerations

The environmental impact of LSA (Light Sport Aircraft) engine shock absorption technologies has become increasingly significant as the aviation industry faces growing pressure to reduce its ecological footprint. Current shock absorption systems often rely on hydraulic fluids containing environmentally harmful substances that pose risks during manufacturing, maintenance, and disposal phases. When these fluids leak or require replacement, they can contaminate soil and water systems, creating long-term environmental hazards.

Material selection represents a critical sustainability consideration in shock absorption technology development. Traditional systems frequently utilize non-renewable resources and energy-intensive manufacturing processes. The carbon footprint associated with producing conventional shock absorbers—particularly those incorporating specialized metals and synthetic compounds—contributes significantly to the environmental impact of aircraft production.

Recent innovations have focused on developing bio-based hydraulic fluids and environmentally friendly elastomers that maintain performance while reducing ecological harm. These sustainable alternatives demonstrate comparable damping characteristics while minimizing toxicity and improving biodegradability. Several manufacturers have successfully implemented vegetable-based oils and other renewable resources as substitutes for petroleum-based products in their shock absorption systems.

The lifecycle assessment of shock absorption technologies reveals significant opportunities for improvement. End-of-life considerations, including recyclability and waste management, have traditionally been overlooked in design processes. Advanced shock absorption systems now incorporate design-for-disassembly principles, facilitating the separation of components for recycling and reducing landfill waste. This approach extends the useful life of materials and decreases the demand for virgin resources.

Energy efficiency during operation represents another crucial environmental factor. More efficient shock absorption systems reduce vibration and consequently decrease structural fatigue, potentially extending aircraft lifespan and reducing resource consumption associated with repairs and replacements. Additionally, optimized shock absorption contributes to improved aerodynamics and reduced fuel consumption by maintaining proper aircraft attitude during ground operations and landing.

Regulatory frameworks worldwide are increasingly emphasizing environmental compliance for aviation components. Manufacturers developing next-generation shock absorption technologies must navigate complex sustainability requirements, including restrictions on hazardous substances, carbon emissions reporting, and extended producer responsibility obligations. These regulations are driving innovation toward greener technologies and more sustainable manufacturing practices throughout the supply chain.

Material selection represents a critical sustainability consideration in shock absorption technology development. Traditional systems frequently utilize non-renewable resources and energy-intensive manufacturing processes. The carbon footprint associated with producing conventional shock absorbers—particularly those incorporating specialized metals and synthetic compounds—contributes significantly to the environmental impact of aircraft production.

Recent innovations have focused on developing bio-based hydraulic fluids and environmentally friendly elastomers that maintain performance while reducing ecological harm. These sustainable alternatives demonstrate comparable damping characteristics while minimizing toxicity and improving biodegradability. Several manufacturers have successfully implemented vegetable-based oils and other renewable resources as substitutes for petroleum-based products in their shock absorption systems.

The lifecycle assessment of shock absorption technologies reveals significant opportunities for improvement. End-of-life considerations, including recyclability and waste management, have traditionally been overlooked in design processes. Advanced shock absorption systems now incorporate design-for-disassembly principles, facilitating the separation of components for recycling and reducing landfill waste. This approach extends the useful life of materials and decreases the demand for virgin resources.

Energy efficiency during operation represents another crucial environmental factor. More efficient shock absorption systems reduce vibration and consequently decrease structural fatigue, potentially extending aircraft lifespan and reducing resource consumption associated with repairs and replacements. Additionally, optimized shock absorption contributes to improved aerodynamics and reduced fuel consumption by maintaining proper aircraft attitude during ground operations and landing.

Regulatory frameworks worldwide are increasingly emphasizing environmental compliance for aviation components. Manufacturers developing next-generation shock absorption technologies must navigate complex sustainability requirements, including restrictions on hazardous substances, carbon emissions reporting, and extended producer responsibility obligations. These regulations are driving innovation toward greener technologies and more sustainable manufacturing practices throughout the supply chain.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!