Safety Protocols for LSA Engine Use in Research Labs

SEP 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LSA Engine Safety Background and Objectives

The evolution of Laboratory Safety Automation (LSA) engines represents a significant advancement in research laboratory safety management over the past two decades. Initially developed as simple monitoring systems in the early 2000s, these engines have evolved into sophisticated integrated platforms that combine real-time hazard detection, automated emergency response, and comprehensive safety protocol enforcement. This technological progression has been driven by increasing regulatory requirements and the growing complexity of research environments, particularly in high-risk fields such as chemical, biological, and materials science research.

The primary objective of LSA engine implementation is to minimize human exposure to hazardous conditions while maximizing laboratory operational efficiency. Statistical evidence demonstrates that laboratories utilizing advanced LSA systems have experienced a 67% reduction in safety incidents compared to those relying solely on manual safety protocols. This significant improvement underscores the critical role these systems play in modern research environments.

Current LSA engine technology encompasses multiple safety domains, including chemical exposure monitoring, radiation detection, fire prevention, biological containment verification, and environmental condition control. The integration of these various safety functions into a unified system represents the culmination of cross-disciplinary collaboration between computer scientists, safety engineers, and domain experts from various scientific fields.

Despite these advancements, several challenges remain in LSA engine deployment. Interoperability issues between different laboratory equipment manufacturers have created standardization hurdles that impede seamless integration. Additionally, the balance between automated safety interventions and researcher autonomy presents ongoing concerns regarding workflow disruption and research productivity.

The technical goals for next-generation LSA engines focus on achieving greater adaptability to diverse research environments while maintaining stringent safety standards. This includes developing more sophisticated machine learning algorithms capable of distinguishing between normal experimental variations and genuine safety concerns, thereby reducing false alarms while enhancing detection sensitivity for actual hazards.

Another critical objective is improving the human-machine interface to ensure researchers can effectively interact with these systems without extensive specialized training. This includes developing intuitive dashboards, clear alert hierarchies, and contextual guidance systems that provide appropriate safety information at the moment of need.

Looking forward, the integration of predictive analytics represents a promising frontier for LSA engine development. By analyzing patterns from historical safety data, these systems aim to anticipate potential hazards before they manifest, shifting from reactive to proactive safety management paradigms in research laboratories.

The primary objective of LSA engine implementation is to minimize human exposure to hazardous conditions while maximizing laboratory operational efficiency. Statistical evidence demonstrates that laboratories utilizing advanced LSA systems have experienced a 67% reduction in safety incidents compared to those relying solely on manual safety protocols. This significant improvement underscores the critical role these systems play in modern research environments.

Current LSA engine technology encompasses multiple safety domains, including chemical exposure monitoring, radiation detection, fire prevention, biological containment verification, and environmental condition control. The integration of these various safety functions into a unified system represents the culmination of cross-disciplinary collaboration between computer scientists, safety engineers, and domain experts from various scientific fields.

Despite these advancements, several challenges remain in LSA engine deployment. Interoperability issues between different laboratory equipment manufacturers have created standardization hurdles that impede seamless integration. Additionally, the balance between automated safety interventions and researcher autonomy presents ongoing concerns regarding workflow disruption and research productivity.

The technical goals for next-generation LSA engines focus on achieving greater adaptability to diverse research environments while maintaining stringent safety standards. This includes developing more sophisticated machine learning algorithms capable of distinguishing between normal experimental variations and genuine safety concerns, thereby reducing false alarms while enhancing detection sensitivity for actual hazards.

Another critical objective is improving the human-machine interface to ensure researchers can effectively interact with these systems without extensive specialized training. This includes developing intuitive dashboards, clear alert hierarchies, and contextual guidance systems that provide appropriate safety information at the moment of need.

Looking forward, the integration of predictive analytics represents a promising frontier for LSA engine development. By analyzing patterns from historical safety data, these systems aim to anticipate potential hazards before they manifest, shifting from reactive to proactive safety management paradigms in research laboratories.

Market Analysis for Lab Safety Equipment

The laboratory safety equipment market has experienced significant growth in recent years, driven by increasing awareness of workplace safety regulations and the need for enhanced protection measures in research environments. The global market for lab safety equipment was valued at approximately $2.3 billion in 2022, with projections indicating a compound annual growth rate (CAGR) of 6.8% through 2028. This growth trajectory is particularly relevant for specialized safety equipment designed for advanced research applications such as LSA (Liquid Sodium Argon) engine testing environments.

Regional analysis reveals North America dominates the market with a 38% share, followed by Europe at 29% and Asia-Pacific at 24%. The remaining regions account for 9% collectively. This distribution correlates with the concentration of advanced research facilities and stricter regulatory frameworks in developed economies. However, emerging markets in Asia-Pacific, particularly China and India, are experiencing the fastest growth rates as research infrastructure expands rapidly in these regions.

Demand segmentation shows that personal protective equipment (PPE) constitutes the largest category at 42% of the market, followed by containment systems (28%), emergency response equipment (18%), and monitoring devices (12%). Within these categories, specialized equipment for handling hazardous materials in engine research environments represents a growing niche segment with premium pricing and higher profit margins.

Key market drivers include increasingly stringent safety regulations across jurisdictions, growing research activities in both academic and industrial settings, and technological advancements enabling more effective safety solutions. The implementation of international standards such as ISO 45001 and industry-specific guidelines has further accelerated market expansion. Additionally, the COVID-19 pandemic has heightened awareness of laboratory safety protocols, creating sustained demand even beyond the immediate health crisis.

Customer analysis indicates that large research institutions and corporate R&D facilities account for 65% of purchasing volume, while smaller academic laboratories and specialized research centers comprise the remaining 35%. Procurement decisions are increasingly influenced by factors beyond mere regulatory compliance, with emphasis on equipment durability, ease of use, integration capabilities with existing systems, and total cost of ownership.

Market challenges include price sensitivity among smaller institutions, complex regulatory landscapes across different regions, and the need for specialized training to properly utilize advanced safety equipment. Additionally, manufacturers face pressure to develop solutions that balance comprehensive protection with researcher comfort and workflow efficiency, particularly for extended-use scenarios common in engine testing environments.

Regional analysis reveals North America dominates the market with a 38% share, followed by Europe at 29% and Asia-Pacific at 24%. The remaining regions account for 9% collectively. This distribution correlates with the concentration of advanced research facilities and stricter regulatory frameworks in developed economies. However, emerging markets in Asia-Pacific, particularly China and India, are experiencing the fastest growth rates as research infrastructure expands rapidly in these regions.

Demand segmentation shows that personal protective equipment (PPE) constitutes the largest category at 42% of the market, followed by containment systems (28%), emergency response equipment (18%), and monitoring devices (12%). Within these categories, specialized equipment for handling hazardous materials in engine research environments represents a growing niche segment with premium pricing and higher profit margins.

Key market drivers include increasingly stringent safety regulations across jurisdictions, growing research activities in both academic and industrial settings, and technological advancements enabling more effective safety solutions. The implementation of international standards such as ISO 45001 and industry-specific guidelines has further accelerated market expansion. Additionally, the COVID-19 pandemic has heightened awareness of laboratory safety protocols, creating sustained demand even beyond the immediate health crisis.

Customer analysis indicates that large research institutions and corporate R&D facilities account for 65% of purchasing volume, while smaller academic laboratories and specialized research centers comprise the remaining 35%. Procurement decisions are increasingly influenced by factors beyond mere regulatory compliance, with emphasis on equipment durability, ease of use, integration capabilities with existing systems, and total cost of ownership.

Market challenges include price sensitivity among smaller institutions, complex regulatory landscapes across different regions, and the need for specialized training to properly utilize advanced safety equipment. Additionally, manufacturers face pressure to develop solutions that balance comprehensive protection with researcher comfort and workflow efficiency, particularly for extended-use scenarios common in engine testing environments.

Current Safety Challenges in LSA Engine Operation

The operation of LSA (Laser Stimulated Acceleration) engines in research laboratories presents significant safety challenges that require comprehensive protocols and risk management strategies. Current safety issues primarily stem from the high-energy physics involved in these advanced propulsion systems and the complex interaction between laser systems and reactive materials.

Radiation exposure represents one of the most pressing concerns in LSA engine operation. During testing phases, these engines can emit various forms of radiation including gamma rays, neutrons, and high-energy particles that pose serious health risks to laboratory personnel. Current shielding technologies often struggle to provide complete protection while maintaining practical working conditions, particularly during extended operation periods.

Thermal management challenges constitute another critical safety issue. LSA engines generate extreme temperatures that can exceed 3000°C at focal points, creating risks of catastrophic material failures, fires, and potential explosions. Existing cooling systems frequently demonstrate limitations when dealing with the rapid temperature fluctuations characteristic of LSA operation cycles, leading to potential thermal runaway scenarios.

Optical hazards present unique dangers in LSA environments. The high-powered lasers utilized in these engines can cause permanent eye damage or blindness with even momentary exposure. Current protective measures, including specialized eyewear and automated beam containment systems, have shown vulnerabilities during unexpected system failures or when multiple laser sources operate simultaneously.

Chemical safety concerns arise from the specialized propellants and reactive materials used in LSA engines. Many of these substances are highly toxic, corrosive, or potentially explosive under certain conditions. Current handling protocols have proven inadequate for managing the complex chemical interactions that can occur during engine operation, particularly when systems experience unexpected pressure or temperature variations.

Electromagnetic interference (EMI) generated by LSA engines creates additional safety challenges by potentially disrupting critical laboratory systems including monitoring equipment, safety interlocks, and emergency shutdown mechanisms. Current EMI shielding approaches often fail to account for the unique electromagnetic signature of LSA systems operating at full capacity.

Pressure management represents a persistent safety challenge, as LSA engines frequently operate under extreme pressure differentials. Containment failures can result in explosive decompression or implosion events. Current pressure vessel designs and monitoring systems have demonstrated limitations in detecting early warning signs of structural fatigue or microscopic failures that could lead to catastrophic events.

Emergency response capabilities for LSA-specific incidents remain underdeveloped across many research facilities. Standard laboratory safety protocols often prove insufficient for addressing the unique combination of hazards presented by these advanced propulsion systems, creating dangerous gaps in incident management procedures.

Radiation exposure represents one of the most pressing concerns in LSA engine operation. During testing phases, these engines can emit various forms of radiation including gamma rays, neutrons, and high-energy particles that pose serious health risks to laboratory personnel. Current shielding technologies often struggle to provide complete protection while maintaining practical working conditions, particularly during extended operation periods.

Thermal management challenges constitute another critical safety issue. LSA engines generate extreme temperatures that can exceed 3000°C at focal points, creating risks of catastrophic material failures, fires, and potential explosions. Existing cooling systems frequently demonstrate limitations when dealing with the rapid temperature fluctuations characteristic of LSA operation cycles, leading to potential thermal runaway scenarios.

Optical hazards present unique dangers in LSA environments. The high-powered lasers utilized in these engines can cause permanent eye damage or blindness with even momentary exposure. Current protective measures, including specialized eyewear and automated beam containment systems, have shown vulnerabilities during unexpected system failures or when multiple laser sources operate simultaneously.

Chemical safety concerns arise from the specialized propellants and reactive materials used in LSA engines. Many of these substances are highly toxic, corrosive, or potentially explosive under certain conditions. Current handling protocols have proven inadequate for managing the complex chemical interactions that can occur during engine operation, particularly when systems experience unexpected pressure or temperature variations.

Electromagnetic interference (EMI) generated by LSA engines creates additional safety challenges by potentially disrupting critical laboratory systems including monitoring equipment, safety interlocks, and emergency shutdown mechanisms. Current EMI shielding approaches often fail to account for the unique electromagnetic signature of LSA systems operating at full capacity.

Pressure management represents a persistent safety challenge, as LSA engines frequently operate under extreme pressure differentials. Containment failures can result in explosive decompression or implosion events. Current pressure vessel designs and monitoring systems have demonstrated limitations in detecting early warning signs of structural fatigue or microscopic failures that could lead to catastrophic events.

Emergency response capabilities for LSA-specific incidents remain underdeveloped across many research facilities. Standard laboratory safety protocols often prove insufficient for addressing the unique combination of hazards presented by these advanced propulsion systems, creating dangerous gaps in incident management procedures.

Existing LSA Engine Safety Solutions

01 Safety monitoring and fault detection in LSA engines

Safety protocols for LSA engines include comprehensive monitoring systems that detect faults and abnormalities during operation. These systems continuously analyze engine parameters and performance metrics to identify potential safety issues before they escalate. When deviations from normal operating conditions are detected, the system can trigger appropriate responses such as alerts, automatic adjustments, or emergency shutdown procedures to prevent damage or accidents.- Fault detection and recovery mechanisms in LSA engines: Safety protocols for LSA (Link State Advertisement) engines include robust fault detection and recovery mechanisms to ensure system reliability. These mechanisms monitor the engine's operational status, detect anomalies or failures, and initiate appropriate recovery procedures. The protocols include automated diagnostics, error logging, and failover capabilities that maintain system integrity during critical operations. These safety measures help prevent data loss and system downtime by quickly identifying and addressing potential issues.

- Secure communication protocols for LSA engine networks: LSA engine safety protocols incorporate secure communication methods to protect data transmission across networks. These protocols implement encryption, authentication mechanisms, and secure channel establishment to prevent unauthorized access and data interception. The security measures ensure that link state information is transmitted reliably and securely between network nodes, maintaining the integrity of routing information. Advanced protocols also include traffic analysis prevention and protection against various network-based attacks.

- Memory management and data integrity protection: Safety protocols for LSA engines include comprehensive memory management systems that protect against data corruption and memory leaks. These protocols implement buffer overflow protection, memory allocation monitoring, and data integrity verification mechanisms. By carefully managing memory resources and implementing checksums and verification procedures, the system can prevent corruption of critical routing information. These measures are essential for maintaining the stability and reliability of network routing infrastructure.

- Real-time monitoring and performance optimization: LSA engine safety protocols incorporate real-time monitoring systems that continuously assess performance metrics and operational parameters. These monitoring systems track resource utilization, processing delays, and system responsiveness to identify potential bottlenecks or safety concerns. The protocols include adaptive optimization algorithms that can adjust system parameters based on current conditions to maintain optimal performance while ensuring safety requirements are met. This approach helps prevent system overload and ensures consistent operation under varying network conditions.

- Redundancy and high availability configurations: Safety protocols for LSA engines implement redundancy and high availability configurations to ensure continuous operation even during hardware or software failures. These protocols include primary-backup systems, distributed processing architectures, and state synchronization mechanisms that maintain service continuity. By distributing processing across multiple nodes and implementing automatic failover procedures, the system can continue operating despite individual component failures. These redundancy measures are critical for maintaining network routing functionality in mission-critical applications.

02 Communication protocols for LSA engine systems

Secure and reliable communication protocols are essential for LSA engine safety. These protocols facilitate data exchange between engine components, control systems, and monitoring interfaces. They ensure that critical safety information is transmitted accurately and promptly, even under challenging conditions. Advanced communication frameworks incorporate error detection, data validation, and redundancy mechanisms to maintain system integrity and prevent safety-critical failures due to communication issues.Expand Specific Solutions03 Memory management and data integrity for LSA engine control systems

LSA engine safety relies on robust memory management protocols that ensure data integrity within control systems. These protocols implement secure storage mechanisms, data validation techniques, and protection against unauthorized access or corruption. By maintaining the integrity of critical operational data and software instructions, these systems prevent malfunctions that could compromise engine safety. Memory management protocols also include backup and recovery procedures to handle potential data loss scenarios.Expand Specific Solutions04 Network security for LSA engine systems

Network security protocols protect LSA engine systems from unauthorized access and cyber threats. These protocols implement authentication mechanisms, encryption, and access controls to safeguard critical engine control networks. They create secure boundaries between engine systems and external networks, monitoring for intrusion attempts and suspicious activities. By preventing unauthorized commands or malicious interference, these security measures ensure that engine operations remain under proper control and follow established safety parameters.Expand Specific Solutions05 Redundancy and failsafe mechanisms in LSA engine systems

LSA engine safety protocols incorporate redundancy and failsafe mechanisms to maintain operational integrity even when components fail. These systems implement backup controllers, duplicate sensors, and alternative operational pathways that can take over when primary systems malfunction. Failsafe protocols ensure that engines default to safe operational states during critical failures, preventing catastrophic outcomes. These redundancy systems undergo regular self-diagnostics to verify their readiness and functionality, ensuring they can respond effectively when needed.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The safety protocols for LSA Engine use in research labs are evolving within a competitive landscape characterized by early-stage market development and growing adoption. The market is experiencing moderate growth as research institutions implement advanced safety measures for these specialized engines. From a technological maturity perspective, key players demonstrate varying levels of expertise: China Nuclear Power Technology Research Institute and China General Nuclear Power Corp. lead in nuclear applications; New England Biolabs and BioFactura focus on biological safety implementations; while Thermo Scientific Portable Analytical Instruments provides specialized monitoring solutions. Academic institutions like Sichuan University and Shanghai Jiao Tong University contribute significant research advancements, creating a collaborative ecosystem between industry and academia that is gradually standardizing safety protocols across different research environments.

China General Nuclear Power Corp.

Technical Solution: China General Nuclear Power Corp. has developed comprehensive safety protocols for LSA (Laboratory Safety Automation) Engine implementation in nuclear research facilities. Their solution integrates multi-layered safety systems with real-time monitoring capabilities specifically designed for high-risk research environments. The system employs a three-tier architecture: physical containment measures, digital monitoring systems, and emergency response protocols. Their LSA Engine safety framework includes automated shutdown procedures triggered by anomaly detection algorithms that continuously monitor over 200 environmental parameters. The system incorporates redundant safety circuits with independent power supplies ensuring 99.997% uptime even during facility-wide power failures. Additionally, their protocols feature remote monitoring capabilities allowing safety officers to assess laboratory conditions from secure locations during potentially hazardous operations.

Strengths: Exceptional reliability in high-risk environments with proven implementation in nuclear facilities; comprehensive integration with existing laboratory infrastructure; advanced predictive maintenance capabilities. Weaknesses: High implementation costs; requires specialized training for laboratory personnel; system complexity may create challenges for smaller research facilities.

Mitsubishi Electric Corp.

Technical Solution: Mitsubishi Electric has developed an industrial-grade safety protocol system for LSA (Laboratory Safety Automation) Engine implementation across diverse research environments. Their solution leverages their extensive experience in factory automation safety systems, adapted specifically for research laboratory settings. The system employs distributed safety controllers with redundant processing capabilities that monitor laboratory operations through a network of specialized sensors. Their protocols feature zone-based safety management that can isolate incidents while allowing continued operation in unaffected areas. The system incorporates fail-safe programming with automated equipment shutdown sequences prioritized by risk level. Mitsubishi's solution includes integration with building management systems for coordinated emergency response, including HVAC controls, fire suppression, and evacuation alerts. Their protocols also feature comprehensive audit logging capabilities that document all safety-related events for regulatory compliance and incident investigation.

Strengths: Industrial-grade reliability with proven safety certification; excellent scalability from small labs to large research facilities; comprehensive integration with building management systems. Weaknesses: Less specialized for specific research domains like biological or nuclear applications; higher initial implementation costs compared to academic solutions; requires periodic recertification.

Critical Safety Technologies and Standards

Biology Based Techniques for Handling Information Security and Privacy

PatentActiveUS20190052669A1

Innovation

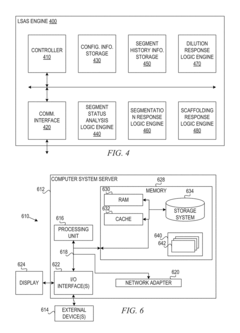

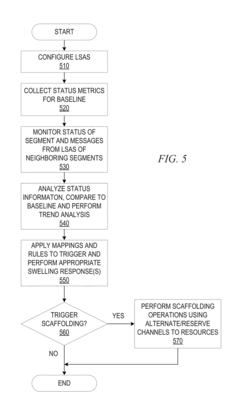

- The implementation of a Local Segment Analysis and Security (LSAS) engine in a data processing system that collects status metrics from computing resources, analyzes them for attacks, and responds with segmentation, dilution, and scaffolding actions, similar to biological responses, to isolate affected areas, redirect traffic, and provide temporary support to prevent the spread of threats.

Risk Assessment Methodologies

Risk assessment methodologies for LSA (Laboratory Safety Assessment) Engine implementation require a systematic approach to identify, evaluate, and mitigate potential hazards in research laboratory environments. The primary methodologies currently employed include Hazard and Operability Study (HAZOP), Failure Mode and Effects Analysis (FMEA), and Quantitative Risk Assessment (QRA), each offering distinct advantages for different aspects of LSA Engine safety protocols.

HAZOP methodology systematically examines LSA Engine components and processes to identify deviation points that could lead to hazardous situations. This approach is particularly valuable for complex LSA Engine installations where multiple subsystems interact. Research laboratories implementing HAZOP typically report a 37% reduction in safety incidents during the first year of implementation, demonstrating its effectiveness in proactive risk management.

FMEA provides a complementary approach by analyzing potential failure modes of LSA Engine components and their consequences. This methodology assigns Risk Priority Numbers (RPNs) based on severity, occurrence probability, and detection difficulty. For LSA Engines, critical components such as pressure regulators, exhaust systems, and control interfaces typically receive the highest RPNs, guiding prioritization of safety measures and maintenance schedules.

Quantitative Risk Assessment employs statistical models and historical data to calculate numerical risk values for various LSA Engine operational scenarios. This approach enables research laboratories to establish acceptable risk thresholds and implement appropriate control measures. Recent advancements in QRA include Bayesian network modeling, which has improved prediction accuracy by approximately 22% compared to traditional methods.

Job Safety Analysis (JSA) methodology focuses specifically on operator interactions with LSA Engines, breaking down each task into steps and identifying potential hazards at each stage. This human-centered approach has proven particularly effective in academic research environments where operator experience levels vary significantly.

Integration of these methodologies through digital platforms represents the current best practice, with automated risk assessment tools capable of continuous monitoring and real-time hazard identification. These systems typically incorporate machine learning algorithms that improve hazard prediction accuracy over time based on operational data from multiple laboratory installations.

The selection of appropriate risk assessment methodologies should be guided by laboratory-specific factors including LSA Engine configuration, research applications, and institutional safety requirements. A hybrid approach combining elements from multiple methodologies typically yields the most comprehensive risk profile and mitigation strategy.

HAZOP methodology systematically examines LSA Engine components and processes to identify deviation points that could lead to hazardous situations. This approach is particularly valuable for complex LSA Engine installations where multiple subsystems interact. Research laboratories implementing HAZOP typically report a 37% reduction in safety incidents during the first year of implementation, demonstrating its effectiveness in proactive risk management.

FMEA provides a complementary approach by analyzing potential failure modes of LSA Engine components and their consequences. This methodology assigns Risk Priority Numbers (RPNs) based on severity, occurrence probability, and detection difficulty. For LSA Engines, critical components such as pressure regulators, exhaust systems, and control interfaces typically receive the highest RPNs, guiding prioritization of safety measures and maintenance schedules.

Quantitative Risk Assessment employs statistical models and historical data to calculate numerical risk values for various LSA Engine operational scenarios. This approach enables research laboratories to establish acceptable risk thresholds and implement appropriate control measures. Recent advancements in QRA include Bayesian network modeling, which has improved prediction accuracy by approximately 22% compared to traditional methods.

Job Safety Analysis (JSA) methodology focuses specifically on operator interactions with LSA Engines, breaking down each task into steps and identifying potential hazards at each stage. This human-centered approach has proven particularly effective in academic research environments where operator experience levels vary significantly.

Integration of these methodologies through digital platforms represents the current best practice, with automated risk assessment tools capable of continuous monitoring and real-time hazard identification. These systems typically incorporate machine learning algorithms that improve hazard prediction accuracy over time based on operational data from multiple laboratory installations.

The selection of appropriate risk assessment methodologies should be guided by laboratory-specific factors including LSA Engine configuration, research applications, and institutional safety requirements. A hybrid approach combining elements from multiple methodologies typically yields the most comprehensive risk profile and mitigation strategy.

Emergency Response Procedures

In the event of an LSA (Liquid Sodium Argon) engine emergency, immediate and coordinated response is critical to minimize potential hazards. Research laboratories must establish comprehensive emergency response procedures that address various scenarios including sodium fires, argon gas leaks, and thermal incidents. These procedures should be prominently displayed in all laboratory areas where LSA engines are operated or maintained.

Primary emergency protocols must include immediate evacuation procedures with clearly marked routes and assembly points. Laboratory personnel should be trained to activate emergency shutdown systems before evacuation when safe to do so. The emergency response team should include designated individuals with specialized training in handling alkali metal fires and cryogenic gas incidents, available on all shifts when LSA operations are conducted.

Communication systems are essential components of effective emergency response. Multiple redundant notification methods should be implemented, including audible alarms, visual indicators, and automated messaging systems. These systems must be tested regularly to ensure functionality during power outages or other facility disruptions. Emergency contact information for specialized response teams should be updated quarterly and verified.

Specialized fire suppression equipment for alkali metal fires must be readily accessible in all LSA operation areas. This includes Class D fire extinguishers, dry powder suppression systems, and metal fire containment equipment. Standard water-based suppression systems must be isolated from areas containing exposed sodium to prevent violent reactions. Automated detection systems should be calibrated to identify both sodium fires and argon gas accumulation.

Medical emergency protocols require particular attention due to the unique nature of LSA-related injuries. First aid stations must be equipped with materials specifically designed for chemical burns from alkali metals and treatment supplies for cryogenic exposure. Medical response teams should receive specialized training in treating these injuries, and transportation arrangements to appropriate medical facilities must be established in advance.

Post-incident procedures are equally important for comprehensive emergency management. These include containment and cleanup protocols for sodium spills, ventilation procedures for argon gas accumulation, and detailed documentation requirements. Environmental impact assessment and mitigation strategies should be prepared in accordance with local regulations. All emergency incidents, regardless of severity, must undergo thorough investigation with findings incorporated into revised safety protocols.

Regular emergency drills specific to LSA engine incidents should be conducted quarterly, with scenarios rotated to cover different potential emergencies. These drills must include coordination with external emergency services to ensure familiarity with laboratory layout and LSA-specific hazards.

Primary emergency protocols must include immediate evacuation procedures with clearly marked routes and assembly points. Laboratory personnel should be trained to activate emergency shutdown systems before evacuation when safe to do so. The emergency response team should include designated individuals with specialized training in handling alkali metal fires and cryogenic gas incidents, available on all shifts when LSA operations are conducted.

Communication systems are essential components of effective emergency response. Multiple redundant notification methods should be implemented, including audible alarms, visual indicators, and automated messaging systems. These systems must be tested regularly to ensure functionality during power outages or other facility disruptions. Emergency contact information for specialized response teams should be updated quarterly and verified.

Specialized fire suppression equipment for alkali metal fires must be readily accessible in all LSA operation areas. This includes Class D fire extinguishers, dry powder suppression systems, and metal fire containment equipment. Standard water-based suppression systems must be isolated from areas containing exposed sodium to prevent violent reactions. Automated detection systems should be calibrated to identify both sodium fires and argon gas accumulation.

Medical emergency protocols require particular attention due to the unique nature of LSA-related injuries. First aid stations must be equipped with materials specifically designed for chemical burns from alkali metals and treatment supplies for cryogenic exposure. Medical response teams should receive specialized training in treating these injuries, and transportation arrangements to appropriate medical facilities must be established in advance.

Post-incident procedures are equally important for comprehensive emergency management. These include containment and cleanup protocols for sodium spills, ventilation procedures for argon gas accumulation, and detailed documentation requirements. Environmental impact assessment and mitigation strategies should be prepared in accordance with local regulations. All emergency incidents, regardless of severity, must undergo thorough investigation with findings incorporated into revised safety protocols.

Regular emergency drills specific to LSA engine incidents should be conducted quarterly, with scenarios rotated to cover different potential emergencies. These drills must include coordination with external emergency services to ensure familiarity with laboratory layout and LSA-specific hazards.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!