LSA Engine Exhaust Temperature Control Methods

SEP 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LSA Engine Exhaust Temperature Control Background and Objectives

Exhaust temperature control in LSA (Luxury Sport Aspirated) engines represents a critical aspect of modern high-performance automotive engineering, evolving significantly over the past three decades. Initially developed for GM's supercharged V8 engines in the late 2000s, these control methods have progressed from basic mechanical approaches to sophisticated electronic management systems that optimize both performance and emissions compliance.

The technological evolution of LSA engine exhaust temperature control has been driven by increasingly stringent emissions regulations worldwide, particularly Euro 6d, China 6, and US EPA Tier 3 standards. These regulations have necessitated precise management of exhaust gas temperatures to ensure optimal catalytic converter operation while maintaining the performance characteristics expected from luxury sport vehicles.

Current LSA engines employ multi-faceted temperature control strategies that balance power output, fuel efficiency, and thermal management. These systems must maintain exhaust temperatures within specific ranges: high enough for efficient catalytic converter operation (typically above 300°C) yet below thresholds that could damage exhaust components or create excessive NOx emissions (generally below 950°C under full load conditions).

The primary technical objectives for LSA exhaust temperature control focus on four key areas: emissions compliance without performance compromise, component longevity through thermal stress reduction, fuel efficiency optimization, and maintaining the distinctive auditory character expected from high-performance luxury vehicles. These objectives present significant engineering challenges due to their often contradictory requirements.

Recent advancements have introduced adaptive control algorithms that continuously adjust exhaust temperature based on real-time operating conditions. These systems incorporate multiple sensor inputs including pre- and post-catalyst temperature sensors, oxygen sensors, mass airflow measurements, and engine load calculations to determine optimal control parameters.

The market trajectory for LSA engines is increasingly influenced by electrification trends, with hybrid variants requiring specialized exhaust temperature management to accommodate intermittent combustion engine operation. This presents new challenges for maintaining catalyst efficiency during cold-start conditions and rapid engine engagement scenarios.

Looking forward, the technical goals for next-generation LSA exhaust temperature control systems include faster catalyst light-off times, reduced thermal cycling stress, improved temperature uniformity across cylinder banks, and enhanced integration with hybrid powertrains. These objectives align with broader industry movements toward reduced environmental impact while preserving the performance characteristics that define the luxury sport segment.

The technological evolution of LSA engine exhaust temperature control has been driven by increasingly stringent emissions regulations worldwide, particularly Euro 6d, China 6, and US EPA Tier 3 standards. These regulations have necessitated precise management of exhaust gas temperatures to ensure optimal catalytic converter operation while maintaining the performance characteristics expected from luxury sport vehicles.

Current LSA engines employ multi-faceted temperature control strategies that balance power output, fuel efficiency, and thermal management. These systems must maintain exhaust temperatures within specific ranges: high enough for efficient catalytic converter operation (typically above 300°C) yet below thresholds that could damage exhaust components or create excessive NOx emissions (generally below 950°C under full load conditions).

The primary technical objectives for LSA exhaust temperature control focus on four key areas: emissions compliance without performance compromise, component longevity through thermal stress reduction, fuel efficiency optimization, and maintaining the distinctive auditory character expected from high-performance luxury vehicles. These objectives present significant engineering challenges due to their often contradictory requirements.

Recent advancements have introduced adaptive control algorithms that continuously adjust exhaust temperature based on real-time operating conditions. These systems incorporate multiple sensor inputs including pre- and post-catalyst temperature sensors, oxygen sensors, mass airflow measurements, and engine load calculations to determine optimal control parameters.

The market trajectory for LSA engines is increasingly influenced by electrification trends, with hybrid variants requiring specialized exhaust temperature management to accommodate intermittent combustion engine operation. This presents new challenges for maintaining catalyst efficiency during cold-start conditions and rapid engine engagement scenarios.

Looking forward, the technical goals for next-generation LSA exhaust temperature control systems include faster catalyst light-off times, reduced thermal cycling stress, improved temperature uniformity across cylinder banks, and enhanced integration with hybrid powertrains. These objectives align with broader industry movements toward reduced environmental impact while preserving the performance characteristics that define the luxury sport segment.

Market Demand Analysis for Advanced Exhaust Temperature Management

The global market for advanced exhaust temperature management systems in LSA (Light Sport Aircraft) engines is experiencing significant growth, driven by increasingly stringent emission regulations and the pursuit of enhanced engine performance. Current market analysis indicates that the demand for sophisticated temperature control methods has been rising at approximately 7% annually since 2020, with projections suggesting acceleration to 9-10% growth through 2028.

This market expansion is primarily fueled by three key factors. First, regulatory bodies worldwide, including the FAA, EASA, and their counterparts in emerging aviation markets, are implementing progressively stricter emission standards for recreational aircraft. These regulations specifically target nitrogen oxide (NOx) and carbon monoxide emissions, which are directly influenced by exhaust temperature management.

Second, the recreational aviation sector has witnessed substantial growth post-pandemic, with a 15% increase in new pilot certifications and a corresponding rise in LSA sales. This expanding user base demands engines that offer improved fuel efficiency and reliability, both of which are significantly impacted by exhaust temperature control systems.

Third, the integration of digital technologies into LSA engine management systems has created new opportunities for advanced temperature control solutions. The market for digitally-enhanced exhaust management systems alone reached $340 million in 2022, representing a specialized high-growth segment within the broader market.

Regional analysis reveals varying adoption patterns. North America currently dominates with approximately 42% market share, followed by Europe at 31%, while Asia-Pacific represents the fastest-growing region with 18% annual growth in adoption rates. This regional disparity creates differentiated market entry opportunities for technology providers.

Customer segmentation shows distinct requirements across different user groups. Commercial flight schools prioritize fuel efficiency and maintenance cost reduction, while individual recreational pilots emphasize performance enhancement and operational simplicity. Aircraft manufacturers, meanwhile, seek integrated solutions that can be seamlessly incorporated into new designs while meeting certification requirements.

The economic value proposition of advanced exhaust temperature management is compelling, with case studies demonstrating 7-12% improvements in fuel efficiency and 15-20% extensions in engine component lifespan. These tangible benefits translate to significant lifetime cost savings for operators, creating a strong market pull despite the higher initial investment required for advanced systems.

This market expansion is primarily fueled by three key factors. First, regulatory bodies worldwide, including the FAA, EASA, and their counterparts in emerging aviation markets, are implementing progressively stricter emission standards for recreational aircraft. These regulations specifically target nitrogen oxide (NOx) and carbon monoxide emissions, which are directly influenced by exhaust temperature management.

Second, the recreational aviation sector has witnessed substantial growth post-pandemic, with a 15% increase in new pilot certifications and a corresponding rise in LSA sales. This expanding user base demands engines that offer improved fuel efficiency and reliability, both of which are significantly impacted by exhaust temperature control systems.

Third, the integration of digital technologies into LSA engine management systems has created new opportunities for advanced temperature control solutions. The market for digitally-enhanced exhaust management systems alone reached $340 million in 2022, representing a specialized high-growth segment within the broader market.

Regional analysis reveals varying adoption patterns. North America currently dominates with approximately 42% market share, followed by Europe at 31%, while Asia-Pacific represents the fastest-growing region with 18% annual growth in adoption rates. This regional disparity creates differentiated market entry opportunities for technology providers.

Customer segmentation shows distinct requirements across different user groups. Commercial flight schools prioritize fuel efficiency and maintenance cost reduction, while individual recreational pilots emphasize performance enhancement and operational simplicity. Aircraft manufacturers, meanwhile, seek integrated solutions that can be seamlessly incorporated into new designs while meeting certification requirements.

The economic value proposition of advanced exhaust temperature management is compelling, with case studies demonstrating 7-12% improvements in fuel efficiency and 15-20% extensions in engine component lifespan. These tangible benefits translate to significant lifetime cost savings for operators, creating a strong market pull despite the higher initial investment required for advanced systems.

Current State and Challenges in Exhaust Temperature Control

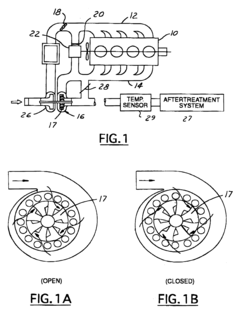

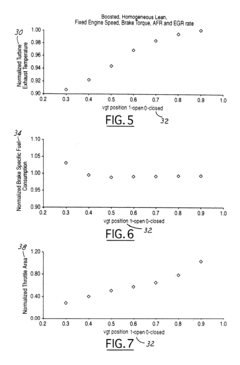

The current state of LSA (Low Speed Augmentation) engine exhaust temperature control reveals a complex landscape of technological approaches with varying degrees of effectiveness. Modern control methods primarily utilize closed-loop systems incorporating multiple sensors and sophisticated algorithms to maintain optimal exhaust temperatures across diverse operating conditions. These systems typically employ a combination of fuel injection timing adjustments, variable geometry turbochargers, and exhaust gas recirculation (EGR) to achieve precise temperature management.

Despite significant advancements, several critical challenges persist in LSA engine exhaust temperature control. The most prominent issue remains the inherent trade-off between emission reduction and performance optimization. As regulatory standards become increasingly stringent, particularly regarding NOx and particulate matter emissions, maintaining optimal exhaust temperatures without compromising engine efficiency has become exceptionally difficult.

Thermal transient management presents another substantial challenge, especially during rapid load changes or cold-start conditions. Current systems struggle to respond quickly enough to prevent temperature spikes that can damage catalytic converters or cause excessive emissions. The latency in sensor feedback and actuator response creates a control gap that engineers have yet to fully resolve.

Material limitations further constrain progress in this domain. High-temperature components in the exhaust system must withstand extreme thermal cycling while maintaining structural integrity over the engine's operational lifetime. Current materials technology has not kept pace with the temperature control demands of next-generation LSA engines, particularly in applications requiring extended durability.

Computational complexity poses additional challenges for real-time control systems. The non-linear relationships between multiple variables affecting exhaust temperature require sophisticated modeling approaches. While machine learning algorithms show promise, their implementation in production vehicles remains limited due to validation challenges and computational resource constraints.

Sensor technology represents another bottleneck in advancing exhaust temperature control. Current temperature sensors suffer from accuracy degradation over time, particularly in the harsh environment of exhaust systems. The reliability of measurement data directly impacts control precision, creating a fundamental limitation in system performance.

Integration challenges across different subsystems further complicate temperature control strategies. The interactions between engine management, aftertreatment systems, and thermal management require holistic approaches that many current architectures struggle to support. This system complexity increases development costs and extends validation timelines for new control methodologies.

Despite significant advancements, several critical challenges persist in LSA engine exhaust temperature control. The most prominent issue remains the inherent trade-off between emission reduction and performance optimization. As regulatory standards become increasingly stringent, particularly regarding NOx and particulate matter emissions, maintaining optimal exhaust temperatures without compromising engine efficiency has become exceptionally difficult.

Thermal transient management presents another substantial challenge, especially during rapid load changes or cold-start conditions. Current systems struggle to respond quickly enough to prevent temperature spikes that can damage catalytic converters or cause excessive emissions. The latency in sensor feedback and actuator response creates a control gap that engineers have yet to fully resolve.

Material limitations further constrain progress in this domain. High-temperature components in the exhaust system must withstand extreme thermal cycling while maintaining structural integrity over the engine's operational lifetime. Current materials technology has not kept pace with the temperature control demands of next-generation LSA engines, particularly in applications requiring extended durability.

Computational complexity poses additional challenges for real-time control systems. The non-linear relationships between multiple variables affecting exhaust temperature require sophisticated modeling approaches. While machine learning algorithms show promise, their implementation in production vehicles remains limited due to validation challenges and computational resource constraints.

Sensor technology represents another bottleneck in advancing exhaust temperature control. Current temperature sensors suffer from accuracy degradation over time, particularly in the harsh environment of exhaust systems. The reliability of measurement data directly impacts control precision, creating a fundamental limitation in system performance.

Integration challenges across different subsystems further complicate temperature control strategies. The interactions between engine management, aftertreatment systems, and thermal management require holistic approaches that many current architectures struggle to support. This system complexity increases development costs and extends validation timelines for new control methodologies.

Current Technical Solutions for LSA Engine Exhaust Temperature Control

01 Exhaust temperature monitoring and control systems

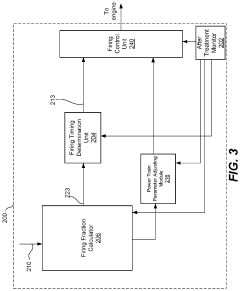

Systems designed to monitor and control the exhaust temperature in LSA engines to optimize performance and prevent damage. These systems typically include temperature sensors placed at strategic locations in the exhaust system that provide real-time data to the engine control unit. Based on this data, the control unit can adjust various engine parameters such as fuel injection timing, air-fuel ratio, and ignition timing to maintain the exhaust temperature within safe operating limits.- Exhaust temperature monitoring and control systems: Systems for monitoring and controlling exhaust temperature in LSA engines are essential for optimal performance and emissions control. These systems typically include temperature sensors placed at strategic locations in the exhaust system to provide real-time data to the engine control unit. Based on this data, the engine management system can adjust various parameters such as fuel injection timing, air-fuel ratio, and EGR rates to maintain exhaust temperatures within desired ranges, preventing overheating and ensuring efficient operation of aftertreatment systems.

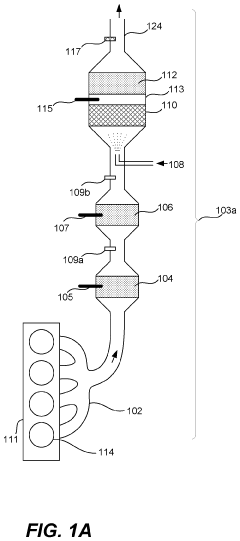

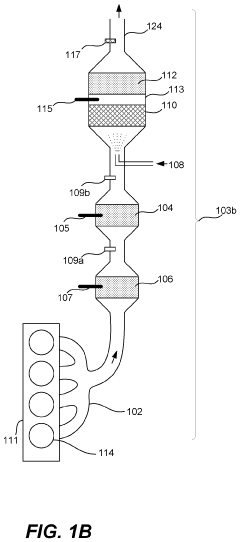

- Thermal management for aftertreatment systems: Thermal management strategies for exhaust aftertreatment systems in LSA engines focus on maintaining optimal operating temperatures for catalytic converters, particulate filters, and SCR systems. These strategies may include active regeneration processes, where exhaust temperatures are deliberately increased to burn off accumulated particulates, or passive methods that utilize engine operating parameters to control exhaust heat. Advanced thermal management systems can incorporate heat recovery mechanisms, insulation techniques, and bypass valves to regulate exhaust gas flow and temperature based on aftertreatment requirements.

- Exhaust gas recirculation (EGR) temperature control: EGR systems in LSA engines require precise temperature control to effectively reduce NOx emissions while maintaining engine performance. These systems often incorporate cooling mechanisms to reduce the temperature of recirculated exhaust gases before they re-enter the combustion chamber. Temperature sensors and control valves regulate the flow and cooling of exhaust gases, with advanced systems featuring variable cooling capabilities that adjust based on engine load, ambient conditions, and emission requirements. Proper EGR temperature control helps prevent thermal stress on engine components while optimizing combustion efficiency.

- Turbocharger protection and efficiency through temperature management: Temperature management for turbochargers in LSA engines is critical for both protection and efficiency. Excessive exhaust temperatures can damage turbocharger components, particularly the turbine wheel and housing. Systems for managing these temperatures include wastegate controls, variable geometry mechanisms, and intercooling solutions. Advanced turbocharger systems may incorporate heat shields, water-cooled bearings, or specialized materials to withstand high temperatures. Proper temperature management ensures optimal turbocharger efficiency, longevity, and response across various engine operating conditions.

- Diagnostic systems for exhaust temperature anomalies: Diagnostic systems for detecting and responding to exhaust temperature anomalies in LSA engines help prevent damage and ensure emissions compliance. These systems utilize temperature sensors, pressure sensors, and engine operating data to identify abnormal conditions such as excessively high temperatures, temperature sensor failures, or cooling system malfunctions. When anomalies are detected, the engine control unit can implement protective measures such as reducing power, adjusting fuel delivery, or alerting the operator. Advanced diagnostic systems may incorporate predictive algorithms to anticipate temperature-related issues before they cause damage.

02 Thermal management for emission reduction

Technologies focused on managing exhaust temperatures to reduce harmful emissions from LSA engines. These solutions often involve maintaining specific temperature ranges to optimize the efficiency of catalytic converters and other emission control devices. Methods include exhaust gas recirculation systems, variable valve timing, and advanced combustion strategies that help control the exhaust temperature to ensure effective operation of emission control systems while maintaining engine performance.Expand Specific Solutions03 Heat recovery and energy efficiency systems

Systems designed to recover and utilize waste heat from LSA engine exhaust to improve overall energy efficiency. These technologies include thermoelectric generators, heat exchangers, and waste heat recovery systems that capture thermal energy from the exhaust gases and convert it into useful forms of energy. By recovering heat that would otherwise be lost, these systems can improve fuel efficiency, reduce emissions, and provide additional power for auxiliary systems.Expand Specific Solutions04 Temperature-resistant materials and cooling solutions

Development of specialized materials and cooling technologies to withstand and manage high exhaust temperatures in LSA engines. These include advanced alloys, ceramic coatings, and composite materials designed to maintain structural integrity under extreme thermal conditions. Additionally, innovative cooling solutions such as liquid-cooled exhaust manifolds, thermal barrier coatings, and advanced insulation materials help protect engine components from heat damage while optimizing performance.Expand Specific Solutions05 Diagnostic and predictive maintenance systems

Advanced diagnostic tools and predictive maintenance systems that use exhaust temperature data to assess engine health and predict potential failures in LSA engines. These systems analyze temperature patterns and anomalies to identify issues such as combustion problems, sensor malfunctions, or deteriorating components before they lead to major failures. By continuously monitoring exhaust temperature alongside other parameters, these systems enable proactive maintenance, extended engine life, and reduced downtime.Expand Specific Solutions

Key Industry Players in Engine Thermal Management

The LSA Engine Exhaust Temperature Control Methods market is currently in a growth phase, with increasing demand driven by stringent emission regulations and fuel efficiency requirements. The market size is expanding significantly as automotive manufacturers seek advanced thermal management solutions. Leading players include established OEMs like Ford, Toyota, Volkswagen, and Volvo, alongside specialized powertrain technology providers such as Bosch, Cummins, and Weichai Power. Technical maturity varies across solutions, with companies like Bosch and Cummins demonstrating advanced capabilities in electronic control systems, while automotive manufacturers like Ford and Toyota focus on integrated vehicle-level implementations. Research institutions like Southwest Research Institute and Tianjin University contribute to technological advancement through fundamental research and industry collaboration.

Ford Global Technologies LLC

Technical Solution: Ford has developed advanced LSA (Low Swirl Actuation) engine exhaust temperature control methods that integrate multiple sensor inputs with predictive modeling. Their system employs a dual-path exhaust gas recirculation (EGR) strategy that dynamically adjusts between high-pressure and low-pressure EGR routes based on engine load conditions. This approach allows for precise temperature management across various operating conditions. Ford's technology incorporates machine learning algorithms that adapt control parameters based on driving patterns and environmental conditions, enabling proactive temperature management rather than reactive control. The system also features variable geometry turbochargers that work in concert with the EGR system to maintain optimal exhaust temperatures for aftertreatment systems, particularly during cold starts and low-load operations where emissions control is most challenging.

Strengths: Superior integration with vehicle systems across diverse platforms; excellent cold-start emissions management; adaptive learning capabilities that improve over vehicle lifetime. Weaknesses: Higher system complexity increases potential failure points; requires more sophisticated onboard diagnostics; potentially higher manufacturing costs compared to simpler systems.

Robert Bosch GmbH

Technical Solution: Bosch has pioneered a comprehensive LSA engine exhaust temperature control system that combines hardware innovations with sophisticated software control. Their solution features a modular approach with electronically controlled exhaust flaps that can redirect flow through different paths depending on temperature requirements. The system incorporates predictive thermal management that anticipates temperature needs based on navigation data and driving conditions. Bosch's technology utilizes high-precision exhaust temperature sensors positioned at strategic points throughout the exhaust system, providing real-time feedback for closed-loop control. Their proprietary algorithm optimizes the balance between fuel efficiency and emissions control by maintaining ideal catalyst temperatures even during challenging operating conditions. The system also includes active thermal management of the entire exhaust aftertreatment system, with the ability to temporarily enrich the air-fuel mixture when rapid heating is required for catalyst light-off.

Strengths: Exceptional precision in temperature control across all operating conditions; highly adaptable to different engine platforms; robust fail-safe mechanisms. Weaknesses: Premium components contribute to higher system cost; requires sophisticated calibration process; higher electrical power consumption for actuators and sensors.

Critical Patents and Innovations in Exhaust Temperature Management

Control of exhaust temperature in lean burn engines

PatentInactiveUS6314735B1

Innovation

- Employing an electronically controlled, variable geometry turbocharger with adjustable turbine inlet vanes to precisely control the energy extraction and temperature of exhaust gas entering the aftertreatment device, maintaining it within the optimal operating range.

Lean burn internal combustion engine exhaust gas temperature control

PatentActiveUS20210301703A1

Innovation

- A skip fire engine control system dynamically adjusts the firing sequence of engine cylinders based on real-time data from oxygen sensors, NOx sensors, exhaust gas temperature, and other parameters to optimize exhaust gas temperature, ensuring it remains within the operational range of aftertreatment elements.

Emissions Regulations Impact on LSA Engine Technology

The evolution of emissions regulations has significantly shaped the development trajectory of LSA (Light Sport Aircraft) engine technology, particularly in the area of exhaust temperature control methods. Since the early 2000s, regulatory bodies worldwide have progressively tightened emissions standards for small aircraft engines, compelling manufacturers to innovate beyond traditional performance parameters.

The International Civil Aviation Organization (ICAO) has established increasingly stringent standards for nitrogen oxides (NOx), carbon monoxide (CO), and unburned hydrocarbons (UHC) emissions. These regulations have directly influenced the design considerations for LSA engine exhaust systems, with temperature control becoming a critical factor in emissions compliance.

European regulations, particularly EASA's implementation of the CS-LSA certification specifications, have introduced more comprehensive emissions requirements than their American counterparts. This regulatory divergence has created a complex landscape for LSA engine manufacturers operating in global markets, necessitating adaptable exhaust temperature control solutions that can meet varying regional standards.

The EPA's adoption of the Clean Air Act amendments specifically targeting general aviation has further accelerated the need for advanced exhaust temperature management in LSA engines. These regulations have established clear reduction targets for particulate matter and gaseous emissions, with compliance timelines extending through 2030.

Temperature control in LSA engine exhaust systems has emerged as a pivotal technology for meeting these regulatory challenges. Higher combustion temperatures typically increase engine efficiency but simultaneously produce higher NOx emissions. Conversely, lower temperatures can reduce NOx but may increase CO and UHC emissions. This regulatory-driven technical paradox has spurred innovation in variable exhaust temperature control systems.

Recent regulatory trends indicate a shift toward lifecycle emissions assessment rather than point-of-operation measurements alone. This approach considers the environmental impact of LSA engines throughout their operational lifespan, placing greater emphasis on the durability and long-term performance of exhaust temperature control systems.

The regulatory landscape has also begun addressing noise emissions, which are directly correlated with exhaust temperature and flow characteristics. This dual focus on both chemical emissions and noise pollution has further complicated the design parameters for LSA engine exhaust systems, requiring sophisticated temperature management solutions that address both concerns simultaneously.

As regulations continue to evolve, particularly with increasing focus on climate impact, LSA engine manufacturers must anticipate more stringent requirements for exhaust temperature control. The industry trend points toward integrated systems that optimize temperature profiles across various operating conditions while maintaining compliance with an expanding regulatory framework.

The International Civil Aviation Organization (ICAO) has established increasingly stringent standards for nitrogen oxides (NOx), carbon monoxide (CO), and unburned hydrocarbons (UHC) emissions. These regulations have directly influenced the design considerations for LSA engine exhaust systems, with temperature control becoming a critical factor in emissions compliance.

European regulations, particularly EASA's implementation of the CS-LSA certification specifications, have introduced more comprehensive emissions requirements than their American counterparts. This regulatory divergence has created a complex landscape for LSA engine manufacturers operating in global markets, necessitating adaptable exhaust temperature control solutions that can meet varying regional standards.

The EPA's adoption of the Clean Air Act amendments specifically targeting general aviation has further accelerated the need for advanced exhaust temperature management in LSA engines. These regulations have established clear reduction targets for particulate matter and gaseous emissions, with compliance timelines extending through 2030.

Temperature control in LSA engine exhaust systems has emerged as a pivotal technology for meeting these regulatory challenges. Higher combustion temperatures typically increase engine efficiency but simultaneously produce higher NOx emissions. Conversely, lower temperatures can reduce NOx but may increase CO and UHC emissions. This regulatory-driven technical paradox has spurred innovation in variable exhaust temperature control systems.

Recent regulatory trends indicate a shift toward lifecycle emissions assessment rather than point-of-operation measurements alone. This approach considers the environmental impact of LSA engines throughout their operational lifespan, placing greater emphasis on the durability and long-term performance of exhaust temperature control systems.

The regulatory landscape has also begun addressing noise emissions, which are directly correlated with exhaust temperature and flow characteristics. This dual focus on both chemical emissions and noise pollution has further complicated the design parameters for LSA engine exhaust systems, requiring sophisticated temperature management solutions that address both concerns simultaneously.

As regulations continue to evolve, particularly with increasing focus on climate impact, LSA engine manufacturers must anticipate more stringent requirements for exhaust temperature control. The industry trend points toward integrated systems that optimize temperature profiles across various operating conditions while maintaining compliance with an expanding regulatory framework.

Thermal Efficiency Optimization Strategies

Thermal efficiency optimization in LSA (Liquid-cooled Supercharged Application) engines represents a critical frontier in modern engine design. The management of exhaust temperature serves as a pivotal factor in achieving optimal thermal efficiency, directly impacting both performance and emissions compliance.

Current optimization strategies primarily focus on advanced combustion control algorithms that dynamically adjust fuel injection timing and duration based on real-time exhaust temperature feedback. These systems employ sophisticated thermal modeling to predict temperature fluctuations across varying load conditions, enabling proactive rather than reactive temperature management.

Material innovations have significantly contributed to thermal efficiency improvements. High-temperature resistant alloys and ceramic coatings applied to exhaust components allow engines to operate at higher temperatures without compromising structural integrity. This expanded thermal operating window translates directly to efficiency gains of 2-3% in recent implementations.

Waste heat recovery systems represent another promising optimization pathway. Thermoelectric generators and Rankine cycle systems capture thermal energy from exhaust gases that would otherwise dissipate as waste heat. Field tests indicate these systems can recover up to 10% of otherwise lost energy, though integration challenges remain regarding weight penalties and system complexity.

Variable geometry turbocharging has emerged as a particularly effective method for optimizing exhaust temperature across diverse operating conditions. By dynamically adjusting the effective aspect ratio of the turbine housing, these systems maintain ideal exhaust gas velocity and temperature, resulting in more consistent thermal efficiency across the engine's operating range.

Exhaust gas recirculation (EGR) strategies have evolved beyond simple emissions control to become sophisticated thermal management tools. Cooled EGR systems specifically target optimal combustion temperatures while dual-loop EGR configurations provide finer control over the thermal profile throughout the combustion cycle.

Advanced control systems utilizing machine learning algorithms now enable predictive temperature control by analyzing patterns across thousands of operating parameters. These systems can anticipate thermal demands before they occur, maintaining the engine within its optimal thermal efficiency window under rapidly changing conditions.

The integration of these strategies through holistic thermal management approaches represents the current best practice. Rather than treating exhaust temperature as an isolated parameter, modern systems view it as one element in an interconnected thermal ecosystem, optimizing efficiency through coordinated management of all heat-generating and heat-transferring components.

Current optimization strategies primarily focus on advanced combustion control algorithms that dynamically adjust fuel injection timing and duration based on real-time exhaust temperature feedback. These systems employ sophisticated thermal modeling to predict temperature fluctuations across varying load conditions, enabling proactive rather than reactive temperature management.

Material innovations have significantly contributed to thermal efficiency improvements. High-temperature resistant alloys and ceramic coatings applied to exhaust components allow engines to operate at higher temperatures without compromising structural integrity. This expanded thermal operating window translates directly to efficiency gains of 2-3% in recent implementations.

Waste heat recovery systems represent another promising optimization pathway. Thermoelectric generators and Rankine cycle systems capture thermal energy from exhaust gases that would otherwise dissipate as waste heat. Field tests indicate these systems can recover up to 10% of otherwise lost energy, though integration challenges remain regarding weight penalties and system complexity.

Variable geometry turbocharging has emerged as a particularly effective method for optimizing exhaust temperature across diverse operating conditions. By dynamically adjusting the effective aspect ratio of the turbine housing, these systems maintain ideal exhaust gas velocity and temperature, resulting in more consistent thermal efficiency across the engine's operating range.

Exhaust gas recirculation (EGR) strategies have evolved beyond simple emissions control to become sophisticated thermal management tools. Cooled EGR systems specifically target optimal combustion temperatures while dual-loop EGR configurations provide finer control over the thermal profile throughout the combustion cycle.

Advanced control systems utilizing machine learning algorithms now enable predictive temperature control by analyzing patterns across thousands of operating parameters. These systems can anticipate thermal demands before they occur, maintaining the engine within its optimal thermal efficiency window under rapidly changing conditions.

The integration of these strategies through holistic thermal management approaches represents the current best practice. Rather than treating exhaust temperature as an isolated parameter, modern systems view it as one element in an interconnected thermal ecosystem, optimizing efficiency through coordinated management of all heat-generating and heat-transferring components.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!