LSA Engine vs Jet Engines: Efficiency Metrics

SEP 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LSA Engine and Jet Engine Development History and Objectives

The evolution of aircraft propulsion systems has been marked by continuous innovation aimed at achieving greater efficiency, power, and reliability. Light Sport Aircraft (LSA) engines and jet engines represent two distinct branches in this technological evolution, each developed to address specific operational requirements and performance metrics.

LSA engines emerged in the early 20th century, with the Wright brothers' first powered flight utilizing a simple 12-horsepower engine. By the 1930s, manufacturers like Continental and Lycoming had established themselves as pioneers in developing reliable piston engines for light aircraft. The post-World War II era saw significant advancements in LSA engine technology, with improvements in power-to-weight ratios, fuel efficiency, and operational reliability.

In contrast, jet engine development began in earnest during the 1930s, with Frank Whittle in the UK and Hans von Ohain in Germany independently developing the first practical jet engines. The first operational jet aircraft, the Heinkel He 178, took flight in 1939, marking the beginning of a new era in aviation propulsion. Following World War II, jet engine technology advanced rapidly, with the introduction of turbojet, turbofan, and high-bypass turbofan designs that progressively improved efficiency and performance.

The primary objective driving LSA engine development has been to create lightweight, fuel-efficient power plants suitable for recreational and training aircraft. These engines typically prioritize simplicity, reliability, and low operating costs over raw power output. Modern LSA engines aim to achieve specific fuel consumption rates of 0.4-0.5 pounds per horsepower-hour while maintaining power outputs between 80-130 horsepower.

Jet engine development, conversely, has been driven by the pursuit of higher thrust-to-weight ratios, improved specific fuel consumption, and increased operational ceilings and speeds. Early turbojets had thrust-specific fuel consumption (TSFC) values around 1.0-1.2 pounds of fuel per pound of thrust per hour, while modern high-bypass turbofans have achieved TSFC values as low as 0.5-0.6, representing a significant efficiency improvement.

The technological trajectories of these engine types reflect fundamentally different design philosophies and operational requirements. LSA engines have evolved toward greater reliability and reduced maintenance requirements, with recent innovations focusing on electronic ignition systems, fuel injection, and alternative fuel compatibility. Jet engines have pursued increasingly sophisticated compressor and turbine designs, advanced materials capable of withstanding extreme temperatures, and complex control systems to optimize performance across diverse flight regimes.

Understanding the historical development and objectives of these propulsion systems provides essential context for evaluating their respective efficiency metrics and identifying potential areas for future innovation and cross-pollination of technologies.

LSA engines emerged in the early 20th century, with the Wright brothers' first powered flight utilizing a simple 12-horsepower engine. By the 1930s, manufacturers like Continental and Lycoming had established themselves as pioneers in developing reliable piston engines for light aircraft. The post-World War II era saw significant advancements in LSA engine technology, with improvements in power-to-weight ratios, fuel efficiency, and operational reliability.

In contrast, jet engine development began in earnest during the 1930s, with Frank Whittle in the UK and Hans von Ohain in Germany independently developing the first practical jet engines. The first operational jet aircraft, the Heinkel He 178, took flight in 1939, marking the beginning of a new era in aviation propulsion. Following World War II, jet engine technology advanced rapidly, with the introduction of turbojet, turbofan, and high-bypass turbofan designs that progressively improved efficiency and performance.

The primary objective driving LSA engine development has been to create lightweight, fuel-efficient power plants suitable for recreational and training aircraft. These engines typically prioritize simplicity, reliability, and low operating costs over raw power output. Modern LSA engines aim to achieve specific fuel consumption rates of 0.4-0.5 pounds per horsepower-hour while maintaining power outputs between 80-130 horsepower.

Jet engine development, conversely, has been driven by the pursuit of higher thrust-to-weight ratios, improved specific fuel consumption, and increased operational ceilings and speeds. Early turbojets had thrust-specific fuel consumption (TSFC) values around 1.0-1.2 pounds of fuel per pound of thrust per hour, while modern high-bypass turbofans have achieved TSFC values as low as 0.5-0.6, representing a significant efficiency improvement.

The technological trajectories of these engine types reflect fundamentally different design philosophies and operational requirements. LSA engines have evolved toward greater reliability and reduced maintenance requirements, with recent innovations focusing on electronic ignition systems, fuel injection, and alternative fuel compatibility. Jet engines have pursued increasingly sophisticated compressor and turbine designs, advanced materials capable of withstanding extreme temperatures, and complex control systems to optimize performance across diverse flight regimes.

Understanding the historical development and objectives of these propulsion systems provides essential context for evaluating their respective efficiency metrics and identifying potential areas for future innovation and cross-pollination of technologies.

Market Analysis for Efficient Aviation Propulsion Systems

The aviation propulsion market is experiencing a significant shift as efficiency becomes a paramount concern for manufacturers, operators, and regulators alike. The global commercial aviation propulsion systems market, valued at approximately $68.5 billion in 2022, is projected to grow at a CAGR of 8.7% through 2030, driven primarily by demand for more fuel-efficient engines. This growth trajectory is shaped by increasing environmental regulations, volatile fuel prices, and competitive pressures to reduce operating costs.

LSA (Liquid Air Cycle) engines represent an emerging technology in this landscape, competing with traditional jet engines on efficiency metrics. Market analysis indicates that fuel efficiency improvements offer substantial economic benefits - a mere 1% improvement in fuel efficiency can translate to annual savings of $300,000 per aircraft for commercial airlines. This economic incentive is creating a receptive market for LSA technology, which promises 15-20% greater fuel efficiency compared to conventional turbofan engines.

The regional distribution of market demand shows varying adoption patterns. North America and Europe lead in terms of early adoption potential, driven by stringent emission regulations and higher operating costs. The Asia-Pacific region, while currently dominated by conventional propulsion systems, represents the fastest-growing market segment with projected annual growth rates exceeding 10% as air travel expands rapidly in emerging economies.

Market segmentation analysis reveals distinct customer profiles. Major commercial airlines prioritize proven reliability alongside efficiency gains, while regional carriers and low-cost operators demonstrate greater sensitivity to initial acquisition costs. The emerging urban air mobility sector presents a specialized niche with unique requirements balancing efficiency with noise reduction and operational flexibility.

Competitive analysis indicates that established jet engine manufacturers are investing heavily in incremental efficiency improvements, with companies like GE Aviation, Rolls-Royce, and Pratt & Whitney allocating 12-15% of annual revenue to R&D. Meanwhile, several technology startups focused exclusively on LSA and other alternative propulsion systems have secured venture funding exceeding $2 billion collectively since 2018.

Market barriers for LSA technology adoption include certification hurdles, integration challenges with existing aircraft designs, and the aviation industry's inherent conservatism regarding safety-critical systems. However, the potential market penetration is substantial, with industry analysts projecting that alternative propulsion technologies could capture 25-30% of new installations by 2035 if current efficiency advantages can be maintained while addressing reliability concerns.

LSA (Liquid Air Cycle) engines represent an emerging technology in this landscape, competing with traditional jet engines on efficiency metrics. Market analysis indicates that fuel efficiency improvements offer substantial economic benefits - a mere 1% improvement in fuel efficiency can translate to annual savings of $300,000 per aircraft for commercial airlines. This economic incentive is creating a receptive market for LSA technology, which promises 15-20% greater fuel efficiency compared to conventional turbofan engines.

The regional distribution of market demand shows varying adoption patterns. North America and Europe lead in terms of early adoption potential, driven by stringent emission regulations and higher operating costs. The Asia-Pacific region, while currently dominated by conventional propulsion systems, represents the fastest-growing market segment with projected annual growth rates exceeding 10% as air travel expands rapidly in emerging economies.

Market segmentation analysis reveals distinct customer profiles. Major commercial airlines prioritize proven reliability alongside efficiency gains, while regional carriers and low-cost operators demonstrate greater sensitivity to initial acquisition costs. The emerging urban air mobility sector presents a specialized niche with unique requirements balancing efficiency with noise reduction and operational flexibility.

Competitive analysis indicates that established jet engine manufacturers are investing heavily in incremental efficiency improvements, with companies like GE Aviation, Rolls-Royce, and Pratt & Whitney allocating 12-15% of annual revenue to R&D. Meanwhile, several technology startups focused exclusively on LSA and other alternative propulsion systems have secured venture funding exceeding $2 billion collectively since 2018.

Market barriers for LSA technology adoption include certification hurdles, integration challenges with existing aircraft designs, and the aviation industry's inherent conservatism regarding safety-critical systems. However, the potential market penetration is substantial, with industry analysts projecting that alternative propulsion technologies could capture 25-30% of new installations by 2035 if current efficiency advantages can be maintained while addressing reliability concerns.

Current Technical Challenges in Engine Efficiency Metrics

The assessment of engine efficiency metrics presents significant challenges when comparing LSA (Light Sport Aircraft) engines with conventional jet engines. Current measurement methodologies often fail to provide standardized frameworks that account for the fundamental differences in design philosophy, operational parameters, and intended use cases between these propulsion systems.

One primary challenge lies in the definition of efficiency itself. While jet engines are typically evaluated based on thrust-specific fuel consumption (TSFC), LSA engines are more commonly assessed through brake-specific fuel consumption (BSFC). These differing baseline metrics create immediate comparison difficulties, as they measure fundamentally different output characteristics - thrust versus shaft power.

Environmental operating conditions further complicate efficiency evaluations. LSA engines predominantly operate at lower altitudes and speeds where air density is higher, while jet engines achieve optimal efficiency at high altitudes with reduced atmospheric drag. Current metrics inadequately normalize these environmental variables, leading to potentially misleading efficiency comparisons when engines operate outside their design envelopes.

The scale disparity between these engine types presents another significant challenge. Jet engines benefit from economies of scale in thermodynamic efficiency that smaller LSA powerplants cannot achieve. Current efficiency metrics rarely incorporate scaling factors to account for these inherent thermodynamic advantages, creating an uneven comparison landscape.

Weight-to-power ratios represent another critical challenge area. LSA applications demand extremely lightweight propulsion solutions, often sacrificing some efficiency for weight reduction. Contemporary efficiency metrics typically fail to incorporate weight considerations, despite their crucial importance in overall aircraft performance, particularly for light sport applications.

Lifecycle assessment presents perhaps the most complex challenge. Current efficiency metrics predominantly focus on operational fuel consumption while neglecting manufacturing energy inputs, maintenance requirements, and end-of-life considerations. This narrow view provides an incomplete efficiency picture, especially problematic when comparing the relatively simple LSA engines against highly complex jet turbines.

Technological hybridization further complicates metric standardization. As both engine categories increasingly incorporate electric components, battery systems, and alternative fuels, traditional efficiency metrics struggle to capture the full energy conversion pathway. The lack of comprehensive metrics that account for these hybrid systems represents a significant gap in current evaluation frameworks.

One primary challenge lies in the definition of efficiency itself. While jet engines are typically evaluated based on thrust-specific fuel consumption (TSFC), LSA engines are more commonly assessed through brake-specific fuel consumption (BSFC). These differing baseline metrics create immediate comparison difficulties, as they measure fundamentally different output characteristics - thrust versus shaft power.

Environmental operating conditions further complicate efficiency evaluations. LSA engines predominantly operate at lower altitudes and speeds where air density is higher, while jet engines achieve optimal efficiency at high altitudes with reduced atmospheric drag. Current metrics inadequately normalize these environmental variables, leading to potentially misleading efficiency comparisons when engines operate outside their design envelopes.

The scale disparity between these engine types presents another significant challenge. Jet engines benefit from economies of scale in thermodynamic efficiency that smaller LSA powerplants cannot achieve. Current efficiency metrics rarely incorporate scaling factors to account for these inherent thermodynamic advantages, creating an uneven comparison landscape.

Weight-to-power ratios represent another critical challenge area. LSA applications demand extremely lightweight propulsion solutions, often sacrificing some efficiency for weight reduction. Contemporary efficiency metrics typically fail to incorporate weight considerations, despite their crucial importance in overall aircraft performance, particularly for light sport applications.

Lifecycle assessment presents perhaps the most complex challenge. Current efficiency metrics predominantly focus on operational fuel consumption while neglecting manufacturing energy inputs, maintenance requirements, and end-of-life considerations. This narrow view provides an incomplete efficiency picture, especially problematic when comparing the relatively simple LSA engines against highly complex jet turbines.

Technological hybridization further complicates metric standardization. As both engine categories increasingly incorporate electric components, battery systems, and alternative fuels, traditional efficiency metrics struggle to capture the full energy conversion pathway. The lack of comprehensive metrics that account for these hybrid systems represents a significant gap in current evaluation frameworks.

Comparative Analysis of LSA and Jet Engine Efficiency Solutions

01 Advanced combustion systems for jet engines

Various combustion systems have been developed to enhance jet engine efficiency. These include improved fuel injection methods, combustion chamber designs, and flame stabilization techniques. Advanced combustion systems optimize the air-fuel mixture, reduce emissions, and increase thermal efficiency, resulting in better overall engine performance and reduced fuel consumption.- Advanced combustion systems for jet engines: Various combustion system designs have been developed to enhance jet engine efficiency. These include improved fuel injection systems, combustion chamber geometries, and flame stabilization mechanisms. Advanced combustion technologies aim to achieve more complete fuel burning, reduced emissions, and better thermal management, all contributing to overall engine efficiency improvements.

- Aerodynamic improvements in turbine design: Aerodynamic enhancements in turbine components significantly impact jet engine efficiency. These improvements include optimized blade profiles, advanced airfoil designs, and innovative flow control mechanisms. By reducing aerodynamic losses and improving air flow through the engine, these designs contribute to higher thrust-to-weight ratios and better fuel economy in modern jet engines.

- Lightweight materials and structural innovations: The use of lightweight materials and structural innovations plays a crucial role in enhancing jet engine efficiency. Advanced materials such as composites, ceramic matrix composites, and specialized alloys reduce overall engine weight while maintaining structural integrity at high temperatures. These materials enable higher operating temperatures, improved thermal efficiency, and reduced fuel consumption in both LSA and conventional jet engines.

- Thermal management and cooling systems: Effective thermal management and cooling systems are essential for maximizing jet engine efficiency. Innovative cooling techniques for turbine blades, combustion chambers, and other high-temperature components allow engines to operate at higher temperatures without material failure. These systems include advanced air cooling circuits, thermal barrier coatings, and heat exchanger designs that recover waste heat and improve overall thermal efficiency.

- Integration of electronic control systems: Modern jet engines incorporate sophisticated electronic control systems to optimize performance across various operating conditions. These systems provide precise control of fuel flow, air-fuel ratios, and engine parameters in real-time. Advanced sensors, digital engine control units, and adaptive algorithms enable engines to maintain peak efficiency during different flight phases, altitude changes, and varying atmospheric conditions, resulting in significant fuel savings and performance improvements.

02 Aerodynamic improvements in turbine design

Aerodynamic enhancements in turbine components significantly improve jet engine efficiency. These include optimized blade profiles, advanced airfoil designs, and improved flow path geometries. By reducing aerodynamic losses and improving air flow through the engine, these innovations increase thrust output while decreasing fuel consumption, leading to more efficient engine operation across various flight regimes.Expand Specific Solutions03 Lightweight structural materials and components

The use of lightweight materials and innovative structural designs has significantly improved engine efficiency. Advanced alloys, composites, and ceramic materials reduce the overall weight of engine components while maintaining or improving strength and heat resistance. These lightweight structures decrease the power required for propulsion, resulting in better fuel economy and increased payload capacity for aircraft.Expand Specific Solutions04 Thermal management and cooling systems

Effective thermal management systems are crucial for maintaining optimal jet engine efficiency. Advanced cooling techniques for turbine blades, combustion chambers, and other high-temperature components allow engines to operate at higher temperatures without material failure. These systems include innovative air cooling channels, thermal barrier coatings, and heat exchangers that improve thermodynamic efficiency and extend component lifespan.Expand Specific Solutions05 Electronic control systems for performance optimization

Sophisticated electronic control systems have revolutionized jet engine efficiency. These systems continuously monitor and adjust engine parameters such as fuel flow, compression ratios, and turbine speeds to optimize performance under varying conditions. Advanced sensors, digital controllers, and adaptive algorithms enable real-time adjustments that maximize efficiency, reduce fuel consumption, and extend engine life while ensuring safe operation across all flight phases.Expand Specific Solutions

Key Industry Players in Aviation Propulsion Systems

The LSA Engine vs Jet Engines efficiency metrics landscape is currently in a growth phase, with increasing market demand driven by sustainability concerns. The global market is expanding as aerospace companies seek more fuel-efficient propulsion systems. Leading players like Rolls-Royce, GE, MTU Aero Engines, and Safran Aircraft Engines are investing heavily in research and development to improve efficiency metrics. Newer entrants such as Mountain Aerospace Research Solutions and ePropelled are introducing innovative technologies, while established manufacturers including Boeing, Airbus, and Mitsubishi Heavy Industries are integrating these advancements into their platforms. The technology is approaching maturity with major players demonstrating significant efficiency improvements, though full commercial implementation across all aviation sectors remains in progress.

Rolls-Royce Plc

Technical Solution: Rolls-Royce has developed advanced UltraFan® technology that represents their approach to LSA (Low Speed Augmentor) propulsion systems with significantly improved efficiency metrics compared to conventional jet engines. Their design incorporates a planetary gearbox that enables the fan and turbine to rotate at their optimal speeds, dramatically improving propulsive efficiency. The UltraFan architecture features a variable pitch fan system that optimizes performance across different flight regimes, particularly excelling at lower speeds where traditional jets are less efficient. Rolls-Royce has implemented advanced ceramic matrix composite components in the high-pressure turbine that withstand extreme temperatures while reducing weight. Their proprietary ALECSys (Advanced Low Emissions Combustion System) technology achieves near-complete fuel combustion, minimizing both emissions and fuel consumption. The company's integrated design approach considers aerodynamic, thermal, and structural aspects simultaneously, resulting in a propulsion system that delivers up to 25% better fuel efficiency compared to their first-generation Trent engines while maintaining comparable thrust capabilities and significantly reducing noise footprint.

Strengths: Extensive experience in large civil and military engine development; comprehensive testing infrastructure validates performance claims; advanced manufacturing capabilities ensure production readiness. Weaknesses: Significant upfront investment requirements; complex planetary gearbox introduces potential reliability concerns; challenges in retrofitting technology to existing aircraft platforms.

MTU Aero Engines AG

Technical Solution: MTU Aero Engines has developed sophisticated LSA (Low Speed Augmentor) technology that represents a significant advancement in propulsion efficiency metrics compared to conventional jet engines. Their approach focuses on geared turbofan architecture with enhanced low-pressure systems that optimize performance at various flight regimes. MTU's technology incorporates advanced high-temperature materials, including titanium aluminide turbine blades and ceramic matrix composites, enabling higher operating temperatures and improved thermodynamic efficiency. Their proprietary blade designs feature optimized 3D aerodynamics that reduce losses while maintaining structural integrity under extreme conditions. MTU has implemented innovative cooling techniques that minimize the amount of air diverted from the core flow, thereby increasing the available energy for propulsion. Their LSA systems demonstrate approximately 20% lower specific fuel consumption compared to conventional engines while maintaining comparable thrust capabilities. MTU's technology also incorporates sophisticated active clearance control systems that maintain optimal component gaps throughout the flight envelope, further enhancing efficiency by minimizing leakage losses and improving component durability.

Strengths: Specialized expertise in high-temperature materials and manufacturing processes; modular design approach facilitates maintenance and upgrades; demonstrated reliability in operational environments. Weaknesses: Limited experience as prime contractor for complete engine systems; higher manufacturing complexity increases production costs; potential challenges in scaling technology to larger thrust classes.

Critical Patents and Innovations in Engine Efficiency Measurement

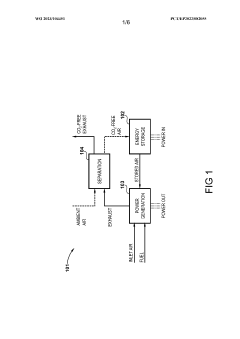

Power generation and storage

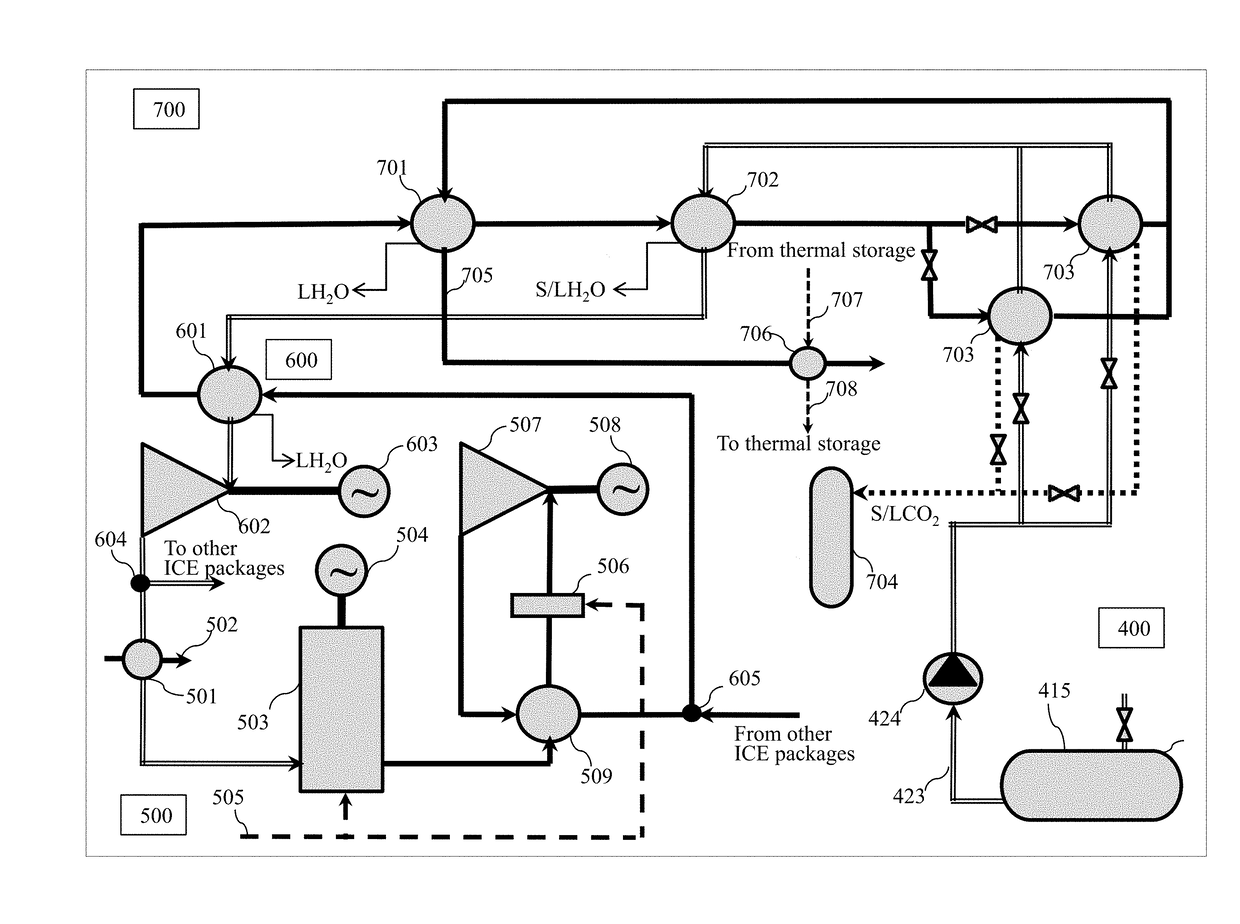

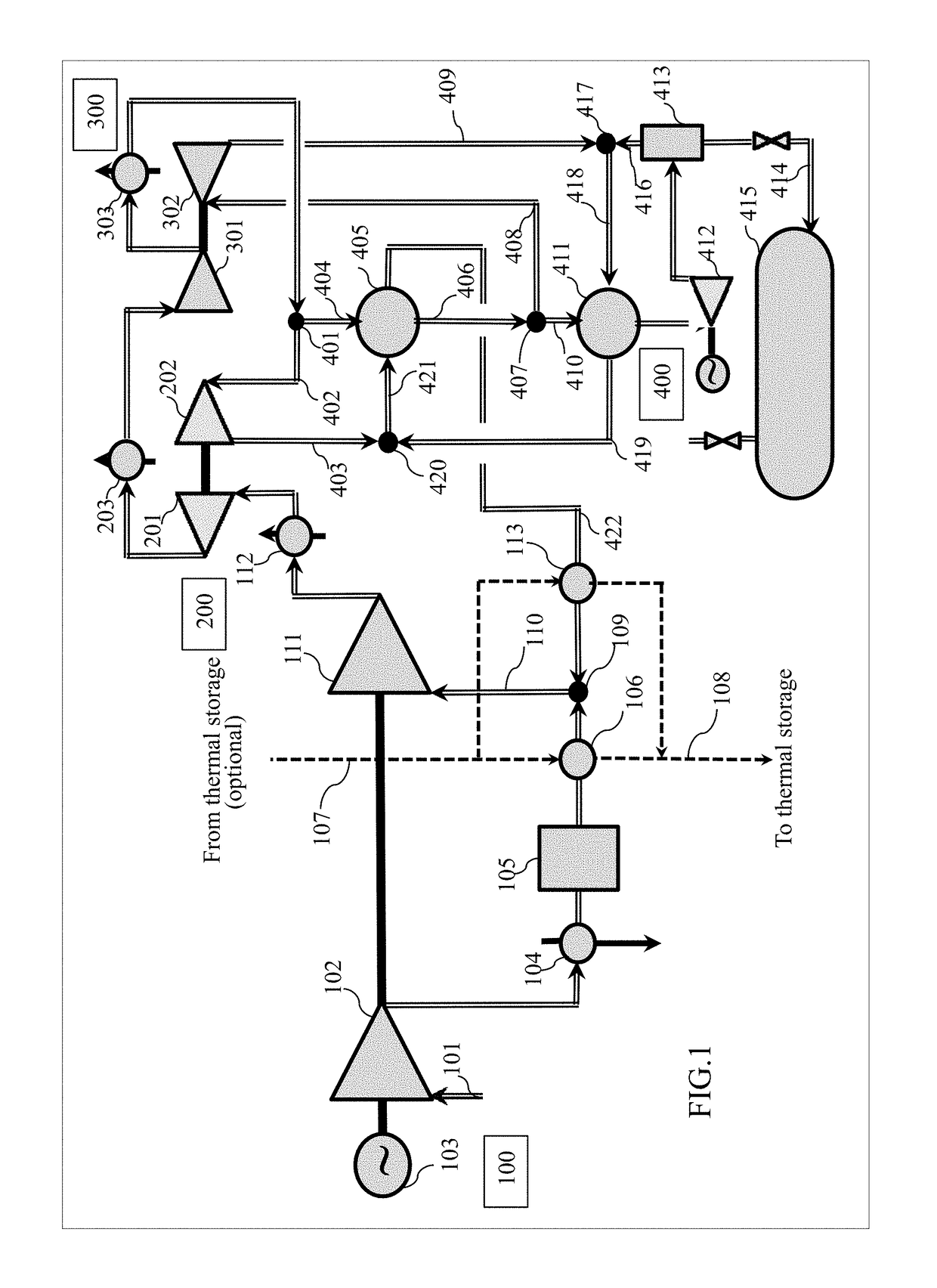

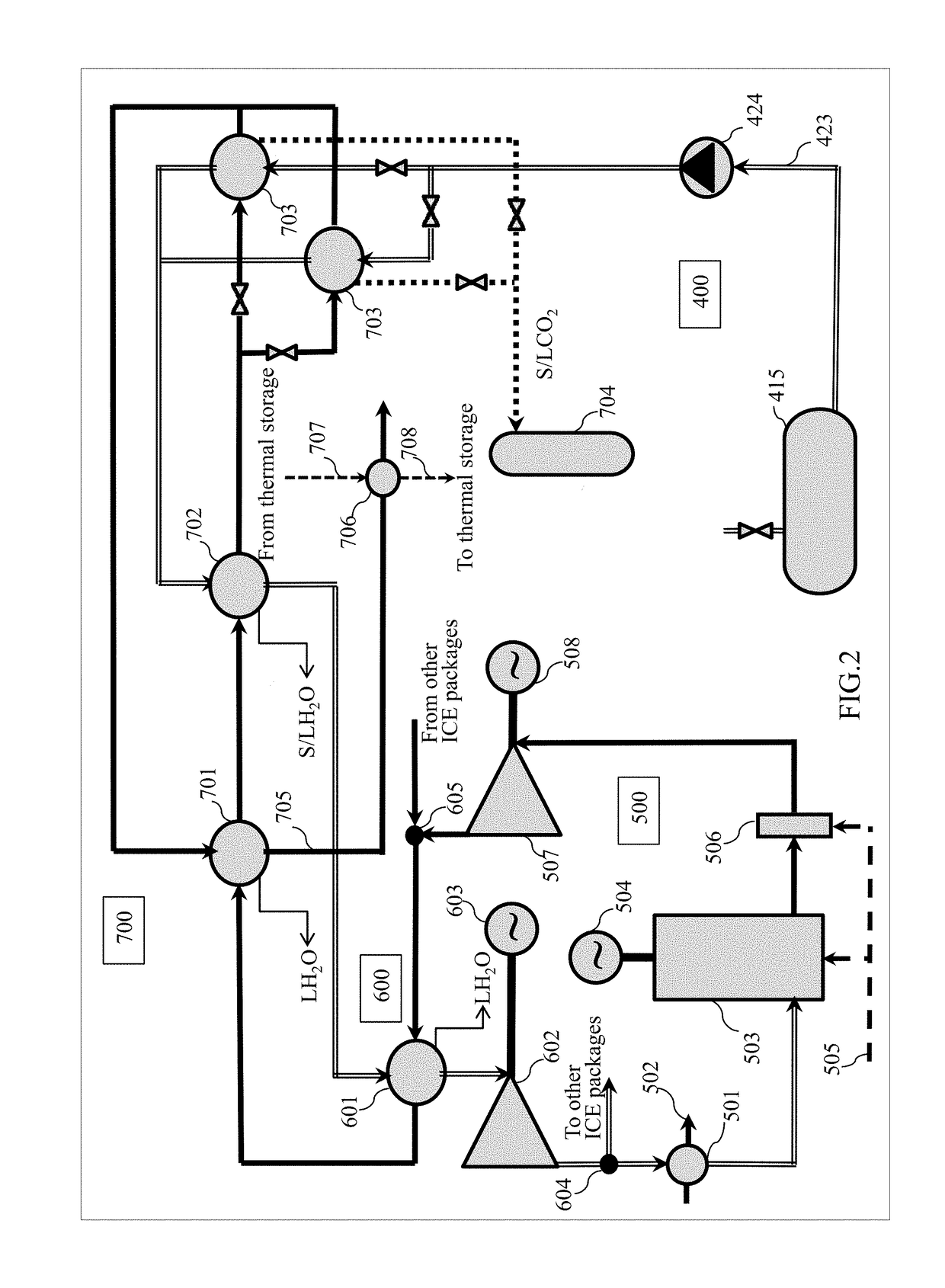

PatentWO2023104451A1

Innovation

- A combined cycle power generation and storage system that integrates a liquid air energy storage system with a combustion engine, heat recovery system, and air expansion machine, along with a separation system using a reverse Brayton cycle to separate and manage carbon dioxide, enhancing energy recovery and reducing emissions.

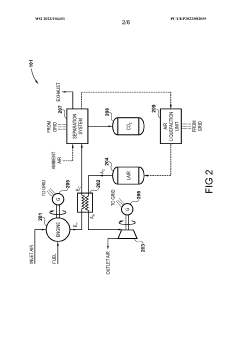

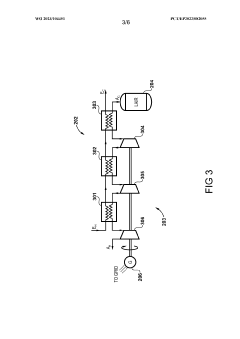

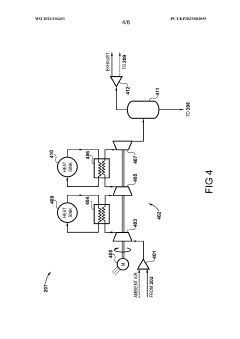

Method for Liquid Air Energy Storage with Fueled and Zero Carbon Emitting Power Output Augmentation

PatentActiveUS20180221807A1

Innovation

- The method involves using a fueled supercharged reciprocating Internal Combustion Engine (ICE) for power augmentation, cryogenic carbon dioxide capture, and efficient energy storage by pumping liquid air to high pressures, with a multi-stage turbo-expander system and recuperative heat recovery to enhance energy output and capture efficiency while minimizing carbon emissions.

Environmental Impact and Sustainability Considerations

The environmental footprint of aviation propulsion systems has become a critical consideration in the aerospace industry, with increasing regulatory pressure and public awareness driving the need for more sustainable solutions. LSA (Liquid Air Cycle) engines and conventional jet engines present distinctly different environmental profiles that merit thorough examination.

LSA engines demonstrate significant advantages in emissions reduction compared to traditional jet engines. By utilizing atmospheric air as the primary working fluid, these systems produce substantially lower carbon dioxide emissions during operation. Studies indicate potential reductions of 30-45% in greenhouse gas emissions compared to conventional turbofan engines of similar thrust ratings. Additionally, LSA technology produces virtually no nitrogen oxide (NOx) emissions during cruise operation, addressing one of the most environmentally damaging aspects of high-altitude jet engine operation.

Noise pollution represents another critical environmental metric where LSA engines demonstrate superior performance. The thermodynamic cycle of LSA engines inherently produces lower exhaust velocities, resulting in noise reductions of approximately 15-20 decibels compared to conventional jet engines. This characteristic makes LSA technology particularly attractive for urban air mobility applications and operations near populated areas.

Resource consumption patterns differ significantly between these propulsion technologies. While jet engines rely heavily on refined petroleum products, LSA engines can potentially operate using electricity from renewable sources for the liquefaction process. This pathway offers a potential route to carbon-neutral aviation when paired with sustainable energy infrastructure. Furthermore, LSA systems require fewer rare earth elements and specialized materials in their construction, reducing the environmental impact associated with mining and processing these resources.

Life cycle assessment (LCA) studies comparing these technologies reveal important sustainability considerations beyond operational emissions. Jet engines typically demonstrate higher manufacturing-phase environmental impacts due to the complex metallurgy required for high-temperature operation. Conversely, LSA engines may present higher impacts during the use phase due to energy requirements for air liquefaction, though this balance shifts favorably when renewable energy sources are employed.

End-of-life considerations also favor LSA technology, with simpler material separation and higher recyclability rates for major components. The absence of fuel combustion residues and lower operating temperatures result in less material degradation over the service life, potentially extending useful component lifespans by 15-25% compared to conventional jet engine parts.

LSA engines demonstrate significant advantages in emissions reduction compared to traditional jet engines. By utilizing atmospheric air as the primary working fluid, these systems produce substantially lower carbon dioxide emissions during operation. Studies indicate potential reductions of 30-45% in greenhouse gas emissions compared to conventional turbofan engines of similar thrust ratings. Additionally, LSA technology produces virtually no nitrogen oxide (NOx) emissions during cruise operation, addressing one of the most environmentally damaging aspects of high-altitude jet engine operation.

Noise pollution represents another critical environmental metric where LSA engines demonstrate superior performance. The thermodynamic cycle of LSA engines inherently produces lower exhaust velocities, resulting in noise reductions of approximately 15-20 decibels compared to conventional jet engines. This characteristic makes LSA technology particularly attractive for urban air mobility applications and operations near populated areas.

Resource consumption patterns differ significantly between these propulsion technologies. While jet engines rely heavily on refined petroleum products, LSA engines can potentially operate using electricity from renewable sources for the liquefaction process. This pathway offers a potential route to carbon-neutral aviation when paired with sustainable energy infrastructure. Furthermore, LSA systems require fewer rare earth elements and specialized materials in their construction, reducing the environmental impact associated with mining and processing these resources.

Life cycle assessment (LCA) studies comparing these technologies reveal important sustainability considerations beyond operational emissions. Jet engines typically demonstrate higher manufacturing-phase environmental impacts due to the complex metallurgy required for high-temperature operation. Conversely, LSA engines may present higher impacts during the use phase due to energy requirements for air liquefaction, though this balance shifts favorably when renewable energy sources are employed.

End-of-life considerations also favor LSA technology, with simpler material separation and higher recyclability rates for major components. The absence of fuel combustion residues and lower operating temperatures result in less material degradation over the service life, potentially extending useful component lifespans by 15-25% compared to conventional jet engine parts.

Regulatory Framework for Aircraft Engine Certification

The regulatory landscape for aircraft engine certification represents a complex framework of standards, protocols, and compliance requirements established by international and national aviation authorities. For LSA (Light Sport Aircraft) engines and conventional jet engines, these certification processes differ significantly due to their distinct operational parameters, safety considerations, and environmental impacts.

The Federal Aviation Administration (FAA) in the United States and the European Union Aviation Safety Agency (EASA) have established comprehensive certification standards for aircraft engines. For jet engines, these include FAR Part 33 (FAA) and CS-E (EASA), which mandate rigorous testing for performance, durability, reliability, and safety under extreme conditions. These regulations require extensive documentation of design specifications, manufacturing processes, and quality control procedures.

LSA engines, by contrast, operate under less stringent certification requirements, typically following ASTM F2339 standards. This framework acknowledges the lower operational demands and reduced risk profile of light sport aircraft while still ensuring adequate safety margins. The certification process emphasizes simplicity, affordability, and accessibility for small manufacturers and recreational pilots.

Environmental considerations have become increasingly prominent in engine certification frameworks. Current regulations impose strict limits on emissions of nitrogen oxides (NOx), carbon monoxide, unburned hydrocarbons, and particulate matter. The International Civil Aviation Organization (ICAO) has established global standards through Annex 16, which both the FAA and EASA have incorporated into their certification requirements.

Noise certification requirements also differ significantly between engine types. Jet engines must comply with Stage 5 noise standards under FAR Part 36, requiring sophisticated noise reduction technologies. LSA engines face less stringent noise requirements, though local regulations may impose additional restrictions in noise-sensitive areas.

The certification timeline and cost implications vary dramatically between engine types. Jet engine certification typically requires 5-7 years and investments exceeding $50 million, while LSA engine certification can be completed in 1-2 years at a fraction of the cost. This disparity reflects the fundamental differences in complexity, performance expectations, and safety implications between these propulsion systems.

Recent regulatory trends indicate a movement toward performance-based certification standards rather than prescriptive requirements, potentially allowing for more innovative approaches to efficiency improvements in both engine categories while maintaining rigorous safety standards.

The Federal Aviation Administration (FAA) in the United States and the European Union Aviation Safety Agency (EASA) have established comprehensive certification standards for aircraft engines. For jet engines, these include FAR Part 33 (FAA) and CS-E (EASA), which mandate rigorous testing for performance, durability, reliability, and safety under extreme conditions. These regulations require extensive documentation of design specifications, manufacturing processes, and quality control procedures.

LSA engines, by contrast, operate under less stringent certification requirements, typically following ASTM F2339 standards. This framework acknowledges the lower operational demands and reduced risk profile of light sport aircraft while still ensuring adequate safety margins. The certification process emphasizes simplicity, affordability, and accessibility for small manufacturers and recreational pilots.

Environmental considerations have become increasingly prominent in engine certification frameworks. Current regulations impose strict limits on emissions of nitrogen oxides (NOx), carbon monoxide, unburned hydrocarbons, and particulate matter. The International Civil Aviation Organization (ICAO) has established global standards through Annex 16, which both the FAA and EASA have incorporated into their certification requirements.

Noise certification requirements also differ significantly between engine types. Jet engines must comply with Stage 5 noise standards under FAR Part 36, requiring sophisticated noise reduction technologies. LSA engines face less stringent noise requirements, though local regulations may impose additional restrictions in noise-sensitive areas.

The certification timeline and cost implications vary dramatically between engine types. Jet engine certification typically requires 5-7 years and investments exceeding $50 million, while LSA engine certification can be completed in 1-2 years at a fraction of the cost. This disparity reflects the fundamental differences in complexity, performance expectations, and safety implications between these propulsion systems.

Recent regulatory trends indicate a movement toward performance-based certification standards rather than prescriptive requirements, potentially allowing for more innovative approaches to efficiency improvements in both engine categories while maintaining rigorous safety standards.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!