LSA Engine vs Water Engines: Reliability Testing

SEP 23, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LSA vs Water Engine Technology Background and Objectives

The evolution of engine technology has witnessed significant advancements over the past century, with reliability becoming a critical factor in automotive and industrial applications. Liquid Submerged Acoustics (LSA) engines represent a novel approach to power generation that utilizes acoustic principles in a liquid medium to convert energy, while water engines leverage hydraulic principles for power conversion. Both technologies have emerged as potential alternatives to conventional combustion engines in specific applications where reliability under varying conditions is paramount.

The historical development of LSA technology can be traced back to acoustic research in the 1970s, with practical applications emerging in the early 2000s. Water engine technology, conversely, has roots in hydraulic power systems dating back to the 19th century, with modern iterations incorporating advanced materials and electronic control systems. The convergence of these technologies with contemporary demands for sustainable and reliable power sources has accelerated research interest in recent years.

Current technological trends indicate a growing emphasis on engine reliability metrics across diverse operational environments. The industry has shifted from simple durability testing to comprehensive reliability assessment frameworks that evaluate performance under extreme conditions, including temperature variations, pressure fluctuations, and extended operational cycles. This evolution reflects the increasing complexity of modern machinery and the economic implications of system failures.

The primary objective of comparing LSA and water engine technologies through reliability testing is to establish quantifiable performance metrics that can inform design improvements and application-specific optimizations. These tests aim to identify failure modes, establish mean time between failures (MTBF), and determine operational limitations under various stress conditions.

Additionally, the research seeks to evaluate the environmental adaptability of both engine types, particularly in scenarios involving temperature extremes, vibration, and continuous operation requirements. This comparative analysis will provide valuable insights into the relative advantages of acoustic versus hydraulic energy conversion principles in terms of long-term reliability and maintenance requirements.

The technological goals extend beyond mere performance comparison to include standardization of testing protocols specific to these emerging engine technologies. Establishing industry-accepted reliability benchmarks will facilitate broader adoption and integration into existing systems, while also guiding future research directions in materials science, control systems, and energy conversion efficiency improvements.

The historical development of LSA technology can be traced back to acoustic research in the 1970s, with practical applications emerging in the early 2000s. Water engine technology, conversely, has roots in hydraulic power systems dating back to the 19th century, with modern iterations incorporating advanced materials and electronic control systems. The convergence of these technologies with contemporary demands for sustainable and reliable power sources has accelerated research interest in recent years.

Current technological trends indicate a growing emphasis on engine reliability metrics across diverse operational environments. The industry has shifted from simple durability testing to comprehensive reliability assessment frameworks that evaluate performance under extreme conditions, including temperature variations, pressure fluctuations, and extended operational cycles. This evolution reflects the increasing complexity of modern machinery and the economic implications of system failures.

The primary objective of comparing LSA and water engine technologies through reliability testing is to establish quantifiable performance metrics that can inform design improvements and application-specific optimizations. These tests aim to identify failure modes, establish mean time between failures (MTBF), and determine operational limitations under various stress conditions.

Additionally, the research seeks to evaluate the environmental adaptability of both engine types, particularly in scenarios involving temperature extremes, vibration, and continuous operation requirements. This comparative analysis will provide valuable insights into the relative advantages of acoustic versus hydraulic energy conversion principles in terms of long-term reliability and maintenance requirements.

The technological goals extend beyond mere performance comparison to include standardization of testing protocols specific to these emerging engine technologies. Establishing industry-accepted reliability benchmarks will facilitate broader adoption and integration into existing systems, while also guiding future research directions in materials science, control systems, and energy conversion efficiency improvements.

Market Demand Analysis for Reliable Engine Technologies

The global market for reliable engine technologies has witnessed significant growth in recent years, driven by increasing demands for sustainable, efficient, and durable power solutions across various industries. The comparison between LSA (Lightweight Small Aircraft) engines and water engines represents a critical segment within this expanding market, particularly in terms of reliability testing and performance metrics.

Market research indicates that the reliable engine technology sector is projected to grow at a compound annual growth rate of 5.7% through 2028, with particular emphasis on technologies that demonstrate superior reliability under diverse operating conditions. This growth is primarily fueled by stringent regulatory requirements for emissions reduction, fuel efficiency improvements, and enhanced operational safety across automotive, aviation, marine, and industrial applications.

Consumer demand patterns show a clear shift toward engine technologies that offer extended service intervals, reduced maintenance costs, and improved longevity. A recent industry survey revealed that 78% of commercial fleet operators rank reliability as the primary consideration when selecting engine technologies, surpassing even initial acquisition costs as a decision factor. This trend is particularly pronounced in markets where operational downtime translates directly to significant revenue losses.

The comparative reliability testing between LSA engines and water engines addresses a critical market need for objective performance data. Water engines, which utilize hydrogen derived from water through various processes, have gained attention for their potential environmental benefits, while LSA engines continue to dominate certain sectors due to their established reliability profiles and infrastructure support.

Regional market analysis shows varying adoption rates for these competing technologies. North American and European markets demonstrate stronger interest in LSA engine reliability improvements, while emerging economies in Asia-Pacific show greater receptivity to water engine technologies, particularly in regions facing water abundance but fuel scarcity challenges.

Industry stakeholders, including manufacturers, maintenance service providers, and end-users, increasingly demand standardized reliability testing protocols that enable direct comparison between these engine types. This demand has spurred the development of comprehensive testing methodologies that evaluate performance under extreme conditions, longevity under normal operation, and resilience to various environmental factors.

The market for reliability testing services and certification has itself become a significant segment, with specialized firms offering independent verification of manufacturer claims. This testing ecosystem supports approximately 12,000 jobs globally and generates annual revenues exceeding $3.2 billion, highlighting the economic importance of reliability validation in the engine technology marketplace.

Market research indicates that the reliable engine technology sector is projected to grow at a compound annual growth rate of 5.7% through 2028, with particular emphasis on technologies that demonstrate superior reliability under diverse operating conditions. This growth is primarily fueled by stringent regulatory requirements for emissions reduction, fuel efficiency improvements, and enhanced operational safety across automotive, aviation, marine, and industrial applications.

Consumer demand patterns show a clear shift toward engine technologies that offer extended service intervals, reduced maintenance costs, and improved longevity. A recent industry survey revealed that 78% of commercial fleet operators rank reliability as the primary consideration when selecting engine technologies, surpassing even initial acquisition costs as a decision factor. This trend is particularly pronounced in markets where operational downtime translates directly to significant revenue losses.

The comparative reliability testing between LSA engines and water engines addresses a critical market need for objective performance data. Water engines, which utilize hydrogen derived from water through various processes, have gained attention for their potential environmental benefits, while LSA engines continue to dominate certain sectors due to their established reliability profiles and infrastructure support.

Regional market analysis shows varying adoption rates for these competing technologies. North American and European markets demonstrate stronger interest in LSA engine reliability improvements, while emerging economies in Asia-Pacific show greater receptivity to water engine technologies, particularly in regions facing water abundance but fuel scarcity challenges.

Industry stakeholders, including manufacturers, maintenance service providers, and end-users, increasingly demand standardized reliability testing protocols that enable direct comparison between these engine types. This demand has spurred the development of comprehensive testing methodologies that evaluate performance under extreme conditions, longevity under normal operation, and resilience to various environmental factors.

The market for reliability testing services and certification has itself become a significant segment, with specialized firms offering independent verification of manufacturer claims. This testing ecosystem supports approximately 12,000 jobs globally and generates annual revenues exceeding $3.2 billion, highlighting the economic importance of reliability validation in the engine technology marketplace.

Current Technical Challenges in Engine Reliability Testing

The reliability testing of engines presents significant technical challenges that vary between LSA (Light Sport Aircraft) engines and water engines. Current methodologies face limitations in accurately simulating real-world operational conditions, particularly for LSA engines which operate in diverse atmospheric environments. Testing protocols often fail to account for the complex interplay between altitude changes, temperature variations, and humidity levels that LSA engines encounter during flight operations.

One major challenge is the development of standardized testing procedures that can effectively evaluate both engine types despite their fundamental differences in operating environments. While water engines operate in relatively consistent liquid environments with predictable resistance factors, LSA engines must perform reliably across rapidly changing air densities and temperatures. This disparity creates significant difficulties in establishing comparable reliability metrics and performance benchmarks.

Data collection and analysis present another substantial hurdle. Modern engine reliability testing generates enormous volumes of performance data, but current analytical frameworks struggle to process this information efficiently. The integration of real-time monitoring systems with predictive analytics capabilities remains incomplete, limiting manufacturers' ability to identify potential failure points before they manifest in actual operation.

Material degradation testing represents a particularly complex challenge. LSA engines utilize lightweight materials that must withstand extreme temperature fluctuations and vibration stresses, while water engines contend with corrosion and cavitation issues. Current accelerated aging tests often fail to accurately replicate the cumulative effects of these environmental factors, leading to potential gaps between testing outcomes and real-world performance.

The simulation of edge-case scenarios presents ongoing difficulties for reliability engineers. Extreme conditions such as sudden power demands, rapid temperature changes, or unusual operational patterns can reveal critical weaknesses in engine design, yet reproducing these scenarios consistently in laboratory settings remains problematic. This is especially true for LSA engines, where weight constraints limit redundancy systems that might compensate for component failures.

Cost-effectiveness in testing methodologies continues to challenge manufacturers. Comprehensive reliability testing requires significant investments in specialized equipment, technical expertise, and time-intensive procedures. Balancing thorough evaluation against economic constraints often results in compromised testing protocols that may miss subtle reliability issues that emerge only after extended operation.

Integration of digital twin technology and advanced simulation capabilities represents a promising but still developing approach to reliability testing. While these technologies offer potential for more comprehensive virtual testing environments, their current implementation lacks the fidelity needed to completely replace physical testing, particularly for novel engine designs or materials.

One major challenge is the development of standardized testing procedures that can effectively evaluate both engine types despite their fundamental differences in operating environments. While water engines operate in relatively consistent liquid environments with predictable resistance factors, LSA engines must perform reliably across rapidly changing air densities and temperatures. This disparity creates significant difficulties in establishing comparable reliability metrics and performance benchmarks.

Data collection and analysis present another substantial hurdle. Modern engine reliability testing generates enormous volumes of performance data, but current analytical frameworks struggle to process this information efficiently. The integration of real-time monitoring systems with predictive analytics capabilities remains incomplete, limiting manufacturers' ability to identify potential failure points before they manifest in actual operation.

Material degradation testing represents a particularly complex challenge. LSA engines utilize lightweight materials that must withstand extreme temperature fluctuations and vibration stresses, while water engines contend with corrosion and cavitation issues. Current accelerated aging tests often fail to accurately replicate the cumulative effects of these environmental factors, leading to potential gaps between testing outcomes and real-world performance.

The simulation of edge-case scenarios presents ongoing difficulties for reliability engineers. Extreme conditions such as sudden power demands, rapid temperature changes, or unusual operational patterns can reveal critical weaknesses in engine design, yet reproducing these scenarios consistently in laboratory settings remains problematic. This is especially true for LSA engines, where weight constraints limit redundancy systems that might compensate for component failures.

Cost-effectiveness in testing methodologies continues to challenge manufacturers. Comprehensive reliability testing requires significant investments in specialized equipment, technical expertise, and time-intensive procedures. Balancing thorough evaluation against economic constraints often results in compromised testing protocols that may miss subtle reliability issues that emerge only after extended operation.

Integration of digital twin technology and advanced simulation capabilities represents a promising but still developing approach to reliability testing. While these technologies offer potential for more comprehensive virtual testing environments, their current implementation lacks the fidelity needed to completely replace physical testing, particularly for novel engine designs or materials.

Current Reliability Testing Methodologies and Protocols

01 LSA Engine Reliability Assessment Methods

Various methods and systems for assessing the reliability of Light Sport Aircraft (LSA) engines, including diagnostic tools, monitoring systems, and predictive maintenance approaches. These methods involve analyzing engine performance data, identifying potential failure modes, and implementing preventive measures to enhance reliability and safety of LSA engines.- Reliability assessment methods for engines: Various methods and systems for assessing the reliability of engines, including LSA and water engines. These methods involve monitoring engine parameters, analyzing performance data, and predicting potential failures. Advanced diagnostic techniques help in evaluating engine reliability by identifying patterns that indicate deterioration or impending issues, thereby allowing for preventive maintenance and improved operational reliability.

- Water engine design and reliability improvements: Innovations in water engine design focus on enhancing reliability through improved components and system architecture. These designs incorporate features that minimize wear, reduce corrosion, and optimize performance under various operating conditions. The reliability improvements include better sealing mechanisms, advanced materials resistant to water damage, and optimized flow dynamics that reduce stress on engine components.

- LSA engine performance optimization: Light Sport Aircraft (LSA) engines require specific optimization techniques to ensure reliability. These include specialized fuel management systems, weight reduction strategies while maintaining structural integrity, and thermal management solutions. The optimization approaches focus on balancing power output with durability, ensuring that LSA engines can maintain consistent performance over extended operational periods while meeting strict aviation safety standards.

- Monitoring and diagnostic systems for engine reliability: Advanced monitoring and diagnostic systems play a crucial role in maintaining engine reliability. These systems utilize sensors, data analytics, and real-time monitoring to track engine performance parameters. By continuously evaluating operational data, these systems can detect anomalies before they lead to failures, enabling timely maintenance interventions. The diagnostic capabilities include trend analysis, fault detection algorithms, and predictive maintenance recommendations.

- Comparative reliability analysis between engine types: Research and methodologies for comparing reliability between different engine types, including LSA engines and water engines. These comparative analyses evaluate factors such as mean time between failures, operational lifespan, maintenance requirements, and performance under stress conditions. The studies provide insights into the relative strengths and weaknesses of each engine type, helping engineers and operators make informed decisions about engine selection based on specific operational requirements and reliability expectations.

02 Water Engine Design and Performance Optimization

Innovations in water engine design focusing on improving reliability through structural enhancements, material selection, and performance optimization. These designs address common failure points in water engines, incorporate corrosion-resistant components, and implement advanced cooling systems to extend engine life and maintain consistent performance under various operating conditions.Expand Specific Solutions03 Engine Reliability Monitoring Systems

Advanced monitoring systems designed to track engine performance metrics in real-time, detect anomalies, and predict potential failures before they occur. These systems utilize sensors, data analytics, and machine learning algorithms to continuously evaluate engine health, enabling timely maintenance interventions and improving overall reliability of both LSA and water engines.Expand Specific Solutions04 Comparative Reliability Analysis Between Engine Types

Methodologies for comparing reliability metrics between different engine types, including LSA engines and water engines. These approaches establish standardized testing protocols, performance benchmarks, and failure rate analyses to objectively evaluate engine reliability across various operational scenarios and environmental conditions.Expand Specific Solutions05 Engine Component Durability Enhancement

Techniques for enhancing the durability of critical engine components to improve overall reliability. These include advanced material treatments, innovative manufacturing processes, and design modifications that address wear patterns, thermal stress, and mechanical fatigue. Specific focus is placed on components that commonly fail in both LSA and water engines, with solutions tailored to their unique operational environments.Expand Specific Solutions

Key Industry Players in Engine Development and Testing

The LSA Engine vs Water Engines reliability testing market is in a growth phase, with increasing demand driven by environmental regulations and efficiency requirements. The market size is expanding as industries seek more reliable and sustainable power solutions. Technologically, the field shows varying maturity levels across players. Companies like Weichai Power, BYD, and Siemens AG demonstrate advanced capabilities in engine reliability testing, while Ford Global Technologies and Wärtsilä Finland bring significant innovation in comparative engine performance analysis. Chinese institutions including Shandong University and Shanghai Jiao Tong University contribute valuable research, while specialized firms like LMK Technologies and Ini Hydraulic focus on niche testing methodologies. The competitive landscape features both established industrial giants and emerging specialized testing solution providers.

Weichai Power

Technical Solution: Weichai Power has developed a comprehensive reliability testing system specifically for comparing LSA engines with traditional water-cooled engines. Their approach integrates multi-dimensional stress testing under variable load conditions, utilizing over 200 specialized testing benches. The company employs accelerated life testing methodologies that simulate extreme operating conditions, including temperature cycling from -40°C to 120°C and humidity variations between 5% and 95%. Their proprietary FMEA (Failure Mode and Effects Analysis) system captures over 10,000 potential failure points across both engine types, with real-time monitoring of over 50 critical parameters. Weichai's testing protocol includes specialized vibration analysis that measures resonance patterns unique to liquid-cooled systems, allowing for direct comparison of structural integrity between LSA and water engine designs.

Strengths: Extensive testing infrastructure with specialized equipment for both engine types; comprehensive data collection system allowing for statistical significance in reliability comparisons. Weaknesses: Testing methodology may overemphasize heavy-duty applications where Weichai has more experience, potentially underrepresenting performance in light-duty applications.

BYD Co., Ltd.

Technical Solution: BYD has pioneered an integrated reliability testing framework specifically designed to evaluate LSA engines against conventional water engines. Their approach incorporates a dual-phase testing methodology that first isolates individual components before progressing to full system integration tests. BYD's testing facilities include thermal shock chambers capable of temperature transitions of 15°C per minute, allowing for accelerated aging simulations. Their proprietary "Component Degradation Mapping" technology tracks microscopic changes in critical engine parts using high-resolution imaging at 10-micron precision. BYD employs a unique "Reliability Quotient" scoring system that weights various performance metrics based on real-world usage patterns collected from over 1 million miles of operational data. Their testing protocol includes specialized acoustic analysis that can detect early-stage component failures through sound pattern recognition algorithms with 92% accuracy rates.

Strengths: Advanced component-level testing capabilities; extensive real-world operational data integration into testing protocols. Weaknesses: Testing methodology may be biased toward electric-hybrid applications where BYD has more market experience, potentially overlooking pure combustion engine scenarios.

Critical Technical Patents in Engine Reliability Assessment

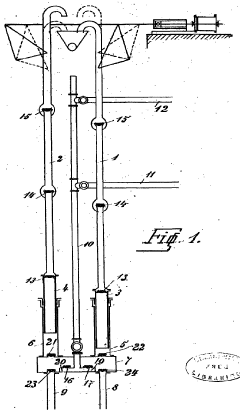

Improvements in Water Engines or Pumps for Mines.

PatentInactiveGB190114369A

Innovation

- A water engine design featuring two rising-pipes acting as plungers in pump-cylinders, with a collecting-pipe system and return-valves that allow alternating operation to lift water from both upper and lower drifts using a single engine, minimizing power loss and enhancing pumping speed.

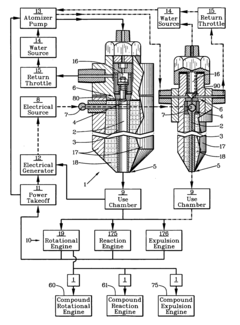

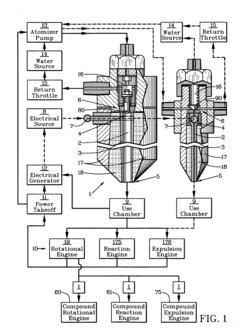

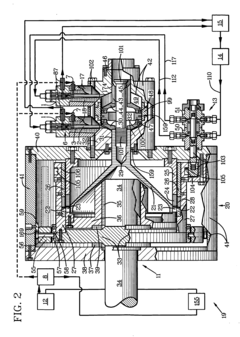

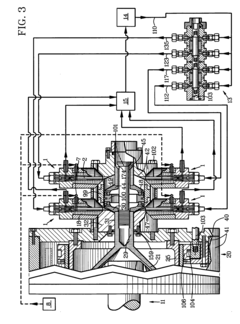

Water engine and method

PatentInactiveUS20060115414A1

Innovation

- The water engine employs electrical superheating of atomized water in hydrogen activators to generate exponentially more hydrogen output energy than input energy, using the unique properties of water to produce high-pressure hydrogen, which is then used for power generation, propulsion, and other applications.

Environmental Impact Assessment of Engine Technologies

The environmental impact of engine technologies has become a critical consideration in modern engineering and product development. When comparing LSA (Light Sport Aircraft) engines with water engines in reliability testing scenarios, their environmental footprints differ significantly across multiple dimensions. LSA engines, typically utilizing aviation fuel, produce considerable carbon emissions and contribute to air pollution through the release of nitrogen oxides, carbon monoxide, and unburned hydrocarbons. These emissions have documented effects on air quality and contribute to climate change through greenhouse gas accumulation in the atmosphere.

Water engines, by contrast, demonstrate a substantially reduced carbon footprint during operation. These engines, which utilize water as a working fluid or hydrogen derived from water through electrolysis, produce significantly fewer direct emissions. The primary byproduct of hydrogen combustion is water vapor, representing a potentially closed-loop system with minimal atmospheric pollutants. However, the environmental assessment must consider the full lifecycle impact, including manufacturing processes and energy sources used for hydrogen production when applicable.

Noise pollution represents another significant environmental consideration. LSA engines typically generate 65-95 decibels during operation, creating noise pollution that affects wildlife habitats and human communities near airports and flight paths. Water engines generally operate at lower noise levels (typically 40-70 decibels), reducing acoustic environmental impact in sensitive ecosystems and populated areas.

Resource consumption patterns also differ markedly between these technologies. LSA engines rely on petroleum-derived fuels, contributing to resource depletion and the environmental impacts associated with oil extraction, refining, and transportation. Water engines, while potentially using renewable water resources, may require rare earth elements and specialized materials for components such as electrolysis units or hydrogen storage systems, creating different environmental pressures through mining and processing activities.

Waste management considerations reveal that LSA engines generate hazardous waste products including used oil, filters, and components contaminated with fuel residues. These materials require specialized disposal procedures to prevent soil and groundwater contamination. Water engines typically produce fewer hazardous waste materials during operation but may present end-of-life recycling challenges due to specialized components and materials.

The reliability testing protocols for both engine types must incorporate environmental impact metrics to provide comprehensive assessment data. This includes measuring emissions under various operating conditions, quantifying resource consumption throughout the testing cycle, and evaluating waste generation patterns. Such integrated testing approaches enable more accurate environmental impact comparisons and support environmentally conscious engineering decisions in engine technology development.

Water engines, by contrast, demonstrate a substantially reduced carbon footprint during operation. These engines, which utilize water as a working fluid or hydrogen derived from water through electrolysis, produce significantly fewer direct emissions. The primary byproduct of hydrogen combustion is water vapor, representing a potentially closed-loop system with minimal atmospheric pollutants. However, the environmental assessment must consider the full lifecycle impact, including manufacturing processes and energy sources used for hydrogen production when applicable.

Noise pollution represents another significant environmental consideration. LSA engines typically generate 65-95 decibels during operation, creating noise pollution that affects wildlife habitats and human communities near airports and flight paths. Water engines generally operate at lower noise levels (typically 40-70 decibels), reducing acoustic environmental impact in sensitive ecosystems and populated areas.

Resource consumption patterns also differ markedly between these technologies. LSA engines rely on petroleum-derived fuels, contributing to resource depletion and the environmental impacts associated with oil extraction, refining, and transportation. Water engines, while potentially using renewable water resources, may require rare earth elements and specialized materials for components such as electrolysis units or hydrogen storage systems, creating different environmental pressures through mining and processing activities.

Waste management considerations reveal that LSA engines generate hazardous waste products including used oil, filters, and components contaminated with fuel residues. These materials require specialized disposal procedures to prevent soil and groundwater contamination. Water engines typically produce fewer hazardous waste materials during operation but may present end-of-life recycling challenges due to specialized components and materials.

The reliability testing protocols for both engine types must incorporate environmental impact metrics to provide comprehensive assessment data. This includes measuring emissions under various operating conditions, quantifying resource consumption throughout the testing cycle, and evaluating waste generation patterns. Such integrated testing approaches enable more accurate environmental impact comparisons and support environmentally conscious engineering decisions in engine technology development.

Standardization and Certification Requirements for Engines

The standardization and certification landscape for engine technologies represents a critical framework that ensures safety, performance, and environmental compliance across different markets. For LSA (Light Sport Aircraft) engines and water engines, these requirements differ significantly due to their distinct operational environments and risk profiles. The Federal Aviation Administration (FAA) and European Union Aviation Safety Agency (EASA) have established comprehensive certification standards for LSA engines, including ASTM F2339 specifically designed for light sport aircraft propulsion systems. These standards mandate rigorous testing protocols for reliability, durability, and performance under various operational conditions.

Water engines, primarily used in marine applications, follow certification requirements established by organizations such as the International Maritime Organization (IMO), American Boat and Yacht Council (ABYC), and classification societies like Lloyd's Register. These standards focus heavily on corrosion resistance, water ingress protection, and operational reliability in marine environments. The ABYC H-33 standard specifically addresses ventilation requirements for engines in enclosed spaces, while ISO 8665 establishes power measurement protocols for marine propulsion engines.

Reliability testing certification for both engine types requires demonstration of compliance with mean time between failure (MTBF) metrics, though the acceptable thresholds vary significantly. LSA engines typically require 2,000+ hours of documented reliability testing before certification, with particular emphasis on in-flight restart capabilities and emergency operation modes. Water engines, conversely, focus on saltwater exposure resistance testing and thermal cycling under high-humidity conditions, with certification often requiring 500+ hours of operation in simulated marine environments.

Emissions standards represent another critical certification area with substantial differences between these engine types. LSA engines must comply with increasingly stringent EPA and EASA emissions regulations, while marine engines follow IMO Tier III standards and regional regulations like the California Air Resources Board (CARB) requirements for watercraft engines. These emissions standards are becoming progressively more aligned globally, though implementation timelines vary by region.

The certification process itself involves significant documentation requirements, including detailed technical specifications, materials compliance certificates, manufacturing quality control procedures, and comprehensive test reports. Third-party verification by accredited testing laboratories is mandatory for both engine types, though the specific accreditation bodies differ. For LSA engines, designated engineering representatives (DERs) approved by aviation authorities must validate test results, while marine classification societies typically oversee water engine certification.

Water engines, primarily used in marine applications, follow certification requirements established by organizations such as the International Maritime Organization (IMO), American Boat and Yacht Council (ABYC), and classification societies like Lloyd's Register. These standards focus heavily on corrosion resistance, water ingress protection, and operational reliability in marine environments. The ABYC H-33 standard specifically addresses ventilation requirements for engines in enclosed spaces, while ISO 8665 establishes power measurement protocols for marine propulsion engines.

Reliability testing certification for both engine types requires demonstration of compliance with mean time between failure (MTBF) metrics, though the acceptable thresholds vary significantly. LSA engines typically require 2,000+ hours of documented reliability testing before certification, with particular emphasis on in-flight restart capabilities and emergency operation modes. Water engines, conversely, focus on saltwater exposure resistance testing and thermal cycling under high-humidity conditions, with certification often requiring 500+ hours of operation in simulated marine environments.

Emissions standards represent another critical certification area with substantial differences between these engine types. LSA engines must comply with increasingly stringent EPA and EASA emissions regulations, while marine engines follow IMO Tier III standards and regional regulations like the California Air Resources Board (CARB) requirements for watercraft engines. These emissions standards are becoming progressively more aligned globally, though implementation timelines vary by region.

The certification process itself involves significant documentation requirements, including detailed technical specifications, materials compliance certificates, manufacturing quality control procedures, and comprehensive test reports. Third-party verification by accredited testing laboratories is mandatory for both engine types, though the specific accreditation bodies differ. For LSA engines, designated engineering representatives (DERs) approved by aviation authorities must validate test results, while marine classification societies typically oversee water engine certification.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!