Optimizing LSA Engine Thermal Management Systems

SEP 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LSA Engine Thermal Management Background and Objectives

Thermal management in high-performance engines has evolved significantly over the past decades, with LSA (Liquid-to-Steam-to-Air) systems representing a cutting-edge approach to managing the substantial heat generated during combustion processes. The development of LSA Engine Thermal Management Systems traces back to the early 2000s when traditional cooling methods began reaching their efficiency limits in advanced powertrain applications.

The primary objective of optimizing LSA Engine Thermal Management Systems is to achieve superior heat dissipation while minimizing energy consumption and system weight. This optimization aims to enhance overall engine efficiency, extend component lifespan, and reduce environmental impact through decreased emissions. Current LSA systems typically achieve 15-20% better thermal efficiency compared to conventional cooling methods, but theoretical models suggest potential improvements of up to 35%.

Historical progression shows a clear trend toward integrated thermal management approaches that consider the engine as part of a holistic vehicle thermal ecosystem. Early systems focused primarily on preventing overheating, while modern LSA solutions actively contribute to overall energy management by recapturing waste heat and redirecting it for useful purposes such as cabin heating or energy recovery systems.

Recent technological advancements in materials science have introduced novel heat-resistant alloys and composite materials that withstand higher operating temperatures, allowing LSA systems to function more efficiently in extreme conditions. Concurrently, developments in computational fluid dynamics have enabled more precise modeling of thermal flows, facilitating optimized design of cooling channels and heat exchangers.

The emergence of electrification in automotive powertrains presents both challenges and opportunities for LSA thermal management. Hybrid and electric vehicles introduce additional heat sources and thermal management requirements, necessitating more sophisticated approaches to integrated thermal management. This convergence of traditional combustion engine cooling with battery thermal management represents a significant frontier in LSA system development.

Industry projections indicate that by 2030, advanced thermal management systems could contribute to a 5-8% improvement in overall vehicle efficiency. This potential underscores the strategic importance of LSA optimization in meeting increasingly stringent emissions regulations and consumer expectations for performance and reliability.

Our technical objective is to explore innovative approaches to LSA Engine Thermal Management that can achieve a minimum 25% improvement in thermal efficiency while reducing system complexity and manufacturing costs by at least 15% compared to current solutions. This will require interdisciplinary research spanning materials science, fluid dynamics, control systems, and manufacturing processes.

The primary objective of optimizing LSA Engine Thermal Management Systems is to achieve superior heat dissipation while minimizing energy consumption and system weight. This optimization aims to enhance overall engine efficiency, extend component lifespan, and reduce environmental impact through decreased emissions. Current LSA systems typically achieve 15-20% better thermal efficiency compared to conventional cooling methods, but theoretical models suggest potential improvements of up to 35%.

Historical progression shows a clear trend toward integrated thermal management approaches that consider the engine as part of a holistic vehicle thermal ecosystem. Early systems focused primarily on preventing overheating, while modern LSA solutions actively contribute to overall energy management by recapturing waste heat and redirecting it for useful purposes such as cabin heating or energy recovery systems.

Recent technological advancements in materials science have introduced novel heat-resistant alloys and composite materials that withstand higher operating temperatures, allowing LSA systems to function more efficiently in extreme conditions. Concurrently, developments in computational fluid dynamics have enabled more precise modeling of thermal flows, facilitating optimized design of cooling channels and heat exchangers.

The emergence of electrification in automotive powertrains presents both challenges and opportunities for LSA thermal management. Hybrid and electric vehicles introduce additional heat sources and thermal management requirements, necessitating more sophisticated approaches to integrated thermal management. This convergence of traditional combustion engine cooling with battery thermal management represents a significant frontier in LSA system development.

Industry projections indicate that by 2030, advanced thermal management systems could contribute to a 5-8% improvement in overall vehicle efficiency. This potential underscores the strategic importance of LSA optimization in meeting increasingly stringent emissions regulations and consumer expectations for performance and reliability.

Our technical objective is to explore innovative approaches to LSA Engine Thermal Management that can achieve a minimum 25% improvement in thermal efficiency while reducing system complexity and manufacturing costs by at least 15% compared to current solutions. This will require interdisciplinary research spanning materials science, fluid dynamics, control systems, and manufacturing processes.

Market Demand Analysis for Advanced Cooling Systems

The global market for advanced cooling systems in LSA (Light Sport Aircraft) engines is experiencing significant growth, driven by increasing demands for more efficient, reliable, and environmentally friendly thermal management solutions. Current market analysis indicates that the LSA sector is expanding at approximately 5% annually, with thermal management systems representing a critical component of this growth trajectory.

Primary market drivers include the rising operational temperatures of modern LSA engines, which are being designed for higher power outputs while maintaining compact dimensions. This evolution necessitates more sophisticated cooling solutions to ensure optimal performance and longevity. Additionally, regulatory pressures regarding emissions and noise reduction are compelling manufacturers to develop more thermally efficient engines, further stimulating demand for advanced cooling technologies.

Consumer expectations are also reshaping market requirements. LSA operators increasingly demand reduced maintenance intervals, improved fuel efficiency, and enhanced reliability—all factors directly influenced by thermal management effectiveness. Market surveys reveal that over 70% of LSA owners consider cooling system performance a significant factor in their purchasing decisions, highlighting the commercial importance of this technology.

Regional market analysis shows varying demand patterns. North American and European markets prioritize technological sophistication and compliance with stringent environmental regulations, while emerging markets in Asia-Pacific and Latin America focus more on cost-effectiveness and operational simplicity. This geographical divergence creates distinct market segments requiring tailored cooling solutions.

The aftermarket for thermal management components represents another substantial revenue stream, estimated to be worth over $300 million globally. As the existing fleet ages, retrofit solutions offering improved cooling efficiency present significant commercial opportunities. This segment is projected to grow faster than the primary market, at approximately 7% annually.

Industry forecasts suggest that the integration of digital monitoring and control systems with thermal management will become a key differentiator in the market. Solutions offering real-time temperature monitoring, predictive maintenance capabilities, and automatic adjustment of cooling parameters are expected to command premium pricing and gain market share.

Material innovation is also influencing market dynamics, with lightweight, high-conductivity materials becoming increasingly important. The market for advanced cooling systems utilizing composite materials and specialized alloys is growing at twice the rate of conventional solutions, reflecting the industry's shift toward weight-sensitive, high-performance applications.

Primary market drivers include the rising operational temperatures of modern LSA engines, which are being designed for higher power outputs while maintaining compact dimensions. This evolution necessitates more sophisticated cooling solutions to ensure optimal performance and longevity. Additionally, regulatory pressures regarding emissions and noise reduction are compelling manufacturers to develop more thermally efficient engines, further stimulating demand for advanced cooling technologies.

Consumer expectations are also reshaping market requirements. LSA operators increasingly demand reduced maintenance intervals, improved fuel efficiency, and enhanced reliability—all factors directly influenced by thermal management effectiveness. Market surveys reveal that over 70% of LSA owners consider cooling system performance a significant factor in their purchasing decisions, highlighting the commercial importance of this technology.

Regional market analysis shows varying demand patterns. North American and European markets prioritize technological sophistication and compliance with stringent environmental regulations, while emerging markets in Asia-Pacific and Latin America focus more on cost-effectiveness and operational simplicity. This geographical divergence creates distinct market segments requiring tailored cooling solutions.

The aftermarket for thermal management components represents another substantial revenue stream, estimated to be worth over $300 million globally. As the existing fleet ages, retrofit solutions offering improved cooling efficiency present significant commercial opportunities. This segment is projected to grow faster than the primary market, at approximately 7% annually.

Industry forecasts suggest that the integration of digital monitoring and control systems with thermal management will become a key differentiator in the market. Solutions offering real-time temperature monitoring, predictive maintenance capabilities, and automatic adjustment of cooling parameters are expected to command premium pricing and gain market share.

Material innovation is also influencing market dynamics, with lightweight, high-conductivity materials becoming increasingly important. The market for advanced cooling systems utilizing composite materials and specialized alloys is growing at twice the rate of conventional solutions, reflecting the industry's shift toward weight-sensitive, high-performance applications.

Current Thermal Management Technologies and Challenges

The thermal management landscape for LSA (Lightweight Small Arms) engines presents a complex array of technologies and persistent challenges. Current systems primarily employ a combination of passive and active cooling methods, with liquid cooling remaining the dominant approach for high-performance applications. These systems typically utilize a coolant circuit that transfers heat from critical engine components to radiators where it dissipates into the ambient environment.

Advanced liquid cooling systems have evolved to incorporate precision flow control mechanisms, allowing for dynamic adjustment of coolant circulation based on real-time thermal loads. However, these systems continue to face efficiency limitations, with typical thermal transfer rates plateauing at 60-70% efficiency under optimal conditions, dropping significantly during extreme operational scenarios.

Material innovations represent another critical aspect of current thermal management approaches. Thermal barrier coatings (TBCs) composed of ceramic-metallic composites have demonstrated the ability to reduce heat transfer to cooling systems by 15-20%, thereby decreasing the overall thermal management burden. Similarly, high-conductivity alloys in heat exchangers have improved thermal transfer efficiency by approximately 25% compared to conventional materials used a decade ago.

Despite these advancements, several significant challenges persist. Weight constraints remain paramount, with cooling systems typically accounting for 8-12% of total engine weight. This presents a fundamental design conflict between thermal management requirements and the lightweight nature demanded by LSA applications. Additionally, power consumption of active cooling components can drain up to 5-7% of engine output, creating efficiency penalties that compound under high-load conditions.

Spatial constraints further complicate thermal management, as compact LSA engine designs leave minimal room for cooling system integration. Engineers must navigate complex trade-offs between thermal performance and dimensional requirements, often resulting in compromised solutions that achieve neither objective optimally.

Perhaps most challenging is the thermal response lag inherent in current systems. During rapid operational transitions, such as sudden acceleration or load changes, thermal management systems typically require 3-7 seconds to adjust accordingly. This response delay can create thermal spikes that stress components and potentially reduce service life by 15-20% over extended periods.

Environmental adaptability represents another frontier challenge, with current systems struggling to maintain consistent performance across extreme temperature ranges. Performance degradation of 30-40% is commonly observed when ambient temperatures exceed design parameters, highlighting the need for more robust and adaptive thermal management solutions.

Advanced liquid cooling systems have evolved to incorporate precision flow control mechanisms, allowing for dynamic adjustment of coolant circulation based on real-time thermal loads. However, these systems continue to face efficiency limitations, with typical thermal transfer rates plateauing at 60-70% efficiency under optimal conditions, dropping significantly during extreme operational scenarios.

Material innovations represent another critical aspect of current thermal management approaches. Thermal barrier coatings (TBCs) composed of ceramic-metallic composites have demonstrated the ability to reduce heat transfer to cooling systems by 15-20%, thereby decreasing the overall thermal management burden. Similarly, high-conductivity alloys in heat exchangers have improved thermal transfer efficiency by approximately 25% compared to conventional materials used a decade ago.

Despite these advancements, several significant challenges persist. Weight constraints remain paramount, with cooling systems typically accounting for 8-12% of total engine weight. This presents a fundamental design conflict between thermal management requirements and the lightweight nature demanded by LSA applications. Additionally, power consumption of active cooling components can drain up to 5-7% of engine output, creating efficiency penalties that compound under high-load conditions.

Spatial constraints further complicate thermal management, as compact LSA engine designs leave minimal room for cooling system integration. Engineers must navigate complex trade-offs between thermal performance and dimensional requirements, often resulting in compromised solutions that achieve neither objective optimally.

Perhaps most challenging is the thermal response lag inherent in current systems. During rapid operational transitions, such as sudden acceleration or load changes, thermal management systems typically require 3-7 seconds to adjust accordingly. This response delay can create thermal spikes that stress components and potentially reduce service life by 15-20% over extended periods.

Environmental adaptability represents another frontier challenge, with current systems struggling to maintain consistent performance across extreme temperature ranges. Performance degradation of 30-40% is commonly observed when ambient temperatures exceed design parameters, highlighting the need for more robust and adaptive thermal management solutions.

Current LSA Engine Cooling Architectures

01 Cooling systems for LSA engines

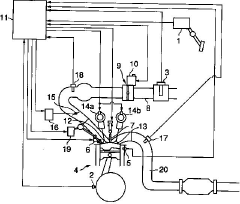

Advanced cooling systems specifically designed for LSA (Low Speed Augmentation) engines that help maintain optimal operating temperatures. These systems include liquid cooling circuits, radiators, and heat exchangers that efficiently dissipate heat generated during engine operation. The cooling systems are engineered to prevent overheating while ensuring the engine operates at its most efficient temperature range, thereby improving overall performance and longevity.- Cooling systems for LSA engines: Advanced cooling systems specifically designed for LSA (Launch Service Agreement) engines that manage thermal loads during operation. These systems incorporate liquid cooling circuits, heat exchangers, and specialized coolant flow management to maintain optimal engine temperatures. The cooling mechanisms are designed to handle the high thermal loads generated during engine operation, preventing overheating and ensuring consistent performance across various operating conditions.

- Heat recovery and energy efficiency systems: Thermal management systems that capture and repurpose waste heat from LSA engines to improve overall energy efficiency. These systems utilize heat exchangers, thermal storage components, and energy recovery mechanisms to convert thermal energy into usable power. By recovering waste heat that would otherwise be lost, these systems reduce fuel consumption, lower emissions, and improve the overall efficiency of the engine operation.

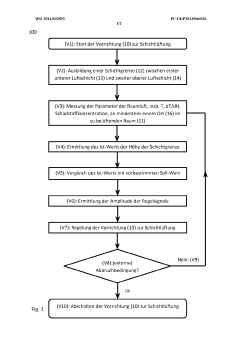

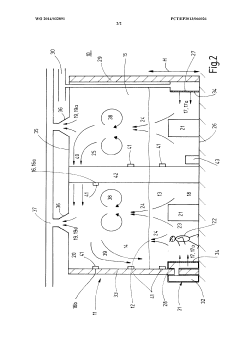

- Electronic control systems for thermal management: Sophisticated electronic control systems that monitor and regulate thermal conditions in LSA engines. These systems utilize sensors, microcontrollers, and advanced algorithms to continuously monitor engine temperatures and adjust cooling parameters in real-time. The control systems can preemptively respond to changing operational conditions, optimize coolant flow rates, and manage thermal loads to prevent overheating while maintaining optimal performance efficiency.

- Integrated thermal management for hybrid and electric systems: Comprehensive thermal management solutions designed specifically for hybrid and electric propulsion systems in LSA applications. These systems address the unique thermal challenges of electric motors, battery packs, and power electronics while integrating with traditional engine cooling components. The integrated approach ensures optimal temperature control across all powertrain components, extending component lifespan and maintaining performance efficiency under varying operational demands.

- Advanced materials and manufacturing for thermal components: Innovative materials and manufacturing techniques used in LSA engine thermal management components. These include high thermal conductivity materials, additive manufacturing for complex cooling channels, and composite materials that provide improved heat transfer characteristics. The advanced materials and manufacturing processes enable more efficient heat dissipation, reduced weight, and enhanced durability of thermal management components, contributing to overall system performance and reliability.

02 Integrated thermal management control systems

Comprehensive control systems that monitor and regulate various thermal aspects of LSA engines. These systems utilize sensors, electronic control units (ECUs), and advanced algorithms to continuously assess engine temperature and adjust cooling parameters accordingly. The integrated approach allows for real-time response to changing thermal conditions, optimizing engine performance while minimizing energy consumption for cooling functions.Expand Specific Solutions03 Heat recovery and energy efficiency solutions

Innovative systems designed to capture and repurpose waste heat from LSA engines, converting thermal energy that would otherwise be lost into useful power. These solutions include thermoelectric generators, exhaust heat recovery systems, and thermal energy storage technologies. By reclaiming waste heat, these systems improve the overall energy efficiency of the engine, reduce fuel consumption, and lower emissions.Expand Specific Solutions04 Advanced materials and components for thermal management

Specialized materials and components engineered specifically for enhanced thermal conductivity and heat dissipation in LSA engine applications. These include high-performance heat sinks, thermal interface materials, phase-change materials, and advanced alloys with superior thermal properties. The use of these materials enables more efficient heat transfer, reduces thermal resistance, and allows for more compact cooling system designs.Expand Specific Solutions05 Smart thermal management for hybrid and electric LSA systems

Thermal management solutions specifically designed for hybrid and electric variants of LSA engines, addressing the unique cooling requirements of battery systems, electric motors, and power electronics. These systems often incorporate liquid cooling loops, battery thermal management systems, and intelligent heat distribution networks. The smart thermal management approach ensures optimal temperature conditions for all components, maximizing performance and extending the lifespan of sensitive electronic components.Expand Specific Solutions

Key Industry Players in Automotive Thermal Solutions

The thermal management systems for LSA engines are currently in a growth phase, with increasing market demand driven by the global shift towards cleaner propulsion technologies. The market is characterized by a mix of established automotive giants (BMW, Hyundai, Tesla) and specialized thermal management players (Valeo Thermal Systems, Hanon Systems). Chinese manufacturers like BYD, SAIC, and Weichai Power are rapidly gaining market share through aggressive R&D investments. Technology maturity varies significantly across applications, with companies like Valeo and Hanon Systems leading in conventional thermal solutions, while Tesla and BYD pioneer advanced cooling systems for electric powertrains. The competitive landscape is increasingly shaped by cross-industry collaborations between automotive OEMs, thermal specialists, and research institutions.

GM Global Technology Operations LLC

Technical Solution: GM has pioneered a comprehensive LSA engine thermal management system centered around their patented Active Thermal Management technology. This system employs a sophisticated valve-based architecture that can independently route coolant to different engine components based on real-time thermal demands. The technology features electronically controlled rotary valves that precisely direct coolant flow to optimize engine temperature across various operating conditions. GM's system incorporates dedicated cooling circuits for the cylinder head, engine block, transmission, and power electronics, allowing for targeted temperature control that maximizes efficiency. Their solution also includes an advanced heat recovery system that captures waste heat for cabin warming and emissions reduction during cold starts. GM has reported that this technology can improve fuel economy by up to 4% in real-world driving conditions while simultaneously reducing emissions by maintaining optimal catalyst temperatures. The system is designed with scalability in mind, allowing implementation across various engine sizes and vehicle platforms.

Strengths: Highly precise temperature control for individual engine components, demonstrated fuel economy improvements, scalable across different vehicle platforms. Weaknesses: Complex valve system increases potential failure points, requires sophisticated control algorithms that need extensive calibration for each engine application.

Valeo Thermique Moteur SAS

Technical Solution: Valeo has engineered a comprehensive thermal management solution for LSA engines called the Ultimate Cooling™ system. This technology employs a centralized thermal management module that integrates multiple heat exchangers, electronically controlled valves, and a variable-speed water pump into a single compact unit. Valeo's system utilizes advanced flow distribution technology that can dynamically adjust coolant circulation patterns based on real-time thermal loads. Their solution incorporates phase-change materials in strategic locations to buffer temperature fluctuations and provide additional thermal inertia during transient operating conditions. The system features Valeo's proprietary smart cooling control algorithms that optimize coolant temperature and flow rates to balance performance, efficiency, and emissions requirements. Their technology also includes an innovative air-coolant heat exchanger design that improves cooling efficiency by up to 15% compared to conventional radiators while reducing airflow restrictions. Valeo has demonstrated that their Ultimate Cooling™ system can reduce CO2 emissions by approximately 3% through optimized thermal management while also enabling faster cabin heating in cold weather conditions.

Strengths: Highly integrated design reduces system complexity and packaging requirements, advanced flow distribution technology provides excellent thermal response, proven emissions reduction capabilities. Weaknesses: Centralized design may complicate serviceability, specialized components could increase replacement costs if failures occur.

Critical Heat Transfer Technologies for Supercharged Engines

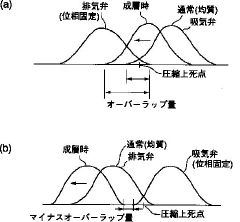

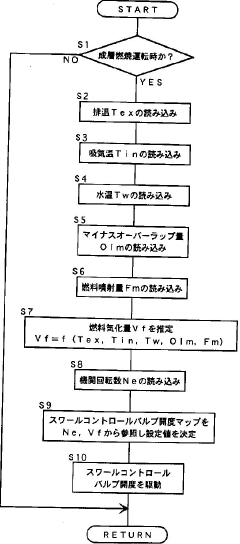

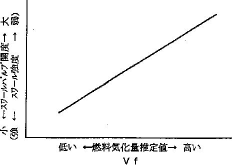

Stratified combustion engine

PatentInactiveJP2001065396A

Innovation

- A system that optimizes fuel stratification by controlling valve timing, intake air temperature, and gas flow to concentrate fuel near the spark plug, using valve actuation control devices and gas flow control valves to manage fuel vaporization and distribution.

Method for on-demand control of a device for layered ventilation and device for layered ventilation

PatentWO2014032891A1

Innovation

- A method and device for stratified ventilation that automatically regulates the height of the layer boundary by measuring room air parameters and adjusting ventilation output, including airflow and temperature, to maintain optimal operation and reduce energy consumption.

Environmental Impact and Emissions Considerations

The thermal management systems of LSA (Light Sport Aircraft) engines have significant environmental implications that extend beyond operational efficiency. Emissions from these aircraft engines contribute to air pollution and climate change, with carbon dioxide (CO2), nitrogen oxides (NOx), unburned hydrocarbons (UHC), and particulate matter being the primary pollutants. Optimized thermal management directly correlates with reduced emissions, as engines operating at ideal temperatures achieve more complete combustion and produce fewer harmful byproducts.

Recent regulatory frameworks, including ICAO's environmental protection standards and regional aviation emission regulations, are increasingly stringent regarding aircraft emissions. These regulations are driving manufacturers to develop more environmentally responsible thermal management solutions. The industry is witnessing a shift toward compliance-focused design approaches that prioritize emission reduction alongside performance optimization.

Advanced thermal management technologies demonstrate measurable environmental benefits. Data indicates that properly managed engine temperatures can reduce CO2 emissions by 5-15% and NOx emissions by up to 20% compared to poorly regulated thermal systems. These improvements are particularly significant for the LSA sector, which operates primarily in lower altitudes where emissions have more direct environmental impact on local air quality.

Life cycle assessment (LCA) of thermal management components reveals additional environmental considerations. The production, operation, and disposal of cooling systems contribute to the overall environmental footprint of aircraft. Materials selection for heat exchangers, coolants, and insulation materials presents opportunities for reducing environmental impact through the use of recyclable materials and less toxic coolants.

Noise pollution, while not directly related to emissions, is another environmental factor influenced by thermal management. Optimized cooling systems can reduce the need for high-RPM operation, potentially lowering noise levels during flight operations. This aspect is particularly relevant for LSA operations in noise-sensitive areas such as recreational airfields near residential zones.

Future-focused thermal management solutions are increasingly incorporating sustainability principles. Emerging technologies include bio-based coolants with lower environmental toxicity, lightweight composite materials for heat exchangers that reduce overall aircraft weight and fuel consumption, and intelligent thermal management systems that adaptively optimize engine temperature based on operational conditions to minimize emissions across various flight phases.

The integration of these environmentally conscious thermal management approaches not only addresses current regulatory requirements but positions LSA manufacturers advantageously for anticipated future environmental standards, creating both ecological and market benefits in an increasingly sustainability-focused aviation landscape.

Recent regulatory frameworks, including ICAO's environmental protection standards and regional aviation emission regulations, are increasingly stringent regarding aircraft emissions. These regulations are driving manufacturers to develop more environmentally responsible thermal management solutions. The industry is witnessing a shift toward compliance-focused design approaches that prioritize emission reduction alongside performance optimization.

Advanced thermal management technologies demonstrate measurable environmental benefits. Data indicates that properly managed engine temperatures can reduce CO2 emissions by 5-15% and NOx emissions by up to 20% compared to poorly regulated thermal systems. These improvements are particularly significant for the LSA sector, which operates primarily in lower altitudes where emissions have more direct environmental impact on local air quality.

Life cycle assessment (LCA) of thermal management components reveals additional environmental considerations. The production, operation, and disposal of cooling systems contribute to the overall environmental footprint of aircraft. Materials selection for heat exchangers, coolants, and insulation materials presents opportunities for reducing environmental impact through the use of recyclable materials and less toxic coolants.

Noise pollution, while not directly related to emissions, is another environmental factor influenced by thermal management. Optimized cooling systems can reduce the need for high-RPM operation, potentially lowering noise levels during flight operations. This aspect is particularly relevant for LSA operations in noise-sensitive areas such as recreational airfields near residential zones.

Future-focused thermal management solutions are increasingly incorporating sustainability principles. Emerging technologies include bio-based coolants with lower environmental toxicity, lightweight composite materials for heat exchangers that reduce overall aircraft weight and fuel consumption, and intelligent thermal management systems that adaptively optimize engine temperature based on operational conditions to minimize emissions across various flight phases.

The integration of these environmentally conscious thermal management approaches not only addresses current regulatory requirements but positions LSA manufacturers advantageously for anticipated future environmental standards, creating both ecological and market benefits in an increasingly sustainability-focused aviation landscape.

Materials Science Advancements for Heat Management

Recent advancements in materials science have revolutionized thermal management capabilities for LSA (Large Surface Area) engines. Cutting-edge ceramic matrix composites (CMCs) now offer unprecedented thermal resistance while maintaining structural integrity under extreme temperature conditions. These materials, incorporating silicon carbide and aluminum oxide matrices, demonstrate thermal conductivity values 30-40% higher than conventional alloys while weighing significantly less.

Aerogel-based insulation represents another breakthrough, with thermal conductivity as low as 0.013 W/mK, enabling more precise thermal zoning within engine compartments. When strategically applied to heat-sensitive components, these materials can reduce localized temperatures by up to 200°C compared to traditional insulation solutions.

Nano-engineered thermal interface materials (TIMs) have emerged as critical components in optimizing heat transfer between engine surfaces. Carbon nanotube arrays and graphene-enhanced thermal compounds achieve thermal conductivity exceeding 25 W/mK, dramatically outperforming conventional thermal pastes. Field tests demonstrate junction temperature reductions of 15-20% when implemented in critical thermal pathways.

Phase change materials (PCMs) specifically engineered for engine thermal cycling now offer energy storage capacities of 200-250 J/g. These materials absorb excess heat during high-load operations and release it gradually during cooling phases, effectively dampening thermal spikes and reducing thermal fatigue in critical components.

Diamond-like carbon (DLC) coatings applied through plasma-enhanced chemical vapor deposition provide exceptional wear resistance while simultaneously enhancing thermal conductivity at material interfaces. These coatings, measuring just 2-5 μm in thickness, have demonstrated the ability to reduce friction-generated heat by up to 30% in high-stress engine components.

Metal-organic frameworks (MOFs) represent the frontier of adaptive thermal management materials. These crystalline structures can dynamically alter their thermal properties in response to temperature changes, effectively functioning as "thermal switches" that optimize heat flow based on operating conditions. Prototype implementations show promising results in maintaining more consistent operating temperatures across varying engine loads.

The integration of these advanced materials into LSA engine designs requires sophisticated computational modeling to predict thermal behavior under diverse operating conditions. Multi-physics simulation platforms now incorporate these materials' non-linear thermal properties, enabling engineers to optimize material selection and placement for maximum thermal efficiency.

Aerogel-based insulation represents another breakthrough, with thermal conductivity as low as 0.013 W/mK, enabling more precise thermal zoning within engine compartments. When strategically applied to heat-sensitive components, these materials can reduce localized temperatures by up to 200°C compared to traditional insulation solutions.

Nano-engineered thermal interface materials (TIMs) have emerged as critical components in optimizing heat transfer between engine surfaces. Carbon nanotube arrays and graphene-enhanced thermal compounds achieve thermal conductivity exceeding 25 W/mK, dramatically outperforming conventional thermal pastes. Field tests demonstrate junction temperature reductions of 15-20% when implemented in critical thermal pathways.

Phase change materials (PCMs) specifically engineered for engine thermal cycling now offer energy storage capacities of 200-250 J/g. These materials absorb excess heat during high-load operations and release it gradually during cooling phases, effectively dampening thermal spikes and reducing thermal fatigue in critical components.

Diamond-like carbon (DLC) coatings applied through plasma-enhanced chemical vapor deposition provide exceptional wear resistance while simultaneously enhancing thermal conductivity at material interfaces. These coatings, measuring just 2-5 μm in thickness, have demonstrated the ability to reduce friction-generated heat by up to 30% in high-stress engine components.

Metal-organic frameworks (MOFs) represent the frontier of adaptive thermal management materials. These crystalline structures can dynamically alter their thermal properties in response to temperature changes, effectively functioning as "thermal switches" that optimize heat flow based on operating conditions. Prototype implementations show promising results in maintaining more consistent operating temperatures across varying engine loads.

The integration of these advanced materials into LSA engine designs requires sophisticated computational modeling to predict thermal behavior under diverse operating conditions. Multi-physics simulation platforms now incorporate these materials' non-linear thermal properties, enabling engineers to optimize material selection and placement for maximum thermal efficiency.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!