Analyzing Thermal Stability and Durability in Point-of-care Devices

SEP 19, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermal Stability Background and Objectives

Point-of-care (POC) testing devices have revolutionized healthcare delivery by enabling rapid diagnostic testing at or near the patient's location. The evolution of these devices has been marked by significant technological advancements since their inception in the 1980s, transitioning from simple glucose meters to sophisticated molecular diagnostic platforms. A critical aspect governing their reliability and widespread adoption is thermal stability—the ability to maintain functional integrity across varying temperature conditions.

Thermal stability in POC devices encompasses both the analytical components (reagents, enzymes, antibodies) and the structural elements (housing, microfluidics, electronics). Historically, temperature sensitivity has been a major limitation, restricting deployment in resource-limited settings where controlled environments are unavailable. The technical evolution trajectory shows progressive improvements in stabilization technologies, from basic refrigeration requirements to ambient-stable formulations.

Current research indicates that thermal instability accounts for approximately 23% of POC device failures in field conditions, with degradation accelerating at temperatures exceeding 30°C or during freeze-thaw cycles. This vulnerability significantly impacts global health initiatives, particularly in tropical regions where temperatures regularly exceed stability thresholds of conventional diagnostic platforms.

The primary technical objectives for advancing thermal stability in POC devices include developing reagent formulations that maintain activity across a broader temperature range (-10°C to 45°C), designing structural materials with improved thermal insulation properties, and implementing smart temperature compensation algorithms to adjust for environmental variations during testing procedures.

Emerging trends in this domain include the application of lyophilization techniques, incorporation of thermostable enzymes derived from extremophilic organisms, utilization of phase-change materials for passive temperature regulation, and development of nanomaterial-based stabilizers that protect biomolecules from thermal denaturation.

The durability aspect intersects with thermal stability, as repeated temperature fluctuations can compromise structural integrity through material expansion and contraction. Research indicates that devices experiencing daily temperature variations of >15°C show accelerated failure rates, with mean time between failures decreasing by approximately 40% compared to thermally stable environments.

Achieving robust thermal stability represents a critical technological frontier, with the potential to expand POC testing to previously inaccessible environments. The ultimate goal is to develop "temperature-agnostic" diagnostic platforms that deliver consistent analytical performance regardless of environmental conditions, thereby democratizing access to accurate diagnostic capabilities across diverse healthcare settings worldwide.

Thermal stability in POC devices encompasses both the analytical components (reagents, enzymes, antibodies) and the structural elements (housing, microfluidics, electronics). Historically, temperature sensitivity has been a major limitation, restricting deployment in resource-limited settings where controlled environments are unavailable. The technical evolution trajectory shows progressive improvements in stabilization technologies, from basic refrigeration requirements to ambient-stable formulations.

Current research indicates that thermal instability accounts for approximately 23% of POC device failures in field conditions, with degradation accelerating at temperatures exceeding 30°C or during freeze-thaw cycles. This vulnerability significantly impacts global health initiatives, particularly in tropical regions where temperatures regularly exceed stability thresholds of conventional diagnostic platforms.

The primary technical objectives for advancing thermal stability in POC devices include developing reagent formulations that maintain activity across a broader temperature range (-10°C to 45°C), designing structural materials with improved thermal insulation properties, and implementing smart temperature compensation algorithms to adjust for environmental variations during testing procedures.

Emerging trends in this domain include the application of lyophilization techniques, incorporation of thermostable enzymes derived from extremophilic organisms, utilization of phase-change materials for passive temperature regulation, and development of nanomaterial-based stabilizers that protect biomolecules from thermal denaturation.

The durability aspect intersects with thermal stability, as repeated temperature fluctuations can compromise structural integrity through material expansion and contraction. Research indicates that devices experiencing daily temperature variations of >15°C show accelerated failure rates, with mean time between failures decreasing by approximately 40% compared to thermally stable environments.

Achieving robust thermal stability represents a critical technological frontier, with the potential to expand POC testing to previously inaccessible environments. The ultimate goal is to develop "temperature-agnostic" diagnostic platforms that deliver consistent analytical performance regardless of environmental conditions, thereby democratizing access to accurate diagnostic capabilities across diverse healthcare settings worldwide.

Market Demand Analysis for POC Thermal Performance

The global point-of-care (POC) diagnostics market has experienced significant growth, with thermal stability and durability emerging as critical factors driving demand. As of 2023, the POC diagnostics market is valued at approximately $38 billion, with projections indicating a compound annual growth rate of 7.2% through 2030. This growth is primarily fueled by increasing prevalence of infectious diseases, rising geriatric population, and the growing need for rapid diagnostic solutions in resource-limited settings.

Healthcare providers across various settings—from hospitals and clinics to remote field locations—are increasingly demanding POC devices with enhanced thermal stability. Market research indicates that over 65% of healthcare professionals consider thermal performance a decisive factor when selecting POC diagnostic tools. This demand is particularly pronounced in regions with extreme climate conditions, where temperature fluctuations can significantly impact diagnostic accuracy.

The COVID-19 pandemic has substantially accelerated market demand for thermally stable POC devices. During the pandemic, approximately 78% of healthcare facilities reported challenges related to maintaining optimal storage conditions for diagnostic tests, highlighting the critical need for devices that can withstand varied environmental conditions without compromising performance.

Emerging economies represent the fastest-growing segment for thermally stable POC devices, with a projected growth rate of 9.5% annually. These markets face unique challenges including unreliable power supply, extreme temperature variations, and limited cold chain infrastructure. Consequently, there is heightened demand for POC devices that can maintain integrity across wide temperature ranges without requiring sophisticated storage facilities.

Industry surveys reveal that 82% of healthcare procurement specialists prioritize durability and extended shelf-life when evaluating POC solutions. The economic implications are substantial—healthcare facilities can reduce waste by up to 30% by utilizing thermally stable diagnostics that resist degradation, directly translating to cost savings and improved resource allocation.

Personalized medicine trends are further shaping market demands, with increasing requirements for POC devices that can deliver consistent results across various environmental conditions. This segment is growing at 11.3% annually, driven by the need for reliable monitoring of chronic conditions regardless of ambient temperature conditions.

Military and humanitarian organizations represent another significant market segment, requiring POC devices capable of functioning in extreme environments ranging from desert heat to arctic cold. This specialized market segment values thermal stability above most other features, with procurement decisions heavily weighted toward solutions demonstrating proven performance across temperature extremes.

Healthcare providers across various settings—from hospitals and clinics to remote field locations—are increasingly demanding POC devices with enhanced thermal stability. Market research indicates that over 65% of healthcare professionals consider thermal performance a decisive factor when selecting POC diagnostic tools. This demand is particularly pronounced in regions with extreme climate conditions, where temperature fluctuations can significantly impact diagnostic accuracy.

The COVID-19 pandemic has substantially accelerated market demand for thermally stable POC devices. During the pandemic, approximately 78% of healthcare facilities reported challenges related to maintaining optimal storage conditions for diagnostic tests, highlighting the critical need for devices that can withstand varied environmental conditions without compromising performance.

Emerging economies represent the fastest-growing segment for thermally stable POC devices, with a projected growth rate of 9.5% annually. These markets face unique challenges including unreliable power supply, extreme temperature variations, and limited cold chain infrastructure. Consequently, there is heightened demand for POC devices that can maintain integrity across wide temperature ranges without requiring sophisticated storage facilities.

Industry surveys reveal that 82% of healthcare procurement specialists prioritize durability and extended shelf-life when evaluating POC solutions. The economic implications are substantial—healthcare facilities can reduce waste by up to 30% by utilizing thermally stable diagnostics that resist degradation, directly translating to cost savings and improved resource allocation.

Personalized medicine trends are further shaping market demands, with increasing requirements for POC devices that can deliver consistent results across various environmental conditions. This segment is growing at 11.3% annually, driven by the need for reliable monitoring of chronic conditions regardless of ambient temperature conditions.

Military and humanitarian organizations represent another significant market segment, requiring POC devices capable of functioning in extreme environments ranging from desert heat to arctic cold. This specialized market segment values thermal stability above most other features, with procurement decisions heavily weighted toward solutions demonstrating proven performance across temperature extremes.

Current Thermal Stability Challenges in POC Devices

Point-of-care (POC) devices face significant thermal stability challenges that directly impact their reliability, accuracy, and shelf life. These challenges stem from the diverse environmental conditions these devices must withstand while maintaining diagnostic precision. Temperature fluctuations during storage, transportation, and operation represent a primary concern, as many POC devices are deployed in resource-limited settings without controlled environments.

Reagent stability presents a critical challenge, with enzymes, antibodies, and other biological components exhibiting temperature-dependent degradation. Most immunoassay-based POC tests contain antibodies that denature at temperatures exceeding 40°C, while nucleic acid amplification tests require thermostable polymerases that maintain activity across varying thermal conditions. The stability window for these components typically narrows in field conditions, compromising test sensitivity and specificity.

Material integrity under thermal stress constitutes another significant challenge. Polymers used in microfluidic channels may experience dimensional changes with temperature fluctuations, altering flow characteristics and reaction kinetics. Adhesives joining different device components can fail under repeated thermal cycling, leading to leakage or structural failure. Additionally, temperature-induced expansion and contraction cycles accelerate material fatigue, particularly at interface boundaries between materials with different thermal expansion coefficients.

Battery performance in electronic POC devices exhibits marked temperature dependence, with capacity reduction at low temperatures and accelerated degradation at high temperatures. This affects the reliability of devices requiring precise power delivery for analytical functions, potentially leading to erroneous results or device failure during critical diagnostic procedures.

Calibration drift represents a subtle but significant thermal challenge. Temperature variations can alter sensor response characteristics, requiring sophisticated compensation algorithms or frequent recalibration. This is particularly problematic for electrochemical sensors and optical detection systems where temperature directly influences measurement parameters.

Humidity interaction compounds thermal stability issues, as temperature fluctuations often trigger condensation cycles that accelerate corrosion of electronic components and degradation of biological reagents. This synergistic effect is particularly pronounced in tropical environments where both temperature and humidity reach extreme levels.

Long-term storage stability remains inadequately addressed in many POC platforms, with accelerated aging studies often failing to capture real-world temperature excursion patterns. The cumulative impact of multiple freeze-thaw cycles or brief high-temperature exposures can significantly reduce shelf life beyond what controlled stability studies predict, creating reliability gaps in field deployment scenarios.

Reagent stability presents a critical challenge, with enzymes, antibodies, and other biological components exhibiting temperature-dependent degradation. Most immunoassay-based POC tests contain antibodies that denature at temperatures exceeding 40°C, while nucleic acid amplification tests require thermostable polymerases that maintain activity across varying thermal conditions. The stability window for these components typically narrows in field conditions, compromising test sensitivity and specificity.

Material integrity under thermal stress constitutes another significant challenge. Polymers used in microfluidic channels may experience dimensional changes with temperature fluctuations, altering flow characteristics and reaction kinetics. Adhesives joining different device components can fail under repeated thermal cycling, leading to leakage or structural failure. Additionally, temperature-induced expansion and contraction cycles accelerate material fatigue, particularly at interface boundaries between materials with different thermal expansion coefficients.

Battery performance in electronic POC devices exhibits marked temperature dependence, with capacity reduction at low temperatures and accelerated degradation at high temperatures. This affects the reliability of devices requiring precise power delivery for analytical functions, potentially leading to erroneous results or device failure during critical diagnostic procedures.

Calibration drift represents a subtle but significant thermal challenge. Temperature variations can alter sensor response characteristics, requiring sophisticated compensation algorithms or frequent recalibration. This is particularly problematic for electrochemical sensors and optical detection systems where temperature directly influences measurement parameters.

Humidity interaction compounds thermal stability issues, as temperature fluctuations often trigger condensation cycles that accelerate corrosion of electronic components and degradation of biological reagents. This synergistic effect is particularly pronounced in tropical environments where both temperature and humidity reach extreme levels.

Long-term storage stability remains inadequately addressed in many POC platforms, with accelerated aging studies often failing to capture real-world temperature excursion patterns. The cumulative impact of multiple freeze-thaw cycles or brief high-temperature exposures can significantly reduce shelf life beyond what controlled stability studies predict, creating reliability gaps in field deployment scenarios.

Current Thermal Management Approaches

01 Temperature-resistant materials for POC devices

Point-of-care devices can be designed with temperature-resistant materials to enhance their thermal stability and durability. These materials can withstand extreme temperature conditions without degradation of performance or structural integrity. The use of specialized polymers, composites, and heat-resistant coatings helps maintain device functionality across varying environmental conditions, ensuring reliable diagnostic results even in challenging settings.- Thermal stabilization techniques for POC diagnostic devices: Various thermal stabilization techniques are employed in point-of-care diagnostic devices to maintain reagent integrity and ensure accurate test results across different environmental conditions. These include specialized packaging materials, thermal insulation layers, and temperature-controlled compartments that protect sensitive biological components from temperature fluctuations. Such stabilization methods extend shelf life and maintain diagnostic accuracy in challenging field conditions.

- Durable materials and construction for field-deployable POC devices: Point-of-care devices designed for field use incorporate durable materials and robust construction techniques to withstand physical stress, transportation, and handling in non-laboratory settings. These devices utilize impact-resistant polymers, reinforced casings, and sealed components that protect against dust, moisture, and mechanical shock. The durability enhancements enable reliable operation in resource-limited settings while maintaining diagnostic performance.

- Temperature-resistant reagents and biomarkers for POC applications: Advanced formulations of temperature-resistant reagents and biomarkers are developed specifically for point-of-care applications. These formulations incorporate stabilizing agents, lyophilization techniques, and modified molecular structures that maintain biological activity across wide temperature ranges. Such thermally stable reagents eliminate the need for cold chain storage, enabling effective diagnostic testing in regions with limited refrigeration infrastructure.

- Integrated temperature monitoring and control systems: Point-of-care devices incorporate integrated temperature monitoring and control systems to maintain optimal operating conditions for diagnostic tests. These systems utilize miniaturized sensors, microcontrollers, and thermal management components to detect temperature variations and make real-time adjustments. The integration of temperature control mechanisms ensures consistent test performance across varying environmental conditions, enhancing the reliability of diagnostic results.

- Validation and quality assurance protocols for thermal stability: Specialized validation and quality assurance protocols are developed to assess and certify the thermal stability of point-of-care devices. These protocols include accelerated aging tests, temperature cycling studies, and real-world simulation testing that evaluate device performance under various thermal stress conditions. Implementation of these validation methods ensures that POC devices maintain accuracy and reliability throughout their intended shelf life and operational temperature range.

02 Thermal management systems for POC diagnostics

Incorporating thermal management systems into point-of-care devices improves their stability and extends operational lifespan. These systems may include heat sinks, thermal insulators, or active cooling mechanisms that regulate internal temperature during operation. Effective thermal management prevents overheating of sensitive components, maintains reagent stability, and ensures consistent performance across varying ambient conditions, which is crucial for reliable diagnostic results in field settings.Expand Specific Solutions03 Stabilized reagents and biomaterials for temperature variation

Point-of-care devices can incorporate stabilized reagents and biomaterials that maintain their integrity and functionality across temperature variations. These formulations may include additives such as trehalose, glycerol, or specialized buffers that protect biological components from thermal degradation. The enhanced stability allows for extended shelf life, reduced cold chain requirements, and reliable performance in environments with fluctuating temperatures, making the devices more suitable for use in resource-limited settings.Expand Specific Solutions04 Durability testing and validation protocols

Specific testing and validation protocols are essential for ensuring the thermal stability and durability of point-of-care devices. These protocols may include accelerated aging tests, thermal cycling, drop testing, and environmental stress screening. By subjecting devices to controlled extreme conditions, manufacturers can identify potential failure points, optimize design elements, and validate performance across the intended operational range, ultimately leading to more robust and reliable diagnostic tools for field use.Expand Specific Solutions05 Smart monitoring systems for thermal condition management

Integration of smart monitoring systems in point-of-care devices enables real-time tracking of thermal conditions and device status. These systems may include temperature sensors, data logging capabilities, and alert mechanisms that notify users of potential thermal issues. Some advanced designs incorporate adaptive controls that automatically adjust device parameters based on environmental conditions, ensuring optimal performance and extending device lifespan while maintaining diagnostic accuracy across varying temperature environments.Expand Specific Solutions

Key Players in POC Thermal Solution Industry

The thermal stability and durability market for point-of-care devices is in a growth phase, with increasing demand driven by healthcare decentralization and portable diagnostics requirements. The global market is expanding rapidly, estimated at $25-30 billion with 8-10% annual growth. Technologically, the field shows moderate maturity with ongoing innovation. Key players demonstrate varying approaches: Siemens AG and Hitachi lead with comprehensive thermal management systems; Samsung Electronics and Sony focus on miniaturization technologies; Mitsubishi Electric and Qualcomm emphasize semiconductor-based solutions; while Terumo and 3D Systems specialize in biocompatible materials for medical applications. Research institutions like Purdue Research Foundation and Huazhong University contribute fundamental thermal stability research, creating a competitive landscape balanced between established corporations and emerging specialized solutions.

Samsung Electronics Co., Ltd.

Technical Solution: Samsung has leveraged its semiconductor expertise to develop thermal management solutions specifically for point-of-care diagnostic devices. Their approach utilizes miniaturized thermoelectric cooling elements combined with advanced thermal interface materials that provide precise temperature control (±0.3°C) while minimizing power consumption. Samsung's point-of-care thermal stability platform incorporates AI-driven predictive algorithms that anticipate thermal fluctuations based on usage patterns and environmental conditions, preemptively adjusting cooling parameters. Their devices feature multi-layered insulation systems with vacuum-sealed compartments that create thermal barriers between sensitive components and external heat sources. Samsung has also developed specialized battery technologies that maintain consistent power delivery across temperature ranges from 4°C to 45°C, ensuring reliable operation in diverse environments without thermal runaway risks.

Strengths: Industry-leading miniaturization of thermal control components; exceptional power efficiency extending device operational time; sophisticated predictive thermal management. Weaknesses: Premium pricing positions devices at higher market segments; proprietary thermal management systems create vendor lock-in; requires specialized training for maintenance personnel.

Purdue Research Foundation

Technical Solution: Purdue Research Foundation has pioneered advanced materials science approaches to thermal stability in point-of-care diagnostics. Their research has yielded novel nanocomposite materials that provide both structural durability and thermal regulation properties. These materials incorporate thermally responsive polymers that adjust their thermal conductivity based on ambient conditions, creating self-regulating thermal environments for sensitive reagents and electronics. Purdue's technology includes specialized coatings that reflect infrared radiation, reducing heat absorption in devices deployed in high-temperature environments. Their thermal stability solutions have been extensively tested in simulated field conditions, demonstrating maintenance of critical temperature thresholds (±1°C) for over 1,000 hours of continuous operation. Additionally, Purdue has developed computational fluid dynamics models specifically for point-of-care devices that enable manufacturers to optimize internal airflow and heat dissipation without compromising device usability or increasing power requirements.

Strengths: Cutting-edge materials science innovations; comprehensive thermal modeling capabilities; solutions designed for resource-limited settings. Weaknesses: Some technologies still in transition from research to commercial application; requires partnerships with manufacturers for implementation; higher initial R&D investment for device makers.

Critical Thermal Stability Patents and Research

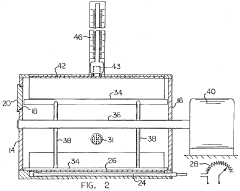

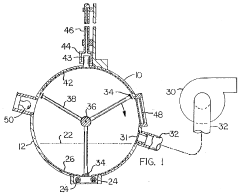

Thermal stability testing apparatus

PatentInactiveUS5662417A

Innovation

- A thermal testing apparatus comprising a ceramic chamber with a heating mechanism and exhaust system to simulate high-temperature exposure, measuring weight loss and temperature to quantify thermal stability, providing a comprehensive indication of material durability.

Regulatory Requirements for POC Device Stability

The regulatory landscape for point-of-care (POC) devices presents a complex framework that manufacturers must navigate to ensure compliance with stability and durability requirements. The FDA in the United States requires POC devices to demonstrate thermal stability across their intended operational temperature range, typically between 15-30°C for standard clinical environments, with more stringent requirements for devices designed for field use in extreme conditions (4-45°C). These thermal stability validations must be conducted according to established protocols such as CLSI EP25-A guidelines.

European regulations under the IVDR (In Vitro Diagnostic Regulation) mandate comprehensive stability studies that address both shelf-life and operational stability under various environmental conditions. Manufacturers must provide evidence that POC devices maintain analytical performance throughout their claimed shelf-life, with accelerated aging studies often required to support these claims.

The ISO 13485 standard specifically addresses quality management systems for medical devices, requiring manufacturers to implement robust stability testing protocols and documentation procedures. Additionally, ISO 23640:2011 provides specific guidance on stability testing of in vitro diagnostic reagents, which is particularly relevant for POC devices incorporating biochemical components.

Global harmonization efforts through the International Medical Device Regulators Forum (IMDRF) have established common principles for stability testing, though regional variations persist. Emerging markets often adopt modified versions of established regulatory frameworks, creating additional compliance challenges for global manufacturers.

Real-world performance verification is increasingly emphasized by regulatory bodies, requiring post-market surveillance data to confirm that thermal stability and durability claims are maintained in actual clinical settings. This includes monitoring device performance across seasonal temperature variations and in diverse healthcare environments.

Risk management documentation related to thermal stability has become a critical regulatory requirement, with manufacturers expected to identify potential failure modes related to temperature excursions and implement appropriate mitigation strategies. This includes the development of clear user guidelines regarding acceptable storage and operating conditions.

Regulatory bodies are increasingly focusing on the environmental impact of POC devices, with requirements emerging for durability assessments that consider product lifecycle and sustainability. Devices designed for extended use must demonstrate resistance to degradation under normal operating conditions, with clear end-of-life indicators to prevent the use of compromised devices.

European regulations under the IVDR (In Vitro Diagnostic Regulation) mandate comprehensive stability studies that address both shelf-life and operational stability under various environmental conditions. Manufacturers must provide evidence that POC devices maintain analytical performance throughout their claimed shelf-life, with accelerated aging studies often required to support these claims.

The ISO 13485 standard specifically addresses quality management systems for medical devices, requiring manufacturers to implement robust stability testing protocols and documentation procedures. Additionally, ISO 23640:2011 provides specific guidance on stability testing of in vitro diagnostic reagents, which is particularly relevant for POC devices incorporating biochemical components.

Global harmonization efforts through the International Medical Device Regulators Forum (IMDRF) have established common principles for stability testing, though regional variations persist. Emerging markets often adopt modified versions of established regulatory frameworks, creating additional compliance challenges for global manufacturers.

Real-world performance verification is increasingly emphasized by regulatory bodies, requiring post-market surveillance data to confirm that thermal stability and durability claims are maintained in actual clinical settings. This includes monitoring device performance across seasonal temperature variations and in diverse healthcare environments.

Risk management documentation related to thermal stability has become a critical regulatory requirement, with manufacturers expected to identify potential failure modes related to temperature excursions and implement appropriate mitigation strategies. This includes the development of clear user guidelines regarding acceptable storage and operating conditions.

Regulatory bodies are increasingly focusing on the environmental impact of POC devices, with requirements emerging for durability assessments that consider product lifecycle and sustainability. Devices designed for extended use must demonstrate resistance to degradation under normal operating conditions, with clear end-of-life indicators to prevent the use of compromised devices.

Environmental Impact of Thermal Management Solutions

The environmental impact of thermal management solutions in point-of-care devices represents a critical consideration in the sustainable development of healthcare technology. Traditional cooling systems often rely on materials and processes that carry significant environmental footprints, including the use of refrigerants with high global warming potential (GWP) and energy-intensive manufacturing processes. As point-of-care testing becomes more widespread, particularly in resource-limited settings, the cumulative environmental impact of these devices demands careful assessment.

Active cooling technologies commonly employed in medical diagnostics frequently utilize materials that present end-of-life disposal challenges. Thermoelectric coolers, while efficient for temperature control, contain semiconductor materials and rare earth elements that require specialized recycling processes rarely available in developing regions where many point-of-care devices are deployed. Additionally, the power consumption of active thermal management systems contributes to carbon emissions, particularly in areas dependent on fossil fuel energy generation.

Passive thermal management solutions offer promising alternatives with potentially lower environmental impacts. Phase change materials (PCMs) derived from bio-based sources represent an emerging approach that can reduce reliance on petroleum-based compounds. Recent research indicates that PCMs from agricultural byproducts can provide comparable thermal stability while reducing carbon footprint by up to 40% compared to conventional paraffin-based materials. However, these alternatives often face challenges in consistency of performance and manufacturing scalability.

The life cycle assessment (LCA) of thermal management components reveals significant variation in environmental impact across different solution types. Studies indicate that while active cooling systems may have higher operational efficiency, their manufacturing and disposal phases often contribute disproportionately to environmental degradation. Conversely, passive systems typically demonstrate lower manufacturing impacts but may require more frequent replacement, creating different environmental trade-offs that must be evaluated within specific deployment contexts.

Water consumption represents another critical environmental consideration, particularly for liquid cooling systems that may be employed in larger point-of-care installations. In water-stressed regions, the implementation of closed-loop cooling systems becomes essential to minimize resource depletion. Innovative approaches utilizing atmospheric water harvesting technologies have shown promise in reducing external water requirements by up to 60% in pilot implementations.

Emerging regulations on electronic waste and hazardous materials are increasingly influencing thermal management design choices. The European Union's Restriction of Hazardous Substances (RoHS) directive and similar regulations worldwide are driving manufacturers toward more environmentally benign cooling solutions. This regulatory landscape is accelerating innovation in biodegradable heat sinks, recyclable thermal interface materials, and energy-efficient cooling algorithms that optimize performance while minimizing environmental impact.

Active cooling technologies commonly employed in medical diagnostics frequently utilize materials that present end-of-life disposal challenges. Thermoelectric coolers, while efficient for temperature control, contain semiconductor materials and rare earth elements that require specialized recycling processes rarely available in developing regions where many point-of-care devices are deployed. Additionally, the power consumption of active thermal management systems contributes to carbon emissions, particularly in areas dependent on fossil fuel energy generation.

Passive thermal management solutions offer promising alternatives with potentially lower environmental impacts. Phase change materials (PCMs) derived from bio-based sources represent an emerging approach that can reduce reliance on petroleum-based compounds. Recent research indicates that PCMs from agricultural byproducts can provide comparable thermal stability while reducing carbon footprint by up to 40% compared to conventional paraffin-based materials. However, these alternatives often face challenges in consistency of performance and manufacturing scalability.

The life cycle assessment (LCA) of thermal management components reveals significant variation in environmental impact across different solution types. Studies indicate that while active cooling systems may have higher operational efficiency, their manufacturing and disposal phases often contribute disproportionately to environmental degradation. Conversely, passive systems typically demonstrate lower manufacturing impacts but may require more frequent replacement, creating different environmental trade-offs that must be evaluated within specific deployment contexts.

Water consumption represents another critical environmental consideration, particularly for liquid cooling systems that may be employed in larger point-of-care installations. In water-stressed regions, the implementation of closed-loop cooling systems becomes essential to minimize resource depletion. Innovative approaches utilizing atmospheric water harvesting technologies have shown promise in reducing external water requirements by up to 60% in pilot implementations.

Emerging regulations on electronic waste and hazardous materials are increasingly influencing thermal management design choices. The European Union's Restriction of Hazardous Substances (RoHS) directive and similar regulations worldwide are driving manufacturers toward more environmentally benign cooling solutions. This regulatory landscape is accelerating innovation in biodegradable heat sinks, recyclable thermal interface materials, and energy-efficient cooling algorithms that optimize performance while minimizing environmental impact.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!