Exploring Electrode Kinetics in Point-of-care Devices

SEP 19, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Electrode Kinetics Background and Objectives

Electrode kinetics has evolved significantly over the past decades, transforming from a purely theoretical field into a critical component of modern diagnostic technologies. The study of electrode kinetics focuses on understanding the rates and mechanisms of electron transfer processes occurring at electrode-solution interfaces. This fundamental electrochemical concept has become increasingly important in the development of point-of-care (POC) devices, which aim to provide rapid, accurate, and accessible diagnostic capabilities outside traditional laboratory settings.

The historical progression of electrode kinetics research began in the early 20th century with basic electrochemical theories, advancing through significant breakthroughs in the 1950s with the Butler-Volmer equation and Marcus theory. These foundational principles established the mathematical framework for describing electron transfer processes. By the 1980s and 1990s, miniaturization technologies enabled the application of these theories to smaller electrode systems, coinciding with the emergence of biosensor technologies.

Recent technological advancements have accelerated the integration of electrode kinetics into practical applications, particularly in healthcare diagnostics. The miniaturization of electrochemical systems, coupled with advances in materials science and nanotechnology, has enabled the development of increasingly sensitive and specific POC devices. These developments have been further enhanced by digital technologies and data analytics, allowing for more sophisticated interpretation of electrochemical signals.

The primary objective of exploring electrode kinetics in POC devices is to optimize the performance parameters critical for clinical applications. This includes enhancing sensitivity to detect biomarkers at clinically relevant concentrations, improving specificity to minimize false results, and increasing the speed of analysis to enable rapid decision-making. Additionally, there is a focus on developing robust systems that can operate reliably in diverse environmental conditions outside controlled laboratory settings.

Another key goal is to address the challenges of electrode fouling and stability, which can significantly impact the reliability and longevity of POC devices. Understanding the kinetic processes at the electrode surface can lead to innovative solutions for maintaining consistent performance over time and multiple uses. This is particularly important for devices intended for continuous monitoring or repeated use in resource-limited settings.

Looking forward, the field is trending toward multi-analyte detection capabilities, where a single POC device can simultaneously measure multiple biomarkers. This requires sophisticated electrode designs and kinetic models that can differentiate between various electrochemical reactions occurring concurrently. The ultimate aim is to develop integrated systems that combine sample preparation, detection, and data analysis into user-friendly platforms accessible to healthcare providers with minimal specialized training.

The historical progression of electrode kinetics research began in the early 20th century with basic electrochemical theories, advancing through significant breakthroughs in the 1950s with the Butler-Volmer equation and Marcus theory. These foundational principles established the mathematical framework for describing electron transfer processes. By the 1980s and 1990s, miniaturization technologies enabled the application of these theories to smaller electrode systems, coinciding with the emergence of biosensor technologies.

Recent technological advancements have accelerated the integration of electrode kinetics into practical applications, particularly in healthcare diagnostics. The miniaturization of electrochemical systems, coupled with advances in materials science and nanotechnology, has enabled the development of increasingly sensitive and specific POC devices. These developments have been further enhanced by digital technologies and data analytics, allowing for more sophisticated interpretation of electrochemical signals.

The primary objective of exploring electrode kinetics in POC devices is to optimize the performance parameters critical for clinical applications. This includes enhancing sensitivity to detect biomarkers at clinically relevant concentrations, improving specificity to minimize false results, and increasing the speed of analysis to enable rapid decision-making. Additionally, there is a focus on developing robust systems that can operate reliably in diverse environmental conditions outside controlled laboratory settings.

Another key goal is to address the challenges of electrode fouling and stability, which can significantly impact the reliability and longevity of POC devices. Understanding the kinetic processes at the electrode surface can lead to innovative solutions for maintaining consistent performance over time and multiple uses. This is particularly important for devices intended for continuous monitoring or repeated use in resource-limited settings.

Looking forward, the field is trending toward multi-analyte detection capabilities, where a single POC device can simultaneously measure multiple biomarkers. This requires sophisticated electrode designs and kinetic models that can differentiate between various electrochemical reactions occurring concurrently. The ultimate aim is to develop integrated systems that combine sample preparation, detection, and data analysis into user-friendly platforms accessible to healthcare providers with minimal specialized training.

Market Analysis for Point-of-care Diagnostic Devices

The global point-of-care diagnostic devices market has experienced substantial growth, valued at approximately $23.5 billion in 2020 and projected to reach $46.7 billion by 2027, with a compound annual growth rate (CAGR) of 10.2%. This remarkable expansion is driven by several key factors, including the increasing prevalence of chronic and infectious diseases, growing demand for rapid diagnostic results, and technological advancements in electrode kinetics and biosensor technologies.

The COVID-19 pandemic has significantly accelerated market growth, creating unprecedented demand for rapid, accurate, and accessible diagnostic solutions. This has catalyzed innovation in electrode-based point-of-care testing devices, particularly those utilizing electrochemical detection methods that leverage advanced electrode kinetics for improved sensitivity and specificity.

Geographically, North America currently dominates the market with approximately 40% share, followed by Europe at 30% and Asia-Pacific at 20%. However, the Asia-Pacific region is expected to witness the fastest growth rate of 12.5% through 2027, driven by improving healthcare infrastructure, rising healthcare expenditure, and increasing awareness about early disease diagnosis.

By application segment, infectious disease testing represents the largest market share at 35%, followed by cardiac markers (20%), blood glucose testing (15%), and coagulation testing (10%). The infectious disease segment is projected to maintain its dominant position due to the ongoing global focus on pandemic preparedness and antimicrobial resistance monitoring.

Consumer preferences are increasingly shifting toward devices that offer faster results, improved accuracy, and connectivity features. Devices incorporating advanced electrode kinetics that enable rapid electrochemical reactions and signal amplification are gaining significant market traction. Additionally, there is growing demand for multiplexed testing capabilities that can detect multiple analytes simultaneously using a single sample.

Key market challenges include stringent regulatory requirements, reimbursement issues, and the need for standardization across different point-of-care platforms. However, these challenges are being addressed through collaborative efforts between industry stakeholders, regulatory bodies, and healthcare providers.

The competitive landscape is characterized by both established medical device manufacturers and innovative startups focusing on electrode technology advancements. Strategic partnerships between technology developers and healthcare providers are becoming increasingly common to accelerate market penetration and adoption of novel electrode-based diagnostic solutions.

The COVID-19 pandemic has significantly accelerated market growth, creating unprecedented demand for rapid, accurate, and accessible diagnostic solutions. This has catalyzed innovation in electrode-based point-of-care testing devices, particularly those utilizing electrochemical detection methods that leverage advanced electrode kinetics for improved sensitivity and specificity.

Geographically, North America currently dominates the market with approximately 40% share, followed by Europe at 30% and Asia-Pacific at 20%. However, the Asia-Pacific region is expected to witness the fastest growth rate of 12.5% through 2027, driven by improving healthcare infrastructure, rising healthcare expenditure, and increasing awareness about early disease diagnosis.

By application segment, infectious disease testing represents the largest market share at 35%, followed by cardiac markers (20%), blood glucose testing (15%), and coagulation testing (10%). The infectious disease segment is projected to maintain its dominant position due to the ongoing global focus on pandemic preparedness and antimicrobial resistance monitoring.

Consumer preferences are increasingly shifting toward devices that offer faster results, improved accuracy, and connectivity features. Devices incorporating advanced electrode kinetics that enable rapid electrochemical reactions and signal amplification are gaining significant market traction. Additionally, there is growing demand for multiplexed testing capabilities that can detect multiple analytes simultaneously using a single sample.

Key market challenges include stringent regulatory requirements, reimbursement issues, and the need for standardization across different point-of-care platforms. However, these challenges are being addressed through collaborative efforts between industry stakeholders, regulatory bodies, and healthcare providers.

The competitive landscape is characterized by both established medical device manufacturers and innovative startups focusing on electrode technology advancements. Strategic partnerships between technology developers and healthcare providers are becoming increasingly common to accelerate market penetration and adoption of novel electrode-based diagnostic solutions.

Current Challenges in Electrode Technology

Despite significant advancements in electrode technology for point-of-care (POC) devices, several critical challenges persist that impede optimal performance and widespread adoption. The miniaturization requirements for POC applications create fundamental constraints on electrode design and functionality, often resulting in compromised sensitivity and specificity compared to laboratory-based systems.

Surface fouling remains one of the most significant obstacles, particularly in biological sample testing. When electrodes come into contact with complex matrices such as whole blood, plasma, or saliva, proteins and other biomolecules rapidly adsorb onto the electrode surface, forming a passivation layer that alters electron transfer kinetics and diminishes signal integrity over time. This biofouling effect is especially problematic for continuous monitoring applications.

Stability and reproducibility issues present another major challenge. Environmental factors including temperature fluctuations, humidity, and mechanical stress can significantly alter electrode performance in field settings. The batch-to-batch variability in electrode manufacturing further complicates standardization efforts, leading to inconsistent results across devices and limiting clinical reliability.

The trade-off between sensitivity and selectivity continues to challenge researchers. While nanomaterial-modified electrodes have demonstrated enhanced sensitivity, they often suffer from reduced selectivity in complex biological samples where multiple electroactive species may be present. This interference problem becomes particularly acute when targeting analytes at extremely low concentrations in the presence of abundant interfering compounds.

Power constraints represent another significant hurdle for electrode technology in POC devices. The electrochemical techniques required for sensitive detection often demand substantial power, conflicting with the need for portable, battery-operated systems with extended operational lifetimes. This energy limitation restricts the application of certain high-performance electrochemical methods in resource-limited settings.

Manufacturing scalability and cost-effectiveness remain persistent challenges. Advanced electrode materials with superior performance characteristics, such as nanopatterned gold or platinum-based systems, involve complex fabrication processes that are difficult to scale economically. This creates a significant barrier to widespread implementation, particularly in low-resource environments where cost constraints are paramount.

Integration challenges with other system components further complicate electrode implementation. The interface between electrodes and signal processing electronics often introduces noise and signal degradation, while packaging requirements for maintaining electrode integrity can conflict with the need for sample accessibility and device compactness.

Surface fouling remains one of the most significant obstacles, particularly in biological sample testing. When electrodes come into contact with complex matrices such as whole blood, plasma, or saliva, proteins and other biomolecules rapidly adsorb onto the electrode surface, forming a passivation layer that alters electron transfer kinetics and diminishes signal integrity over time. This biofouling effect is especially problematic for continuous monitoring applications.

Stability and reproducibility issues present another major challenge. Environmental factors including temperature fluctuations, humidity, and mechanical stress can significantly alter electrode performance in field settings. The batch-to-batch variability in electrode manufacturing further complicates standardization efforts, leading to inconsistent results across devices and limiting clinical reliability.

The trade-off between sensitivity and selectivity continues to challenge researchers. While nanomaterial-modified electrodes have demonstrated enhanced sensitivity, they often suffer from reduced selectivity in complex biological samples where multiple electroactive species may be present. This interference problem becomes particularly acute when targeting analytes at extremely low concentrations in the presence of abundant interfering compounds.

Power constraints represent another significant hurdle for electrode technology in POC devices. The electrochemical techniques required for sensitive detection often demand substantial power, conflicting with the need for portable, battery-operated systems with extended operational lifetimes. This energy limitation restricts the application of certain high-performance electrochemical methods in resource-limited settings.

Manufacturing scalability and cost-effectiveness remain persistent challenges. Advanced electrode materials with superior performance characteristics, such as nanopatterned gold or platinum-based systems, involve complex fabrication processes that are difficult to scale economically. This creates a significant barrier to widespread implementation, particularly in low-resource environments where cost constraints are paramount.

Integration challenges with other system components further complicate electrode implementation. The interface between electrodes and signal processing electronics often introduces noise and signal degradation, while packaging requirements for maintaining electrode integrity can conflict with the need for sample accessibility and device compactness.

Current Electrode Solutions for POC Applications

01 Electrode kinetics measurement and analysis methods

Various methods and systems for measuring and analyzing electrode kinetics in electrochemical reactions. These include techniques for determining reaction rates, electron transfer processes, and kinetic parameters at electrode surfaces. Advanced analytical approaches help understand the fundamental mechanisms of electrode reactions, which is crucial for optimizing electrochemical systems and devices.- Electrode kinetics measurement and analysis methods: Various methods and systems for measuring and analyzing electrode kinetics in electrochemical reactions. These include techniques for determining reaction rates, electron transfer processes, and kinetic parameters at electrode interfaces. Advanced analytical approaches help understand the fundamental mechanisms governing electrode reactions and can be applied to optimize electrochemical systems.

- Electrode materials and surface modifications for enhanced kinetics: Development of specialized electrode materials and surface modifications to improve reaction kinetics. This includes novel catalyst compositions, nanostructured surfaces, and functionalized electrodes designed to accelerate electron transfer processes. These innovations reduce energy barriers for electrochemical reactions and enhance overall system efficiency.

- Thermal management systems for electrode kinetics control: Thermal management approaches for controlling electrode kinetics in electrochemical devices. These systems regulate temperature to optimize reaction rates and prevent degradation mechanisms. Precise thermal control allows for manipulation of kinetic parameters, extending electrode lifetime and improving performance consistency in applications ranging from batteries to fuel cells.

- Microfluidic and lab-on-chip platforms for electrode kinetics studies: Miniaturized systems for studying electrode kinetics using microfluidic and lab-on-chip technologies. These platforms enable high-throughput analysis of electrochemical processes under precisely controlled conditions. The integration of sensors, electrodes, and analysis tools in compact devices facilitates rapid screening of reaction parameters and kinetic modeling.

- Computational modeling and simulation of electrode kinetics: Advanced computational approaches for modeling and simulating electrode kinetics. These include numerical methods, machine learning algorithms, and theoretical frameworks that predict electrochemical behavior. Computational tools enable researchers to understand complex kinetic phenomena, optimize electrode designs, and accelerate the development of new electrochemical technologies.

02 Electrode materials and surface modifications for enhanced kinetics

Development of specialized electrode materials and surface modifications to improve reaction kinetics. This includes novel catalyst compositions, nanostructured surfaces, and functionalized electrodes that facilitate faster electron transfer and improved electrochemical performance. These advancements are critical for applications requiring rapid electrode responses and efficient energy conversion.Expand Specific Solutions03 Microfluidic and miniaturized electrode systems

Miniaturized electrode systems and microfluidic devices designed for studying electrode kinetics in confined spaces. These systems allow for precise control of reaction conditions and enable the investigation of kinetic phenomena at microscale. Applications include lab-on-chip devices, sensors, and analytical instruments where space constraints and rapid analysis are important considerations.Expand Specific Solutions04 Thermal management for electrode kinetics optimization

Systems and methods for thermal management to optimize electrode kinetics. Temperature control significantly affects reaction rates and electron transfer processes at electrode interfaces. These innovations include heating/cooling mechanisms, temperature monitoring systems, and thermally responsive electrode designs that maintain optimal conditions for electrochemical reactions across various operating environments.Expand Specific Solutions05 Computational modeling and simulation of electrode kinetics

Advanced computational approaches for modeling and simulating electrode kinetics. These include algorithms, software tools, and mathematical frameworks that predict electrochemical behavior, reaction pathways, and kinetic parameters. Such computational methods enable researchers to design experiments more efficiently, interpret complex data, and develop theoretical understanding of electrode processes without extensive physical testing.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The electrode kinetics market in point-of-care devices is currently in a growth phase, with increasing demand for rapid, accurate diagnostic solutions. The global market is expanding at approximately 8-10% annually, driven by healthcare decentralization and the need for immediate clinical decisions. Technologically, the field shows varying maturity levels, with established players like Abbott Point of Care and Philips leading innovation through extensive R&D investments. Boston Scientific, Medtronic, and ICU Medical are advancing electrode materials and sensing technologies, while academic institutions like Beihang University and IIT Guwahati contribute fundamental research. Emerging companies such as Elidah and Biomagnetic Sciences are introducing specialized applications, creating a competitive landscape balanced between established medical device manufacturers and innovative startups focused on niche applications.

Boston Scientific Scimed, Inc.

Technical Solution: Boston Scientific has developed specialized electrode technologies primarily focused on electrochemical sensing in implantable and minimally invasive medical devices. Their approach to electrode kinetics centers on long-term stability and biocompatibility while maintaining sensitivity in biological environments. The company utilizes proprietary noble metal alloy electrodes with nanoporous surface structures that significantly increase effective surface area while maintaining dimensional stability. These electrodes incorporate specialized coatings that mitigate protein adsorption and cellular adhesion, preserving electrochemical performance over extended periods. Boston Scientific has pioneered adaptive polarization techniques that dynamically adjust electrode potentials to compensate for surface changes and maintain optimal reaction kinetics despite biofouling. Their systems employ multiplexed sensing arrays with differential measurement capabilities that enhance signal discrimination in complex biological matrices[4][7]. Recent developments include integration of machine learning algorithms that continuously optimize measurement parameters based on individual patient physiology and electrode performance history.

Strengths: Exceptional long-term electrode stability in biological environments; sophisticated signal processing capabilities; extensive experience with regulatory pathways for implantable sensing technologies. Weaknesses: Technologies primarily optimized for continuous monitoring rather than rapid diagnostic applications; higher manufacturing complexity leading to increased costs; more limited experience in traditional point-of-care markets.

Koninklijke Philips NV

Technical Solution: Philips has developed innovative electrode technologies for point-of-care diagnostics focusing on miniaturization and integration with digital health platforms. Their approach combines screen-printed carbon electrodes with specialized conductive polymers to enhance electron transfer rates at the electrode-sample interface. The company's Minicare platform utilizes electrochemical impedance spectroscopy with frequency-dependent analysis to characterize complex biological samples with minimal preprocessing. Philips has implemented advanced surface chemistry modifications including self-assembled monolayers and nanoparticle-enhanced sensing layers that significantly improve electrode stability and reduce biofouling in direct sample testing. Their systems incorporate real-time kinetic measurements that allow for dynamic adjustment of measurement parameters based on sample characteristics, improving accuracy across diverse patient populations[2][5]. The technology also features integrated quality control mechanisms that continuously monitor electrode performance and degradation.

Strengths: Excellent system integration with existing healthcare IT infrastructure; sophisticated data analytics capabilities; user-friendly interfaces designed for non-laboratory personnel. Weaknesses: More limited test menu compared to some competitors; higher initial capital investment; requires regular calibration to maintain electrode performance.

Key Innovations in Electrode Kinetics Research

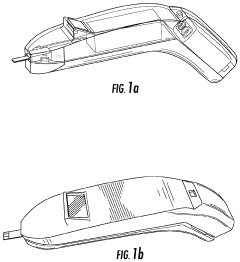

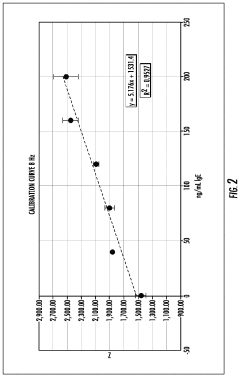

Point-of-care apparatus and methods for analyte detections using electrochemical impedance or capacitance

PatentActiveUS11714083B2

Innovation

- The use of Electrochemical Impedance Spectroscopy (EIS) or Electrochemical Capacitance Spectroscopy (ECS) in combination with molecular recognition elements (MREs) on a working electrode, applying alternating current voltage to measure impedance and phase shift for analyte detection, with native optimal frequencies enabling detection limits within clinically relevant ranges.

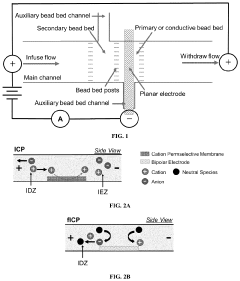

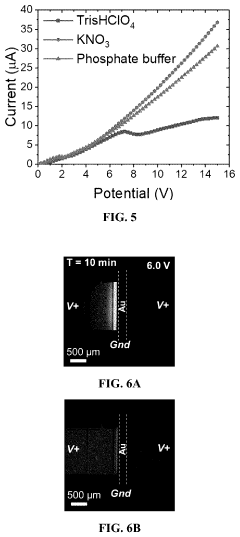

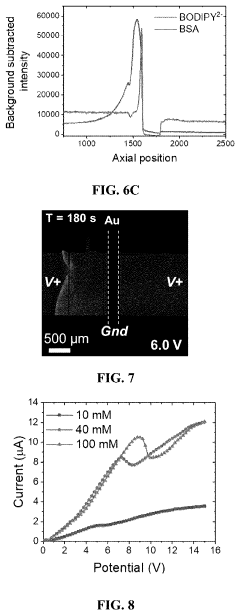

Device for electrokinetic focusing and electrical detection of particles and chemical species facilitated by a porous electrode

PatentPendingUS20240011876A1

Innovation

- A microfluidic device with a 3D flow-through electrode and/or permselective structure, incorporating conductive or permselective microbeads, that enables stable, high-throughput focusing of charged species through counter-flow focusing driven by electrokinetic enrichment, allowing for in situ optical and electrical detection without the need for fluorescent labels.

Regulatory Framework for POC Diagnostic Devices

The regulatory landscape for Point-of-Care (POC) diagnostic devices incorporating electrode kinetics technology is complex and multifaceted, requiring manufacturers to navigate various approval pathways across different jurisdictions. In the United States, the Food and Drug Administration (FDA) classifies most POC devices under Class II medical devices, necessitating 510(k) clearance that demonstrates substantial equivalence to legally marketed devices. For novel electrode kinetics applications, De Novo classification or Premarket Approval (PMA) may be required, particularly when the technology represents significant advancements in diagnostic capabilities.

The European Union has implemented the In Vitro Diagnostic Regulation (IVDR 2017/746), which replaced the previous IVDD directive in May 2022, introducing more stringent requirements for clinical evidence, post-market surveillance, and risk classification. POC devices utilizing advanced electrode kinetics typically fall under higher risk categories (Class C or D), requiring conformity assessment by Notified Bodies and comprehensive technical documentation demonstrating analytical and clinical performance.

International standards play a crucial role in regulatory compliance for electrode-based POC devices. ISO 13485 for quality management systems and IEC 61010 for safety requirements form the foundation, while more specific standards such as ISO 15197 for blood glucose monitoring systems and ISO 17593 for self-testing of oral anticoagulant therapy provide targeted guidance for particular applications of electrode technology.

Emerging markets present additional regulatory considerations. China's National Medical Products Administration (NMPA) has implemented reforms aligning more closely with global standards but maintains unique requirements for clinical evaluation and technical review. India's Central Drugs Standard Control Organization (CDSCO) classifies most POC devices as Class C or D medical devices, requiring extensive documentation and potentially local clinical trials.

Regulatory harmonization efforts through the International Medical Device Regulators Forum (IMDRF) aim to streamline approval processes globally, with initiatives like the Medical Device Single Audit Program (MDSAP) reducing redundant inspections across multiple jurisdictions. However, significant regional variations persist, particularly regarding performance requirements for electrode-based diagnostic systems.

Post-market surveillance requirements have become increasingly stringent worldwide, with manufacturers expected to implement robust systems for monitoring device performance, adverse event reporting, and continuous risk assessment. For POC devices utilizing electrode kinetics, particular attention must be paid to drift in electrode performance over time, interference from environmental factors, and user-related errors that may impact diagnostic accuracy.

The European Union has implemented the In Vitro Diagnostic Regulation (IVDR 2017/746), which replaced the previous IVDD directive in May 2022, introducing more stringent requirements for clinical evidence, post-market surveillance, and risk classification. POC devices utilizing advanced electrode kinetics typically fall under higher risk categories (Class C or D), requiring conformity assessment by Notified Bodies and comprehensive technical documentation demonstrating analytical and clinical performance.

International standards play a crucial role in regulatory compliance for electrode-based POC devices. ISO 13485 for quality management systems and IEC 61010 for safety requirements form the foundation, while more specific standards such as ISO 15197 for blood glucose monitoring systems and ISO 17593 for self-testing of oral anticoagulant therapy provide targeted guidance for particular applications of electrode technology.

Emerging markets present additional regulatory considerations. China's National Medical Products Administration (NMPA) has implemented reforms aligning more closely with global standards but maintains unique requirements for clinical evaluation and technical review. India's Central Drugs Standard Control Organization (CDSCO) classifies most POC devices as Class C or D medical devices, requiring extensive documentation and potentially local clinical trials.

Regulatory harmonization efforts through the International Medical Device Regulators Forum (IMDRF) aim to streamline approval processes globally, with initiatives like the Medical Device Single Audit Program (MDSAP) reducing redundant inspections across multiple jurisdictions. However, significant regional variations persist, particularly regarding performance requirements for electrode-based diagnostic systems.

Post-market surveillance requirements have become increasingly stringent worldwide, with manufacturers expected to implement robust systems for monitoring device performance, adverse event reporting, and continuous risk assessment. For POC devices utilizing electrode kinetics, particular attention must be paid to drift in electrode performance over time, interference from environmental factors, and user-related errors that may impact diagnostic accuracy.

Miniaturization Strategies for Electrode Systems

The miniaturization of electrode systems represents a critical advancement in point-of-care device development, enabling portable, user-friendly diagnostic tools with enhanced performance characteristics. Current miniaturization strategies focus on several key approaches that balance technical feasibility with practical application requirements.

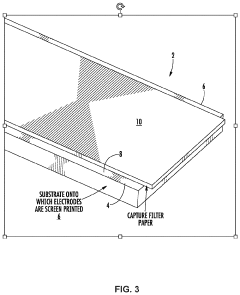

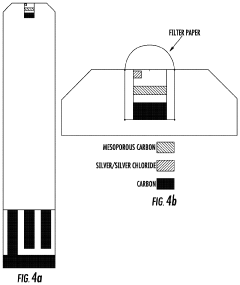

Microfabrication techniques, particularly photolithography and screen printing, have emerged as dominant methods for creating miniaturized electrode arrays. These processes allow for precise control of electrode dimensions down to the micrometer scale, facilitating the development of multi-electrode systems on a single chip. The integration of microfluidic channels with these electrode arrays further enhances functionality by enabling controlled sample delivery and reaction environments.

Nanomaterial incorporation has revolutionized electrode design, with carbon nanotubes, graphene, and metal nanoparticles significantly increasing the effective surface area while maintaining minimal physical dimensions. These materials provide enhanced electron transfer rates and improved signal-to-noise ratios, addressing key limitations in traditional miniaturized systems. For instance, gold nanoparticle-modified electrodes have demonstrated up to 100-fold improvements in sensitivity for glucose detection compared to conventional electrodes of similar dimensions.

Flexible substrate technologies represent another frontier in electrode miniaturization. Polymeric materials such as polyimide and PDMS enable the creation of conformable electrode systems that can adapt to various sample interfaces while maintaining electrical performance. These substrates support roll-to-roll manufacturing processes that significantly reduce production costs and increase scalability.

3D printing has emerged as a versatile approach for rapid prototyping of electrode housings and even direct printing of conductive elements. This technology allows for iterative design optimization without the high costs associated with traditional manufacturing methods. Recent advances in conductive ink formulations have enabled direct printing of functional electrodes with feature sizes approaching 50 micrometers.

Integration strategies that combine multiple miniaturization approaches have shown particular promise. Layer-by-layer assembly techniques enable the creation of complex electrode architectures with precisely controlled surface chemistry. These hybrid approaches often yield synergistic benefits, such as when combining nanomaterial modification with microfluidic integration to achieve both enhanced sensitivity and improved sample handling.

The ultimate challenge in electrode miniaturization remains balancing reduced dimensions with maintained or enhanced electrochemical performance. Innovative approaches to electrode geometry, such as interdigitated arrays and 3D electrode structures, maximize active surface area while minimizing overall device footprint. These design considerations are particularly crucial for applications requiring multiplexed detection capabilities within space-constrained point-of-care formats.

Microfabrication techniques, particularly photolithography and screen printing, have emerged as dominant methods for creating miniaturized electrode arrays. These processes allow for precise control of electrode dimensions down to the micrometer scale, facilitating the development of multi-electrode systems on a single chip. The integration of microfluidic channels with these electrode arrays further enhances functionality by enabling controlled sample delivery and reaction environments.

Nanomaterial incorporation has revolutionized electrode design, with carbon nanotubes, graphene, and metal nanoparticles significantly increasing the effective surface area while maintaining minimal physical dimensions. These materials provide enhanced electron transfer rates and improved signal-to-noise ratios, addressing key limitations in traditional miniaturized systems. For instance, gold nanoparticle-modified electrodes have demonstrated up to 100-fold improvements in sensitivity for glucose detection compared to conventional electrodes of similar dimensions.

Flexible substrate technologies represent another frontier in electrode miniaturization. Polymeric materials such as polyimide and PDMS enable the creation of conformable electrode systems that can adapt to various sample interfaces while maintaining electrical performance. These substrates support roll-to-roll manufacturing processes that significantly reduce production costs and increase scalability.

3D printing has emerged as a versatile approach for rapid prototyping of electrode housings and even direct printing of conductive elements. This technology allows for iterative design optimization without the high costs associated with traditional manufacturing methods. Recent advances in conductive ink formulations have enabled direct printing of functional electrodes with feature sizes approaching 50 micrometers.

Integration strategies that combine multiple miniaturization approaches have shown particular promise. Layer-by-layer assembly techniques enable the creation of complex electrode architectures with precisely controlled surface chemistry. These hybrid approaches often yield synergistic benefits, such as when combining nanomaterial modification with microfluidic integration to achieve both enhanced sensitivity and improved sample handling.

The ultimate challenge in electrode miniaturization remains balancing reduced dimensions with maintained or enhanced electrochemical performance. Innovative approaches to electrode geometry, such as interdigitated arrays and 3D electrode structures, maximize active surface area while minimizing overall device footprint. These design considerations are particularly crucial for applications requiring multiplexed detection capabilities within space-constrained point-of-care formats.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!