Antifreeze Developments in Battery Thermal Management Systems

JUL 2, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Antifreeze Evolution

The evolution of antifreeze technology in Battery Thermal Management Systems (BTMS) has been a critical factor in advancing the performance and safety of electric vehicles. Initially, traditional glycol-based coolants were adapted from internal combustion engines, providing basic thermal regulation for early electric vehicle batteries.

As battery technology progressed, the limitations of conventional antifreeze became apparent. The need for more efficient heat transfer, lower electrical conductivity, and enhanced fire safety drove the development of specialized coolants. This led to the introduction of silicone-based and dielectric fluids in the mid-2010s, offering improved thermal properties and reduced risk of electrical short circuits.

The next significant leap came with the development of phase change materials (PCMs) integrated into antifreeze solutions. These PCMs could absorb or release large amounts of latent heat during phase transitions, providing more stable temperature control for battery packs. This innovation helped address the challenges of rapid temperature fluctuations during high-power charging and discharging cycles.

Nanotechnology has played a crucial role in recent antifreeze advancements. The incorporation of nanoparticles into coolant formulations has dramatically enhanced heat transfer efficiency. Carbon nanotubes and graphene-based additives have shown particular promise, offering superior thermal conductivity and the potential for reduced pumping power requirements in BTMS.

Environmental concerns have also shaped the evolution of antifreeze technology. The shift towards more biodegradable and less toxic formulations has gained momentum, with plant-based glycols and other eco-friendly alternatives emerging as viable options. These green coolants aim to reduce the environmental impact of electric vehicle production and end-of-life disposal.

The latest frontier in antifreeze development focuses on smart fluids with adaptive properties. These advanced coolants can change their viscosity or thermal conductivity in response to temperature or electrical stimuli, allowing for more dynamic and efficient thermal management. Research into magnetorheological and electrorheological fluids shows potential for creating highly responsive BTMS that can adapt to varying driving conditions and battery states.

As the demand for faster charging and higher energy density batteries continues to grow, antifreeze technology is evolving to meet these challenges. Current research is exploring the integration of artificial intelligence to optimize coolant flow and composition in real-time, potentially revolutionizing the efficiency and longevity of electric vehicle batteries.

As battery technology progressed, the limitations of conventional antifreeze became apparent. The need for more efficient heat transfer, lower electrical conductivity, and enhanced fire safety drove the development of specialized coolants. This led to the introduction of silicone-based and dielectric fluids in the mid-2010s, offering improved thermal properties and reduced risk of electrical short circuits.

The next significant leap came with the development of phase change materials (PCMs) integrated into antifreeze solutions. These PCMs could absorb or release large amounts of latent heat during phase transitions, providing more stable temperature control for battery packs. This innovation helped address the challenges of rapid temperature fluctuations during high-power charging and discharging cycles.

Nanotechnology has played a crucial role in recent antifreeze advancements. The incorporation of nanoparticles into coolant formulations has dramatically enhanced heat transfer efficiency. Carbon nanotubes and graphene-based additives have shown particular promise, offering superior thermal conductivity and the potential for reduced pumping power requirements in BTMS.

Environmental concerns have also shaped the evolution of antifreeze technology. The shift towards more biodegradable and less toxic formulations has gained momentum, with plant-based glycols and other eco-friendly alternatives emerging as viable options. These green coolants aim to reduce the environmental impact of electric vehicle production and end-of-life disposal.

The latest frontier in antifreeze development focuses on smart fluids with adaptive properties. These advanced coolants can change their viscosity or thermal conductivity in response to temperature or electrical stimuli, allowing for more dynamic and efficient thermal management. Research into magnetorheological and electrorheological fluids shows potential for creating highly responsive BTMS that can adapt to varying driving conditions and battery states.

As the demand for faster charging and higher energy density batteries continues to grow, antifreeze technology is evolving to meet these challenges. Current research is exploring the integration of artificial intelligence to optimize coolant flow and composition in real-time, potentially revolutionizing the efficiency and longevity of electric vehicle batteries.

EV Market Demand

The electric vehicle (EV) market has experienced significant growth in recent years, driven by increasing environmental concerns, government incentives, and advancements in battery technology. This surge in demand has placed a spotlight on the critical role of battery thermal management systems (BTMS) in ensuring optimal performance, safety, and longevity of EV batteries.

As consumers become more aware of the benefits of electric vehicles, the market demand for EVs has been steadily rising. In 2022, global EV sales reached 10.5 million units, representing a 55% increase compared to the previous year. This growth trend is expected to continue, with projections suggesting that EVs could account for 30% of all vehicle sales by 2030.

The increasing adoption of EVs has led to a corresponding demand for more efficient and reliable battery thermal management systems. Consumers are seeking vehicles with longer driving ranges, faster charging capabilities, and improved overall performance. These requirements directly impact the BTMS, as maintaining optimal battery temperature is crucial for achieving these desired characteristics.

One of the key factors driving the demand for advanced BTMS is the need for improved cold-weather performance in EVs. Many consumers, particularly in regions with harsh winters, have expressed concerns about reduced battery efficiency and range in low temperatures. This has created a strong market pull for innovative antifreeze solutions in BTMS, as manufacturers strive to address these challenges and expand their market share in colder climates.

The growing focus on fast charging technologies has also contributed to the increased demand for sophisticated BTMS. As consumers expect shorter charging times, the heat generated during rapid charging processes becomes a significant concern. Effective thermal management systems that can dissipate heat quickly and maintain optimal battery temperature during fast charging are becoming increasingly important in meeting market expectations.

Safety considerations have further fueled the demand for advanced BTMS with antifreeze capabilities. High-profile incidents involving battery fires have heightened consumer awareness of the importance of proper thermal management in EVs. As a result, there is a growing market demand for BTMS that can prevent battery overheating and ensure safe operation across a wide range of environmental conditions.

The commercial EV sector, including electric buses and trucks, has also contributed to the increasing demand for robust BTMS. These vehicles often operate under more demanding conditions and require thermal management systems that can handle higher loads and maintain consistent performance over extended periods.

As the EV market continues to evolve, the demand for innovative antifreeze solutions in BTMS is expected to grow. Manufacturers that can develop and implement effective thermal management technologies will likely gain a competitive edge in this rapidly expanding market.

As consumers become more aware of the benefits of electric vehicles, the market demand for EVs has been steadily rising. In 2022, global EV sales reached 10.5 million units, representing a 55% increase compared to the previous year. This growth trend is expected to continue, with projections suggesting that EVs could account for 30% of all vehicle sales by 2030.

The increasing adoption of EVs has led to a corresponding demand for more efficient and reliable battery thermal management systems. Consumers are seeking vehicles with longer driving ranges, faster charging capabilities, and improved overall performance. These requirements directly impact the BTMS, as maintaining optimal battery temperature is crucial for achieving these desired characteristics.

One of the key factors driving the demand for advanced BTMS is the need for improved cold-weather performance in EVs. Many consumers, particularly in regions with harsh winters, have expressed concerns about reduced battery efficiency and range in low temperatures. This has created a strong market pull for innovative antifreeze solutions in BTMS, as manufacturers strive to address these challenges and expand their market share in colder climates.

The growing focus on fast charging technologies has also contributed to the increased demand for sophisticated BTMS. As consumers expect shorter charging times, the heat generated during rapid charging processes becomes a significant concern. Effective thermal management systems that can dissipate heat quickly and maintain optimal battery temperature during fast charging are becoming increasingly important in meeting market expectations.

Safety considerations have further fueled the demand for advanced BTMS with antifreeze capabilities. High-profile incidents involving battery fires have heightened consumer awareness of the importance of proper thermal management in EVs. As a result, there is a growing market demand for BTMS that can prevent battery overheating and ensure safe operation across a wide range of environmental conditions.

The commercial EV sector, including electric buses and trucks, has also contributed to the increasing demand for robust BTMS. These vehicles often operate under more demanding conditions and require thermal management systems that can handle higher loads and maintain consistent performance over extended periods.

As the EV market continues to evolve, the demand for innovative antifreeze solutions in BTMS is expected to grow. Manufacturers that can develop and implement effective thermal management technologies will likely gain a competitive edge in this rapidly expanding market.

Current Challenges

The development of antifreeze solutions for battery thermal management systems (BTMS) faces several significant challenges. One of the primary obstacles is the need for improved thermal conductivity and heat transfer efficiency. Current antifreeze formulations often struggle to maintain optimal battery temperature across a wide range of operating conditions, particularly in extreme environments.

Another critical challenge is the long-term stability and durability of antifreeze solutions. As batteries undergo numerous charge-discharge cycles, the antifreeze must maintain its performance characteristics over an extended period. Degradation of the antifreeze can lead to reduced thermal management efficiency and potentially compromise battery safety and longevity.

Compatibility with battery materials and components presents an ongoing challenge. Antifreeze solutions must be non-corrosive and chemically inert to prevent adverse reactions with battery electrodes, separators, and other internal components. Achieving this balance while maintaining optimal thermal properties remains a complex task for researchers and engineers.

Environmental concerns and regulatory compliance pose additional challenges. As the automotive industry shifts towards more sustainable practices, there is a growing demand for eco-friendly antifreeze solutions that minimize environmental impact. Developing formulations that are both effective and environmentally benign requires significant research and innovation.

The cost-effectiveness of antifreeze solutions is another hurdle in their widespread adoption. High-performance antifreeze formulations often come with increased production costs, which can impact the overall affordability of electric vehicles. Striking a balance between performance and cost remains a key challenge for manufacturers.

Scalability and mass production of advanced antifreeze solutions present logistical challenges. As the demand for electric vehicles grows, ensuring a consistent supply of high-quality antifreeze at scale becomes crucial. This requires optimizing manufacturing processes and securing reliable sources of raw materials.

Integration of antifreeze solutions with advanced BTMS designs poses engineering challenges. As battery technologies evolve, thermal management systems must adapt to new form factors and energy densities. Developing flexible antifreeze solutions that can be easily integrated into various BTMS architectures is an ongoing area of research.

Lastly, the need for standardization in antifreeze performance metrics and testing protocols presents a challenge for the industry. Establishing uniform standards for evaluating antifreeze effectiveness across different battery types and operating conditions is essential for ensuring consistent performance and safety across the electric vehicle market.

Another critical challenge is the long-term stability and durability of antifreeze solutions. As batteries undergo numerous charge-discharge cycles, the antifreeze must maintain its performance characteristics over an extended period. Degradation of the antifreeze can lead to reduced thermal management efficiency and potentially compromise battery safety and longevity.

Compatibility with battery materials and components presents an ongoing challenge. Antifreeze solutions must be non-corrosive and chemically inert to prevent adverse reactions with battery electrodes, separators, and other internal components. Achieving this balance while maintaining optimal thermal properties remains a complex task for researchers and engineers.

Environmental concerns and regulatory compliance pose additional challenges. As the automotive industry shifts towards more sustainable practices, there is a growing demand for eco-friendly antifreeze solutions that minimize environmental impact. Developing formulations that are both effective and environmentally benign requires significant research and innovation.

The cost-effectiveness of antifreeze solutions is another hurdle in their widespread adoption. High-performance antifreeze formulations often come with increased production costs, which can impact the overall affordability of electric vehicles. Striking a balance between performance and cost remains a key challenge for manufacturers.

Scalability and mass production of advanced antifreeze solutions present logistical challenges. As the demand for electric vehicles grows, ensuring a consistent supply of high-quality antifreeze at scale becomes crucial. This requires optimizing manufacturing processes and securing reliable sources of raw materials.

Integration of antifreeze solutions with advanced BTMS designs poses engineering challenges. As battery technologies evolve, thermal management systems must adapt to new form factors and energy densities. Developing flexible antifreeze solutions that can be easily integrated into various BTMS architectures is an ongoing area of research.

Lastly, the need for standardization in antifreeze performance metrics and testing protocols presents a challenge for the industry. Establishing uniform standards for evaluating antifreeze effectiveness across different battery types and operating conditions is essential for ensuring consistent performance and safety across the electric vehicle market.

Existing Solutions

01 Antifreeze compositions for battery thermal management

Specialized antifreeze compositions are developed for use in battery thermal management systems. These formulations are designed to provide optimal heat transfer properties while also offering protection against freezing and corrosion. The compositions may include a mixture of glycols, corrosion inhibitors, and other additives tailored for the specific requirements of battery cooling systems.- Antifreeze compositions for battery thermal management: Specialized antifreeze compositions are developed for use in battery thermal management systems. These formulations are designed to provide effective heat transfer, prevent freezing, and protect battery components from corrosion. The compositions may include a mixture of glycols, corrosion inhibitors, and other additives tailored for optimal performance in battery environments.

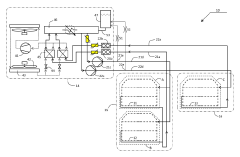

- Cooling systems with antifreeze circulation: Battery thermal management systems utilize cooling circuits that circulate antifreeze solutions. These systems are designed to efficiently remove heat from battery cells and maintain optimal operating temperatures. The circulation systems may include pumps, heat exchangers, and temperature sensors to regulate the flow and temperature of the antifreeze coolant.

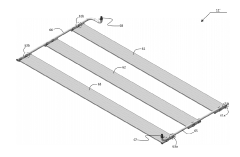

- Integration of antifreeze systems with battery packs: Antifreeze-based thermal management systems are integrated directly into battery pack designs. This integration involves creating channels or passages within the battery structure for antifreeze circulation, ensuring uniform cooling across all cells. The design may also incorporate insulation and sealing to prevent antifreeze leakage and maintain system integrity.

- Smart control systems for antifreeze-based cooling: Advanced control systems are implemented to manage the antifreeze-based thermal management of batteries. These systems use sensors, algorithms, and predictive models to optimize coolant flow, temperature, and overall system efficiency. They can adjust cooling parameters based on battery state, ambient conditions, and vehicle operating modes.

- Eco-friendly and high-performance antifreeze formulations: Research focuses on developing environmentally friendly and high-performance antifreeze formulations for battery thermal management. These new formulations aim to improve heat transfer efficiency, extend battery life, and reduce environmental impact. They may incorporate bio-based materials, nanoparticles, or advanced synthetic compounds to enhance thermal properties and reduce toxicity.

02 Thermal management system design for electric vehicle batteries

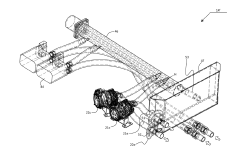

Advanced thermal management systems are designed specifically for electric vehicle batteries. These systems incorporate cooling channels, heat exchangers, and circulation pumps to efficiently regulate battery temperature. The design focuses on maintaining optimal operating conditions for the battery pack, enhancing performance and longevity while using antifreeze solutions as the heat transfer medium.Expand Specific Solutions03 Smart control strategies for battery cooling systems

Intelligent control strategies are implemented in battery thermal management systems to optimize cooling efficiency. These strategies may include adaptive algorithms, predictive models, and real-time temperature monitoring to adjust antifreeze flow rates and cooling intensity based on battery load, ambient conditions, and vehicle operating parameters.Expand Specific Solutions04 Integration of phase change materials in battery cooling

Phase change materials (PCMs) are incorporated into battery thermal management systems to enhance temperature regulation. These materials, used in conjunction with antifreeze solutions, can absorb excess heat during high-load conditions and release it during cooler periods, providing an additional layer of thermal stability for the battery pack.Expand Specific Solutions05 Eco-friendly and high-performance antifreeze formulations

Research focuses on developing environmentally friendly antifreeze formulations that maintain high performance in battery thermal management systems. These new formulations may use bio-based materials, have lower toxicity, and offer improved biodegradability while still providing excellent heat transfer and anti-corrosion properties for battery cooling applications.Expand Specific Solutions

Key Industry Players

The antifreeze developments in Battery Thermal Management Systems (BTMS) are in a growth phase, with increasing market size driven by the expanding electric vehicle industry. The technology is maturing rapidly, with major players like Nissan, BYD, and Ford Global Technologies actively advancing solutions. Companies such as BASF and Valeo Thermal Systems Japan are contributing to the development of advanced antifreeze formulations and thermal management systems. The competitive landscape is diverse, including automotive manufacturers, chemical companies, and specialized thermal management firms, indicating a multifaceted approach to innovation in this field.

BYD Co., Ltd.

Technical Solution: BYD has developed an innovative Blade Battery technology that incorporates a novel thermal management system. This system utilizes a heat-conducting silicone material and a liquid cooling plate to efficiently dissipate heat[1]. The Blade Battery's unique structure allows for better heat distribution and improved thermal stability. BYD has also implemented a smart temperature control system that adjusts cooling based on real-time battery conditions, enhancing overall performance and safety[2]. Additionally, BYD has explored the use of phase change materials (PCMs) in their battery packs to absorb excess heat during high-load operations and release it during low-load periods, effectively regulating battery temperature[3].

Strengths: Improved thermal stability, efficient heat dissipation, and smart temperature control. Weaknesses: Potential increased complexity and cost of manufacturing.

Ford Global Technologies LLC

Technical Solution: Ford has developed a comprehensive battery thermal management system that incorporates both active and passive cooling strategies. Their system utilizes a liquid coolant that circulates through channels integrated into the battery pack structure[10]. Ford has also implemented a heat pump system that can both cool and heat the battery, improving efficiency in cold weather conditions[11]. The company has explored the use of advanced materials, such as graphene-enhanced composites, to improve thermal conductivity within the battery pack. Ford's thermal management system also includes intelligent control algorithms that adjust cooling based on battery usage patterns and environmental conditions, optimizing performance and longevity[12].

Strengths: Versatile cooling and heating capabilities, use of advanced materials, and intelligent control systems. Weaknesses: Potential for increased system complexity and higher production costs.

Core Innovations

Battery Thermal Management System for Electric Vehicle

PatentInactiveKR1020230103670A

Innovation

- A thermal management system with a circulation path network that includes last-in-first-out cooling water input/output relationships and multi-channel tubes, along with a heating and cooling unit featuring a bypass flow path and air bleeding structure to manage temperature uniformly across multiple battery packs, reducing flow resistance and ensuring consistent heat transfer.

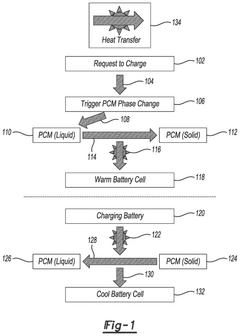

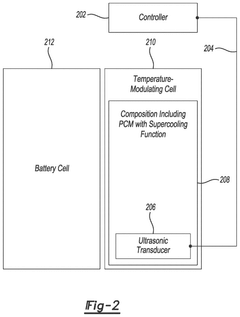

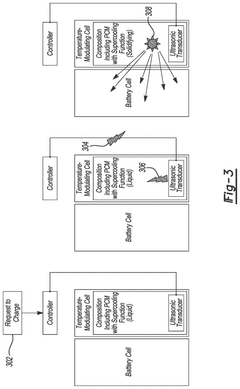

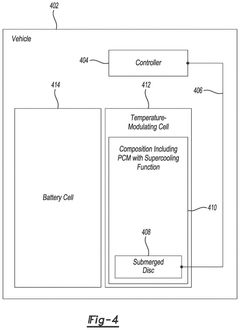

Battery arrangements with supercooled phase change materials

PatentPendingUS20250087782A1

Innovation

- A method and apparatus utilizing a supercooled phase change material (PCM) adjacent to the battery, triggered by an ultrasonic transducer or submerged disc, to release latent heat and warm the battery before charging, while also cooling the battery during charging.

Environmental Impact

The environmental impact of antifreeze developments in battery thermal management systems is a critical consideration in the pursuit of sustainable energy solutions. As the demand for electric vehicles and energy storage systems continues to grow, the need for effective thermal management becomes increasingly important. Traditional antifreeze solutions often contain toxic chemicals that pose significant environmental risks if leaked or improperly disposed of.

Recent advancements in antifreeze technology for battery thermal management systems have focused on developing more environmentally friendly alternatives. These new solutions aim to reduce the ecological footprint of battery systems while maintaining or improving their thermal performance. One promising approach involves the use of bio-based antifreeze formulations derived from renewable resources such as plant extracts or agricultural by-products. These bio-based solutions offer biodegradability and reduced toxicity compared to conventional petroleum-based antifreeze.

Another area of development is the creation of nanofluids, which incorporate nanoparticles into the antifreeze solution to enhance thermal conductivity and heat transfer efficiency. By improving the overall performance of the thermal management system, nanofluids can potentially reduce the volume of antifreeze required, thereby minimizing environmental impact. Additionally, some researchers are exploring the use of ionic liquids as antifreeze agents, which offer low volatility and high thermal stability, reducing the risk of environmental contamination through evaporation or degradation.

The shift towards more environmentally friendly antifreeze solutions also extends to the manufacturing processes involved. Companies are increasingly adopting green chemistry principles to reduce waste, energy consumption, and the use of hazardous substances during production. This holistic approach to environmental stewardship encompasses the entire lifecycle of antifreeze products, from raw material sourcing to end-of-life disposal.

Furthermore, advancements in antifreeze technology are contributing to the overall sustainability of battery systems by extending their lifespan and improving their efficiency. By maintaining optimal operating temperatures more effectively, these innovative thermal management solutions can reduce battery degradation and enhance the longevity of energy storage systems. This, in turn, reduces the frequency of battery replacements and the associated environmental impacts of battery production and disposal.

As the industry continues to evolve, there is a growing emphasis on developing closed-loop systems for antifreeze recycling and reuse. These systems aim to minimize waste and reduce the need for new antifreeze production, further decreasing the environmental footprint of battery thermal management systems. By addressing the environmental concerns associated with antifreeze use, these developments are playing a crucial role in advancing the sustainability of energy storage technologies and supporting the transition to a cleaner, more efficient energy future.

Recent advancements in antifreeze technology for battery thermal management systems have focused on developing more environmentally friendly alternatives. These new solutions aim to reduce the ecological footprint of battery systems while maintaining or improving their thermal performance. One promising approach involves the use of bio-based antifreeze formulations derived from renewable resources such as plant extracts or agricultural by-products. These bio-based solutions offer biodegradability and reduced toxicity compared to conventional petroleum-based antifreeze.

Another area of development is the creation of nanofluids, which incorporate nanoparticles into the antifreeze solution to enhance thermal conductivity and heat transfer efficiency. By improving the overall performance of the thermal management system, nanofluids can potentially reduce the volume of antifreeze required, thereby minimizing environmental impact. Additionally, some researchers are exploring the use of ionic liquids as antifreeze agents, which offer low volatility and high thermal stability, reducing the risk of environmental contamination through evaporation or degradation.

The shift towards more environmentally friendly antifreeze solutions also extends to the manufacturing processes involved. Companies are increasingly adopting green chemistry principles to reduce waste, energy consumption, and the use of hazardous substances during production. This holistic approach to environmental stewardship encompasses the entire lifecycle of antifreeze products, from raw material sourcing to end-of-life disposal.

Furthermore, advancements in antifreeze technology are contributing to the overall sustainability of battery systems by extending their lifespan and improving their efficiency. By maintaining optimal operating temperatures more effectively, these innovative thermal management solutions can reduce battery degradation and enhance the longevity of energy storage systems. This, in turn, reduces the frequency of battery replacements and the associated environmental impacts of battery production and disposal.

As the industry continues to evolve, there is a growing emphasis on developing closed-loop systems for antifreeze recycling and reuse. These systems aim to minimize waste and reduce the need for new antifreeze production, further decreasing the environmental footprint of battery thermal management systems. By addressing the environmental concerns associated with antifreeze use, these developments are playing a crucial role in advancing the sustainability of energy storage technologies and supporting the transition to a cleaner, more efficient energy future.

Safety Regulations

Safety regulations play a crucial role in the development and implementation of antifreeze solutions for battery thermal management systems (BTMS). As the electric vehicle (EV) market continues to grow, regulatory bodies worldwide have recognized the need for stringent safety standards to address the unique challenges posed by battery systems, particularly in extreme temperature conditions.

The United States National Highway Traffic Safety Administration (NHTSA) has established guidelines for EV battery safety, including requirements for thermal management systems. These regulations mandate that BTMS must maintain battery temperatures within safe operating ranges, even in extreme cold or hot environments. This has directly influenced the development of antifreeze solutions, pushing manufacturers to create more efficient and reliable formulations.

In the European Union, the Economic Commission for Europe (ECE) has implemented regulations specifically addressing the safety of rechargeable energy storage systems (REESS) in vehicles. These regulations include provisions for thermal shock and cycling tests, which evaluate the performance of BTMS and antifreeze solutions under various temperature conditions. Compliance with these standards has become a key driver for innovation in antifreeze technologies.

China, as a major player in the EV market, has also introduced comprehensive safety standards for new energy vehicles. The GB/T 31467 standard series outlines requirements for battery system safety, including thermal management. These regulations have spurred significant research and development efforts in antifreeze solutions tailored to the unique climate conditions found across China's diverse regions.

International standards, such as those developed by the International Electrotechnical Commission (IEC), have further harmonized safety requirements for EV batteries and their thermal management systems. The IEC 62660 series, for instance, provides guidelines for performance and reliability testing of lithium-ion batteries, including thermal cycling tests that directly impact antifreeze development.

As safety regulations continue to evolve, they are driving advancements in antifreeze formulations for BTMS. Manufacturers are now focusing on developing solutions that not only provide excellent thermal management properties but also meet or exceed safety standards across different jurisdictions. This has led to the emergence of new antifreeze compounds with improved fire resistance, reduced toxicity, and enhanced thermal stability.

The regulatory landscape has also prompted increased collaboration between automakers, battery manufacturers, and chemical companies to develop integrated BTMS solutions that comply with safety standards while optimizing vehicle performance. This collaborative approach has accelerated the pace of innovation in antifreeze technologies, resulting in more sophisticated and effective thermal management solutions for EV batteries.

The United States National Highway Traffic Safety Administration (NHTSA) has established guidelines for EV battery safety, including requirements for thermal management systems. These regulations mandate that BTMS must maintain battery temperatures within safe operating ranges, even in extreme cold or hot environments. This has directly influenced the development of antifreeze solutions, pushing manufacturers to create more efficient and reliable formulations.

In the European Union, the Economic Commission for Europe (ECE) has implemented regulations specifically addressing the safety of rechargeable energy storage systems (REESS) in vehicles. These regulations include provisions for thermal shock and cycling tests, which evaluate the performance of BTMS and antifreeze solutions under various temperature conditions. Compliance with these standards has become a key driver for innovation in antifreeze technologies.

China, as a major player in the EV market, has also introduced comprehensive safety standards for new energy vehicles. The GB/T 31467 standard series outlines requirements for battery system safety, including thermal management. These regulations have spurred significant research and development efforts in antifreeze solutions tailored to the unique climate conditions found across China's diverse regions.

International standards, such as those developed by the International Electrotechnical Commission (IEC), have further harmonized safety requirements for EV batteries and their thermal management systems. The IEC 62660 series, for instance, provides guidelines for performance and reliability testing of lithium-ion batteries, including thermal cycling tests that directly impact antifreeze development.

As safety regulations continue to evolve, they are driving advancements in antifreeze formulations for BTMS. Manufacturers are now focusing on developing solutions that not only provide excellent thermal management properties but also meet or exceed safety standards across different jurisdictions. This has led to the emergence of new antifreeze compounds with improved fire resistance, reduced toxicity, and enhanced thermal stability.

The regulatory landscape has also prompted increased collaboration between automakers, battery manufacturers, and chemical companies to develop integrated BTMS solutions that comply with safety standards while optimizing vehicle performance. This collaborative approach has accelerated the pace of innovation in antifreeze technologies, resulting in more sophisticated and effective thermal management solutions for EV batteries.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!