Antifreeze in Next-Gen Robotics: Managing Thermal Stresses

JUL 2, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Robotic Antifreeze Tech Evolution and Objectives

The evolution of antifreeze technology in robotics has been driven by the increasing demand for robots to operate in extreme temperature environments. Initially, antifreeze solutions were primarily focused on preventing the freezing of fluids in robotic systems, similar to those used in automotive applications. However, as robotics advanced into more diverse and challenging environments, the scope of antifreeze technology expanded to address a broader range of thermal management issues.

In the early stages of robotic development, antifreeze solutions were relatively simple, often consisting of ethylene glycol or propylene glycol-based mixtures. These solutions were effective in preventing fluid freezing but did not address the complex thermal stresses experienced by advanced robotic systems. As robots became more sophisticated and were deployed in extreme environments such as arctic exploration, deep-sea operations, and space missions, the need for more advanced thermal management solutions became apparent.

The evolution of robotic antifreeze technology has seen a shift from passive protection to active thermal management systems. This transition has been marked by the development of smart materials, phase-change coolants, and adaptive thermal control algorithms. These advancements have enabled robots to not only withstand extreme temperatures but also maintain optimal performance across a wide range of thermal conditions.

One of the key objectives in the development of next-generation robotic antifreeze technology is to create systems that can dynamically respond to changing thermal stresses. This includes the ability to rapidly dissipate heat during high-intensity operations and retain heat in extremely cold environments. Another important goal is to develop antifreeze solutions that are environmentally friendly and compatible with the diverse materials used in modern robotics.

The current frontier of robotic antifreeze technology focuses on nanotechnology-based solutions. Researchers are exploring the use of nanofluids and nanocomposites that can significantly enhance heat transfer efficiency and provide superior thermal protection. These advanced materials offer the potential for dramatic improvements in the thermal management capabilities of robotic systems, enabling them to operate in environments that were previously considered too extreme.

Looking ahead, the objectives for future robotic antifreeze technology include the development of self-healing thermal management systems, integration of artificial intelligence for predictive thermal regulation, and the creation of ultra-lightweight, high-efficiency thermal materials. These advancements aim to push the boundaries of robotic capabilities, allowing for extended operations in the harshest environments on Earth and beyond.

In the early stages of robotic development, antifreeze solutions were relatively simple, often consisting of ethylene glycol or propylene glycol-based mixtures. These solutions were effective in preventing fluid freezing but did not address the complex thermal stresses experienced by advanced robotic systems. As robots became more sophisticated and were deployed in extreme environments such as arctic exploration, deep-sea operations, and space missions, the need for more advanced thermal management solutions became apparent.

The evolution of robotic antifreeze technology has seen a shift from passive protection to active thermal management systems. This transition has been marked by the development of smart materials, phase-change coolants, and adaptive thermal control algorithms. These advancements have enabled robots to not only withstand extreme temperatures but also maintain optimal performance across a wide range of thermal conditions.

One of the key objectives in the development of next-generation robotic antifreeze technology is to create systems that can dynamically respond to changing thermal stresses. This includes the ability to rapidly dissipate heat during high-intensity operations and retain heat in extremely cold environments. Another important goal is to develop antifreeze solutions that are environmentally friendly and compatible with the diverse materials used in modern robotics.

The current frontier of robotic antifreeze technology focuses on nanotechnology-based solutions. Researchers are exploring the use of nanofluids and nanocomposites that can significantly enhance heat transfer efficiency and provide superior thermal protection. These advanced materials offer the potential for dramatic improvements in the thermal management capabilities of robotic systems, enabling them to operate in environments that were previously considered too extreme.

Looking ahead, the objectives for future robotic antifreeze technology include the development of self-healing thermal management systems, integration of artificial intelligence for predictive thermal regulation, and the creation of ultra-lightweight, high-efficiency thermal materials. These advancements aim to push the boundaries of robotic capabilities, allowing for extended operations in the harshest environments on Earth and beyond.

Market Demand for Cold-Resistant Robots

The market demand for cold-resistant robots has been steadily increasing, driven by the growing need for automation in harsh environments and extreme weather conditions. Industries such as agriculture, construction, mining, and polar research are particularly interested in robots that can operate efficiently in sub-zero temperatures.

In the agricultural sector, there is a rising demand for autonomous machines capable of working in cold climates. These robots are expected to perform tasks such as snow removal, winter crop monitoring, and livestock management in freezing conditions. The ability to operate in low temperatures extends the growing season and improves overall productivity in regions with long winters.

The construction industry also shows significant interest in cold-resistant robots. These machines can continue operations during winter months, reducing project delays and increasing efficiency. Tasks such as site surveying, material handling, and even certain building processes can be carried out by robots designed to withstand extreme cold, thereby maintaining productivity throughout the year.

In the mining sector, particularly in regions like Canada, Russia, and Scandinavia, there is a strong demand for robots that can operate in sub-zero temperatures. These machines are crucial for maintaining continuous operations in open-pit mines and for exploring new mineral deposits in Arctic regions. The ability to function in extreme cold allows for safer and more efficient resource extraction in these challenging environments.

Scientific research, especially in polar regions, represents another significant market for cold-resistant robots. Autonomous vehicles and drones capable of withstanding Arctic and Antarctic conditions are invaluable for data collection, environmental monitoring, and exploration in these remote and inhospitable areas. The demand for such robots is expected to grow as climate research intensifies and as nations increase their presence in polar regions.

The military and defense sector also contributes to the market demand for cold-resistant robots. These machines are used for surveillance, reconnaissance, and logistics support in cold climate operations. The ability to deploy robots in extreme cold reduces the risk to human personnel and enhances operational capabilities in challenging environments.

As urban areas in cold regions seek to improve their winter maintenance capabilities, there is a growing interest in autonomous snow removal and de-icing robots. These machines can operate around the clock, improving the efficiency of winter road maintenance and reducing the reliance on human labor in harsh conditions.

The market for cold-resistant robots is expected to expand further as advancements in materials science and thermal management technologies improve their performance and reliability. This growth is likely to be accompanied by increased investment in research and development, as companies strive to meet the specific needs of various industries operating in cold environments.

In the agricultural sector, there is a rising demand for autonomous machines capable of working in cold climates. These robots are expected to perform tasks such as snow removal, winter crop monitoring, and livestock management in freezing conditions. The ability to operate in low temperatures extends the growing season and improves overall productivity in regions with long winters.

The construction industry also shows significant interest in cold-resistant robots. These machines can continue operations during winter months, reducing project delays and increasing efficiency. Tasks such as site surveying, material handling, and even certain building processes can be carried out by robots designed to withstand extreme cold, thereby maintaining productivity throughout the year.

In the mining sector, particularly in regions like Canada, Russia, and Scandinavia, there is a strong demand for robots that can operate in sub-zero temperatures. These machines are crucial for maintaining continuous operations in open-pit mines and for exploring new mineral deposits in Arctic regions. The ability to function in extreme cold allows for safer and more efficient resource extraction in these challenging environments.

Scientific research, especially in polar regions, represents another significant market for cold-resistant robots. Autonomous vehicles and drones capable of withstanding Arctic and Antarctic conditions are invaluable for data collection, environmental monitoring, and exploration in these remote and inhospitable areas. The demand for such robots is expected to grow as climate research intensifies and as nations increase their presence in polar regions.

The military and defense sector also contributes to the market demand for cold-resistant robots. These machines are used for surveillance, reconnaissance, and logistics support in cold climate operations. The ability to deploy robots in extreme cold reduces the risk to human personnel and enhances operational capabilities in challenging environments.

As urban areas in cold regions seek to improve their winter maintenance capabilities, there is a growing interest in autonomous snow removal and de-icing robots. These machines can operate around the clock, improving the efficiency of winter road maintenance and reducing the reliance on human labor in harsh conditions.

The market for cold-resistant robots is expected to expand further as advancements in materials science and thermal management technologies improve their performance and reliability. This growth is likely to be accompanied by increased investment in research and development, as companies strive to meet the specific needs of various industries operating in cold environments.

Current Antifreeze Solutions and Challenges

Current antifreeze solutions for managing thermal stresses in next-generation robotics primarily focus on two main approaches: traditional liquid-based systems and advanced materials engineering. Liquid-based antifreeze solutions, such as ethylene glycol and propylene glycol mixtures, have been widely used in various industries, including robotics. These solutions effectively lower the freezing point of water and raise its boiling point, providing a wider operational temperature range for robotic systems.

However, traditional antifreeze solutions face several challenges in next-generation robotics applications. One major issue is the potential for leakage, which can lead to system failures and environmental contamination. Additionally, the viscosity of these liquids can change significantly with temperature fluctuations, affecting the efficiency of heat transfer and potentially impacting the performance of robotic components.

Advanced materials engineering has led to the development of solid-state antifreeze solutions, such as phase-change materials (PCMs) and nanocomposites. PCMs can absorb or release large amounts of latent heat during phase transitions, effectively regulating temperature in robotic systems. Nanocomposites, incorporating nanomaterials like carbon nanotubes or graphene, offer enhanced thermal conductivity and improved heat dissipation properties.

Despite these advancements, solid-state solutions also face challenges. The integration of PCMs and nanocomposites into complex robotic structures can be difficult, often requiring significant redesigns of existing systems. Moreover, the long-term stability and performance of these materials under repeated thermal cycling and mechanical stress remain concerns that need further investigation.

Another emerging approach is the use of active thermal management systems, which combine sensors, control algorithms, and adaptive materials to dynamically respond to changing thermal conditions. While promising, these systems add complexity and potential points of failure to robotic designs, presenting challenges in terms of reliability and maintenance.

The miniaturization of robotic systems poses additional challenges for antifreeze solutions. As robots become smaller and more intricate, the space available for thermal management systems decreases, necessitating more compact and efficient antifreeze solutions. This constraint has driven research into novel materials and designs that can provide effective thermal management in confined spaces.

Furthermore, the diverse operating environments of next-generation robots, from extreme cold to high heat, demand antifreeze solutions with a broad temperature range and adaptability. Developing universal solutions that can perform effectively across various conditions remains a significant challenge in the field.

However, traditional antifreeze solutions face several challenges in next-generation robotics applications. One major issue is the potential for leakage, which can lead to system failures and environmental contamination. Additionally, the viscosity of these liquids can change significantly with temperature fluctuations, affecting the efficiency of heat transfer and potentially impacting the performance of robotic components.

Advanced materials engineering has led to the development of solid-state antifreeze solutions, such as phase-change materials (PCMs) and nanocomposites. PCMs can absorb or release large amounts of latent heat during phase transitions, effectively regulating temperature in robotic systems. Nanocomposites, incorporating nanomaterials like carbon nanotubes or graphene, offer enhanced thermal conductivity and improved heat dissipation properties.

Despite these advancements, solid-state solutions also face challenges. The integration of PCMs and nanocomposites into complex robotic structures can be difficult, often requiring significant redesigns of existing systems. Moreover, the long-term stability and performance of these materials under repeated thermal cycling and mechanical stress remain concerns that need further investigation.

Another emerging approach is the use of active thermal management systems, which combine sensors, control algorithms, and adaptive materials to dynamically respond to changing thermal conditions. While promising, these systems add complexity and potential points of failure to robotic designs, presenting challenges in terms of reliability and maintenance.

The miniaturization of robotic systems poses additional challenges for antifreeze solutions. As robots become smaller and more intricate, the space available for thermal management systems decreases, necessitating more compact and efficient antifreeze solutions. This constraint has driven research into novel materials and designs that can provide effective thermal management in confined spaces.

Furthermore, the diverse operating environments of next-generation robots, from extreme cold to high heat, demand antifreeze solutions with a broad temperature range and adaptability. Developing universal solutions that can perform effectively across various conditions remains a significant challenge in the field.

Existing Antifreeze Implementations

01 Antifreeze compositions for thermal stress management

Specialized antifreeze compositions are developed to manage thermal stresses in various systems. These formulations are designed to withstand extreme temperature fluctuations, prevent freezing, and reduce thermal expansion and contraction. The compositions often include additives that enhance heat transfer properties and provide protection against corrosion.- Antifreeze compositions for thermal stress management: Specialized antifreeze compositions are developed to manage thermal stresses in various systems. These formulations are designed to withstand extreme temperature fluctuations, preventing freezing and reducing thermal expansion. The compositions often include additives that enhance heat transfer properties and protect against corrosion, ensuring optimal performance under thermal stress conditions.

- Thermal stress reduction in electronic components: Techniques are employed to mitigate thermal stresses in electronic components and systems. These methods involve the use of advanced cooling systems, heat-dissipating materials, and thermal management strategies. The focus is on maintaining optimal operating temperatures and preventing damage from thermal cycling, particularly in high-performance computing and power electronics applications.

- Materials with enhanced thermal stress resistance: Development of materials with improved resistance to thermal stresses is crucial in various industries. These materials are engineered to maintain their structural integrity and performance under extreme temperature variations. Research focuses on creating composites, alloys, and coatings that can withstand thermal shocks and cyclic thermal loading without degradation or failure.

- Thermal stress analysis and simulation techniques: Advanced analytical and simulation methods are utilized to predict and evaluate thermal stresses in complex systems. These techniques involve finite element analysis, computational fluid dynamics, and thermal modeling to assess the impact of temperature changes on materials and structures. The goal is to optimize designs and prevent failures due to thermal stresses in various applications.

- Thermal stress management in manufacturing processes: Strategies are developed to control and minimize thermal stresses during manufacturing processes. This includes optimizing heating and cooling cycles, implementing stress-relief techniques, and using specialized equipment to manage temperature gradients. The focus is on improving product quality, reducing defects, and enhancing the overall efficiency of manufacturing operations that involve thermal processing.

02 Thermal stress reduction in electronic components

Techniques are employed to mitigate thermal stresses in electronic components and semiconductor devices. These methods involve the use of advanced materials, cooling systems, and design strategies to dissipate heat effectively and prevent damage from thermal expansion. Solutions may include heat sinks, thermal interface materials, and specialized packaging.Expand Specific Solutions03 Antifreeze solutions for automotive applications

Automotive antifreeze solutions are formulated to address thermal stresses in engine cooling systems. These products are designed to maintain optimal engine temperature, prevent freezing in cold conditions, and resist boiling in high temperatures. Advanced formulations may include corrosion inhibitors and additives to enhance heat transfer efficiency.Expand Specific Solutions04 Thermal stress management in construction materials

Innovations in construction materials and techniques aim to reduce thermal stresses in buildings and infrastructure. These developments include the use of expansion joints, thermal insulation, and materials with low thermal expansion coefficients. Strategies may also involve the incorporation of phase change materials or smart materials that adapt to temperature changes.Expand Specific Solutions05 Cryogenic systems and thermal stress mitigation

Specialized solutions are developed for managing thermal stresses in cryogenic systems and applications involving extreme low temperatures. These include advanced insulation materials, vapor-cooled radiation shields, and multi-layer insulation systems. Techniques may also involve the use of flexible materials and designs that accommodate thermal contraction and expansion.Expand Specific Solutions

Key Players in Robotic Antifreeze

The antifreeze technology in next-generation robotics is in an early development stage, with a growing market driven by the increasing demand for advanced robotics in extreme environments. The global market for thermal management in robotics is expected to expand significantly in the coming years. Companies like FANUC, LG Electronics, and Google are at the forefront of this technology, investing heavily in research and development. While the technology is still evolving, major players are making strides in managing thermal stresses, with solutions ranging from advanced materials to innovative cooling systems. The competitive landscape is diverse, with both established robotics manufacturers and tech giants vying for market share in this emerging field.

BASF Corp.

Technical Solution: BASF, as a leading chemical company, has contributed to next-gen robotics thermal management through the development of advanced materials and coolants. They have created a line of high-performance thermal interface materials (TIMs) specifically designed for robotic applications. These materials offer superior thermal conductivity and can withstand the mechanical stresses typical in robotic operations[10]. BASF has also formulated novel antifreeze solutions that combine low viscosity for efficient pumping with high heat capacity for effective temperature control. Their coolants incorporate corrosion inhibitors to protect robotic components and maintain long-term performance[11]. Furthermore, BASF is researching nanofluid-based coolants that promise even greater heat transfer efficiency for future robotic systems[12].

Strengths: Expertise in material science, comprehensive range of thermal management solutions. Weaknesses: Reliance on other companies for system integration.

FANUC Corp.

Technical Solution: FANUC has developed advanced thermal management solutions for their next-generation robotics systems. Their approach includes the use of high-performance coolants and innovative heat dissipation techniques. FANUC's robots incorporate a closed-loop cooling system that circulates a specialized antifreeze solution through critical components[1]. This system is designed to maintain optimal operating temperatures even in extreme environments, with the ability to function effectively in temperatures ranging from -30°C to 45°C[2]. The company has also implemented adaptive thermal control algorithms that adjust cooling intensity based on real-time temperature monitoring, ensuring efficient energy use while preventing thermal stress[3].

Strengths: Robust temperature range for operation, energy-efficient adaptive cooling. Weaknesses: Potential complexity in maintenance of advanced cooling systems.

Innovative Antifreeze Materials and Methods

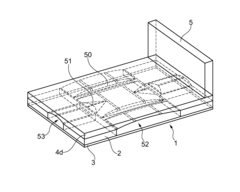

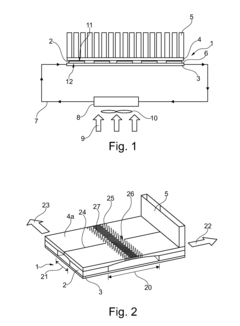

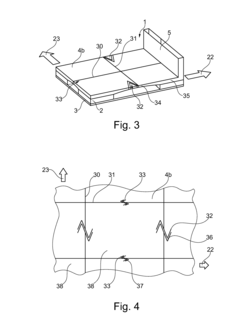

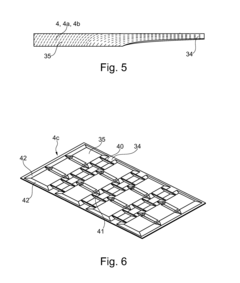

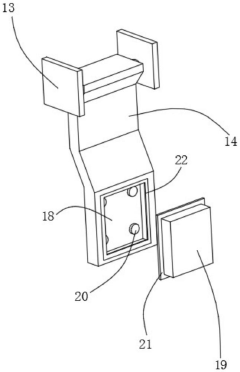

Thermoelectric temperature control unit

PatentInactiveUS20150000307A1

Innovation

- The thermoelectric temperature control unit incorporates Peltier elements connected to cover plates with expansion joints and/or spring structures, which absorb thermal stresses, ensuring the stability and longevity of the unit by compensating for changes in length and maintaining a homogeneous temperature distribution.

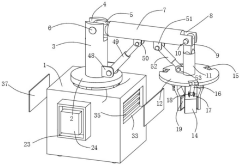

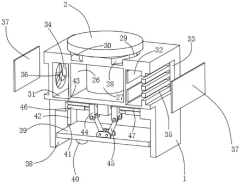

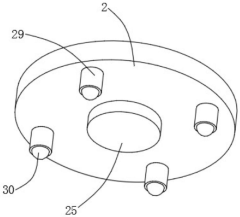

Collaborative robot with pressure sensing function

PatentPendingCN116766231A

Innovation

- A collaborative robot with pressure sensing is designed. By installing a pressure sensor on the plywood, the clamping force is detected in real time and the thrust of the electric push rod is adjusted to avoid excessive clamping force. A heat dissipation mechanism of refrigeration fins and fans is used for rapid cooling. .

Environmental Impact of Antifreeze Tech

The environmental impact of antifreeze technology in next-generation robotics is a critical consideration as the industry advances. Traditional antifreeze solutions, primarily based on ethylene glycol or propylene glycol, have raised concerns due to their potential toxicity and persistence in the environment. As robotics systems become more prevalent in various sectors, the cumulative effect of antifreeze usage and disposal could pose significant ecological risks.

In response to these challenges, the robotics industry is exploring more environmentally friendly alternatives. Bio-based antifreezes derived from renewable resources such as corn, soy, or other plant-based materials are gaining traction. These solutions offer comparable thermal management properties while being biodegradable and less toxic to wildlife and ecosystems. However, their production may raise questions about land use and competition with food crops.

Another promising approach is the development of nano-engineered fluids that enhance heat transfer efficiency, potentially reducing the overall volume of antifreeze required. These advanced coolants incorporate nanoparticles that improve thermal conductivity, allowing for more effective temperature regulation with less environmental impact. However, the long-term effects of nanoparticles on ecosystems are still under investigation.

Closed-loop systems are being implemented to minimize antifreeze release into the environment. These systems aim to recycle and reuse antifreeze solutions within robotic systems, significantly reducing the need for disposal and the associated environmental risks. Additionally, improved sealing technologies and leak detection systems are being integrated to prevent accidental releases during operation.

The robotics industry is also focusing on the end-of-life management of antifreeze solutions. Advanced recycling techniques are being developed to recover and purify used antifreeze, reducing waste and the demand for new production. This circular economy approach not only minimizes environmental impact but also offers potential cost savings for manufacturers and operators.

Regulatory bodies are increasingly scrutinizing the environmental impact of antifreeze in robotics. Stricter guidelines for handling, disposal, and recycling are being implemented in various regions. This regulatory pressure is driving innovation in antifreeze technology, pushing manufacturers to develop more sustainable solutions that comply with evolving environmental standards.

As the robotics industry continues to expand, the cumulative environmental impact of antifreeze technology becomes more significant. Addressing these concerns is crucial for the sustainable development of next-generation robotics, ensuring that the benefits of advanced thermal management do not come at the cost of environmental degradation.

In response to these challenges, the robotics industry is exploring more environmentally friendly alternatives. Bio-based antifreezes derived from renewable resources such as corn, soy, or other plant-based materials are gaining traction. These solutions offer comparable thermal management properties while being biodegradable and less toxic to wildlife and ecosystems. However, their production may raise questions about land use and competition with food crops.

Another promising approach is the development of nano-engineered fluids that enhance heat transfer efficiency, potentially reducing the overall volume of antifreeze required. These advanced coolants incorporate nanoparticles that improve thermal conductivity, allowing for more effective temperature regulation with less environmental impact. However, the long-term effects of nanoparticles on ecosystems are still under investigation.

Closed-loop systems are being implemented to minimize antifreeze release into the environment. These systems aim to recycle and reuse antifreeze solutions within robotic systems, significantly reducing the need for disposal and the associated environmental risks. Additionally, improved sealing technologies and leak detection systems are being integrated to prevent accidental releases during operation.

The robotics industry is also focusing on the end-of-life management of antifreeze solutions. Advanced recycling techniques are being developed to recover and purify used antifreeze, reducing waste and the demand for new production. This circular economy approach not only minimizes environmental impact but also offers potential cost savings for manufacturers and operators.

Regulatory bodies are increasingly scrutinizing the environmental impact of antifreeze in robotics. Stricter guidelines for handling, disposal, and recycling are being implemented in various regions. This regulatory pressure is driving innovation in antifreeze technology, pushing manufacturers to develop more sustainable solutions that comply with evolving environmental standards.

As the robotics industry continues to expand, the cumulative environmental impact of antifreeze technology becomes more significant. Addressing these concerns is crucial for the sustainable development of next-generation robotics, ensuring that the benefits of advanced thermal management do not come at the cost of environmental degradation.

Standardization of Robotic Thermal Testing

The standardization of robotic thermal testing is a critical aspect in the development and deployment of next-generation robotics, particularly in managing thermal stresses and implementing effective antifreeze solutions. This standardization process aims to establish uniform methods and protocols for evaluating the thermal performance and resilience of robotic systems across various environmental conditions.

One of the primary objectives of standardizing robotic thermal testing is to create a common framework that allows for consistent and comparable results across different robotic platforms and manufacturers. This standardization typically involves defining specific temperature ranges, exposure durations, and performance metrics that robots must meet to be considered thermally robust. By establishing these benchmarks, developers and end-users can more accurately assess and compare the thermal capabilities of different robotic systems.

The standardization process often includes the development of specialized testing equipment and procedures. These may involve thermal chambers capable of simulating extreme temperature conditions, from arctic cold to desert heat. Additionally, standardized sensors and data collection methods are crucial for ensuring the accuracy and reliability of thermal performance measurements. This may include the use of thermal imaging cameras, temperature probes, and stress sensors to monitor how different components of a robot respond to thermal challenges.

Another key aspect of standardizing robotic thermal testing is the creation of specific test scenarios that mimic real-world conditions. These scenarios might include rapid temperature fluctuations, prolonged exposure to extreme temperatures, or combinations of temperature and humidity changes. By subjecting robots to these standardized tests, developers can identify potential weaknesses in thermal management systems and make necessary improvements before deployment.

The standardization efforts also extend to the materials and components used in robotic systems. This includes establishing guidelines for the selection and testing of thermal management materials, such as heat-resistant polymers, thermal interface materials, and cooling systems. Standardized testing protocols help ensure that these materials can withstand the thermal stresses encountered in various operational environments.

Furthermore, the standardization of robotic thermal testing plays a crucial role in regulatory compliance and safety certification. As robots become more integrated into various industries and public spaces, there is an increasing need for standardized safety measures, including those related to thermal management. These standards help ensure that robots can operate safely and reliably in diverse thermal conditions, reducing the risk of malfunctions or failures due to temperature-related issues.

In conclusion, the standardization of robotic thermal testing is an essential step in advancing the field of robotics, particularly in addressing the challenges of thermal stress management and antifreeze implementation. By establishing uniform testing methods and performance criteria, this standardization process facilitates innovation, improves product reliability, and enhances the overall safety and effectiveness of next-generation robotic systems across various applications and environments.

One of the primary objectives of standardizing robotic thermal testing is to create a common framework that allows for consistent and comparable results across different robotic platforms and manufacturers. This standardization typically involves defining specific temperature ranges, exposure durations, and performance metrics that robots must meet to be considered thermally robust. By establishing these benchmarks, developers and end-users can more accurately assess and compare the thermal capabilities of different robotic systems.

The standardization process often includes the development of specialized testing equipment and procedures. These may involve thermal chambers capable of simulating extreme temperature conditions, from arctic cold to desert heat. Additionally, standardized sensors and data collection methods are crucial for ensuring the accuracy and reliability of thermal performance measurements. This may include the use of thermal imaging cameras, temperature probes, and stress sensors to monitor how different components of a robot respond to thermal challenges.

Another key aspect of standardizing robotic thermal testing is the creation of specific test scenarios that mimic real-world conditions. These scenarios might include rapid temperature fluctuations, prolonged exposure to extreme temperatures, or combinations of temperature and humidity changes. By subjecting robots to these standardized tests, developers can identify potential weaknesses in thermal management systems and make necessary improvements before deployment.

The standardization efforts also extend to the materials and components used in robotic systems. This includes establishing guidelines for the selection and testing of thermal management materials, such as heat-resistant polymers, thermal interface materials, and cooling systems. Standardized testing protocols help ensure that these materials can withstand the thermal stresses encountered in various operational environments.

Furthermore, the standardization of robotic thermal testing plays a crucial role in regulatory compliance and safety certification. As robots become more integrated into various industries and public spaces, there is an increasing need for standardized safety measures, including those related to thermal management. These standards help ensure that robots can operate safely and reliably in diverse thermal conditions, reducing the risk of malfunctions or failures due to temperature-related issues.

In conclusion, the standardization of robotic thermal testing is an essential step in advancing the field of robotics, particularly in addressing the challenges of thermal stress management and antifreeze implementation. By establishing uniform testing methods and performance criteria, this standardization process facilitates innovation, improves product reliability, and enhances the overall safety and effectiveness of next-generation robotic systems across various applications and environments.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!