Antimicrobial Surface Coatings in Textile Innovation

SEP 29, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Antimicrobial Textile Coating Evolution and Objectives

Antimicrobial textiles have evolved significantly over the past century, with major advancements occurring particularly in the last three decades. The journey began with simple applications of natural antimicrobial substances like copper and silver, which ancient civilizations used to preserve textiles and prevent odor. By the mid-20th century, synthetic antimicrobial agents emerged, offering more controlled and predictable performance characteristics.

The 1990s marked a turning point with the introduction of quaternary ammonium compounds and triclosan in commercial textile applications. These developments coincided with growing consumer awareness about hygiene and the spread of infectious diseases. The early 2000s witnessed the rise of nanotechnology in antimicrobial textiles, with silver nanoparticles becoming particularly prominent due to their enhanced efficacy at lower concentrations.

Recent technological evolution has been driven by increasing concerns about antibiotic resistance and healthcare-associated infections. This has pushed research toward more sustainable and environmentally friendly solutions, including bio-based antimicrobial agents derived from plant extracts, essential oils, and chitosan. Additionally, the development of photocatalytic coatings using titanium dioxide and zinc oxide has introduced self-cleaning properties to antimicrobial textiles.

The COVID-19 pandemic accelerated innovation in this field, with unprecedented demand for protective textiles in healthcare settings, public spaces, and personal use. This catalyzed research into multifunctional coatings that combine antimicrobial properties with antiviral efficacy, creating a new generation of protective textiles.

The primary objectives of current antimicrobial textile coating research include developing solutions with broader spectrum activity against various pathogens while maintaining long-term durability through multiple washing cycles. Researchers aim to create coatings that remain effective throughout the entire lifecycle of the textile product without leaching harmful substances into the environment.

Another critical objective is addressing the growing concern about antimicrobial resistance by designing coatings that inhibit microbial growth through multiple mechanisms, reducing the likelihood of resistance development. The industry is also focused on creating cost-effective manufacturing processes that can be scaled for mass production without compromising performance or sustainability.

Looking forward, the field aims to integrate smart technologies with antimicrobial functionalities, creating textiles that can respond to environmental changes or contamination events. This includes the development of indicators that signal when antimicrobial efficacy has diminished and needs renewal, as well as self-regenerating coatings that can maintain their protective properties over extended periods without external intervention.

The 1990s marked a turning point with the introduction of quaternary ammonium compounds and triclosan in commercial textile applications. These developments coincided with growing consumer awareness about hygiene and the spread of infectious diseases. The early 2000s witnessed the rise of nanotechnology in antimicrobial textiles, with silver nanoparticles becoming particularly prominent due to their enhanced efficacy at lower concentrations.

Recent technological evolution has been driven by increasing concerns about antibiotic resistance and healthcare-associated infections. This has pushed research toward more sustainable and environmentally friendly solutions, including bio-based antimicrobial agents derived from plant extracts, essential oils, and chitosan. Additionally, the development of photocatalytic coatings using titanium dioxide and zinc oxide has introduced self-cleaning properties to antimicrobial textiles.

The COVID-19 pandemic accelerated innovation in this field, with unprecedented demand for protective textiles in healthcare settings, public spaces, and personal use. This catalyzed research into multifunctional coatings that combine antimicrobial properties with antiviral efficacy, creating a new generation of protective textiles.

The primary objectives of current antimicrobial textile coating research include developing solutions with broader spectrum activity against various pathogens while maintaining long-term durability through multiple washing cycles. Researchers aim to create coatings that remain effective throughout the entire lifecycle of the textile product without leaching harmful substances into the environment.

Another critical objective is addressing the growing concern about antimicrobial resistance by designing coatings that inhibit microbial growth through multiple mechanisms, reducing the likelihood of resistance development. The industry is also focused on creating cost-effective manufacturing processes that can be scaled for mass production without compromising performance or sustainability.

Looking forward, the field aims to integrate smart technologies with antimicrobial functionalities, creating textiles that can respond to environmental changes or contamination events. This includes the development of indicators that signal when antimicrobial efficacy has diminished and needs renewal, as well as self-regenerating coatings that can maintain their protective properties over extended periods without external intervention.

Market Analysis for Antimicrobial Textiles

The global antimicrobial textiles market has experienced significant growth in recent years, driven by increasing health awareness and the rising prevalence of hospital-acquired infections. As of 2023, the market is valued at approximately 12.4 billion USD, with projections indicating a compound annual growth rate (CAGR) of 7.2% through 2030, potentially reaching 20.1 billion USD by the end of the forecast period.

Healthcare applications currently dominate the antimicrobial textiles market, accounting for nearly 40% of the total market share. This segment includes medical uniforms, bed linens, surgical drapes, and patient gowns. The COVID-19 pandemic has substantially accelerated demand in this sector, with hospitals and healthcare facilities implementing stricter infection control protocols.

The sportswear and athleisure segment represents the fastest-growing application area, with an estimated CAGR of 8.5%. Consumers increasingly seek odor-resistant and hygiene-enhancing properties in athletic apparel, driving manufacturers to incorporate antimicrobial technologies into their product lines. Major sportswear brands have launched specialized antimicrobial collections, contributing to market expansion.

Geographically, North America leads the market with approximately 35% share, followed by Europe at 28% and Asia-Pacific at 25%. However, the Asia-Pacific region is expected to witness the highest growth rate due to expanding healthcare infrastructure, increasing disposable income, and growing awareness about hygiene in countries like China, India, and Japan.

Consumer preferences are shifting toward sustainable and eco-friendly antimicrobial solutions. The market has observed a 30% increase in demand for naturally derived antimicrobial agents such as chitosan, aloe vera, and tea tree oil extracts. This trend aligns with broader consumer concerns regarding chemical exposure and environmental impact.

Regulatory frameworks significantly influence market dynamics. The European Union's Biocidal Products Regulation (BPR) and the U.S. Environmental Protection Agency's regulations on antimicrobial agents have created stringent approval processes for new antimicrobial textiles. Companies must invest substantially in compliance and testing, which has slowed product development cycles but improved overall product safety.

Price sensitivity varies across market segments. While healthcare institutions prioritize efficacy and durability over cost, the consumer retail segment remains highly price-sensitive. The average price premium for antimicrobial textiles ranges from 15-25% compared to conventional alternatives, presenting challenges for mass-market adoption.

Healthcare applications currently dominate the antimicrobial textiles market, accounting for nearly 40% of the total market share. This segment includes medical uniforms, bed linens, surgical drapes, and patient gowns. The COVID-19 pandemic has substantially accelerated demand in this sector, with hospitals and healthcare facilities implementing stricter infection control protocols.

The sportswear and athleisure segment represents the fastest-growing application area, with an estimated CAGR of 8.5%. Consumers increasingly seek odor-resistant and hygiene-enhancing properties in athletic apparel, driving manufacturers to incorporate antimicrobial technologies into their product lines. Major sportswear brands have launched specialized antimicrobial collections, contributing to market expansion.

Geographically, North America leads the market with approximately 35% share, followed by Europe at 28% and Asia-Pacific at 25%. However, the Asia-Pacific region is expected to witness the highest growth rate due to expanding healthcare infrastructure, increasing disposable income, and growing awareness about hygiene in countries like China, India, and Japan.

Consumer preferences are shifting toward sustainable and eco-friendly antimicrobial solutions. The market has observed a 30% increase in demand for naturally derived antimicrobial agents such as chitosan, aloe vera, and tea tree oil extracts. This trend aligns with broader consumer concerns regarding chemical exposure and environmental impact.

Regulatory frameworks significantly influence market dynamics. The European Union's Biocidal Products Regulation (BPR) and the U.S. Environmental Protection Agency's regulations on antimicrobial agents have created stringent approval processes for new antimicrobial textiles. Companies must invest substantially in compliance and testing, which has slowed product development cycles but improved overall product safety.

Price sensitivity varies across market segments. While healthcare institutions prioritize efficacy and durability over cost, the consumer retail segment remains highly price-sensitive. The average price premium for antimicrobial textiles ranges from 15-25% compared to conventional alternatives, presenting challenges for mass-market adoption.

Current Antimicrobial Surface Technologies and Barriers

The antimicrobial surface coating landscape for textiles currently encompasses several established technologies with varying efficacy, sustainability profiles, and market adoption. Silver-based antimicrobial treatments remain the most widely implemented solution, with silver nanoparticles and silver ions demonstrating broad-spectrum activity against bacteria, fungi, and certain viruses. These coatings typically function through multiple mechanisms including cell membrane disruption and metabolic interference, providing long-lasting protection even after multiple wash cycles.

Quaternary ammonium compounds (QACs) represent another significant category, offering cost-effective antimicrobial performance through their positively charged molecules that disrupt microbial cell membranes. However, concerns regarding potential bacterial resistance development and environmental persistence have prompted increased regulatory scrutiny in certain markets.

Natural antimicrobial agents derived from plant extracts, essential oils, and chitosan have gained substantial attention as sustainable alternatives. These bio-based solutions address growing consumer demand for environmentally friendly textiles but face challenges related to standardization, stability, and durability compared to synthetic counterparts.

Metal oxide nanoparticles, particularly zinc oxide and titanium dioxide, have emerged as multifunctional antimicrobial agents that simultaneously provide UV protection and self-cleaning properties. Their photocatalytic activity generates reactive oxygen species that effectively neutralize microorganisms, though concerns regarding nanoparticle migration and potential environmental impacts persist.

Despite these technological advances, significant barriers impede widespread adoption of antimicrobial textiles. Durability remains a primary challenge, with many coatings demonstrating diminished efficacy after repeated laundering. This necessitates the development of more robust binding mechanisms between antimicrobial agents and textile substrates.

Regulatory frameworks present another substantial hurdle, with fragmented global standards and evolving requirements for antimicrobial claims. The European Union's Biocidal Products Regulation and the US EPA's pesticide registration requirements impose stringent testing protocols and safety documentation that increase development costs and market entry timelines.

Cost considerations further constrain market penetration, particularly for premium antimicrobial technologies. The additional manufacturing expenses associated with specialized coating processes and antimicrobial agents often position these textiles at price points that limit mass-market adoption, especially in price-sensitive segments.

Environmental and health concerns constitute growing barriers, with increasing scrutiny regarding leaching of active ingredients, bioaccumulation potential, and impacts on beneficial microbiomes. The textile industry faces mounting pressure to develop antimicrobial solutions that balance efficacy with ecological responsibility and human safety considerations.

Quaternary ammonium compounds (QACs) represent another significant category, offering cost-effective antimicrobial performance through their positively charged molecules that disrupt microbial cell membranes. However, concerns regarding potential bacterial resistance development and environmental persistence have prompted increased regulatory scrutiny in certain markets.

Natural antimicrobial agents derived from plant extracts, essential oils, and chitosan have gained substantial attention as sustainable alternatives. These bio-based solutions address growing consumer demand for environmentally friendly textiles but face challenges related to standardization, stability, and durability compared to synthetic counterparts.

Metal oxide nanoparticles, particularly zinc oxide and titanium dioxide, have emerged as multifunctional antimicrobial agents that simultaneously provide UV protection and self-cleaning properties. Their photocatalytic activity generates reactive oxygen species that effectively neutralize microorganisms, though concerns regarding nanoparticle migration and potential environmental impacts persist.

Despite these technological advances, significant barriers impede widespread adoption of antimicrobial textiles. Durability remains a primary challenge, with many coatings demonstrating diminished efficacy after repeated laundering. This necessitates the development of more robust binding mechanisms between antimicrobial agents and textile substrates.

Regulatory frameworks present another substantial hurdle, with fragmented global standards and evolving requirements for antimicrobial claims. The European Union's Biocidal Products Regulation and the US EPA's pesticide registration requirements impose stringent testing protocols and safety documentation that increase development costs and market entry timelines.

Cost considerations further constrain market penetration, particularly for premium antimicrobial technologies. The additional manufacturing expenses associated with specialized coating processes and antimicrobial agents often position these textiles at price points that limit mass-market adoption, especially in price-sensitive segments.

Environmental and health concerns constitute growing barriers, with increasing scrutiny regarding leaching of active ingredients, bioaccumulation potential, and impacts on beneficial microbiomes. The textile industry faces mounting pressure to develop antimicrobial solutions that balance efficacy with ecological responsibility and human safety considerations.

Contemporary Antimicrobial Surface Treatment Solutions

01 Metal-based antimicrobial coatings

Metal-based antimicrobial coatings utilize silver, copper, zinc, and other metal ions or nanoparticles to provide long-lasting protection against a wide range of microorganisms. These metals disrupt bacterial cell membranes and interfere with cellular processes, preventing microbial growth on surfaces. Such coatings can be applied to various substrates including medical devices, textiles, and high-touch surfaces in public spaces to reduce infection transmission.- Metal-based antimicrobial coatings: Metal-based antimicrobial coatings utilize silver, copper, zinc, or other metal ions to inhibit microbial growth on surfaces. These metals can be incorporated as nanoparticles, ions, or compounds within coating matrices to provide long-lasting antimicrobial properties. The mechanism typically involves the release of metal ions that disrupt bacterial cell membranes and interfere with cellular processes. These coatings are particularly effective for high-touch surfaces in healthcare settings and public spaces.

- Quaternary ammonium compound coatings: Quaternary ammonium compounds (QACs) are widely used in antimicrobial surface coatings due to their broad-spectrum activity against bacteria, fungi, and some viruses. These compounds contain positively charged nitrogen atoms that interact with and disrupt microbial cell membranes. QAC-based coatings can be formulated to bond covalently to surfaces, creating durable antimicrobial protection that doesn't leach into the environment. Applications include medical devices, textiles, and food contact surfaces.

- Polymer-based antimicrobial coatings: Polymer-based antimicrobial coatings incorporate antimicrobial agents within polymer matrices to create durable protective surfaces. These can include natural polymers like chitosan or synthetic polymers with inherent antimicrobial properties. The polymers can be designed to slowly release active ingredients or to kill microbes on contact through charged functional groups. These coatings offer advantages in terms of durability, controlled release of active agents, and compatibility with various substrate materials.

- Natural and plant-derived antimicrobial coatings: Natural and plant-derived compounds are increasingly being used in antimicrobial surface coatings as environmentally friendly alternatives to synthetic chemicals. These include essential oils, plant extracts, enzymes, and peptides with inherent antimicrobial properties. Such coatings offer advantages in terms of biodegradability, reduced toxicity, and consumer acceptance. They can be incorporated into various carrier materials and applied to surfaces in healthcare, food packaging, and consumer products.

- Photocatalytic antimicrobial coatings: Photocatalytic antimicrobial coatings utilize materials like titanium dioxide that, when exposed to light (typically UV), generate reactive oxygen species that can destroy microorganisms. These coatings provide continuous self-cleaning and disinfecting properties as long as they receive adequate light exposure. The technology is particularly useful for surfaces in well-lit environments and can be enhanced by doping with metals or other compounds to improve activity under visible light. Applications include building materials, medical surfaces, and air purification systems.

02 Polymer-based antimicrobial surface treatments

Polymer-based antimicrobial coatings incorporate active ingredients within polymer matrices to create durable protective surfaces. These formulations may include quaternary ammonium compounds, chitosan derivatives, or other antimicrobial agents chemically bonded to or embedded within polymer structures. The controlled release of antimicrobial agents provides sustained protection, while the polymer base ensures adhesion to various surfaces and resistance to washing or abrasion.Expand Specific Solutions03 Natural and bio-based antimicrobial coatings

Natural and bio-based antimicrobial coatings utilize plant extracts, essential oils, enzymes, and other naturally derived compounds to inhibit microbial growth on surfaces. These environmentally friendly alternatives offer reduced toxicity compared to conventional chemical treatments while providing effective protection against bacteria, fungi, and viruses. The formulations often incorporate carriers such as biopolymers to enhance durability and adhesion to various substrates.Expand Specific Solutions04 Photocatalytic antimicrobial surface technologies

Photocatalytic antimicrobial coatings utilize materials such as titanium dioxide that, when exposed to light, generate reactive oxygen species capable of destroying microorganisms. These self-cleaning surfaces remain active as long as they receive appropriate light exposure, providing continuous disinfection without depleting active ingredients. The technology can be incorporated into paints, glass coatings, and other surface treatments for healthcare facilities, public spaces, and consumer products.Expand Specific Solutions05 Multi-functional protective coatings with antimicrobial properties

Multi-functional protective coatings combine antimicrobial efficacy with additional beneficial properties such as anti-corrosion, anti-fouling, or self-healing capabilities. These advanced formulations may incorporate multiple active ingredients within specialized delivery systems to address various surface protection needs simultaneously. Applications include marine environments, industrial equipment, medical implants, and consumer electronics where protection against both microbial contamination and environmental damage is required.Expand Specific Solutions

Leading Companies in Antimicrobial Textile Innovation

The antimicrobial surface coatings in textile innovation market is currently in a growth phase, with increasing demand driven by heightened hygiene awareness and healthcare applications. The global market size is estimated to reach $8-10 billion by 2026, expanding at a CAGR of approximately 12%. Technologically, the field shows varying maturity levels, with established players like BASF Corp. and Fraunhofer-Gesellschaft leading commercial applications, while research institutions such as MIT and North Carolina State University drive fundamental innovation. Companies like Bio-Gate AG and Orthobond Corp. are developing specialized antimicrobial technologies, while Covidien and Medtronic focus on healthcare applications. The competitive landscape features collaboration between academic institutions and industry players, with Asian entities like Shandong Weigao Group and HKUST increasingly contributing to technological advancement.

Fraunhofer-Gesellschaft eV

Technical Solution: Fraunhofer has developed advanced antimicrobial textile coatings using plasma-assisted deposition techniques that incorporate silver nanoparticles and quaternary ammonium compounds. Their proprietary process enables the creation of durable antimicrobial surfaces with controlled release mechanisms, ensuring long-term efficacy while minimizing environmental impact. The institute has pioneered a two-step approach: first applying a base layer that enhances adhesion to textile fibers, followed by an active antimicrobial layer with tailored release kinetics. This technology has demonstrated effectiveness against a broad spectrum of pathogens including bacteria, fungi, and certain viruses, with antimicrobial efficacy maintained for over 50 washing cycles in laboratory tests. Fraunhofer has also developed environmentally friendly alternatives using natural antimicrobial compounds derived from plant extracts and essential oils, addressing growing concerns about silver nanoparticle accumulation in ecosystems.

Strengths: Superior durability with antimicrobial effects lasting through multiple wash cycles; environmentally conscious formulations; scalable manufacturing processes suitable for industrial implementation. Weaknesses: Higher production costs compared to conventional treatments; some formulations may require specialized application equipment; potential regulatory hurdles for novel antimicrobial compounds.

BASF Corp.

Technical Solution: BASF has developed a comprehensive antimicrobial textile coating platform called HyGentic™, which utilizes a combination of silver-based technology and organic antimicrobial compounds. Their approach incorporates antimicrobial agents directly into polymer matrices that can be applied to textiles through conventional finishing processes, ensuring compatibility with existing manufacturing infrastructure. BASF's technology creates a controlled-release system that gradually dispenses antimicrobial compounds, providing protection that lasts through multiple washing cycles (typically 30-50 industrial washes). The company has also pioneered bio-based antimicrobial solutions derived from natural sources, addressing sustainability concerns while maintaining efficacy against gram-positive and gram-negative bacteria. Their latest innovation includes photocatalytic antimicrobial coatings that utilize titanium dioxide nanoparticles activated by ambient light to generate reactive oxygen species that destroy microbial cell membranes, offering a self-regenerating antimicrobial mechanism.

Strengths: Extensive global manufacturing and distribution network; comprehensive R&D capabilities allowing for customized solutions; strong regulatory expertise ensuring compliance across different markets. Weaknesses: Higher cost compared to conventional treatments; some formulations contain silver which raises environmental concerns; performance may vary depending on textile substrate and usage conditions.

Key Patents and Research in Textile Antimicrobial Coatings

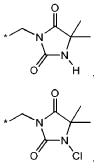

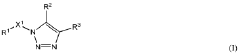

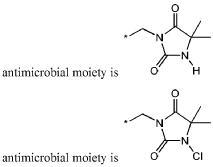

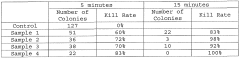

Silane-based antimicrobial coatings and methods of making and using the same

PatentWO2017165961A1

Innovation

- Development of pre-coupled alkoxysilane compounds with a rechargeable halogen-releasing hydantoin moiety, using azide-alkyne Huisgen cycloaddition to form 1,2,3-triazole rings, which can be applied in a single-step reaction without catalysts or solvents, providing both active and passive antimicrobial properties and fluorescent detection capabilities.

Antimicrobial surface and surface coats

PatentWO2011081899A1

Innovation

- A unique antimicrobial surface coating composed of a metallic material (45-80% by weight), epoxy resin (10-25% by weight), epoxy hardener (1-10% by weight), and surfactant (5-15% by weight), which can be applied to various surfaces to provide long-lasting protection against microorganisms like bacteria, fungi, and viruses.

Environmental Impact and Toxicity Considerations

The environmental impact and toxicity considerations of antimicrobial surface coatings in textile innovation represent critical factors that must be thoroughly evaluated before widespread implementation. Traditional antimicrobial agents such as triclosan, silver nanoparticles, and quaternary ammonium compounds have demonstrated efficacy against microorganisms but raise significant environmental concerns throughout their lifecycle.

When these antimicrobial textiles undergo washing processes, a considerable portion of the active compounds can leach into wastewater systems. Studies indicate that silver nanoparticles, commonly used in antimicrobial textiles, can persist in aquatic environments and potentially disrupt microbial communities essential for ecosystem functioning. Research has shown that concentrations as low as 0.1 ppm of certain antimicrobial agents can affect sensitive aquatic organisms.

The bioaccumulation potential of these compounds presents another layer of environmental risk. Some antimicrobial agents have demonstrated the ability to accumulate in aquatic organisms and potentially move up the food chain, raising concerns about long-term ecological impacts. This is particularly concerning for persistent compounds that resist natural degradation processes.

Toxicity considerations extend beyond environmental impacts to human health implications. Direct skin contact with antimicrobial textiles raises questions about potential dermal sensitization, especially with prolonged exposure. The risk of antimicrobial resistance development represents perhaps the most significant long-term concern, as widespread use of antimicrobial surfaces could potentially contribute to the selection of resistant microbial strains.

Recent regulatory frameworks have begun addressing these concerns. The European Union's REACH regulation and the Biocidal Products Regulation have established stricter guidelines for antimicrobial substances, requiring comprehensive toxicity data and environmental impact assessments. Similarly, the EPA in the United States has increased scrutiny of antimicrobial claims and environmental persistence data.

The industry has responded with significant innovation toward more sustainable alternatives. Bio-based antimicrobial compounds derived from plant extracts, essential oils, and chitosan are gaining attention for their reduced environmental footprint. These natural derivatives typically demonstrate enhanced biodegradability while maintaining acceptable antimicrobial efficacy profiles.

Life cycle assessment (LCA) methodologies are increasingly being applied to evaluate the comprehensive environmental impact of antimicrobial textiles from raw material extraction through disposal. These assessments reveal that the environmental benefits of extended product life must be carefully balanced against potential ecological risks from antimicrobial components.

When these antimicrobial textiles undergo washing processes, a considerable portion of the active compounds can leach into wastewater systems. Studies indicate that silver nanoparticles, commonly used in antimicrobial textiles, can persist in aquatic environments and potentially disrupt microbial communities essential for ecosystem functioning. Research has shown that concentrations as low as 0.1 ppm of certain antimicrobial agents can affect sensitive aquatic organisms.

The bioaccumulation potential of these compounds presents another layer of environmental risk. Some antimicrobial agents have demonstrated the ability to accumulate in aquatic organisms and potentially move up the food chain, raising concerns about long-term ecological impacts. This is particularly concerning for persistent compounds that resist natural degradation processes.

Toxicity considerations extend beyond environmental impacts to human health implications. Direct skin contact with antimicrobial textiles raises questions about potential dermal sensitization, especially with prolonged exposure. The risk of antimicrobial resistance development represents perhaps the most significant long-term concern, as widespread use of antimicrobial surfaces could potentially contribute to the selection of resistant microbial strains.

Recent regulatory frameworks have begun addressing these concerns. The European Union's REACH regulation and the Biocidal Products Regulation have established stricter guidelines for antimicrobial substances, requiring comprehensive toxicity data and environmental impact assessments. Similarly, the EPA in the United States has increased scrutiny of antimicrobial claims and environmental persistence data.

The industry has responded with significant innovation toward more sustainable alternatives. Bio-based antimicrobial compounds derived from plant extracts, essential oils, and chitosan are gaining attention for their reduced environmental footprint. These natural derivatives typically demonstrate enhanced biodegradability while maintaining acceptable antimicrobial efficacy profiles.

Life cycle assessment (LCA) methodologies are increasingly being applied to evaluate the comprehensive environmental impact of antimicrobial textiles from raw material extraction through disposal. These assessments reveal that the environmental benefits of extended product life must be carefully balanced against potential ecological risks from antimicrobial components.

Regulatory Framework for Antimicrobial Textile Products

The regulatory landscape governing antimicrobial textile products is complex and multifaceted, varying significantly across global markets. In the United States, the Environmental Protection Agency (EPA) regulates antimicrobial agents under the Federal Insecticide, Fungicide, and Rodenticide Act (FIFRA), requiring registration of substances that claim to kill or repel microorganisms. Concurrently, the Food and Drug Administration (FDA) oversees antimicrobial textiles that make medical claims, classifying them as medical devices subject to premarket approval processes.

The European Union implements more stringent regulations through the Biocidal Products Regulation (BPR) (EU) No 528/2012, which governs the authorization of active substances and products containing them. This framework mandates comprehensive risk assessments and efficacy testing before market entry. Additionally, the EU's REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) regulation imposes further requirements on chemical substances used in antimicrobial treatments.

In Asia, regulatory approaches differ markedly. Japan's Ministry of Health, Labor and Welfare enforces the Pharmaceutical Affairs Law for antimicrobial products with health claims. China has implemented the GB/T 20944 standard specifically for antimicrobial textiles, focusing on testing methods and efficacy evaluation. South Korea utilizes the K-mark certification system for quality assurance of antimicrobial products.

International standards organizations play a crucial role in harmonizing testing methodologies. The International Organization for Standardization (ISO) has developed several standards, including ISO 20743 for determining antibacterial activity of textile products and ISO 18184 for determining antiviral activity. AATCC (American Association of Textile Chemists and Colorists) provides Test Method 100 for antimicrobial fabric assessment, widely recognized in global markets.

Emerging regulatory trends indicate increasing scrutiny of environmental impacts and human safety. The EU's Green Deal and Chemicals Strategy for Sustainability are driving stricter regulations on persistent chemicals, including many antimicrobial agents. Similarly, the United States EPA is enhancing review processes for antimicrobial registrations under its Antimicrobial Testing Program.

Compliance challenges for manufacturers include navigating divergent regional requirements, addressing the growing demand for transparency in chemical formulations, and adapting to rapidly evolving regulations. The cost of regulatory compliance has become a significant factor in product development strategies, with companies increasingly seeking antimicrobial solutions that can achieve global regulatory acceptance.

Future regulatory developments are likely to focus on sustainable antimicrobial technologies, reduced environmental persistence, and enhanced safety profiles. Regulatory frameworks are expected to evolve toward performance-based standards rather than prescriptive requirements, potentially facilitating innovation while maintaining safety standards.

The European Union implements more stringent regulations through the Biocidal Products Regulation (BPR) (EU) No 528/2012, which governs the authorization of active substances and products containing them. This framework mandates comprehensive risk assessments and efficacy testing before market entry. Additionally, the EU's REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) regulation imposes further requirements on chemical substances used in antimicrobial treatments.

In Asia, regulatory approaches differ markedly. Japan's Ministry of Health, Labor and Welfare enforces the Pharmaceutical Affairs Law for antimicrobial products with health claims. China has implemented the GB/T 20944 standard specifically for antimicrobial textiles, focusing on testing methods and efficacy evaluation. South Korea utilizes the K-mark certification system for quality assurance of antimicrobial products.

International standards organizations play a crucial role in harmonizing testing methodologies. The International Organization for Standardization (ISO) has developed several standards, including ISO 20743 for determining antibacterial activity of textile products and ISO 18184 for determining antiviral activity. AATCC (American Association of Textile Chemists and Colorists) provides Test Method 100 for antimicrobial fabric assessment, widely recognized in global markets.

Emerging regulatory trends indicate increasing scrutiny of environmental impacts and human safety. The EU's Green Deal and Chemicals Strategy for Sustainability are driving stricter regulations on persistent chemicals, including many antimicrobial agents. Similarly, the United States EPA is enhancing review processes for antimicrobial registrations under its Antimicrobial Testing Program.

Compliance challenges for manufacturers include navigating divergent regional requirements, addressing the growing demand for transparency in chemical formulations, and adapting to rapidly evolving regulations. The cost of regulatory compliance has become a significant factor in product development strategies, with companies increasingly seeking antimicrobial solutions that can achieve global regulatory acceptance.

Future regulatory developments are likely to focus on sustainable antimicrobial technologies, reduced environmental persistence, and enhanced safety profiles. Regulatory frameworks are expected to evolve toward performance-based standards rather than prescriptive requirements, potentially facilitating innovation while maintaining safety standards.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!