Antimicrobial Surface Coatings with Silver Nanoparticles

SEP 29, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Silver Nanoparticle Antimicrobial Coatings Background & Objectives

Antimicrobial surface coatings incorporating silver nanoparticles represent a significant advancement in the field of materials science and infection control. The development of these coatings can be traced back to the early 2000s, when nanotechnology began to emerge as a transformative field with applications across multiple industries. Silver has been recognized for its antimicrobial properties since ancient times, but the advent of nanotechnology has enabled the manipulation of silver at the nanoscale, dramatically enhancing its efficacy and application potential.

The evolution of silver nanoparticle technology has progressed through several key phases, beginning with basic research into synthesis methods and antimicrobial mechanisms, followed by the development of incorporation techniques into various coating matrices, and more recently, the optimization of these coatings for specific applications and environments. This technological progression has been driven by increasing concerns about hospital-acquired infections, antibiotic-resistant bacteria, and the need for passive antimicrobial protection in high-touch surfaces.

Current research trends indicate a growing focus on developing sustainable, long-lasting antimicrobial coatings that maintain efficacy over extended periods while minimizing silver leaching and potential environmental impacts. There is also significant interest in creating multifunctional coatings that combine antimicrobial properties with other desirable characteristics such as anti-fouling, self-cleaning, or enhanced durability.

The primary technical objectives for silver nanoparticle antimicrobial coatings include: enhancing the stability and longevity of antimicrobial action; optimizing silver ion release rates to maintain efficacy while minimizing environmental concerns; improving adhesion and mechanical properties of coatings on various substrate materials; and developing cost-effective, scalable manufacturing processes suitable for industrial implementation.

Additionally, there are emerging research directions focused on smart or responsive antimicrobial coatings that can release silver ions on demand or in response to specific environmental triggers. These advanced systems aim to provide more targeted antimicrobial action while further reducing the potential for bacterial resistance development and environmental contamination.

The ultimate goal of this technology is to create versatile antimicrobial surface solutions that can be widely deployed in healthcare settings, public spaces, consumer products, and industrial applications to reduce pathogen transmission and infection rates. Success in this field could significantly impact public health outcomes, particularly in addressing healthcare-associated infections and combating the growing challenge of antimicrobial resistance in bacterial populations.

The evolution of silver nanoparticle technology has progressed through several key phases, beginning with basic research into synthesis methods and antimicrobial mechanisms, followed by the development of incorporation techniques into various coating matrices, and more recently, the optimization of these coatings for specific applications and environments. This technological progression has been driven by increasing concerns about hospital-acquired infections, antibiotic-resistant bacteria, and the need for passive antimicrobial protection in high-touch surfaces.

Current research trends indicate a growing focus on developing sustainable, long-lasting antimicrobial coatings that maintain efficacy over extended periods while minimizing silver leaching and potential environmental impacts. There is also significant interest in creating multifunctional coatings that combine antimicrobial properties with other desirable characteristics such as anti-fouling, self-cleaning, or enhanced durability.

The primary technical objectives for silver nanoparticle antimicrobial coatings include: enhancing the stability and longevity of antimicrobial action; optimizing silver ion release rates to maintain efficacy while minimizing environmental concerns; improving adhesion and mechanical properties of coatings on various substrate materials; and developing cost-effective, scalable manufacturing processes suitable for industrial implementation.

Additionally, there are emerging research directions focused on smart or responsive antimicrobial coatings that can release silver ions on demand or in response to specific environmental triggers. These advanced systems aim to provide more targeted antimicrobial action while further reducing the potential for bacterial resistance development and environmental contamination.

The ultimate goal of this technology is to create versatile antimicrobial surface solutions that can be widely deployed in healthcare settings, public spaces, consumer products, and industrial applications to reduce pathogen transmission and infection rates. Success in this field could significantly impact public health outcomes, particularly in addressing healthcare-associated infections and combating the growing challenge of antimicrobial resistance in bacterial populations.

Market Demand Analysis for Antimicrobial Surface Solutions

The global market for antimicrobial surface solutions has experienced significant growth in recent years, primarily driven by increasing awareness of infection control and hygiene across various sectors. The COVID-19 pandemic has further accelerated this demand, creating a heightened consciousness about surface contamination and pathogen transmission. Healthcare facilities, in particular, represent the largest market segment, with hospitals, clinics, and long-term care facilities seeking effective solutions to combat healthcare-associated infections (HAIs).

Market research indicates that the global antimicrobial coatings market was valued at approximately $3.6 billion in 2021 and is projected to reach $6.4 billion by 2026, growing at a compound annual growth rate (CAGR) of 12.1%. Within this broader market, silver nanoparticle-based antimicrobial coatings are emerging as a particularly promising segment due to their broad-spectrum efficacy against bacteria, fungi, and certain viruses.

Consumer-facing industries such as food processing, packaging, and household appliances are increasingly incorporating antimicrobial surfaces into their products. This trend is supported by consumer willingness to pay premium prices for products with enhanced hygiene features. Market surveys reveal that 78% of consumers consider antimicrobial properties an important factor when purchasing certain products post-pandemic.

The transportation sector represents another growing market, with public transit systems, airlines, and ride-sharing companies exploring antimicrobial surface treatments to reassure passengers about safety. Educational institutions and commercial office spaces are similarly investing in antimicrobial infrastructure as part of their return-to-normal strategies.

Regionally, North America currently dominates the market for antimicrobial surface solutions, followed by Europe. However, the Asia-Pacific region is expected to witness the fastest growth rate in the coming years, driven by rapid healthcare infrastructure development, increasing healthcare expenditure, and growing awareness about infection prevention.

Market challenges include concerns about the environmental impact of antimicrobial agents, potential development of microbial resistance, and regulatory hurdles. The EPA and FDA in the United States, along with similar agencies globally, have established stringent guidelines for antimicrobial claims, requiring substantial scientific evidence for efficacy and safety.

Customer requirements are evolving toward solutions that offer long-lasting protection, ease of application, cost-effectiveness, and environmental sustainability. Silver nanoparticle coatings address many of these needs but face competition from alternative technologies such as copper-based solutions, quaternary ammonium compounds, and photocatalytic coatings.

Market research indicates that the global antimicrobial coatings market was valued at approximately $3.6 billion in 2021 and is projected to reach $6.4 billion by 2026, growing at a compound annual growth rate (CAGR) of 12.1%. Within this broader market, silver nanoparticle-based antimicrobial coatings are emerging as a particularly promising segment due to their broad-spectrum efficacy against bacteria, fungi, and certain viruses.

Consumer-facing industries such as food processing, packaging, and household appliances are increasingly incorporating antimicrobial surfaces into their products. This trend is supported by consumer willingness to pay premium prices for products with enhanced hygiene features. Market surveys reveal that 78% of consumers consider antimicrobial properties an important factor when purchasing certain products post-pandemic.

The transportation sector represents another growing market, with public transit systems, airlines, and ride-sharing companies exploring antimicrobial surface treatments to reassure passengers about safety. Educational institutions and commercial office spaces are similarly investing in antimicrobial infrastructure as part of their return-to-normal strategies.

Regionally, North America currently dominates the market for antimicrobial surface solutions, followed by Europe. However, the Asia-Pacific region is expected to witness the fastest growth rate in the coming years, driven by rapid healthcare infrastructure development, increasing healthcare expenditure, and growing awareness about infection prevention.

Market challenges include concerns about the environmental impact of antimicrobial agents, potential development of microbial resistance, and regulatory hurdles. The EPA and FDA in the United States, along with similar agencies globally, have established stringent guidelines for antimicrobial claims, requiring substantial scientific evidence for efficacy and safety.

Customer requirements are evolving toward solutions that offer long-lasting protection, ease of application, cost-effectiveness, and environmental sustainability. Silver nanoparticle coatings address many of these needs but face competition from alternative technologies such as copper-based solutions, quaternary ammonium compounds, and photocatalytic coatings.

Current Status and Challenges in Silver Nanoparticle Technology

Silver nanoparticle (AgNP) technology has advanced significantly in recent years, establishing itself as a leading antimicrobial solution globally. Current research indicates that AgNPs exhibit exceptional efficacy against a broad spectrum of microorganisms, including bacteria, fungi, and viruses, making them particularly valuable for healthcare settings and consumer products. The global market for antimicrobial coatings incorporating silver nanoparticles reached approximately $3.8 billion in 2022, with projections suggesting growth to $6.5 billion by 2027.

Despite these promising developments, several technical challenges persist in the widespread implementation of AgNP-based antimicrobial coatings. Particle size control remains a significant hurdle, as the antimicrobial efficacy of silver nanoparticles is directly correlated with their dimensions. Current manufacturing processes struggle to consistently produce uniform nanoparticles below 10 nm, which is the optimal size range for maximum antimicrobial activity.

Long-term stability presents another major challenge. Silver nanoparticles tend to agglomerate over time, reducing their effective surface area and consequently diminishing their antimicrobial properties. Additionally, when exposed to environmental conditions such as UV light, humidity, and varying pH levels, AgNPs can undergo oxidation, further compromising their performance and longevity.

The controlled release mechanism of silver ions from nanoparticles represents a delicate balance that researchers are still working to optimize. Too rapid release results in short-lived antimicrobial activity, while too slow release may not provide sufficient protection against microbial colonization. Current coating technologies have not yet achieved the ideal sustained-release profile necessary for long-term effectiveness.

From a geographical perspective, research and development in AgNP technology is concentrated primarily in North America, Europe, and East Asia. The United States leads in patent filings related to antimicrobial silver nanoparticle coatings, followed closely by China, Germany, and South Korea. Academic institutions in these regions have established specialized research centers focused on nanomaterial development and applications.

Safety concerns constitute another significant challenge. While silver nanoparticles are generally considered less toxic than other antimicrobial agents, questions remain regarding their potential environmental impact and long-term effects on human health. Regulatory frameworks across different regions vary considerably, creating compliance challenges for companies developing AgNP-based products for global markets.

Cost-effectiveness remains a barrier to widespread adoption, particularly in price-sensitive markets. Current manufacturing processes for high-quality silver nanoparticles are resource-intensive, requiring specialized equipment and precise control parameters. The integration of these nanoparticles into various substrate materials adds further complexity and cost to the production process.

Despite these promising developments, several technical challenges persist in the widespread implementation of AgNP-based antimicrobial coatings. Particle size control remains a significant hurdle, as the antimicrobial efficacy of silver nanoparticles is directly correlated with their dimensions. Current manufacturing processes struggle to consistently produce uniform nanoparticles below 10 nm, which is the optimal size range for maximum antimicrobial activity.

Long-term stability presents another major challenge. Silver nanoparticles tend to agglomerate over time, reducing their effective surface area and consequently diminishing their antimicrobial properties. Additionally, when exposed to environmental conditions such as UV light, humidity, and varying pH levels, AgNPs can undergo oxidation, further compromising their performance and longevity.

The controlled release mechanism of silver ions from nanoparticles represents a delicate balance that researchers are still working to optimize. Too rapid release results in short-lived antimicrobial activity, while too slow release may not provide sufficient protection against microbial colonization. Current coating technologies have not yet achieved the ideal sustained-release profile necessary for long-term effectiveness.

From a geographical perspective, research and development in AgNP technology is concentrated primarily in North America, Europe, and East Asia. The United States leads in patent filings related to antimicrobial silver nanoparticle coatings, followed closely by China, Germany, and South Korea. Academic institutions in these regions have established specialized research centers focused on nanomaterial development and applications.

Safety concerns constitute another significant challenge. While silver nanoparticles are generally considered less toxic than other antimicrobial agents, questions remain regarding their potential environmental impact and long-term effects on human health. Regulatory frameworks across different regions vary considerably, creating compliance challenges for companies developing AgNP-based products for global markets.

Cost-effectiveness remains a barrier to widespread adoption, particularly in price-sensitive markets. Current manufacturing processes for high-quality silver nanoparticles are resource-intensive, requiring specialized equipment and precise control parameters. The integration of these nanoparticles into various substrate materials adds further complexity and cost to the production process.

Current Technical Approaches to Silver Nanoparticle Coatings

01 Silver nanoparticle incorporation methods for antimicrobial coatings

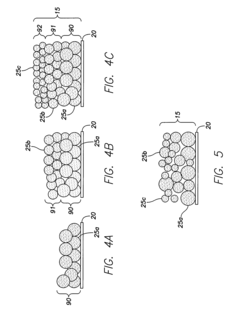

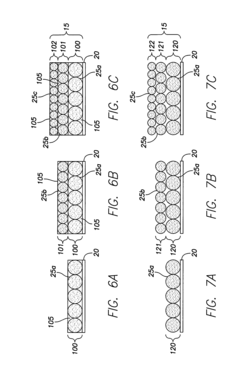

Various methods can be used to incorporate silver nanoparticles into surface coatings to impart antimicrobial properties. These methods include direct mixing of nanoparticles with coating materials, in-situ synthesis of silver nanoparticles within the coating matrix, and surface modification techniques. The incorporation method affects the distribution, stability, and release kinetics of the silver nanoparticles, which in turn influences the antimicrobial efficacy and durability of the coating.- Silver nanoparticle incorporation methods for antimicrobial coatings: Various methods can be used to incorporate silver nanoparticles into surface coatings to impart antimicrobial properties. These methods include direct mixing of silver nanoparticles with coating materials, in-situ synthesis of nanoparticles within the coating matrix, and surface modification techniques. The incorporation method affects the distribution, stability, and release kinetics of the silver nanoparticles, which in turn influences the antimicrobial efficacy and durability of the coating.

- Polymer-based matrices for silver nanoparticle antimicrobial coatings: Polymer matrices serve as effective carriers for silver nanoparticles in antimicrobial coatings. Various polymers including polyurethane, polyacrylates, silicones, and biodegradable polymers can be used as base materials. These polymer matrices not only provide structural support but also control the release rate of silver ions, which is crucial for sustained antimicrobial activity. The choice of polymer affects properties such as adhesion to substrates, durability, and biocompatibility of the coating.

- Silver nanoparticle size, shape and concentration effects on antimicrobial efficacy: The size, shape, and concentration of silver nanoparticles significantly impact the antimicrobial efficacy of surface coatings. Smaller nanoparticles (typically 1-50 nm) generally exhibit enhanced antimicrobial activity due to their larger surface area and increased silver ion release. Spherical, triangular, and rod-shaped nanoparticles demonstrate different antimicrobial potencies. Additionally, the concentration of silver nanoparticles must be optimized to achieve effective antimicrobial properties while avoiding cytotoxicity and environmental concerns.

- Hybrid antimicrobial coatings combining silver nanoparticles with other agents: Hybrid antimicrobial coatings combine silver nanoparticles with other antimicrobial agents to achieve synergistic effects and broader spectrum activity. These additional agents include copper compounds, zinc oxide, titanium dioxide, quaternary ammonium compounds, and natural antimicrobials. Such combinations can enhance antimicrobial efficacy, reduce the required silver content, mitigate bacterial resistance development, and provide multifunctional properties such as self-cleaning or anti-fouling capabilities.

- Controlled release mechanisms for sustained antimicrobial activity: Controlled release mechanisms are essential for maintaining long-term antimicrobial efficacy of silver nanoparticle coatings. Various approaches include pH-responsive release systems, moisture-activated release, temperature-sensitive matrices, and biodegradable carriers. These mechanisms ensure a steady release of silver ions over extended periods, preventing initial burst release while maintaining antimicrobial concentrations above the minimum inhibitory level. Advanced release systems can also respond to the presence of bacteria or biofilms, releasing higher amounts of silver ions when needed.

02 Polymer-based matrices for silver nanoparticle antimicrobial coatings

Polymer matrices serve as effective carriers for silver nanoparticles in antimicrobial coatings. Various polymers including polyurethane, polyacrylates, silicones, and biodegradable polymers can be used as base materials. These polymers provide structural integrity to the coating while controlling the release of silver ions. The selection of polymer matrix affects properties such as adhesion to substrates, durability, biocompatibility, and the sustained release of antimicrobial agents.Expand Specific Solutions03 Size and concentration optimization of silver nanoparticles

The antimicrobial efficacy of silver nanoparticle coatings is significantly influenced by the size and concentration of the nanoparticles. Smaller nanoparticles (typically 1-50 nm) generally exhibit enhanced antimicrobial activity due to their larger surface area and increased ion release. However, the optimal concentration must be determined to balance antimicrobial effectiveness with potential cytotoxicity and cost considerations. Various synthesis methods can be employed to control nanoparticle size distribution and ensure uniform dispersion within the coating.Expand Specific Solutions04 Multi-functional antimicrobial coatings with silver nanoparticles

Advanced antimicrobial coatings incorporate silver nanoparticles along with additional functional components to create multi-functional surfaces. These coatings may combine antimicrobial properties with features such as anti-fouling, self-cleaning, UV protection, or enhanced durability. Some formulations include secondary antimicrobial agents like copper, zinc oxide, or organic biocides to create synergistic effects and reduce the potential for microbial resistance development.Expand Specific Solutions05 Environmental and biomedical applications of silver nanoparticle coatings

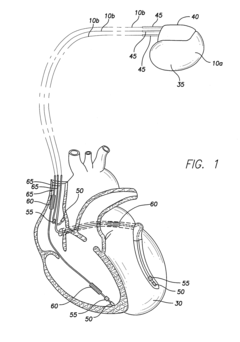

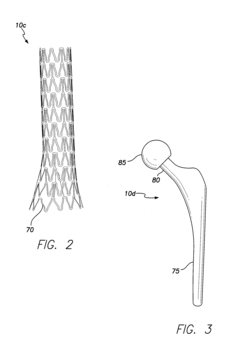

Silver nanoparticle antimicrobial coatings find applications across various sectors. In healthcare, they are used on medical devices, hospital surfaces, and wound dressings to prevent infections. Environmental applications include water treatment systems, air filtration, and food packaging. Consumer products such as textiles, household appliances, and electronics also utilize these coatings. Each application requires specific formulation considerations regarding silver release rates, coating durability, and safety profiles appropriate for the intended use environment.Expand Specific Solutions

Key Industry Players in Antimicrobial Surface Solutions

The antimicrobial surface coatings market with silver nanoparticles is currently in a growth phase, driven by increasing healthcare-associated infections and demand for hygienic surfaces. The global market is projected to reach approximately $3.5 billion by 2025, with a CAGR of 13-15%. Technology maturity varies across players, with established companies like Samsung Electronics, Janssen Pharmaceutica, and Baxter International leading commercial applications, while research institutions such as University of South Australia, Tianjin University, and Agency for Science, Technology & Research are advancing fundamental innovations. Specialized firms like Inhibit Coatings are bridging the gap between research and commercialization with proprietary silver nanoparticle functionalization methods. The technology is transitioning from laboratory research to industrial implementation, with increasing focus on durability, efficacy, and cost-effectiveness.

University of South Australia

Technical Solution: The University of South Australia has developed advanced antimicrobial surface coatings incorporating silver nanoparticles through a patented process that ensures uniform distribution and controlled release. Their technology utilizes a unique sol-gel method to embed silver nanoparticles within a durable silica matrix, creating thin films that can be applied to various substrates including glass, metals, and polymers. The university's research team has optimized the silver nanoparticle size (typically 5-20 nm) and concentration (0.5-5% w/w) to maximize antimicrobial efficacy while minimizing material costs. Their coatings demonstrate broad-spectrum activity against bacteria (including MRSA), fungi, and certain viruses, with documented efficacy lasting up to 24 months under normal use conditions. The technology incorporates controlled release mechanisms that maintain antimicrobial activity while limiting silver ion leaching to environmentally acceptable levels. Recent innovations include the development of photocatalytic silver-titanium dioxide composite coatings that exhibit enhanced antimicrobial properties under both UV and visible light conditions.

Strengths: Superior durability with antimicrobial efficacy lasting up to 24 months; environmentally responsible formulation with controlled silver ion release; versatile application across multiple substrate materials. Weaknesses: Higher production costs compared to conventional coatings; potential for reduced effectiveness in high-wear environments; requires specialized application equipment for optimal performance.

Amity University

Technical Solution: Amity University has developed eco-friendly antimicrobial surface coatings incorporating silver nanoparticles through innovative green synthesis approaches. Their technology utilizes plant extracts (particularly from neem, tulsi, and aloe vera) as both reducing and capping agents for silver nanoparticle formation, eliminating the need for harsh chemicals in the production process. The university's research teams have optimized extraction parameters to produce silver nanoparticles with controlled size distribution (typically 10-30 nm) and enhanced stability in coating formulations. Their approach incorporates these biologically synthesized nanoparticles into natural polymer matrices like chitosan and cellulose derivatives, creating fully biodegradable antimicrobial coatings. The coatings demonstrate broad-spectrum antimicrobial activity, with particular efficacy against waterborne pathogens and food spoilage organisms. Recent innovations include the development of composite coatings that combine silver nanoparticles with natural antimicrobial compounds from plant extracts for synergistic effects. The university has also pioneered low-cost application methods suitable for resource-limited settings, including simple dip-coating and spray techniques that don't require specialized equipment. Their research demonstrates particular promise for applications in water purification systems, food packaging, and agricultural implements in developing regions.

Strengths: Environmentally sustainable green synthesis approach; cost-effective production using readily available plant materials; fully biodegradable formulations suitable for agricultural applications. Weaknesses: Variable batch-to-batch consistency due to natural extract variations; generally lower durability compared to synthetic polymer systems; limited application in high-wear environments.

Critical Patents and Research in Silver Nanoparticle Applications

Silver nanoparticle antimicrobial coating for long-term and short-term infection resistance

PatentInactiveUS9107903B2

Innovation

- An antimicrobial layer comprising three distinct sizes of silver nanoparticles (5 nm, 10 nm, and 15-20 nm) is applied to the surface of implantable medical devices, with the smallest nanoparticles providing immediate antimicrobial protection, medium nanoparticles offering protection over a moderate period, and largest nanoparticles providing long-term protection, using various deposition processes like wet deposition, sintering, or polymer deposition.

Antimicrobial coatings

PatentInactiveGB2472968A

Innovation

- The development of thin-film, vapor-deposited silver-containing nanomaterials combined with copper and zinc oxide, applied using combustion chemical vapor deposition (CCVD) to create a non-continuous, transparent nanolayer that minimizes material usage and maintains antimicrobial efficacy without embedding in polymers, ensuring stability and adherence.

Environmental Impact and Sustainability Considerations

The environmental implications of silver nanoparticle (AgNP) antimicrobial coatings present significant considerations for their widespread adoption. These nanomaterials, while effective against pathogens, can be released into ecosystems through washing, abrasion, and disposal processes. Studies indicate that silver ions leaching from these coatings can accumulate in aquatic environments, potentially disrupting microbial communities essential for nutrient cycling and ecosystem balance. Research has demonstrated that concentrations as low as 0.1 μg/L can adversely affect sensitive aquatic organisms, raising concerns about bioaccumulation in food chains.

The manufacturing process of AgNP coatings also carries substantial environmental costs. Production typically requires energy-intensive processes and potentially hazardous chemicals, contributing to carbon emissions and chemical waste. Life cycle assessments reveal that the environmental footprint of these coatings extends beyond their use phase, with significant impacts during raw material extraction and manufacturing.

Regulatory frameworks addressing these environmental concerns vary globally, creating challenges for standardization. The European Union's REACH regulations impose stricter controls on nanomaterials compared to less comprehensive approaches in other regions. This regulatory divergence complicates global market access for manufacturers and creates inconsistent environmental protection standards.

Recent sustainability innovations are addressing these challenges through several approaches. Controlled-release technologies are being developed to minimize unnecessary silver ion leaching while maintaining antimicrobial efficacy. These systems respond to environmental triggers, releasing active agents only when needed. Additionally, researchers are exploring biodegradable polymer matrices that safely break down after their useful life, reducing long-term environmental persistence.

Green synthesis methods represent another promising direction, utilizing plant extracts and biological processes to produce silver nanoparticles with reduced environmental impact. These approaches significantly decrease the need for harsh reducing agents and toxic chemicals in manufacturing. Furthermore, recovery and recycling systems for silver from discarded products are being implemented to create more circular material flows.

The economic viability of these sustainable alternatives remains a challenge. Currently, environmentally optimized AgNP coatings typically command price premiums of 15-30% over conventional options. However, as regulatory pressures increase and economies of scale improve, this gap is expected to narrow. Forward-thinking companies are increasingly recognizing that early adoption of sustainable practices may provide competitive advantages as environmental regulations tighten globally.

The manufacturing process of AgNP coatings also carries substantial environmental costs. Production typically requires energy-intensive processes and potentially hazardous chemicals, contributing to carbon emissions and chemical waste. Life cycle assessments reveal that the environmental footprint of these coatings extends beyond their use phase, with significant impacts during raw material extraction and manufacturing.

Regulatory frameworks addressing these environmental concerns vary globally, creating challenges for standardization. The European Union's REACH regulations impose stricter controls on nanomaterials compared to less comprehensive approaches in other regions. This regulatory divergence complicates global market access for manufacturers and creates inconsistent environmental protection standards.

Recent sustainability innovations are addressing these challenges through several approaches. Controlled-release technologies are being developed to minimize unnecessary silver ion leaching while maintaining antimicrobial efficacy. These systems respond to environmental triggers, releasing active agents only when needed. Additionally, researchers are exploring biodegradable polymer matrices that safely break down after their useful life, reducing long-term environmental persistence.

Green synthesis methods represent another promising direction, utilizing plant extracts and biological processes to produce silver nanoparticles with reduced environmental impact. These approaches significantly decrease the need for harsh reducing agents and toxic chemicals in manufacturing. Furthermore, recovery and recycling systems for silver from discarded products are being implemented to create more circular material flows.

The economic viability of these sustainable alternatives remains a challenge. Currently, environmentally optimized AgNP coatings typically command price premiums of 15-30% over conventional options. However, as regulatory pressures increase and economies of scale improve, this gap is expected to narrow. Forward-thinking companies are increasingly recognizing that early adoption of sustainable practices may provide competitive advantages as environmental regulations tighten globally.

Regulatory Framework for Nanomaterial-Based Antimicrobials

The regulatory landscape for nanomaterial-based antimicrobials, particularly silver nanoparticle coatings, presents a complex framework that varies significantly across global jurisdictions. In the United States, the Environmental Protection Agency (EPA) regulates antimicrobial silver nanoparticles under the Federal Insecticide, Fungicide, and Rodenticide Act (FIFRA), requiring manufacturers to register products and demonstrate both efficacy and safety. Concurrently, the Food and Drug Administration (FDA) oversees medical applications of these coatings, implementing stringent requirements for biocompatibility testing and clinical validation.

The European Union employs a more precautionary approach through the Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulation and the Biocidal Products Regulation (BPR). These frameworks mandate comprehensive safety assessments, including detailed characterization of nanoparticle properties, potential environmental impacts, and human exposure risks. The EU's definition of nanomaterials (materials containing particles where 50% or more have dimensions between 1-100nm) creates specific regulatory obligations for silver nanoparticle coatings.

Asian markets demonstrate varying regulatory maturity. Japan has established the world's first nano-specific regulatory framework through its Ministry of Economy, Trade and Industry, while China has recently strengthened oversight through the National Center for Nanoscience and Technology, focusing particularly on environmental release concerns.

A significant regulatory challenge lies in standardization of testing protocols for antimicrobial efficacy and safety assessment. The International Organization for Standardization (ISO) has developed several standards (ISO/TR 13014, ISO/TR 13329) specifically addressing nanomaterial characterization and toxicological screening, but implementation remains inconsistent across jurisdictions.

Environmental regulations present another layer of complexity, with increasing focus on the potential ecological impacts of silver ion leaching from antimicrobial coatings. The EPA's Significant New Use Rules (SNURs) and the EU's Environmental Quality Standards Directive both address potential aquatic toxicity concerns, requiring manufacturers to demonstrate minimal environmental persistence.

Labeling requirements also vary substantially, with some jurisdictions mandating explicit disclosure of nanomaterial content while others maintain more general antimicrobial claims oversight. This regulatory fragmentation creates significant compliance challenges for manufacturers operating in global markets.

Recent regulatory trends indicate movement toward harmonization of approaches, with international bodies like the Organization for Economic Cooperation and Development (OECD) developing standardized testing guidelines specifically for nanomaterials. However, the rapid pace of technological innovation in silver nanoparticle coating formulations continues to outpace regulatory framework development, creating uncertainty for commercial deployment.

The European Union employs a more precautionary approach through the Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulation and the Biocidal Products Regulation (BPR). These frameworks mandate comprehensive safety assessments, including detailed characterization of nanoparticle properties, potential environmental impacts, and human exposure risks. The EU's definition of nanomaterials (materials containing particles where 50% or more have dimensions between 1-100nm) creates specific regulatory obligations for silver nanoparticle coatings.

Asian markets demonstrate varying regulatory maturity. Japan has established the world's first nano-specific regulatory framework through its Ministry of Economy, Trade and Industry, while China has recently strengthened oversight through the National Center for Nanoscience and Technology, focusing particularly on environmental release concerns.

A significant regulatory challenge lies in standardization of testing protocols for antimicrobial efficacy and safety assessment. The International Organization for Standardization (ISO) has developed several standards (ISO/TR 13014, ISO/TR 13329) specifically addressing nanomaterial characterization and toxicological screening, but implementation remains inconsistent across jurisdictions.

Environmental regulations present another layer of complexity, with increasing focus on the potential ecological impacts of silver ion leaching from antimicrobial coatings. The EPA's Significant New Use Rules (SNURs) and the EU's Environmental Quality Standards Directive both address potential aquatic toxicity concerns, requiring manufacturers to demonstrate minimal environmental persistence.

Labeling requirements also vary substantially, with some jurisdictions mandating explicit disclosure of nanomaterial content while others maintain more general antimicrobial claims oversight. This regulatory fragmentation creates significant compliance challenges for manufacturers operating in global markets.

Recent regulatory trends indicate movement toward harmonization of approaches, with international bodies like the Organization for Economic Cooperation and Development (OECD) developing standardized testing guidelines specifically for nanomaterials. However, the rapid pace of technological innovation in silver nanoparticle coating formulations continues to outpace regulatory framework development, creating uncertainty for commercial deployment.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!