What Patent Trends Are Emerging in Antimicrobial Surface Coatings

SEP 29, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Antimicrobial Coating Technology Background and Objectives

Antimicrobial surface coatings have evolved significantly over the past several decades, transitioning from simple disinfectant applications to sophisticated engineered surfaces with persistent antimicrobial properties. The historical development began in the 1940s with the introduction of quaternary ammonium compounds, followed by silver-based technologies in the 1970s. The field experienced accelerated growth in the early 2000s with the emergence of nanotechnology, enabling more effective and durable antimicrobial solutions.

The technological evolution has been driven by increasing concerns about healthcare-associated infections, antibiotic resistance, and most recently, pandemic preparedness. Patent activity in this domain has shown consistent growth, with a notable surge following the COVID-19 pandemic, reflecting heightened awareness of surface transmission of pathogens and the critical need for preventive measures.

Current antimicrobial coating technologies can be categorized into several approaches: contact-killing surfaces (quaternary ammonium compounds, antimicrobial peptides), release-based systems (silver, copper, zinc oxide nanoparticles), and anti-adhesion surfaces (hydrophobic or superhydrophobic coatings). Each approach offers distinct advantages and limitations regarding efficacy, durability, and application scope.

The primary objective of contemporary antimicrobial coating research is to develop solutions that provide broad-spectrum efficacy against bacteria, viruses, and fungi while maintaining long-term stability under various environmental conditions. Additional goals include reducing environmental impact, minimizing potential for antimicrobial resistance development, and ensuring cost-effectiveness for widespread adoption.

Patent trends reveal increasing focus on multifunctional coatings that combine antimicrobial properties with other desirable characteristics such as self-cleaning, anti-fouling, or transparency. There is also growing interest in sustainable and biodegradable antimicrobial materials to address environmental concerns associated with traditional biocides.

Geographically, patent filings show concentration in North America, Europe, and East Asia, with the United States, China, and Japan leading in innovation. Academic-industry collaborations have become increasingly common, accelerating the translation of fundamental research into commercial applications.

The technological trajectory suggests movement toward "smart" responsive coatings that can activate antimicrobial properties on demand, reducing unnecessary biocide release and extending functional lifespan. Integration with digital technologies for monitoring efficacy and contamination levels represents another emerging frontier in this field.

The technological evolution has been driven by increasing concerns about healthcare-associated infections, antibiotic resistance, and most recently, pandemic preparedness. Patent activity in this domain has shown consistent growth, with a notable surge following the COVID-19 pandemic, reflecting heightened awareness of surface transmission of pathogens and the critical need for preventive measures.

Current antimicrobial coating technologies can be categorized into several approaches: contact-killing surfaces (quaternary ammonium compounds, antimicrobial peptides), release-based systems (silver, copper, zinc oxide nanoparticles), and anti-adhesion surfaces (hydrophobic or superhydrophobic coatings). Each approach offers distinct advantages and limitations regarding efficacy, durability, and application scope.

The primary objective of contemporary antimicrobial coating research is to develop solutions that provide broad-spectrum efficacy against bacteria, viruses, and fungi while maintaining long-term stability under various environmental conditions. Additional goals include reducing environmental impact, minimizing potential for antimicrobial resistance development, and ensuring cost-effectiveness for widespread adoption.

Patent trends reveal increasing focus on multifunctional coatings that combine antimicrobial properties with other desirable characteristics such as self-cleaning, anti-fouling, or transparency. There is also growing interest in sustainable and biodegradable antimicrobial materials to address environmental concerns associated with traditional biocides.

Geographically, patent filings show concentration in North America, Europe, and East Asia, with the United States, China, and Japan leading in innovation. Academic-industry collaborations have become increasingly common, accelerating the translation of fundamental research into commercial applications.

The technological trajectory suggests movement toward "smart" responsive coatings that can activate antimicrobial properties on demand, reducing unnecessary biocide release and extending functional lifespan. Integration with digital technologies for monitoring efficacy and contamination levels represents another emerging frontier in this field.

Market Analysis for Antimicrobial Surface Solutions

The global antimicrobial surface coatings market has experienced significant growth in recent years, driven by increasing awareness of infection control and hygiene across various sectors. The market was valued at approximately $3.6 billion in 2021 and is projected to reach $6.7 billion by 2027, representing a compound annual growth rate (CAGR) of 10.8% during the forecast period.

Healthcare remains the dominant application segment, accounting for nearly 40% of the market share. This dominance is attributed to the critical need for infection prevention in hospitals, clinics, and other healthcare facilities, particularly in light of the rising incidence of healthcare-associated infections (HAIs) and the emergence of antibiotic-resistant bacteria.

The food and beverage industry represents the second-largest application segment, with a market share of approximately 25%. Antimicrobial coatings in this sector are primarily used for food processing equipment, packaging materials, and storage containers to prevent contamination and extend shelf life.

Consumer electronics has emerged as the fastest-growing application segment, with a CAGR exceeding 12%. The COVID-19 pandemic has significantly accelerated demand in this sector, as consumers and manufacturers alike seek to enhance the hygiene of frequently touched devices such as smartphones, tablets, and wearables.

Geographically, North America holds the largest market share at 35%, followed by Europe at 30% and Asia-Pacific at 25%. However, the Asia-Pacific region is expected to witness the highest growth rate during the forecast period, driven by rapid industrialization, increasing healthcare expenditure, and growing awareness about hygiene and infection control.

Silver-based antimicrobial coatings currently dominate the market with a share of approximately 45%, owing to their broad-spectrum efficacy and relatively low toxicity. However, copper-based coatings are gaining traction due to their cost-effectiveness and natural antimicrobial properties.

Key market challenges include regulatory hurdles, particularly concerning the use of certain biocides, and the relatively high cost of advanced antimicrobial technologies. Additionally, there is growing consumer demand for environmentally friendly and non-toxic antimicrobial solutions, which is driving innovation in bio-based and natural antimicrobial agents.

The COVID-19 pandemic has served as a significant market accelerator, with heightened awareness of surface transmission of pathogens driving demand across all sectors. This trend is expected to continue post-pandemic, as hygiene consciousness becomes more deeply ingrained in consumer behavior and institutional protocols.

Healthcare remains the dominant application segment, accounting for nearly 40% of the market share. This dominance is attributed to the critical need for infection prevention in hospitals, clinics, and other healthcare facilities, particularly in light of the rising incidence of healthcare-associated infections (HAIs) and the emergence of antibiotic-resistant bacteria.

The food and beverage industry represents the second-largest application segment, with a market share of approximately 25%. Antimicrobial coatings in this sector are primarily used for food processing equipment, packaging materials, and storage containers to prevent contamination and extend shelf life.

Consumer electronics has emerged as the fastest-growing application segment, with a CAGR exceeding 12%. The COVID-19 pandemic has significantly accelerated demand in this sector, as consumers and manufacturers alike seek to enhance the hygiene of frequently touched devices such as smartphones, tablets, and wearables.

Geographically, North America holds the largest market share at 35%, followed by Europe at 30% and Asia-Pacific at 25%. However, the Asia-Pacific region is expected to witness the highest growth rate during the forecast period, driven by rapid industrialization, increasing healthcare expenditure, and growing awareness about hygiene and infection control.

Silver-based antimicrobial coatings currently dominate the market with a share of approximately 45%, owing to their broad-spectrum efficacy and relatively low toxicity. However, copper-based coatings are gaining traction due to their cost-effectiveness and natural antimicrobial properties.

Key market challenges include regulatory hurdles, particularly concerning the use of certain biocides, and the relatively high cost of advanced antimicrobial technologies. Additionally, there is growing consumer demand for environmentally friendly and non-toxic antimicrobial solutions, which is driving innovation in bio-based and natural antimicrobial agents.

The COVID-19 pandemic has served as a significant market accelerator, with heightened awareness of surface transmission of pathogens driving demand across all sectors. This trend is expected to continue post-pandemic, as hygiene consciousness becomes more deeply ingrained in consumer behavior and institutional protocols.

Current Challenges in Antimicrobial Coating Development

Despite significant advancements in antimicrobial surface coating technologies, several critical challenges continue to impede widespread adoption and optimal performance. One of the most persistent obstacles is the durability of antimicrobial coatings under real-world conditions. Many current formulations demonstrate excellent antimicrobial efficacy in laboratory settings but fail to maintain their effectiveness when subjected to mechanical abrasion, repeated cleaning protocols, or extended exposure to environmental factors such as UV radiation and humidity fluctuations.

The release kinetics of active antimicrobial agents presents another significant challenge. Achieving the delicate balance between immediate efficacy and sustained long-term performance remains problematic. Coatings that release antimicrobial compounds too rapidly may provide excellent initial protection but quickly become ineffective, while those with overly slow release may not reach the minimum inhibitory concentration necessary to prevent microbial colonization.

Regulatory hurdles constitute a substantial barrier to market entry, particularly for novel antimicrobial technologies. Different regions maintain varying standards and approval processes, creating a complex regulatory landscape that increases development costs and extends time-to-market. The EPA in the United States and the BPR in Europe impose stringent requirements for safety documentation and efficacy validation, often requiring years of testing before approval.

Biocompatibility concerns are especially critical for antimicrobial coatings intended for medical devices or food-contact surfaces. Many effective antimicrobial agents exhibit cytotoxicity or may trigger inflammatory responses in human tissues, limiting their application in healthcare settings. Developing coatings that selectively target microbial cells while remaining benign to human cells represents an ongoing challenge.

The emergence of antimicrobial resistance poses perhaps the most concerning long-term challenge. As antimicrobial coatings become more widespread, selective pressure may drive the evolution of resistant microbial strains. This risk is particularly pronounced in coatings utilizing conventional antibiotics or single-mechanism antimicrobial agents.

Cost-effectiveness remains a significant barrier to commercial adoption. Many advanced antimicrobial technologies incorporate expensive materials such as silver nanoparticles, specialized polymers, or complex surface modification techniques. These elevated production costs often make implementation economically unfeasible for many potential applications, particularly in price-sensitive markets or large-scale deployments.

Environmental impact considerations have gained increasing importance, with growing concerns about the potential ecological effects of leached antimicrobial compounds. Certain biocides may persist in the environment, potentially disrupting microbial ecosystems or accumulating in water systems. Developing environmentally responsible antimicrobial coatings that minimize unintended ecological consequences represents a critical challenge for the industry.

The release kinetics of active antimicrobial agents presents another significant challenge. Achieving the delicate balance between immediate efficacy and sustained long-term performance remains problematic. Coatings that release antimicrobial compounds too rapidly may provide excellent initial protection but quickly become ineffective, while those with overly slow release may not reach the minimum inhibitory concentration necessary to prevent microbial colonization.

Regulatory hurdles constitute a substantial barrier to market entry, particularly for novel antimicrobial technologies. Different regions maintain varying standards and approval processes, creating a complex regulatory landscape that increases development costs and extends time-to-market. The EPA in the United States and the BPR in Europe impose stringent requirements for safety documentation and efficacy validation, often requiring years of testing before approval.

Biocompatibility concerns are especially critical for antimicrobial coatings intended for medical devices or food-contact surfaces. Many effective antimicrobial agents exhibit cytotoxicity or may trigger inflammatory responses in human tissues, limiting their application in healthcare settings. Developing coatings that selectively target microbial cells while remaining benign to human cells represents an ongoing challenge.

The emergence of antimicrobial resistance poses perhaps the most concerning long-term challenge. As antimicrobial coatings become more widespread, selective pressure may drive the evolution of resistant microbial strains. This risk is particularly pronounced in coatings utilizing conventional antibiotics or single-mechanism antimicrobial agents.

Cost-effectiveness remains a significant barrier to commercial adoption. Many advanced antimicrobial technologies incorporate expensive materials such as silver nanoparticles, specialized polymers, or complex surface modification techniques. These elevated production costs often make implementation economically unfeasible for many potential applications, particularly in price-sensitive markets or large-scale deployments.

Environmental impact considerations have gained increasing importance, with growing concerns about the potential ecological effects of leached antimicrobial compounds. Certain biocides may persist in the environment, potentially disrupting microbial ecosystems or accumulating in water systems. Developing environmentally responsible antimicrobial coatings that minimize unintended ecological consequences represents a critical challenge for the industry.

Current Antimicrobial Coating Technical Solutions

01 Metal-based antimicrobial coatings

Metal-based antimicrobial coatings utilize silver, copper, zinc, or other metal ions to provide long-lasting protection against bacteria, fungi, and viruses. These metals disrupt microbial cell membranes and interfere with cellular processes, preventing colonization on surfaces. The metals can be incorporated as nanoparticles, ions, or compounds within various coating matrices to provide controlled release and sustained antimicrobial activity for healthcare settings, public spaces, and consumer products.- Metal-based antimicrobial coatings: Metal-based antimicrobial coatings utilize silver, copper, zinc, and other metal ions or nanoparticles to provide broad-spectrum antimicrobial protection on various surfaces. These metals disrupt bacterial cell membranes and interfere with cellular processes, preventing microbial colonization. The coatings can be applied to medical devices, touch surfaces, and consumer products to reduce pathogen transmission and biofilm formation, with long-lasting efficacy due to the controlled release of active metal ions.

- Polymer-based antimicrobial surface treatments: Polymer-based antimicrobial surface treatments incorporate active antimicrobial agents within polymer matrices to create durable protective coatings. These formulations can include quaternary ammonium compounds, antimicrobial peptides, or other biocides chemically bonded to or embedded within polymers like polyurethane, silicone, or acrylics. The polymer matrix provides controlled release of antimicrobial agents while maintaining surface integrity, offering protection against a wide range of pathogens while resisting wear, cleaning, and environmental factors.

- Natural and plant-derived antimicrobial coatings: Natural and plant-derived antimicrobial coatings utilize extracts from plants, essential oils, and other naturally occurring compounds to create environmentally friendly surface protection. These formulations harness the antimicrobial properties of compounds like chitosan, plant polyphenols, and essential oil components to inhibit microbial growth without synthetic chemicals. The coatings can be applied to food packaging, medical devices, and consumer products, offering sustainable alternatives with reduced environmental impact and toxicity concerns.

- Photocatalytic antimicrobial surface technologies: Photocatalytic antimicrobial surface technologies incorporate materials like titanium dioxide (TiO2) that generate reactive oxygen species when exposed to light. These reactive species destroy microorganisms by oxidizing their cell components. The coatings remain continuously active as long as they receive appropriate light exposure, making them self-cleaning and providing long-term antimicrobial protection. Applications include hospital surfaces, air purification systems, and exterior building materials, with enhanced effectiveness when combined with other antimicrobial agents or nanoparticles.

- Smart and responsive antimicrobial coating systems: Smart and responsive antimicrobial coating systems utilize advanced materials that can adapt to environmental changes or specific triggers to release antimicrobial agents. These include pH-responsive polymers, temperature-sensitive materials, and enzyme-activated systems that release antimicrobial compounds only when microbial contamination is detected. This targeted approach minimizes unnecessary antimicrobial release, reducing the risk of resistance development while maintaining effectiveness. Applications include medical implants, food packaging, and high-touch surfaces in healthcare settings.

02 Quaternary ammonium compound coatings

Quaternary ammonium compounds (QACs) are effective antimicrobial agents that can be incorporated into surface coatings. These compounds disrupt bacterial cell membranes through their positively charged nitrogen atoms, leading to cell death. QAC-based coatings provide broad-spectrum activity against bacteria, fungi, and some viruses, making them suitable for high-touch surfaces in healthcare facilities, food processing areas, and public spaces. These coatings can be formulated to provide both immediate and residual antimicrobial protection.Expand Specific Solutions03 Polymer-based antimicrobial coatings

Polymer-based antimicrobial coatings incorporate active ingredients within polymer matrices to create durable protective surfaces. These coatings can utilize intrinsically antimicrobial polymers or conventional polymers loaded with antimicrobial agents. The polymer matrix provides controlled release of active ingredients, extending the duration of antimicrobial activity while protecting the active compounds from degradation. These coatings can be applied to various substrates including metals, plastics, textiles, and ceramics for applications in healthcare, food processing, and consumer products.Expand Specific Solutions04 Natural and plant-derived antimicrobial coatings

Natural and plant-derived antimicrobial coatings utilize compounds from plants, essential oils, and other natural sources to inhibit microbial growth on surfaces. These environmentally friendly alternatives include extracts from plants like tea tree, oregano, thyme, and cinnamon, which contain active compounds such as polyphenols, terpenes, and flavonoids. These natural antimicrobials can be incorporated into various coating matrices to provide protection against bacteria, fungi, and some viruses while offering reduced toxicity and environmental impact compared to synthetic alternatives.Expand Specific Solutions05 Photocatalytic antimicrobial coatings

Photocatalytic antimicrobial coatings utilize materials like titanium dioxide (TiO2) that generate reactive oxygen species when exposed to light. These reactive species damage microbial cell components including cell walls, membranes, and DNA, effectively killing bacteria, fungi, and viruses on the coated surface. The antimicrobial activity is continuously renewed upon exposure to light, providing long-term protection without depleting active ingredients. These coatings are particularly useful for self-cleaning surfaces in healthcare facilities, public spaces, and building exteriors where light exposure is consistent.Expand Specific Solutions

Key Industry Players and Patent Holders

The antimicrobial surface coatings market is currently in a growth phase, with increasing patent activity reflecting rising demand for infection control solutions across healthcare, food processing, and consumer goods sectors. Market size is projected to exceed $5 billion by 2026, driven by heightened hygiene awareness post-pandemic. Technology maturity varies significantly across players, with established chemical companies like BASF, DuPont, and LANXESS leading in commercial applications, while research institutions such as California Institute of Technology and Agency for Science, Technology & Research drive fundamental innovation. Companies like Microban Products and Orthobond have developed specialized antimicrobial technologies, while healthcare-focused firms including Baxter International and Medtronic are integrating these coatings into medical devices. Academic-industry partnerships are accelerating commercialization pathways for novel nanomaterial-based antimicrobial solutions.

Microban Products Co.

Technical Solution: Microban has developed a comprehensive suite of antimicrobial technologies that can be integrated into various surface materials during manufacturing. Their approach focuses on built-in protection that becomes part of the product's molecular structure rather than surface treatments that wear off over time. Microban's technologies include silver ion technology, zinc technology, and organic antimicrobial solutions that can be customized based on the substrate material, manufacturing process, and intended use environment. Their solutions are designed to inhibit bacterial growth by disrupting key cellular functions when microorganisms come into contact with treated surfaces. The company has demonstrated efficacy against a wide range of bacteria, fungi, and molds with protection lasting for the expected lifetime of the product. Microban has also developed antimicrobial coatings that maintain effectiveness even after repeated cleaning cycles and environmental exposure[1][2].

Strengths: Long-lasting protection integrated at the molecular level; broad-spectrum antimicrobial activity; customizable for different materials and manufacturing processes; established regulatory compliance across global markets. Weaknesses: Higher initial manufacturing costs; potential for microbial adaptation over time; limited viral protection compared to some newer technologies.

Fairleigh Dickinson University

Technical Solution: Fairleigh Dickinson University researchers have developed novel antimicrobial surface coatings using quaternary ammonium compound (QAC) technology combined with nanomaterial delivery systems. Their approach focuses on creating permanently bonded antimicrobial surfaces through covalent attachment of QACs to various substrate materials. The technology employs silane-based chemistry to form durable bonds between the antimicrobial agents and surfaces, creating a "contact-killing" mechanism that physically disrupts microbial cell membranes upon contact. This approach differs from leaching technologies as the active compounds remain permanently anchored to the surface. The university's research has demonstrated long-term efficacy against both gram-positive and gram-negative bacteria, with particular success in healthcare-related applications. Their coating technology has shown effectiveness even after extensive abrasion testing and chemical exposure, indicating exceptional durability. Recent innovations include the incorporation of graphene oxide and other nanomaterials to enhance antimicrobial performance while reducing the potential for antimicrobial resistance development[5][6].

Strengths: Non-leaching technology reduces environmental concerns; permanent surface modification provides long-term protection; effective against a broad spectrum of microorganisms; relatively low manufacturing complexity. Weaknesses: Limited scalability compared to commercial solutions; potential cytotoxicity concerns with some QAC formulations; less effective against certain fungal species; requires specific surface chemistry for optimal bonding.

Critical Patent Analysis and Innovation Insights

Antimicrobial coatings

PatentWO2020035483A1

Innovation

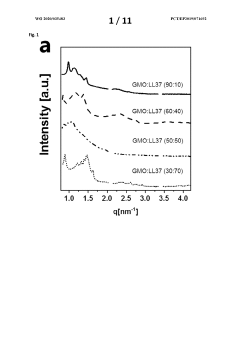

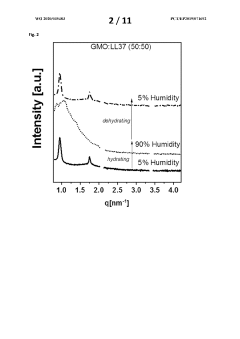

- An antimicrobial liquid crystal composition comprising amphiphilic lipids, antimicrobial agents, and water that forms stable liquid crystals at room temperature, providing sustained and adhesive antimicrobial properties without requiring additional surfactants or polymers, and can be adapted by stimuli like humidity and pH to enhance antimicrobial efficacy.

Antimicrobial coating

PatentWO2022027103A1

Innovation

- An antimicrobial coating comprising a polyurethane and polyacrylate interpenetrating polymer network, combined with hydrophobic particulate solids and metal-containing particulate solids like zinc or silver, which are embedded in the coating to prevent bacterial adhesion and maintain a stable Cassie-Baxter state even when wet.

Environmental and Safety Considerations

The environmental impact and safety profile of antimicrobial surface coatings have become increasingly critical considerations in recent patent filings. Analysis of patent trends reveals a significant shift toward eco-friendly formulations that minimize environmental persistence and toxicity. Traditional antimicrobial coatings often contained heavy metals like silver, copper, and zinc, which can accumulate in ecosystems and potentially disrupt aquatic environments. Recent patents demonstrate a clear pivot toward biodegradable alternatives and naturally derived antimicrobial compounds that maintain efficacy while reducing environmental footprint.

Regulatory frameworks worldwide are driving this evolution, with the European Union's REACH regulations and the U.S. EPA's stricter guidelines prominently influencing patent strategies. Companies are increasingly filing patents for formulations that proactively address these regulatory requirements, particularly focusing on leaching behavior and end-of-life degradation pathways of antimicrobial agents.

Human health considerations represent another dominant theme in recent patent applications. There is growing emphasis on developing coatings that maintain antimicrobial efficacy without contributing to antimicrobial resistance—a global health concern. Patents increasingly incorporate risk assessment methodologies and safety data, particularly for applications in healthcare settings, food processing facilities, and consumer products where human exposure is likely.

Life cycle assessment (LCA) methodologies are increasingly referenced in patent documents, indicating a more holistic approach to environmental impact evaluation. Patents now frequently include data on carbon footprint, water usage, and energy requirements during manufacturing, application, and disposal phases of antimicrobial coatings. This trend aligns with broader sustainability initiatives across industries and responds to market demand for environmentally responsible technologies.

Manufacturing safety has emerged as another key consideration, with patents detailing processes that reduce worker exposure to potentially harmful compounds during production. Innovations in encapsulation technologies and controlled-release mechanisms not only improve coating performance but also enhance safety profiles by minimizing unnecessary release of active ingredients.

The integration of green chemistry principles represents perhaps the most promising direction in recent patent filings. These approaches focus on designing antimicrobial coatings that reduce or eliminate hazardous substances, utilize renewable feedstocks, and incorporate energy-efficient processes. Patents highlighting solvent-free application methods, water-based formulations, and bio-inspired antimicrobial mechanisms demonstrate this commitment to environmentally responsible innovation.

Regulatory frameworks worldwide are driving this evolution, with the European Union's REACH regulations and the U.S. EPA's stricter guidelines prominently influencing patent strategies. Companies are increasingly filing patents for formulations that proactively address these regulatory requirements, particularly focusing on leaching behavior and end-of-life degradation pathways of antimicrobial agents.

Human health considerations represent another dominant theme in recent patent applications. There is growing emphasis on developing coatings that maintain antimicrobial efficacy without contributing to antimicrobial resistance—a global health concern. Patents increasingly incorporate risk assessment methodologies and safety data, particularly for applications in healthcare settings, food processing facilities, and consumer products where human exposure is likely.

Life cycle assessment (LCA) methodologies are increasingly referenced in patent documents, indicating a more holistic approach to environmental impact evaluation. Patents now frequently include data on carbon footprint, water usage, and energy requirements during manufacturing, application, and disposal phases of antimicrobial coatings. This trend aligns with broader sustainability initiatives across industries and responds to market demand for environmentally responsible technologies.

Manufacturing safety has emerged as another key consideration, with patents detailing processes that reduce worker exposure to potentially harmful compounds during production. Innovations in encapsulation technologies and controlled-release mechanisms not only improve coating performance but also enhance safety profiles by minimizing unnecessary release of active ingredients.

The integration of green chemistry principles represents perhaps the most promising direction in recent patent filings. These approaches focus on designing antimicrobial coatings that reduce or eliminate hazardous substances, utilize renewable feedstocks, and incorporate energy-efficient processes. Patents highlighting solvent-free application methods, water-based formulations, and bio-inspired antimicrobial mechanisms demonstrate this commitment to environmentally responsible innovation.

Regulatory Framework for Antimicrobial Products

The regulatory landscape for antimicrobial surface coatings has become increasingly complex as these technologies gain prominence in healthcare, food processing, and consumer products. In the United States, the Environmental Protection Agency (EPA) regulates antimicrobial coatings under the Federal Insecticide, Fungicide, and Rodenticide Act (FIFRA) when they make public health claims. Products must undergo rigorous efficacy testing and safety evaluations before receiving EPA registration, with requirements varying based on the specific antimicrobial claims and intended applications.

The Food and Drug Administration (FDA) maintains oversight when these coatings are used on medical devices or food contact surfaces, requiring manufacturers to demonstrate both safety and efficacy through standardized testing protocols. For medical applications, antimicrobial coatings may be classified as combination products, necessitating compliance with both device and drug regulations.

In the European Union, the Biocidal Products Regulation (BPR) governs antimicrobial coatings, mandating comprehensive risk assessments and authorization processes. The regulation specifically addresses active substances in these coatings, requiring manufacturers to prove both efficacy and environmental safety. Additionally, the EU's REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) regulation imposes further requirements on chemical components used in coating formulations.

Patent analysis reveals increasing regulatory considerations within innovation strategies. Recent patent filings demonstrate a clear trend toward developing antimicrobial technologies that preemptively address regulatory hurdles, particularly regarding leaching concerns and environmental persistence of antimicrobial agents. This represents a significant shift from earlier patents that focused primarily on efficacy without substantial regulatory compliance considerations.

International standards organizations, including ISO and ASTM, have developed testing protocols specifically for antimicrobial surfaces, providing standardized methods for efficacy evaluation. These standards have become increasingly referenced in regulatory submissions and patent applications, indicating their growing importance in the regulatory framework.

Emerging regulatory trends include heightened scrutiny of nanomaterial-based antimicrobial coatings, with specialized risk assessment frameworks being developed in multiple jurisdictions. Additionally, there is growing regulatory emphasis on sustainability aspects, with some regions implementing restrictions on certain biocides due to environmental persistence concerns, directly influencing patent strategies and innovation directions in the field.

The Food and Drug Administration (FDA) maintains oversight when these coatings are used on medical devices or food contact surfaces, requiring manufacturers to demonstrate both safety and efficacy through standardized testing protocols. For medical applications, antimicrobial coatings may be classified as combination products, necessitating compliance with both device and drug regulations.

In the European Union, the Biocidal Products Regulation (BPR) governs antimicrobial coatings, mandating comprehensive risk assessments and authorization processes. The regulation specifically addresses active substances in these coatings, requiring manufacturers to prove both efficacy and environmental safety. Additionally, the EU's REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) regulation imposes further requirements on chemical components used in coating formulations.

Patent analysis reveals increasing regulatory considerations within innovation strategies. Recent patent filings demonstrate a clear trend toward developing antimicrobial technologies that preemptively address regulatory hurdles, particularly regarding leaching concerns and environmental persistence of antimicrobial agents. This represents a significant shift from earlier patents that focused primarily on efficacy without substantial regulatory compliance considerations.

International standards organizations, including ISO and ASTM, have developed testing protocols specifically for antimicrobial surfaces, providing standardized methods for efficacy evaluation. These standards have become increasingly referenced in regulatory submissions and patent applications, indicating their growing importance in the regulatory framework.

Emerging regulatory trends include heightened scrutiny of nanomaterial-based antimicrobial coatings, with specialized risk assessment frameworks being developed in multiple jurisdictions. Additionally, there is growing regulatory emphasis on sustainability aspects, with some regions implementing restrictions on certain biocides due to environmental persistence concerns, directly influencing patent strategies and innovation directions in the field.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!