What Factors Influence the Efficiency of Antimicrobial Surface Coatings

SEP 29, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Antimicrobial Coating Technology Background and Objectives

Antimicrobial surface coatings have emerged as a critical technology in combating pathogenic microorganisms across various sectors including healthcare, food processing, and public facilities. The development of these coatings traces back to the early 20th century, with significant advancements occurring in the past three decades due to increasing concerns about hospital-acquired infections and antibiotic resistance.

The evolution of antimicrobial coating technology has progressed from simple silver-based solutions to sophisticated multi-functional systems incorporating nanotechnology and smart materials. Initially focused primarily on silver ions, the field has expanded to include copper, zinc oxide, titanium dioxide, quaternary ammonium compounds, and various organic antimicrobials, each offering distinct mechanisms of action against pathogens.

Recent technological trends indicate a shift toward environmentally sustainable formulations, reduced toxicity profiles, and enhanced durability. The integration of antimicrobial properties with other functional characteristics such as anti-fouling, self-cleaning, and wear resistance represents a significant advancement in coating technology, addressing multiple performance requirements simultaneously.

The global COVID-19 pandemic has accelerated research and development in this field, highlighting the urgent need for effective surface disinfection strategies in preventing disease transmission. This has catalyzed innovation in rapid-action antimicrobial coatings and stimulated cross-disciplinary collaboration between materials scientists, microbiologists, and public health experts.

The primary technical objectives in antimicrobial coating development include: enhancing long-term efficacy under real-world conditions; developing broad-spectrum activity against bacteria, viruses, and fungi; minimizing the potential for antimicrobial resistance; ensuring biocompatibility for human contact surfaces; and creating cost-effective solutions suitable for large-scale implementation.

Current research aims to understand the complex interplay between coating composition, surface properties, environmental conditions, and microbial response mechanisms. Particular emphasis is placed on elucidating the factors that influence antimicrobial efficiency, including contact time, humidity, temperature, cleaning protocols, and substrate interactions.

The future trajectory of antimicrobial coating technology points toward precision-engineered surfaces with tailored antimicrobial properties, responsive systems that activate upon microbial detection, and sustainable formulations derived from natural compounds. Emerging approaches include biomimetic strategies inspired by naturally antimicrobial surfaces found in certain plants and animals, offering potential breakthroughs in both efficacy and environmental compatibility.

The evolution of antimicrobial coating technology has progressed from simple silver-based solutions to sophisticated multi-functional systems incorporating nanotechnology and smart materials. Initially focused primarily on silver ions, the field has expanded to include copper, zinc oxide, titanium dioxide, quaternary ammonium compounds, and various organic antimicrobials, each offering distinct mechanisms of action against pathogens.

Recent technological trends indicate a shift toward environmentally sustainable formulations, reduced toxicity profiles, and enhanced durability. The integration of antimicrobial properties with other functional characteristics such as anti-fouling, self-cleaning, and wear resistance represents a significant advancement in coating technology, addressing multiple performance requirements simultaneously.

The global COVID-19 pandemic has accelerated research and development in this field, highlighting the urgent need for effective surface disinfection strategies in preventing disease transmission. This has catalyzed innovation in rapid-action antimicrobial coatings and stimulated cross-disciplinary collaboration between materials scientists, microbiologists, and public health experts.

The primary technical objectives in antimicrobial coating development include: enhancing long-term efficacy under real-world conditions; developing broad-spectrum activity against bacteria, viruses, and fungi; minimizing the potential for antimicrobial resistance; ensuring biocompatibility for human contact surfaces; and creating cost-effective solutions suitable for large-scale implementation.

Current research aims to understand the complex interplay between coating composition, surface properties, environmental conditions, and microbial response mechanisms. Particular emphasis is placed on elucidating the factors that influence antimicrobial efficiency, including contact time, humidity, temperature, cleaning protocols, and substrate interactions.

The future trajectory of antimicrobial coating technology points toward precision-engineered surfaces with tailored antimicrobial properties, responsive systems that activate upon microbial detection, and sustainable formulations derived from natural compounds. Emerging approaches include biomimetic strategies inspired by naturally antimicrobial surfaces found in certain plants and animals, offering potential breakthroughs in both efficacy and environmental compatibility.

Market Demand Analysis for Antimicrobial Surface Solutions

The global market for antimicrobial surface coatings has experienced significant growth in recent years, driven primarily by increasing awareness of infection control and hygiene across multiple sectors. Healthcare facilities represent the largest market segment, with hospitals, clinics, and long-term care facilities seeking solutions to reduce healthcare-associated infections (HAIs). The COVID-19 pandemic has substantially accelerated this demand, creating a paradigm shift in how public spaces approach surface hygiene.

Consumer awareness regarding microbial contamination has reached unprecedented levels, extending the market beyond traditional healthcare settings into commercial and residential applications. Food processing facilities, public transportation, educational institutions, and hospitality sectors are increasingly adopting antimicrobial surface technologies to address consumer safety concerns and comply with stricter regulatory standards.

Market research indicates that the global antimicrobial coatings market was valued at approximately 3.9 billion USD in 2021 and is projected to reach 7.2 billion USD by 2028, growing at a compound annual growth rate of 10.8%. The healthcare segment alone accounts for nearly 38% of this market, followed by food and beverage processing at 22%.

Regional analysis reveals North America currently dominates the market with a 35% share, followed closely by Europe at 30% and Asia-Pacific at 25%. However, the Asia-Pacific region is expected to witness the fastest growth due to rapid industrialization, increasing healthcare expenditure, and growing awareness about hygiene in countries like China, India, and Japan.

Consumer preference trends indicate a growing demand for environmentally sustainable antimicrobial solutions with minimal toxicity concerns. This has spurred research into bio-based antimicrobial agents and "green" coating technologies that maintain efficacy while reducing environmental impact. Additionally, there is increasing interest in multifunctional coatings that combine antimicrobial properties with other features such as anti-corrosion, self-cleaning, or wear resistance.

Regulatory factors significantly influence market dynamics, with different regions implementing varying standards for antimicrobial efficacy claims and safety requirements. The FDA, EPA, and similar international bodies have established guidelines that manufacturers must navigate, creating both challenges and opportunities for market differentiation.

The competitive landscape is characterized by continuous innovation, with companies investing heavily in R&D to develop coatings with broader spectrum activity, longer durability, and enhanced performance under diverse environmental conditions. This innovation-driven approach is expected to further expand market applications and drive growth in previously untapped sectors.

Consumer awareness regarding microbial contamination has reached unprecedented levels, extending the market beyond traditional healthcare settings into commercial and residential applications. Food processing facilities, public transportation, educational institutions, and hospitality sectors are increasingly adopting antimicrobial surface technologies to address consumer safety concerns and comply with stricter regulatory standards.

Market research indicates that the global antimicrobial coatings market was valued at approximately 3.9 billion USD in 2021 and is projected to reach 7.2 billion USD by 2028, growing at a compound annual growth rate of 10.8%. The healthcare segment alone accounts for nearly 38% of this market, followed by food and beverage processing at 22%.

Regional analysis reveals North America currently dominates the market with a 35% share, followed closely by Europe at 30% and Asia-Pacific at 25%. However, the Asia-Pacific region is expected to witness the fastest growth due to rapid industrialization, increasing healthcare expenditure, and growing awareness about hygiene in countries like China, India, and Japan.

Consumer preference trends indicate a growing demand for environmentally sustainable antimicrobial solutions with minimal toxicity concerns. This has spurred research into bio-based antimicrobial agents and "green" coating technologies that maintain efficacy while reducing environmental impact. Additionally, there is increasing interest in multifunctional coatings that combine antimicrobial properties with other features such as anti-corrosion, self-cleaning, or wear resistance.

Regulatory factors significantly influence market dynamics, with different regions implementing varying standards for antimicrobial efficacy claims and safety requirements. The FDA, EPA, and similar international bodies have established guidelines that manufacturers must navigate, creating both challenges and opportunities for market differentiation.

The competitive landscape is characterized by continuous innovation, with companies investing heavily in R&D to develop coatings with broader spectrum activity, longer durability, and enhanced performance under diverse environmental conditions. This innovation-driven approach is expected to further expand market applications and drive growth in previously untapped sectors.

Current Challenges in Antimicrobial Coating Development

Despite significant advancements in antimicrobial surface coating technologies, several critical challenges continue to impede widespread implementation and optimal performance. One of the primary obstacles is the durability of these coatings under real-world conditions. Many antimicrobial surfaces demonstrate excellent efficacy in laboratory settings but fail to maintain their performance when subjected to mechanical abrasion, cleaning protocols, or environmental stressors. This durability gap significantly limits their practical application in high-touch or harsh environments.

Another substantial challenge lies in achieving broad-spectrum antimicrobial activity while avoiding microbial resistance development. As antimicrobial coatings become more prevalent, concerns about contributing to the global antimicrobial resistance crisis have intensified. Researchers must balance potent antimicrobial action with mechanisms that minimize selective pressure on microbial populations.

Toxicity and biocompatibility present ongoing concerns, particularly for applications in healthcare settings or food contact surfaces. Many effective antimicrobial agents exhibit cytotoxicity toward mammalian cells or may leach potentially harmful compounds over time. Developing coatings that remain safe for human contact while maintaining antimicrobial efficacy represents a significant technical hurdle.

Cost-effectiveness and scalability continue to limit commercial adoption. Current manufacturing processes for advanced antimicrobial coatings often involve complex multi-step procedures, specialized equipment, or expensive raw materials. These factors drive up production costs and create barriers to market entry, particularly for applications where profit margins are slim.

Regulatory compliance presents another layer of complexity. Different regions maintain varying standards for antimicrobial claims, safety testing, and environmental impact assessments. Navigating this regulatory landscape requires substantial resources and can delay market introduction of promising technologies.

The environmental impact of antimicrobial coatings has also emerged as a critical concern. Many current formulations contain heavy metals, synthetic biocides, or non-biodegradable components that may accumulate in ecosystems. Developing environmentally sustainable alternatives that maintain efficacy remains challenging.

Finally, standardization of testing methodologies represents a significant obstacle to comparative assessment. The antimicrobial coating field lacks universally accepted protocols for evaluating performance under conditions that accurately simulate real-world use. This absence of standardization makes it difficult to compare different technologies or predict field performance based on laboratory results.

Another substantial challenge lies in achieving broad-spectrum antimicrobial activity while avoiding microbial resistance development. As antimicrobial coatings become more prevalent, concerns about contributing to the global antimicrobial resistance crisis have intensified. Researchers must balance potent antimicrobial action with mechanisms that minimize selective pressure on microbial populations.

Toxicity and biocompatibility present ongoing concerns, particularly for applications in healthcare settings or food contact surfaces. Many effective antimicrobial agents exhibit cytotoxicity toward mammalian cells or may leach potentially harmful compounds over time. Developing coatings that remain safe for human contact while maintaining antimicrobial efficacy represents a significant technical hurdle.

Cost-effectiveness and scalability continue to limit commercial adoption. Current manufacturing processes for advanced antimicrobial coatings often involve complex multi-step procedures, specialized equipment, or expensive raw materials. These factors drive up production costs and create barriers to market entry, particularly for applications where profit margins are slim.

Regulatory compliance presents another layer of complexity. Different regions maintain varying standards for antimicrobial claims, safety testing, and environmental impact assessments. Navigating this regulatory landscape requires substantial resources and can delay market introduction of promising technologies.

The environmental impact of antimicrobial coatings has also emerged as a critical concern. Many current formulations contain heavy metals, synthetic biocides, or non-biodegradable components that may accumulate in ecosystems. Developing environmentally sustainable alternatives that maintain efficacy remains challenging.

Finally, standardization of testing methodologies represents a significant obstacle to comparative assessment. The antimicrobial coating field lacks universally accepted protocols for evaluating performance under conditions that accurately simulate real-world use. This absence of standardization makes it difficult to compare different technologies or predict field performance based on laboratory results.

Existing Antimicrobial Coating Mechanisms and Formulations

01 Metal-based antimicrobial coatings

Metal-based antimicrobial coatings utilize silver, copper, zinc, and other metal ions or nanoparticles to provide effective surface protection against microorganisms. These metals disrupt bacterial cell membranes and interfere with cellular processes, offering long-lasting antimicrobial properties. The coatings can be applied to various surfaces including medical devices, textiles, and high-touch areas to reduce pathogen transmission and biofilm formation.- Metal-based antimicrobial coatings: Metal-based antimicrobial coatings utilize silver, copper, zinc, and other metal ions or nanoparticles to provide effective antimicrobial properties on various surfaces. These metals disrupt bacterial cell membranes and interfere with cellular processes, preventing microbial growth and colonization. The coatings can be applied to medical devices, hospital surfaces, and consumer products to reduce infection risks and improve hygiene standards.

- Polymer-based antimicrobial surface technologies: Polymer-based antimicrobial coatings incorporate active ingredients within polymer matrices to create durable antimicrobial surfaces. These formulations can include quaternary ammonium compounds, chitosan derivatives, or antimicrobial peptides embedded in various polymer systems. The controlled release of antimicrobial agents provides long-lasting protection against a broad spectrum of pathogens while maintaining surface integrity and functionality over extended periods.

- Natural and bio-based antimicrobial coating solutions: Natural and bio-based antimicrobial coatings utilize plant extracts, essential oils, enzymes, and other biological compounds to create environmentally friendly antimicrobial surfaces. These sustainable alternatives offer effective protection against microorganisms while reducing reliance on synthetic chemicals. The formulations can be applied to food packaging, textiles, and building materials to provide antimicrobial properties with reduced environmental impact and toxicity concerns.

- Photocatalytic and light-activated antimicrobial surfaces: Photocatalytic antimicrobial coatings utilize materials like titanium dioxide that generate reactive oxygen species when exposed to light, effectively killing microorganisms on contact. These self-cleaning surfaces remain continuously active as long as they receive appropriate light exposure. The technology can be incorporated into various materials including glass, ceramics, and polymers for use in healthcare facilities, public spaces, and consumer products to provide ongoing antimicrobial protection.

- Testing and evaluation methods for antimicrobial coating efficiency: Standardized testing protocols and evaluation methods are essential for determining the efficacy of antimicrobial surface coatings. These include zone of inhibition tests, bacterial adhesion assays, time-kill studies, and durability assessments under various environmental conditions. Advanced analytical techniques such as microscopy, spectroscopy, and molecular biology methods provide comprehensive data on antimicrobial performance, helping to optimize formulations and validate claims about coating effectiveness.

02 Quaternary ammonium compound coatings

Quaternary ammonium compounds (QACs) are widely used in antimicrobial surface coatings due to their broad-spectrum activity against bacteria, fungi, and some viruses. These compounds work by disrupting cell membranes of microorganisms, leading to cell death. QAC-based coatings can be formulated to provide durable protection on various surfaces and are particularly effective in healthcare settings, food processing facilities, and public spaces to reduce cross-contamination.Expand Specific Solutions03 Polymer-based antimicrobial coatings

Polymer-based antimicrobial coatings incorporate active ingredients within polymer matrices to create surfaces with sustained antimicrobial release or contact-killing properties. These coatings can be designed with controlled-release mechanisms that gradually dispense antimicrobial agents or with permanently bound antimicrobial moieties that kill microbes on contact. The polymer matrix enhances durability and can be engineered for specific applications ranging from medical implants to consumer products.Expand Specific Solutions04 Natural and bio-based antimicrobial coatings

Natural and bio-based antimicrobial coatings utilize plant extracts, essential oils, enzymes, and other naturally derived compounds to inhibit microbial growth on surfaces. These environmentally friendly alternatives offer reduced toxicity compared to synthetic antimicrobials while providing effective protection against various pathogens. The coatings can be formulated to maintain antimicrobial efficacy while addressing increasing consumer demand for sustainable and non-toxic surface protection solutions.Expand Specific Solutions05 Testing and evaluation methods for antimicrobial coating efficiency

Standardized testing and evaluation methods are essential for determining the efficiency of antimicrobial surface coatings. These include protocols for measuring zone of inhibition, bacterial reduction rates, biofilm prevention capabilities, and durability under various environmental conditions. Advanced techniques such as confocal microscopy, ATP bioluminescence, and molecular methods provide quantitative assessment of antimicrobial performance, helping to validate claims and optimize formulations for specific applications and target pathogens.Expand Specific Solutions

Leading Manufacturers and Research Institutions Analysis

The antimicrobial surface coatings market is currently in a growth phase, with an estimated global market size exceeding $3.5 billion and projected to expand significantly due to increasing healthcare-associated infection concerns. The competitive landscape features established players like DuPont, Baxter International, and Ecolab alongside specialized firms such as Sciessent and Hecosol GmbH. Academic institutions including University of Stellenbosch, Sichuan University, and Carnegie Mellon University are driving innovation through fundamental research. Technology maturity varies across application sectors, with healthcare applications being most advanced. Companies like Corning and SCHOTT AG are leveraging their materials expertise to develop next-generation coatings with enhanced durability and efficacy, while Asian players such as POSCO Holdings and Jiangsu Biosurf Biotech are rapidly gaining market share through cost-effective solutions.

Rust-Oleum Corp.

Technical Solution: Rust-Oleum has developed commercially viable antimicrobial coating solutions focused on accessibility and ease of application. Their ROC-Shield™ and Mold Defense™ product lines incorporate EPA-registered antimicrobial agents into various coating formulations designed for both professional and consumer applications. Rust-Oleum's technology utilizes silver ion technology embedded in specialized polymer matrices that control release rates based on environmental moisture levels. Their research has optimized the balance between immediate antimicrobial action and long-term efficacy, addressing a key efficiency factor in practical applications. The company has developed proprietary binding technologies that enhance adhesion to multiple surface types while maintaining antimicrobial agent bioavailability. Their formulations incorporate additives that resist UV degradation and maintain performance under harsh environmental conditions. Testing has demonstrated that their coatings maintain >90% of initial antimicrobial efficacy after accelerated weathering equivalent to 3-5 years of real-world exposure, addressing durability concerns that significantly impact long-term efficiency in field applications.

Strengths: Broad market accessibility through retail channels; formulations designed for easy application without specialized equipment; cost-effective implementation compared to institutional solutions. Weaknesses: Generally lower antimicrobial performance compared to medical-grade solutions; limited efficacy against certain resistant pathogens; shorter active lifespan compared to more advanced institutional technologies.

Sciessent LLC

Technical Solution: Sciessent has developed advanced antimicrobial technologies including their flagship Agion® technology, which utilizes controlled release of silver ions as the primary antimicrobial agent. Their approach combines silver with a zeolite carrier system that enables sustained release of antimicrobial agents when conditions for bacterial growth are present (moisture, temperature). The technology creates a multi-modal attack against microbes through silver ion exchange mechanisms that disrupt cell walls, interfere with DNA replication, and inhibit cellular respiration. Sciessent has optimized the ion release kinetics to provide long-lasting protection while maintaining effectiveness across various environmental conditions. Their coatings demonstrate efficacy against a broad spectrum of bacteria, fungi, and certain viruses with documented reduction rates exceeding 99.9% for common pathogens.

Strengths: Controlled release mechanism provides long-term efficacy (3+ years in many applications); environmentally triggered release improves efficiency and reduces unnecessary antimicrobial discharge; broad-spectrum activity against multiple pathogen types. Weaknesses: Silver-based technologies may face increasing regulatory scrutiny; higher cost compared to conventional biocides; potential for development of microbial resistance with prolonged exposure.

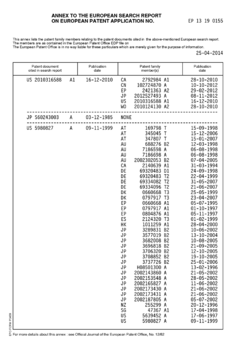

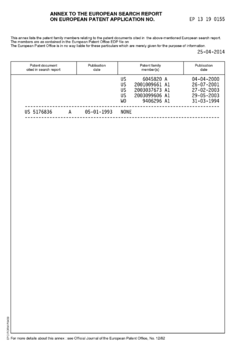

Key Patents and Scientific Breakthroughs in Surface Antimicrobials

Antimicrobial coating compositions

PatentPendingUS20240117196A1

Innovation

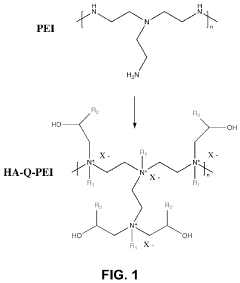

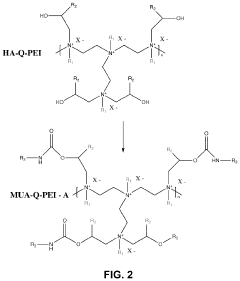

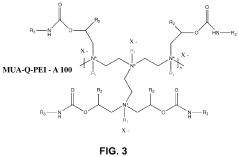

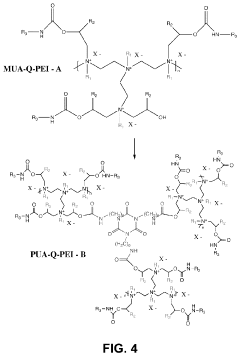

- Development of antimicrobial compositions comprising quaternary ammonium polymers formed from polyethyleneimine oligomers, multifunctional crosslinkers, alkylating agents, and monoisocyanates, which are reacted to create durable, water-resistant, and cost-effective coatings with enhanced antimicrobial properties.

Antimicrobial coating containing quaternary ammonium resin and its regeneration

PatentInactiveEP2740355A1

Innovation

- A strongly basic anion-exchange resin film or coating, free of transition metals, is applied to medical device surfaces, which can be replenished with antimicrobial anions such as iodine or chloride, providing sustained antimicrobial activity through exposure to agents like bleach or Lugol's iodine.

Environmental Impact and Sustainability Considerations

The environmental impact of antimicrobial surface coatings has become increasingly significant as their deployment expands across healthcare, food processing, and public spaces. Traditional antimicrobial agents often contain heavy metals such as silver, copper, and zinc, which can leach into the environment during production, use, and disposal phases. These metals may accumulate in aquatic ecosystems, potentially disrupting microbial communities that are essential for environmental processes and potentially entering the food chain through bioaccumulation.

The manufacturing processes for antimicrobial coatings frequently involve volatile organic compounds (VOCs) and other hazardous substances that contribute to air pollution and pose occupational health risks. Additionally, the energy consumption associated with production processes generates a substantial carbon footprint, particularly for coatings requiring high-temperature curing or complex synthesis methods.

Durability represents a critical sustainability factor, as coatings with short functional lifespans necessitate frequent reapplication, multiplying their environmental impact. Research indicates that mechanical abrasion, chemical cleaning protocols, and environmental exposure can significantly degrade antimicrobial efficacy over time, creating a sustainability challenge that must be addressed through improved formulations.

Recent innovations have focused on developing bio-based alternatives derived from natural sources such as chitosan, plant extracts, and essential oils. These alternatives offer biodegradability advantages while potentially reducing toxicity concerns. Life cycle assessment (LCA) studies comparing conventional and bio-based antimicrobial coatings demonstrate that the latter can reduce environmental impact by 30-60% across multiple impact categories, though performance optimization remains necessary.

Regulatory frameworks worldwide are increasingly incorporating sustainability criteria for antimicrobial products. The European Union's Biocidal Products Regulation and similar frameworks in other regions now require environmental risk assessments and encourage the substitution of hazardous substances with safer alternatives. These regulatory pressures are driving innovation toward greener formulations that maintain antimicrobial efficacy while minimizing ecological harm.

End-of-life considerations present another sustainability challenge, as antimicrobial coatings may complicate recycling processes or contribute to microplastic pollution when applied to disposable items. Developing coatings that are compatible with existing recycling streams or designing for biodegradability represents an important frontier in sustainable antimicrobial technology development.

The manufacturing processes for antimicrobial coatings frequently involve volatile organic compounds (VOCs) and other hazardous substances that contribute to air pollution and pose occupational health risks. Additionally, the energy consumption associated with production processes generates a substantial carbon footprint, particularly for coatings requiring high-temperature curing or complex synthesis methods.

Durability represents a critical sustainability factor, as coatings with short functional lifespans necessitate frequent reapplication, multiplying their environmental impact. Research indicates that mechanical abrasion, chemical cleaning protocols, and environmental exposure can significantly degrade antimicrobial efficacy over time, creating a sustainability challenge that must be addressed through improved formulations.

Recent innovations have focused on developing bio-based alternatives derived from natural sources such as chitosan, plant extracts, and essential oils. These alternatives offer biodegradability advantages while potentially reducing toxicity concerns. Life cycle assessment (LCA) studies comparing conventional and bio-based antimicrobial coatings demonstrate that the latter can reduce environmental impact by 30-60% across multiple impact categories, though performance optimization remains necessary.

Regulatory frameworks worldwide are increasingly incorporating sustainability criteria for antimicrobial products. The European Union's Biocidal Products Regulation and similar frameworks in other regions now require environmental risk assessments and encourage the substitution of hazardous substances with safer alternatives. These regulatory pressures are driving innovation toward greener formulations that maintain antimicrobial efficacy while minimizing ecological harm.

End-of-life considerations present another sustainability challenge, as antimicrobial coatings may complicate recycling processes or contribute to microplastic pollution when applied to disposable items. Developing coatings that are compatible with existing recycling streams or designing for biodegradability represents an important frontier in sustainable antimicrobial technology development.

Regulatory Framework and Safety Standards

The regulatory landscape governing antimicrobial surface coatings has become increasingly complex as these technologies gain wider adoption across healthcare, food processing, and public spaces. In the United States, the Environmental Protection Agency (EPA) regulates antimicrobial coatings under the Federal Insecticide, Fungicide, and Rodenticide Act (FIFRA), requiring manufacturers to register products and substantiate efficacy claims through standardized testing protocols. Similarly, the Food and Drug Administration (FDA) oversees coatings that come into contact with food or medical devices, imposing stringent requirements for biocompatibility and leaching potential.

European regulations, particularly the Biocidal Products Regulation (BPR), have established comprehensive frameworks for antimicrobial products, mandating extensive safety assessments and efficacy documentation. These regulations significantly influence coating efficiency by dictating permissible active ingredients, concentration limits, and application methodologies. The Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) further impacts formulation options by restricting certain chemicals with environmental or health concerns.

International standards organizations have developed specific testing protocols that directly affect efficiency measurements. ISO 22196 and JIS Z 2801 provide standardized methods for evaluating antimicrobial activity on surfaces, while ASTM E2180 addresses the efficacy of incorporated antimicrobial agents against specified microorganisms. These standards ensure consistency in performance claims but may not fully represent real-world conditions, creating a gap between laboratory-certified efficiency and practical application outcomes.

Safety standards increasingly emphasize the long-term environmental impact of antimicrobial coatings. Regulations limiting heavy metal content, particularly silver and copper compounds, have driven innovation toward more environmentally sustainable alternatives, sometimes at the cost of immediate antimicrobial efficiency. The balance between safety compliance and performance optimization represents a significant challenge for manufacturers.

Emerging regulatory trends focus on durability requirements and leaching limitations. Coatings must maintain antimicrobial efficacy over specified timeframes while minimizing the release of active compounds into the environment. These requirements have spurred development of controlled-release technologies and covalently bound antimicrobial agents that maintain efficiency while meeting stricter safety standards.

Cross-border regulatory differences create additional complexity for global manufacturers, as formulations effective and compliant in one region may require significant modification for approval in others. This regulatory fragmentation influences research priorities and commercialization strategies, ultimately affecting which efficient technologies reach widespread implementation.

European regulations, particularly the Biocidal Products Regulation (BPR), have established comprehensive frameworks for antimicrobial products, mandating extensive safety assessments and efficacy documentation. These regulations significantly influence coating efficiency by dictating permissible active ingredients, concentration limits, and application methodologies. The Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) further impacts formulation options by restricting certain chemicals with environmental or health concerns.

International standards organizations have developed specific testing protocols that directly affect efficiency measurements. ISO 22196 and JIS Z 2801 provide standardized methods for evaluating antimicrobial activity on surfaces, while ASTM E2180 addresses the efficacy of incorporated antimicrobial agents against specified microorganisms. These standards ensure consistency in performance claims but may not fully represent real-world conditions, creating a gap between laboratory-certified efficiency and practical application outcomes.

Safety standards increasingly emphasize the long-term environmental impact of antimicrobial coatings. Regulations limiting heavy metal content, particularly silver and copper compounds, have driven innovation toward more environmentally sustainable alternatives, sometimes at the cost of immediate antimicrobial efficiency. The balance between safety compliance and performance optimization represents a significant challenge for manufacturers.

Emerging regulatory trends focus on durability requirements and leaching limitations. Coatings must maintain antimicrobial efficacy over specified timeframes while minimizing the release of active compounds into the environment. These requirements have spurred development of controlled-release technologies and covalently bound antimicrobial agents that maintain efficiency while meeting stricter safety standards.

Cross-border regulatory differences create additional complexity for global manufacturers, as formulations effective and compliant in one region may require significant modification for approval in others. This regulatory fragmentation influences research priorities and commercialization strategies, ultimately affecting which efficient technologies reach widespread implementation.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!