The Role of Nanotechnology in Antimicrobial Surface Coatings

SEP 29, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Nanotechnology in Antimicrobial Coatings: Background and Objectives

Nanotechnology in antimicrobial surface coatings represents a revolutionary approach to combating pathogenic microorganisms in various environments. The field has evolved significantly since the early 2000s, when researchers first began exploring the unique properties of nanomaterials for antimicrobial applications. Initial developments focused primarily on silver nanoparticles, which demonstrated remarkable efficacy against a broad spectrum of bacteria. As the field progressed, the integration of nanotechnology with traditional coating technologies opened new avenues for creating surfaces with inherent antimicrobial properties.

The evolution of this technology has been driven by increasing concerns about hospital-acquired infections, food safety, and the rise of antibiotic-resistant bacteria. Traditional antimicrobial approaches often suffer from limitations such as short-term efficacy, leaching of active compounds, and the development of resistance. Nanotechnology offers potential solutions to these challenges through mechanisms that include direct physical disruption of microbial membranes, controlled release of antimicrobial agents, and photocatalytic generation of reactive oxygen species.

Recent technological trends indicate a shift toward multifunctional nanocomposite coatings that combine antimicrobial properties with other desirable characteristics such as durability, transparency, and self-cleaning capabilities. The convergence of nanotechnology with advanced manufacturing techniques, including 3D printing and layer-by-layer assembly, has further accelerated innovation in this domain. Additionally, the emergence of green nanotechnology approaches utilizing plant extracts and biodegradable polymers reflects growing environmental consciousness within the field.

The primary technical objectives in this area include developing antimicrobial coatings with prolonged efficacy, minimal toxicity to humans and the environment, and compatibility with diverse substrate materials. Researchers aim to create solutions that maintain antimicrobial activity under various environmental conditions while preventing biofilm formation, which represents a particularly challenging form of microbial colonization. Another critical goal involves designing coatings that can selectively target pathogenic microorganisms while preserving beneficial microbial communities.

Looking forward, the field is moving toward smart antimicrobial coatings that can respond to environmental stimuli or bacterial presence, activating their antimicrobial properties only when needed. This approach could minimize the potential for developing resistance while extending the functional lifespan of the coating. The integration of nanotechnology with emerging fields such as synthetic biology and artificial intelligence may further revolutionize how we design and deploy antimicrobial surface technologies.

The ultimate aim of research in this domain is to develop cost-effective, scalable, and sustainable antimicrobial coating technologies that can be widely implemented across healthcare facilities, food processing environments, public spaces, and consumer products to significantly reduce the burden of infectious diseases and improve public health outcomes globally.

The evolution of this technology has been driven by increasing concerns about hospital-acquired infections, food safety, and the rise of antibiotic-resistant bacteria. Traditional antimicrobial approaches often suffer from limitations such as short-term efficacy, leaching of active compounds, and the development of resistance. Nanotechnology offers potential solutions to these challenges through mechanisms that include direct physical disruption of microbial membranes, controlled release of antimicrobial agents, and photocatalytic generation of reactive oxygen species.

Recent technological trends indicate a shift toward multifunctional nanocomposite coatings that combine antimicrobial properties with other desirable characteristics such as durability, transparency, and self-cleaning capabilities. The convergence of nanotechnology with advanced manufacturing techniques, including 3D printing and layer-by-layer assembly, has further accelerated innovation in this domain. Additionally, the emergence of green nanotechnology approaches utilizing plant extracts and biodegradable polymers reflects growing environmental consciousness within the field.

The primary technical objectives in this area include developing antimicrobial coatings with prolonged efficacy, minimal toxicity to humans and the environment, and compatibility with diverse substrate materials. Researchers aim to create solutions that maintain antimicrobial activity under various environmental conditions while preventing biofilm formation, which represents a particularly challenging form of microbial colonization. Another critical goal involves designing coatings that can selectively target pathogenic microorganisms while preserving beneficial microbial communities.

Looking forward, the field is moving toward smart antimicrobial coatings that can respond to environmental stimuli or bacterial presence, activating their antimicrobial properties only when needed. This approach could minimize the potential for developing resistance while extending the functional lifespan of the coating. The integration of nanotechnology with emerging fields such as synthetic biology and artificial intelligence may further revolutionize how we design and deploy antimicrobial surface technologies.

The ultimate aim of research in this domain is to develop cost-effective, scalable, and sustainable antimicrobial coating technologies that can be widely implemented across healthcare facilities, food processing environments, public spaces, and consumer products to significantly reduce the burden of infectious diseases and improve public health outcomes globally.

Market Analysis for Antimicrobial Nanocoating Solutions

The global market for antimicrobial nanocoating solutions has experienced significant growth in recent years, driven by increasing awareness of infection control and hygiene across multiple sectors. The market value reached approximately $1.6 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 20.3% through 2028, potentially reaching $4.8 billion by the end of the forecast period.

Healthcare remains the dominant application sector, accounting for nearly 38% of the total market share. This prominence is attributed to the critical need for infection prevention in hospitals and medical facilities, where healthcare-associated infections (HAIs) pose substantial risks to patient safety and increase treatment costs. The COVID-19 pandemic has further accelerated adoption in this sector, with hospitals increasingly implementing antimicrobial surfaces as standard practice.

The food processing industry represents the second-largest market segment at 24%, where antimicrobial nanocoatings help prevent bacterial contamination on processing equipment and packaging materials. Consumer electronics has emerged as the fastest-growing segment with a 27.5% growth rate, as manufacturers incorporate antimicrobial properties into frequently touched devices like smartphones, tablets, and keyboards.

Regionally, North America leads the market with approximately 35% share, followed by Europe (28%) and Asia-Pacific (25%). The Asia-Pacific region, particularly China and India, is expected to witness the highest growth rate due to rapid industrialization, increasing healthcare expenditure, and growing awareness about hygiene standards.

Silver nanoparticle-based coatings currently dominate the technology landscape with 42% market share, valued for their broad-spectrum antimicrobial properties. However, copper and zinc oxide nanocoatings are gaining traction due to their lower cost and reduced environmental concerns compared to silver. Titanium dioxide photocatalytic coatings represent an emerging segment, particularly for outdoor applications.

Consumer demand is increasingly shifting toward multifunctional coatings that combine antimicrobial properties with other benefits such as scratch resistance, self-cleaning capabilities, or UV protection. This trend is driving innovation among manufacturers to develop more sophisticated nanocoating solutions that address multiple performance requirements simultaneously.

Regulatory considerations remain a significant market factor, with varying approval processes across regions creating barriers to entry for some products. The EPA in the United States and similar bodies in Europe have established specific guidelines for antimicrobial claims, requiring substantial efficacy testing and safety documentation before market approval.

Healthcare remains the dominant application sector, accounting for nearly 38% of the total market share. This prominence is attributed to the critical need for infection prevention in hospitals and medical facilities, where healthcare-associated infections (HAIs) pose substantial risks to patient safety and increase treatment costs. The COVID-19 pandemic has further accelerated adoption in this sector, with hospitals increasingly implementing antimicrobial surfaces as standard practice.

The food processing industry represents the second-largest market segment at 24%, where antimicrobial nanocoatings help prevent bacterial contamination on processing equipment and packaging materials. Consumer electronics has emerged as the fastest-growing segment with a 27.5% growth rate, as manufacturers incorporate antimicrobial properties into frequently touched devices like smartphones, tablets, and keyboards.

Regionally, North America leads the market with approximately 35% share, followed by Europe (28%) and Asia-Pacific (25%). The Asia-Pacific region, particularly China and India, is expected to witness the highest growth rate due to rapid industrialization, increasing healthcare expenditure, and growing awareness about hygiene standards.

Silver nanoparticle-based coatings currently dominate the technology landscape with 42% market share, valued for their broad-spectrum antimicrobial properties. However, copper and zinc oxide nanocoatings are gaining traction due to their lower cost and reduced environmental concerns compared to silver. Titanium dioxide photocatalytic coatings represent an emerging segment, particularly for outdoor applications.

Consumer demand is increasingly shifting toward multifunctional coatings that combine antimicrobial properties with other benefits such as scratch resistance, self-cleaning capabilities, or UV protection. This trend is driving innovation among manufacturers to develop more sophisticated nanocoating solutions that address multiple performance requirements simultaneously.

Regulatory considerations remain a significant market factor, with varying approval processes across regions creating barriers to entry for some products. The EPA in the United States and similar bodies in Europe have established specific guidelines for antimicrobial claims, requiring substantial efficacy testing and safety documentation before market approval.

Current Challenges in Antimicrobial Nanotechnology

Despite significant advancements in nanotechnology-based antimicrobial coatings, several critical challenges continue to impede widespread implementation and optimal performance. The foremost challenge remains the long-term stability of nanoparticles within coating matrices. Many antimicrobial nanoparticles, particularly silver and copper-based systems, exhibit diminished efficacy over time due to oxidation, agglomeration, or leaching from the surface. This degradation significantly reduces the coating's functional lifespan and creates uncertainty regarding maintenance schedules in real-world applications.

Biocompatibility presents another substantial hurdle, especially for medical devices and food contact surfaces. While nanomaterials demonstrate excellent antimicrobial properties, some exhibit cytotoxicity toward mammalian cells or trigger inflammatory responses. The delicate balance between antimicrobial efficacy and biocompatibility remains difficult to achieve, particularly with metal-based nanoparticles that can release potentially harmful ions.

The emergence of antimicrobial resistance mechanisms against nanomaterials represents a growing concern. Recent studies have identified bacterial adaptations that reduce susceptibility to certain nanoparticle-based antimicrobials, raising questions about the long-term viability of these technologies as sustainable solutions to pathogen control.

Manufacturing scalability and cost-effectiveness continue to limit commercial adoption. Current production methods for high-performance antimicrobial nanocoatings often involve complex multi-step processes requiring specialized equipment and precise control parameters. These factors significantly increase production costs and create barriers to mass-market implementation, particularly in cost-sensitive sectors.

Regulatory frameworks worldwide remain inconsistent regarding nanomaterial safety assessment and approval processes. The lack of standardized testing protocols specifically designed for antimicrobial nanocoatings creates uncertainty for manufacturers and delays market entry. Additionally, concerns about potential environmental impacts from nanoparticle release during the product lifecycle have prompted increased scrutiny from regulatory bodies.

Technical integration challenges persist when incorporating nanomaterials into existing coating formulations. Issues such as uniform dispersion, prevention of nanoparticle agglomeration, and maintaining coating mechanical properties (adhesion, hardness, flexibility) while preserving antimicrobial functionality require sophisticated engineering solutions. Many promising laboratory formulations fail during scale-up due to these integration difficulties.

Performance consistency across diverse environmental conditions represents another significant challenge. Antimicrobial nanocoatings must maintain efficacy across varying humidity levels, temperature ranges, pH conditions, and exposure to cleaning agents or UV radiation. Current technologies often demonstrate environment-dependent performance, limiting their practical application in complex real-world settings.

Biocompatibility presents another substantial hurdle, especially for medical devices and food contact surfaces. While nanomaterials demonstrate excellent antimicrobial properties, some exhibit cytotoxicity toward mammalian cells or trigger inflammatory responses. The delicate balance between antimicrobial efficacy and biocompatibility remains difficult to achieve, particularly with metal-based nanoparticles that can release potentially harmful ions.

The emergence of antimicrobial resistance mechanisms against nanomaterials represents a growing concern. Recent studies have identified bacterial adaptations that reduce susceptibility to certain nanoparticle-based antimicrobials, raising questions about the long-term viability of these technologies as sustainable solutions to pathogen control.

Manufacturing scalability and cost-effectiveness continue to limit commercial adoption. Current production methods for high-performance antimicrobial nanocoatings often involve complex multi-step processes requiring specialized equipment and precise control parameters. These factors significantly increase production costs and create barriers to mass-market implementation, particularly in cost-sensitive sectors.

Regulatory frameworks worldwide remain inconsistent regarding nanomaterial safety assessment and approval processes. The lack of standardized testing protocols specifically designed for antimicrobial nanocoatings creates uncertainty for manufacturers and delays market entry. Additionally, concerns about potential environmental impacts from nanoparticle release during the product lifecycle have prompted increased scrutiny from regulatory bodies.

Technical integration challenges persist when incorporating nanomaterials into existing coating formulations. Issues such as uniform dispersion, prevention of nanoparticle agglomeration, and maintaining coating mechanical properties (adhesion, hardness, flexibility) while preserving antimicrobial functionality require sophisticated engineering solutions. Many promising laboratory formulations fail during scale-up due to these integration difficulties.

Performance consistency across diverse environmental conditions represents another significant challenge. Antimicrobial nanocoatings must maintain efficacy across varying humidity levels, temperature ranges, pH conditions, and exposure to cleaning agents or UV radiation. Current technologies often demonstrate environment-dependent performance, limiting their practical application in complex real-world settings.

Current Antimicrobial Nanocoating Technical Solutions

01 Metal nanoparticles for antimicrobial coatings

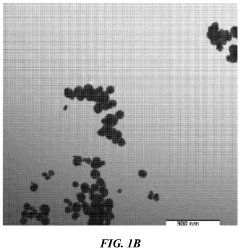

Metal nanoparticles, particularly silver, copper, and zinc oxide, can be incorporated into surface coatings to provide antimicrobial properties. These nanoparticles can disrupt bacterial cell membranes, inhibit enzyme function, and generate reactive oxygen species that kill microorganisms. The small size of nanoparticles increases their surface area and enhances their antimicrobial efficacy while allowing for controlled release of active ions for sustained protection.- Metal nanoparticles for antimicrobial coatings: Metal nanoparticles, particularly silver, copper, and zinc oxide, are incorporated into surface coatings to provide antimicrobial properties. These nanoparticles can disrupt bacterial cell membranes, inhibit enzyme function, and generate reactive oxygen species that kill microorganisms. The small size of nanoparticles increases their surface area and enhances their antimicrobial efficacy while allowing for controlled release of active ions for sustained protection.

- Polymer-based nanocomposite antimicrobial coatings: Antimicrobial nanocomposites combine polymer matrices with nanoscale antimicrobial agents to create durable surface coatings. These systems incorporate antimicrobial nanoparticles within polymer networks that can be applied to various surfaces. The polymer matrix provides controlled release of antimicrobial agents while improving adhesion to substrates and mechanical durability. These nanocomposites can be formulated as paints, sprays, or films for application on medical devices, textiles, and building materials.

- Photocatalytic nanomaterials for self-cleaning antimicrobial surfaces: Photocatalytic nanomaterials, primarily titanium dioxide (TiO2) nanoparticles, create self-cleaning and antimicrobial surfaces when exposed to light. These materials generate reactive oxygen species that decompose organic contaminants and kill microorganisms on the surface. The photocatalytic effect provides continuous antimicrobial action without depleting the active ingredient, making these coatings long-lasting. These nanomaterials can be incorporated into paints, glass coatings, and ceramic surfaces for healthcare facilities and public spaces.

- Quaternary ammonium compound nanocarriers: Quaternary ammonium compounds (QACs) can be incorporated into nanostructured carriers to enhance their antimicrobial efficacy and durability on surfaces. These positively charged molecules disrupt microbial cell membranes, leading to cell death. Nanocarriers provide controlled release of QACs, extending their antimicrobial activity while reducing the total amount needed. This approach is particularly effective for textiles, plastics, and coatings in healthcare settings where long-lasting antimicrobial properties are required.

- Biomimetic and natural antimicrobial nanostructured coatings: Biomimetic and natural antimicrobial nanostructured coatings replicate mechanisms found in nature, such as the nanopatterned surface of cicada wings or lotus leaves. These structures can physically rupture microbial cell membranes without relying on chemical agents. Additionally, natural antimicrobial compounds like chitosan, essential oils, and plant extracts can be encapsulated in nanocarriers for controlled release. These approaches offer environmentally friendly alternatives to traditional antimicrobial agents while reducing the risk of antimicrobial resistance.

02 Polymer-based nanocomposite antimicrobial coatings

Polymer matrices embedded with antimicrobial nanoparticles create effective surface coatings with enhanced durability and functionality. These nanocomposites can be designed to release antimicrobial agents gradually or to maintain a permanent antimicrobial surface. Various polymers including polyurethane, silicone, and acrylics can be used as carriers for nanoparticles, providing additional benefits such as improved adhesion to substrates and resistance to environmental factors.Expand Specific Solutions03 Photocatalytic nanomaterials for self-cleaning antimicrobial surfaces

Photocatalytic nanomaterials, primarily titanium dioxide (TiO2) nanoparticles, can be incorporated into coatings to create self-cleaning antimicrobial surfaces. When exposed to light, these materials generate reactive oxygen species that decompose organic contaminants and kill microorganisms. These coatings provide continuous antimicrobial action without depleting the active ingredient, making them suitable for long-term applications in healthcare settings, public spaces, and consumer products.Expand Specific Solutions04 Controlled-release nanosystems for antimicrobial delivery

Nanotechnology enables the development of controlled-release systems that can deliver antimicrobial agents over extended periods. These systems include nanoencapsulation, layer-by-layer assembly, and stimuli-responsive nanocarriers that release antimicrobial compounds in response to specific triggers such as pH changes, temperature, or bacterial presence. This approach optimizes the efficacy of antimicrobial agents while minimizing the amount needed, reducing potential toxicity and environmental impact.Expand Specific Solutions05 Bio-inspired antimicrobial nanostructured surfaces

Bio-inspired nanostructured surfaces mimic natural antimicrobial mechanisms found in organisms like cicada wings and shark skin. These surfaces feature nanoscale patterns that physically disrupt bacterial cell membranes through mechanical contact rather than chemical action. This approach provides a non-toxic alternative to traditional antimicrobial agents and can help prevent the development of antimicrobial resistance. Advanced fabrication techniques such as nanoimprinting and lithography enable the precise creation of these biomimetic surfaces.Expand Specific Solutions

Key Industry Players in Antimicrobial Nanocoating Sector

The nanotechnology antimicrobial surface coatings market is currently in a growth phase, with increasing adoption across healthcare, food processing, and consumer goods sectors. The global market size is estimated to reach $3.5 billion by 2025, expanding at a CAGR of approximately 15%. Regarding technical maturity, the field shows varying development stages across different applications. Leading research institutions like Agency for Science, Technology & Research, École Polytechnique Fédérale de Lausanne, and Centre National de la Recherche Scientifique are advancing fundamental science, while companies including Orthobond Corp., ItN Nanovation AG, and Gencoa Ltd. are commercializing applications. Boeing and Xerox represent larger corporations integrating these technologies into their product ecosystems. The competitive landscape features a mix of specialized startups, established materials companies, and academic institutions collaborating to overcome challenges in durability, cost-effectiveness, and regulatory compliance.

Agency for Science, Technology & Research

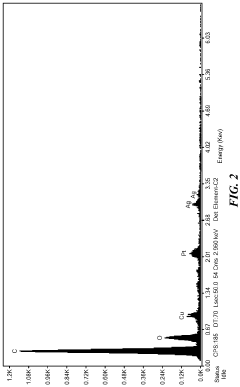

Technical Solution: A*STAR has developed advanced antimicrobial nanocoatings utilizing silver nanoparticles embedded in polymer matrices. Their proprietary technology involves controlled release mechanisms where silver ions are gradually released from the nanostructured coating to provide sustained antimicrobial activity. The research team has optimized the silver nanoparticle size (typically 10-50 nm) and distribution to maximize efficacy while minimizing material usage. A*STAR's approach incorporates a dual-action mechanism combining contact killing through positively charged quaternary ammonium compounds with the release-based activity of silver ions, providing protection against a broad spectrum of bacteria, fungi, and certain viruses[1]. Their coatings demonstrate long-term stability with antimicrobial efficacy lasting up to 24 months under normal use conditions, significantly outperforming conventional solutions.

Strengths: Exceptional durability with sustained antimicrobial activity over extended periods; dual-action mechanism provides broader protection spectrum; optimized nanoparticle distribution improves efficacy while reducing material costs. Weaknesses: Higher initial manufacturing costs compared to conventional coatings; potential environmental concerns regarding silver nanoparticle release; requires specialized application equipment for optimal performance.

Orthobond Corp.

Technical Solution: Orthobond has pioneered a revolutionary approach to antimicrobial nanosurface technology specifically targeting medical implants and devices. Their proprietary NanoGlide™ platform creates covalently bonded nanoscale surface modifications that incorporate antimicrobial compounds at the molecular level. Unlike conventional coatings that rely on leaching mechanisms, Orthobond's technology permanently modifies the surface chemistry of materials through a process called "molecular tethering," where antimicrobial molecules are anchored to surfaces through strong covalent bonds[2]. This approach prevents bacterial adhesion and biofilm formation without releasing potentially harmful compounds into surrounding tissues. The company has demonstrated efficacy against MRSA, E. coli, and other common pathogens with reduction rates exceeding 99.9% in clinical testing. Their technology maintains antimicrobial properties even after extensive wear testing (over 500,000 cycles), addressing a critical limitation of traditional antimicrobial coatings in high-friction applications.

Strengths: Non-leaching technology eliminates concerns about antimicrobial resistance development; exceptional durability in high-wear applications; molecular-level modification provides consistent coverage without affecting bulk material properties. Weaknesses: Higher production costs compared to conventional approaches; limited to specific substrate materials compatible with the covalent bonding process; requires specialized manufacturing facilities and expertise for implementation.

Critical Patents and Research in Antimicrobial Nanosurfaces

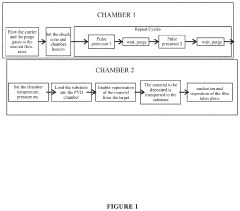

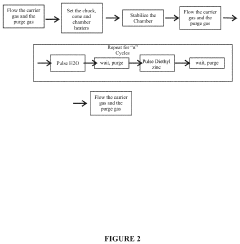

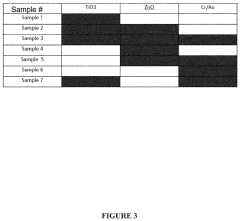

Antimicrobial nanolaminates using vapor deposited methods

PatentPendingUS20230072705A1

Innovation

- The development of thin film nanolaminates using a combination of atomic layer deposition (ALD) and physical vapor deposition (PVD) methods, allowing for controlled thickness and composition of coatings with antimicrobial properties, along with optical, mechanical, and electrical properties, applied to various substrates including glass and medical devices.

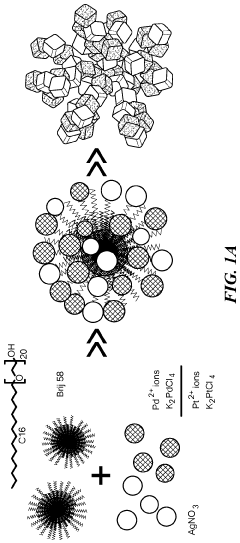

Silver Palladium and Silver Platinum Nanoparticles Useful as Antimicrobial and Anticancer Agents

PatentInactiveUS20210145870A1

Innovation

- The use of nanoparticles comprising alloys of silver (Ag) and either platinum (Pt) or palladium (Pd) with specific ratios and sizes, which exhibit enhanced bacteriocidal and anticancer properties, allowing for effective treatment of bacterial infections and cancer by inhibiting bacterial growth and killing cancer cells while minimizing toxicity to human cells.

Environmental Impact and Sustainability Considerations

The environmental impact of nanotechnology in antimicrobial surface coatings presents a complex sustainability challenge that requires careful consideration. As these coatings gain widespread adoption across healthcare, food processing, and consumer goods industries, their lifecycle environmental footprint becomes increasingly significant. Nanomaterials such as silver, copper, and zinc oxide nanoparticles, while effective against microbes, may leach into aquatic ecosystems during production, use, or disposal phases, potentially disrupting microbial communities that are essential for environmental balance.

Research indicates that nanosilver particles, commonly used in antimicrobial coatings, can persist in the environment and accumulate in organisms, raising concerns about bioaccumulation in food chains. Studies have documented that concentrations as low as 5-10 ppb of certain metal nanoparticles can adversely affect aquatic organisms, highlighting the importance of containment strategies throughout the product lifecycle.

Manufacturing processes for nanomaterial-based coatings often require significant energy inputs and potentially hazardous chemicals, contributing to their overall environmental footprint. Life Cycle Assessment (LCA) studies comparing conventional antimicrobial treatments with nano-enabled coatings show mixed results, with nanomaterials sometimes offering environmental advantages through extended product lifespans and reduced chemical usage, but presenting challenges in end-of-life management.

Recent innovations are addressing these sustainability concerns through several approaches. Biodegradable nanomaterials derived from natural polymers such as chitosan and cellulose are gaining traction as environmentally friendly alternatives to metal nanoparticles. These materials offer comparable antimicrobial efficacy while naturally decomposing at end-of-life, minimizing persistent environmental contamination.

Closed-loop manufacturing systems for nanomaterial production are emerging, with several companies implementing processes that recover and reuse precursor materials, significantly reducing waste generation. Additionally, immobilization techniques that permanently bind nanoparticles within coating matrices are advancing, preventing leaching while maintaining antimicrobial functionality.

Regulatory frameworks worldwide are evolving to address nanomaterial environmental impacts, with the EU's REACH regulations and the EPA's Significant New Use Rules requiring specific environmental risk assessments for nanomaterial applications. Industry leaders are increasingly adopting green chemistry principles in formulation development, selecting benign precursors and minimizing hazardous byproducts in anticipation of stricter future regulations.

The path toward truly sustainable antimicrobial nanotechnology requires continued innovation in material design, manufacturing processes, and end-of-life management strategies. Balancing immediate antimicrobial benefits against long-term environmental considerations remains a critical challenge for researchers and industry stakeholders in this rapidly evolving field.

Research indicates that nanosilver particles, commonly used in antimicrobial coatings, can persist in the environment and accumulate in organisms, raising concerns about bioaccumulation in food chains. Studies have documented that concentrations as low as 5-10 ppb of certain metal nanoparticles can adversely affect aquatic organisms, highlighting the importance of containment strategies throughout the product lifecycle.

Manufacturing processes for nanomaterial-based coatings often require significant energy inputs and potentially hazardous chemicals, contributing to their overall environmental footprint. Life Cycle Assessment (LCA) studies comparing conventional antimicrobial treatments with nano-enabled coatings show mixed results, with nanomaterials sometimes offering environmental advantages through extended product lifespans and reduced chemical usage, but presenting challenges in end-of-life management.

Recent innovations are addressing these sustainability concerns through several approaches. Biodegradable nanomaterials derived from natural polymers such as chitosan and cellulose are gaining traction as environmentally friendly alternatives to metal nanoparticles. These materials offer comparable antimicrobial efficacy while naturally decomposing at end-of-life, minimizing persistent environmental contamination.

Closed-loop manufacturing systems for nanomaterial production are emerging, with several companies implementing processes that recover and reuse precursor materials, significantly reducing waste generation. Additionally, immobilization techniques that permanently bind nanoparticles within coating matrices are advancing, preventing leaching while maintaining antimicrobial functionality.

Regulatory frameworks worldwide are evolving to address nanomaterial environmental impacts, with the EU's REACH regulations and the EPA's Significant New Use Rules requiring specific environmental risk assessments for nanomaterial applications. Industry leaders are increasingly adopting green chemistry principles in formulation development, selecting benign precursors and minimizing hazardous byproducts in anticipation of stricter future regulations.

The path toward truly sustainable antimicrobial nanotechnology requires continued innovation in material design, manufacturing processes, and end-of-life management strategies. Balancing immediate antimicrobial benefits against long-term environmental considerations remains a critical challenge for researchers and industry stakeholders in this rapidly evolving field.

Regulatory Framework for Nanomaterial Surface Applications

The regulatory landscape for nanomaterial surface applications has evolved significantly over the past decade, reflecting growing awareness of both the potential benefits and risks associated with nanotechnology in antimicrobial coatings. Currently, regulatory frameworks vary substantially across different regions, creating a complex compliance environment for manufacturers and researchers.

In the United States, the FDA, EPA, and CPSC share oversight responsibilities for nanomaterial-based antimicrobial coatings. The EPA regulates antimicrobial nanomaterials under the Federal Insecticide, Fungicide, and Rodenticide Act (FIFRA), requiring registration of products making antimicrobial claims. Meanwhile, the FDA oversees nanomaterials in medical devices and food contact surfaces, implementing a case-by-case evaluation approach rather than nanotechnology-specific regulations.

The European Union has adopted a more precautionary stance through the REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) regulation and the Biocidal Products Regulation (BPR). These frameworks explicitly address nanomaterials, requiring specific safety assessments and labeling requirements. The EU's definition of nanomaterials (materials containing particles where 50% or more have one dimension between 1-100nm) provides regulatory clarity but has been criticized for its rigid dimensional approach.

Asian markets present varying regulatory maturity levels. Japan has established the world's first nano-specific regulatory framework through its Ministry of Economy, Trade and Industry. China has recently strengthened its approach with the "Guidelines for Health Risk Assessment of Consumer Products Containing Nanomaterials" in 2021, while South Korea implements nanomaterial reporting requirements through K-REACH.

International harmonization efforts are underway through organizations like the International Organization for Standardization (ISO) and the Organization for Economic Cooperation and Development (OECD). The ISO/TC 229 committee has developed over 90 standards specifically addressing nanotechnology terminology, measurement, and safety protocols for nanomaterials.

Key regulatory challenges include the lack of standardized testing protocols for nanomaterial leaching and durability in antimicrobial coatings, insufficient long-term environmental impact data, and the rapid pace of innovation outstripping regulatory development. The absence of globally harmonized approaches creates market entry barriers and increases compliance costs for manufacturers operating internationally.

Future regulatory trends point toward more risk-based approaches, increased post-market surveillance requirements, and greater emphasis on life-cycle assessment of nanomaterial-containing products. Regulatory science is evolving to address the unique properties of nanomaterials that may not be adequately captured by conventional toxicological testing methods.

In the United States, the FDA, EPA, and CPSC share oversight responsibilities for nanomaterial-based antimicrobial coatings. The EPA regulates antimicrobial nanomaterials under the Federal Insecticide, Fungicide, and Rodenticide Act (FIFRA), requiring registration of products making antimicrobial claims. Meanwhile, the FDA oversees nanomaterials in medical devices and food contact surfaces, implementing a case-by-case evaluation approach rather than nanotechnology-specific regulations.

The European Union has adopted a more precautionary stance through the REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) regulation and the Biocidal Products Regulation (BPR). These frameworks explicitly address nanomaterials, requiring specific safety assessments and labeling requirements. The EU's definition of nanomaterials (materials containing particles where 50% or more have one dimension between 1-100nm) provides regulatory clarity but has been criticized for its rigid dimensional approach.

Asian markets present varying regulatory maturity levels. Japan has established the world's first nano-specific regulatory framework through its Ministry of Economy, Trade and Industry. China has recently strengthened its approach with the "Guidelines for Health Risk Assessment of Consumer Products Containing Nanomaterials" in 2021, while South Korea implements nanomaterial reporting requirements through K-REACH.

International harmonization efforts are underway through organizations like the International Organization for Standardization (ISO) and the Organization for Economic Cooperation and Development (OECD). The ISO/TC 229 committee has developed over 90 standards specifically addressing nanotechnology terminology, measurement, and safety protocols for nanomaterials.

Key regulatory challenges include the lack of standardized testing protocols for nanomaterial leaching and durability in antimicrobial coatings, insufficient long-term environmental impact data, and the rapid pace of innovation outstripping regulatory development. The absence of globally harmonized approaches creates market entry barriers and increases compliance costs for manufacturers operating internationally.

Future regulatory trends point toward more risk-based approaches, increased post-market surveillance requirements, and greater emphasis on life-cycle assessment of nanomaterial-containing products. Regulatory science is evolving to address the unique properties of nanomaterials that may not be adequately captured by conventional toxicological testing methods.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!