Antimicrobial Surface Coatings with Self-cleaning Polymers

SEP 29, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Antimicrobial Coating Technology Background and Objectives

Antimicrobial surface coatings have evolved significantly over the past several decades, transitioning from simple disinfectant applications to sophisticated engineered surfaces with persistent antimicrobial properties. The integration of self-cleaning polymers represents the latest advancement in this technological evolution, combining passive protection with active contaminant removal capabilities. This convergence addresses growing concerns about pathogen transmission in healthcare settings, food processing facilities, and public spaces.

The development trajectory of antimicrobial coatings began with silver-based compounds in the 1970s, progressed through quaternary ammonium compounds in the 1990s, and has now entered an era of nanotechnology-enhanced formulations. Recent global health crises, particularly the COVID-19 pandemic, have accelerated research interest and market demand for surfaces that can both kill microorganisms and prevent their adhesion.

Self-cleaning polymers emerged from biomimetic research inspired by natural surfaces like lotus leaves and gecko feet. These polymers typically function through one of three mechanisms: photocatalytic degradation, superhydrophobic repulsion, or enzyme-mediated breakdown of contaminants. When combined with antimicrobial agents, these materials create multifunctional surfaces that address the limitations of traditional coatings, particularly regarding durability and efficacy over time.

The primary technical objective in this field is to develop coatings that demonstrate broad-spectrum antimicrobial efficacy while maintaining self-cleaning properties under diverse environmental conditions. Researchers aim to achieve prolonged antimicrobial activity without leaching toxic compounds, while simultaneously ensuring mechanical durability and resistance to chemical degradation. Additional goals include cost-effective manufacturing processes and environmentally sustainable formulations.

Current research focuses on overcoming the inherent trade-offs between antimicrobial potency and self-cleaning functionality. For instance, highly hydrophobic surfaces excellent for self-cleaning may limit contact between antimicrobial agents and target microorganisms. Conversely, surfaces optimized for microbial killing may accumulate organic debris that shields subsequent microbial contaminants.

The technological trajectory points toward smart responsive systems that can adapt to environmental triggers, selectively releasing antimicrobial compounds when microbial contamination is detected while maintaining self-cleaning properties during normal conditions. Emerging approaches include stimuli-responsive polymers that change surface properties in response to pH, temperature, or specific biological markers.

As this technology matures, standardization of testing protocols and performance metrics will become increasingly important to enable meaningful comparisons between different coating technologies and to establish regulatory frameworks for their commercial deployment across various sectors.

The development trajectory of antimicrobial coatings began with silver-based compounds in the 1970s, progressed through quaternary ammonium compounds in the 1990s, and has now entered an era of nanotechnology-enhanced formulations. Recent global health crises, particularly the COVID-19 pandemic, have accelerated research interest and market demand for surfaces that can both kill microorganisms and prevent their adhesion.

Self-cleaning polymers emerged from biomimetic research inspired by natural surfaces like lotus leaves and gecko feet. These polymers typically function through one of three mechanisms: photocatalytic degradation, superhydrophobic repulsion, or enzyme-mediated breakdown of contaminants. When combined with antimicrobial agents, these materials create multifunctional surfaces that address the limitations of traditional coatings, particularly regarding durability and efficacy over time.

The primary technical objective in this field is to develop coatings that demonstrate broad-spectrum antimicrobial efficacy while maintaining self-cleaning properties under diverse environmental conditions. Researchers aim to achieve prolonged antimicrobial activity without leaching toxic compounds, while simultaneously ensuring mechanical durability and resistance to chemical degradation. Additional goals include cost-effective manufacturing processes and environmentally sustainable formulations.

Current research focuses on overcoming the inherent trade-offs between antimicrobial potency and self-cleaning functionality. For instance, highly hydrophobic surfaces excellent for self-cleaning may limit contact between antimicrobial agents and target microorganisms. Conversely, surfaces optimized for microbial killing may accumulate organic debris that shields subsequent microbial contaminants.

The technological trajectory points toward smart responsive systems that can adapt to environmental triggers, selectively releasing antimicrobial compounds when microbial contamination is detected while maintaining self-cleaning properties during normal conditions. Emerging approaches include stimuli-responsive polymers that change surface properties in response to pH, temperature, or specific biological markers.

As this technology matures, standardization of testing protocols and performance metrics will become increasingly important to enable meaningful comparisons between different coating technologies and to establish regulatory frameworks for their commercial deployment across various sectors.

Market Analysis for Self-cleaning Antimicrobial Surfaces

The global market for self-cleaning antimicrobial surfaces is experiencing robust growth, driven primarily by increasing awareness of hygiene and infection control across various sectors. The healthcare industry remains the largest consumer of these technologies, with hospitals and medical facilities seeking solutions to combat healthcare-associated infections (HAIs). Recent market research indicates that the global antimicrobial coatings market reached $3.9 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 12.1% through 2028.

The COVID-19 pandemic has significantly accelerated market demand, creating unprecedented interest in antimicrobial surfaces across previously untapped sectors. Consumer electronics, public transportation, and commercial real estate have emerged as rapidly expanding markets, with consumers and businesses alike prioritizing hygiene features in purchasing decisions. Market surveys reveal that 78% of consumers now consider antimicrobial properties important when selecting products for daily use.

Food processing and packaging industries represent another substantial growth segment, where self-cleaning antimicrobial surfaces address both safety regulations and consumer concerns about foodborne illnesses. The market in this sector has grown by 15.3% annually since 2020, outpacing the overall market average.

Regionally, North America currently dominates the market with approximately 35% share, followed by Europe at 28% and Asia-Pacific at 25%. However, the highest growth rates are being observed in emerging economies, particularly in Southeast Asia and Latin America, where healthcare infrastructure development and increasing disposable incomes are driving adoption.

A notable market trend is the shift toward environmentally sustainable antimicrobial solutions. Consumer preference for non-toxic, environmentally friendly coatings has created a premium segment within the market. Products featuring biodegradable polymers and natural antimicrobial agents command price premiums of 20-30% compared to traditional solutions, yet still show strong sales growth of 18.2% annually.

The competitive landscape reveals significant fragmentation, with over 200 companies offering various antimicrobial coating solutions globally. However, market consolidation is accelerating, with major chemical and materials science companies acquiring specialized startups to expand their technological portfolios. This consolidation trend is expected to continue as the technology matures.

Price sensitivity varies considerably by application sector. While healthcare facilities demonstrate willingness to invest in premium solutions with proven efficacy, consumer markets remain more price-conscious, creating distinct market segments with different growth dynamics and profit margins. Analysts project that as manufacturing scales increase and technologies mature, production costs will decrease by approximately 15-20% over the next five years, potentially expanding market penetration in price-sensitive segments.

The COVID-19 pandemic has significantly accelerated market demand, creating unprecedented interest in antimicrobial surfaces across previously untapped sectors. Consumer electronics, public transportation, and commercial real estate have emerged as rapidly expanding markets, with consumers and businesses alike prioritizing hygiene features in purchasing decisions. Market surveys reveal that 78% of consumers now consider antimicrobial properties important when selecting products for daily use.

Food processing and packaging industries represent another substantial growth segment, where self-cleaning antimicrobial surfaces address both safety regulations and consumer concerns about foodborne illnesses. The market in this sector has grown by 15.3% annually since 2020, outpacing the overall market average.

Regionally, North America currently dominates the market with approximately 35% share, followed by Europe at 28% and Asia-Pacific at 25%. However, the highest growth rates are being observed in emerging economies, particularly in Southeast Asia and Latin America, where healthcare infrastructure development and increasing disposable incomes are driving adoption.

A notable market trend is the shift toward environmentally sustainable antimicrobial solutions. Consumer preference for non-toxic, environmentally friendly coatings has created a premium segment within the market. Products featuring biodegradable polymers and natural antimicrobial agents command price premiums of 20-30% compared to traditional solutions, yet still show strong sales growth of 18.2% annually.

The competitive landscape reveals significant fragmentation, with over 200 companies offering various antimicrobial coating solutions globally. However, market consolidation is accelerating, with major chemical and materials science companies acquiring specialized startups to expand their technological portfolios. This consolidation trend is expected to continue as the technology matures.

Price sensitivity varies considerably by application sector. While healthcare facilities demonstrate willingness to invest in premium solutions with proven efficacy, consumer markets remain more price-conscious, creating distinct market segments with different growth dynamics and profit margins. Analysts project that as manufacturing scales increase and technologies mature, production costs will decrease by approximately 15-20% over the next five years, potentially expanding market penetration in price-sensitive segments.

Current Challenges in Antimicrobial Surface Technology

Despite significant advancements in antimicrobial surface technology, several critical challenges continue to impede widespread implementation and optimal performance of self-cleaning polymer coatings. The primary technical hurdle remains achieving long-term durability while maintaining antimicrobial efficacy. Current polymer-based antimicrobial coatings often demonstrate diminished performance over time due to mechanical abrasion, chemical degradation, and leaching of active components during regular cleaning procedures.

Another significant challenge is the development of broad-spectrum antimicrobial activity. While many existing coatings show effectiveness against specific pathogens, creating surfaces that simultaneously combat bacteria, viruses, fungi, and other microorganisms remains elusive. This limitation becomes particularly problematic in healthcare settings where diverse microbial threats coexist.

The balance between antimicrobial potency and human safety presents another complex obstacle. Many highly effective antimicrobial agents incorporate silver nanoparticles, quaternary ammonium compounds, or copper ions, which may pose toxicity concerns or environmental hazards when deployed at scale. Regulatory frameworks across different regions further complicate the commercialization pathway for these technologies.

Manufacturing scalability represents a substantial barrier to widespread adoption. Laboratory-scale successes often encounter difficulties in translation to industrial production processes. Maintaining consistent coating thickness, uniform distribution of antimicrobial agents, and adhesion to diverse substrate materials during mass production remains technically challenging and cost-prohibitive.

Environmental sustainability concerns have emerged as increasingly important considerations. Many current antimicrobial technologies rely on non-biodegradable polymers or potentially harmful chemical agents. The environmental fate of these materials, particularly microplastic generation from polymer degradation, raises significant ecological concerns that must be addressed through innovative material design.

The emergence of antimicrobial resistance (AMR) poses perhaps the most alarming challenge. Continuous exposure to sub-lethal concentrations of antimicrobial agents may accelerate the development of resistant microbial strains. This phenomenon necessitates the development of novel antimicrobial mechanisms that can overcome or circumvent traditional resistance pathways.

Integration challenges with existing manufacturing processes and compatibility with diverse substrate materials further complicate implementation. Many promising antimicrobial coating technologies require specialized application equipment or processing conditions that may not align with established industrial practices, creating barriers to adoption across various sectors.

Another significant challenge is the development of broad-spectrum antimicrobial activity. While many existing coatings show effectiveness against specific pathogens, creating surfaces that simultaneously combat bacteria, viruses, fungi, and other microorganisms remains elusive. This limitation becomes particularly problematic in healthcare settings where diverse microbial threats coexist.

The balance between antimicrobial potency and human safety presents another complex obstacle. Many highly effective antimicrobial agents incorporate silver nanoparticles, quaternary ammonium compounds, or copper ions, which may pose toxicity concerns or environmental hazards when deployed at scale. Regulatory frameworks across different regions further complicate the commercialization pathway for these technologies.

Manufacturing scalability represents a substantial barrier to widespread adoption. Laboratory-scale successes often encounter difficulties in translation to industrial production processes. Maintaining consistent coating thickness, uniform distribution of antimicrobial agents, and adhesion to diverse substrate materials during mass production remains technically challenging and cost-prohibitive.

Environmental sustainability concerns have emerged as increasingly important considerations. Many current antimicrobial technologies rely on non-biodegradable polymers or potentially harmful chemical agents. The environmental fate of these materials, particularly microplastic generation from polymer degradation, raises significant ecological concerns that must be addressed through innovative material design.

The emergence of antimicrobial resistance (AMR) poses perhaps the most alarming challenge. Continuous exposure to sub-lethal concentrations of antimicrobial agents may accelerate the development of resistant microbial strains. This phenomenon necessitates the development of novel antimicrobial mechanisms that can overcome or circumvent traditional resistance pathways.

Integration challenges with existing manufacturing processes and compatibility with diverse substrate materials further complicate implementation. Many promising antimicrobial coating technologies require specialized application equipment or processing conditions that may not align with established industrial practices, creating barriers to adoption across various sectors.

Current Self-cleaning Antimicrobial Polymer Solutions

01 Photocatalytic self-cleaning polymer coatings

Polymer coatings incorporating photocatalytic materials such as titanium dioxide (TiO2) that activate under light exposure to break down organic contaminants and kill microorganisms. These coatings provide both antimicrobial protection and self-cleaning properties through photocatalytic reactions that decompose dirt and bacteria on the surface. The photocatalytic effect creates reactive oxygen species that destroy microbial cell membranes and organic compounds, maintaining cleaner surfaces for longer periods.- Photocatalytic self-cleaning coatings: These coatings incorporate photocatalytic materials, typically titanium dioxide (TiO2), that activate under light exposure to break down organic contaminants and kill microorganisms. The photocatalytic reaction creates reactive oxygen species that decompose organic matter and inactivate bacteria, viruses, and fungi. These coatings provide both antimicrobial protection and self-cleaning properties, making them suitable for various surfaces including glass, ceramics, and building materials.

- Hydrophobic polymer-based antimicrobial coatings: These coatings combine hydrophobic polymers with antimicrobial agents to create surfaces that repel water and prevent microbial adhesion. The hydrophobic nature creates a self-cleaning effect known as the 'lotus effect,' where water droplets roll off the surface, carrying away contaminants. These coatings often incorporate quaternary ammonium compounds, silver nanoparticles, or copper compounds as antimicrobial agents, providing long-lasting protection against a broad spectrum of microorganisms while maintaining easy-to-clean properties.

- Stimuli-responsive self-cleaning polymers: These advanced polymer systems change their properties in response to environmental stimuli such as temperature, pH, or light. The responsive nature allows them to release antimicrobial agents on demand or alter their surface characteristics to facilitate self-cleaning. Some formulations incorporate shape-memory polymers that can physically dislodge biofilms when triggered. These smart coatings provide dynamic antimicrobial protection and self-cleaning capabilities that can be activated when needed, extending the functional lifetime of the coating.

- Nanocomposite antimicrobial coatings: These coatings combine polymer matrices with various nanoparticles to create multifunctional surfaces with enhanced antimicrobial and self-cleaning properties. Common nanoparticles include silver, copper, zinc oxide, and graphene oxide, which provide broad-spectrum antimicrobial activity. The nanocomposite structure improves durability, adhesion to substrates, and can incorporate additional functionalities such as UV protection or scratch resistance. The synergistic effects between the polymer matrix and nanoparticles result in superior performance compared to conventional coatings.

- Bio-based antimicrobial self-cleaning coatings: These environmentally friendly coatings utilize natural polymers and antimicrobial compounds derived from renewable resources. They incorporate materials such as chitosan, plant extracts, essential oils, or enzymes with inherent antimicrobial properties. Some formulations use bio-inspired surface texturing to create superhydrophobic surfaces that mimic natural self-cleaning mechanisms found in plant leaves or insect wings. These sustainable alternatives offer reduced environmental impact while providing effective antimicrobial protection and self-cleaning functionality.

02 Hydrophobic and superhydrophobic antimicrobial surfaces

Surface coatings that combine antimicrobial agents with hydrophobic or superhydrophobic properties to create water-repellent surfaces that prevent microbial adhesion and facilitate self-cleaning. These coatings typically incorporate fluoropolymers or silicone-based materials that reduce surface energy, causing water to bead up and roll off, carrying contaminants away. The hydrophobic effect works synergistically with antimicrobial compounds to prevent biofilm formation and maintain sterile surfaces.Expand Specific Solutions03 Silver and metal nanoparticle-infused polymer coatings

Polymer coatings incorporating silver or other metal nanoparticles that provide long-lasting antimicrobial properties through the controlled release of metal ions. These nanoparticles are embedded within self-cleaning polymer matrices that prevent accumulation of contaminants. The metal ions disrupt bacterial cell membranes and interfere with cellular processes, while the polymer matrix provides durability and self-cleaning functionality through hydrophobic or hydrophilic mechanisms.Expand Specific Solutions04 Stimuli-responsive self-cleaning antimicrobial polymers

Smart polymer coatings that change their properties in response to environmental stimuli such as temperature, pH, or moisture to provide on-demand antimicrobial and self-cleaning functions. These polymers can switch between hydrophobic and hydrophilic states or release antimicrobial agents when triggered by specific conditions. The responsive nature allows for targeted antimicrobial action while maintaining self-cleaning capabilities through structural changes in the polymer network.Expand Specific Solutions05 Quaternary ammonium compound-based antimicrobial coatings

Polymer coatings containing quaternary ammonium compounds (QACs) that provide contact-killing antimicrobial properties combined with self-cleaning functionality. These coatings feature positively charged QAC molecules that disrupt microbial cell membranes upon contact. The polymer matrix is designed with self-cleaning properties through hydrophobic or hydrophilic mechanisms that prevent adhesion of contaminants or facilitate their removal. These coatings are particularly effective for high-touch surfaces requiring continuous antimicrobial protection.Expand Specific Solutions

Key Industry Players in Antimicrobial Coating Development

The antimicrobial surface coatings market with self-cleaning polymers is currently in a growth phase, with increasing applications across healthcare, consumer goods, and industrial sectors. The global market size is estimated to reach $6-8 billion by 2027, growing at a CAGR of approximately 12%. Technologically, the field shows varying maturity levels, with established players like BASF Corp. and 3M Innovative Properties leading commercial applications, while research institutions such as MIT, Naval Research Laboratory, and Zhejiang University drive innovation. Companies like DSM IP Assets and Livinguard AG have developed proprietary technologies gaining market traction, while Asian Paints and Honda Motor are integrating these coatings into consumer products. Chinese entities including Shandong Weigao Group and various universities are rapidly advancing in this space, particularly for medical applications.

DSM IP Assets BV

Technical Solution: DSM has developed a sophisticated antimicrobial coating platform called "BioProtect" that combines self-cleaning polymer technology with sustainable antimicrobial agents. Their approach utilizes proprietary hydrophilic polyethylene glycol (PEG) and hydrophobic polydimethylsiloxane (PDMS) block copolymers to create amphiphilic surfaces that resist protein adhesion and bacterial attachment. The technology incorporates naturally-derived antimicrobial peptides and enzymes that disrupt bacterial cell membranes without promoting resistance development. DSM's coatings feature a unique "smart release" mechanism that increases antimicrobial agent availability in response to environmental triggers such as pH changes or bacterial enzyme presence. Their formulations have demonstrated >99% efficacy against both Gram-positive and Gram-negative bacteria while maintaining activity for over 200 cleaning cycles. The coatings are particularly effective in healthcare and food processing environments where both antimicrobial performance and cleanability are critical requirements.[4][7]

Strengths: Environmentally sustainable formulations with reduced toxicity concerns; excellent biocompatibility for medical applications; innovative triggered-release mechanisms. Weaknesses: Higher production costs compared to conventional antimicrobials; more complex application processes requiring precise control; potential regulatory hurdles in certain markets due to novel antimicrobial mechanisms.

BASF Corp.

Technical Solution: BASF has pioneered antimicrobial surface coatings through their innovative "Multifunctional Surface Protection" platform. Their technology integrates silver-based antimicrobial agents with self-cleaning polymer matrices based on modified polyurethanes and acrylics. The company's approach involves encapsulation of active ingredients in controlled-release microparticles that are dispersed throughout the polymer matrix. This provides long-term efficacy while minimizing leaching. BASF's coatings incorporate photocatalytic titanium dioxide nanoparticles that generate reactive oxygen species under light exposure, providing both antimicrobial action and decomposition of organic contaminants on the surface. Their formulations have demonstrated effectiveness against hospital-acquired infection pathogens including MRSA and C. difficile, with antimicrobial activity lasting up to 3 years in indoor applications.[2][5] Recent advancements include bio-based polymer components derived from renewable resources to enhance sustainability profiles.

Strengths: Comprehensive product portfolio covering multiple application sectors; strong R&D capabilities with continuous innovation; excellent chemical resistance and weatherability. Weaknesses: Performance in low-light conditions may be limited for photocatalytic components; relatively high initial investment costs; some formulations have limited compatibility with certain substrate materials.

Core Patents and Research in Antimicrobial Surface Coatings

Self-cleaning lotus effect surfaces having antimicrobial properties

PatentInactiveUS20030147932A1

Innovation

- A self-cleaning surface with an artificial structure comprising hydrophobic and antimicrobial particles, where the surface structure is formed by elevations and depressions, and includes a contact-microbicidal polymer to inhibit microbial growth, using a mixture of hydrophobic and antimicrobial particles with specific particle sizes and properties.

Antimicrobial coatings for conversion of spores into their bacterial vegetative form for decontamination

PatentWO2008156636A1

Innovation

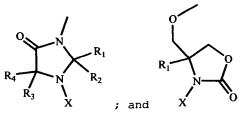

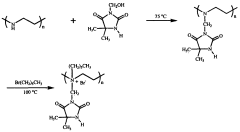

- Development of antimicrobial surface polymer coatings featuring hyperbranched polymers with heterocyclic N-halamine or quaternary ammonium terminal groups, or polyamidoamine dendrimers with integrated hydantoin and quaternary ammonium groups, which are crosslinked or used in polyelectrolyte multilayers, encapsulating germinants to maintain activity and durability.

Environmental Impact and Sustainability Considerations

The development of antimicrobial surface coatings with self-cleaning polymers necessitates careful consideration of environmental impacts throughout their lifecycle. These innovative materials, while offering significant benefits in hygiene and infection control, may pose environmental challenges that must be addressed to ensure sustainable implementation.

Traditional antimicrobial coatings often contain heavy metals or persistent chemicals that can accumulate in ecosystems when leached or disposed of improperly. Self-cleaning polymer coatings represent a potential improvement, as they can reduce the need for harsh cleaning chemicals and frequent reapplication. However, comprehensive lifecycle assessments reveal that some polymer formulations may still contribute to microplastic pollution or release potentially harmful compounds during degradation.

Recent advancements have focused on developing biodegradable antimicrobial polymers derived from renewable resources. These bio-based alternatives, including chitosan derivatives and modified cellulose, demonstrate promising antimicrobial efficacy while significantly reducing environmental persistence. Studies indicate that such materials can degrade into non-toxic components within controlled timeframes, minimizing long-term ecological impacts.

Water consumption represents another critical sustainability consideration. Self-cleaning surfaces can substantially reduce water usage in maintenance operations, with some estimates suggesting water savings of 30-50% compared to conventional cleaning regimens. This benefit becomes particularly significant in water-stressed regions and large-scale applications such as healthcare facilities or public transportation systems.

Energy requirements for manufacturing antimicrobial polymer coatings must also be evaluated. Current production methods often involve energy-intensive processes, though innovations in green chemistry and low-temperature polymerization are gradually reducing the carbon footprint associated with these materials. Several manufacturers have reported energy efficiency improvements of 15-25% through optimized production techniques.

Regulatory frameworks worldwide are increasingly emphasizing environmental criteria for antimicrobial products. The European Union's REACH regulations and similar initiatives in North America and Asia have established stricter guidelines for chemical safety and environmental impact. Consequently, research efforts are increasingly directed toward developing antimicrobial coatings that meet both performance requirements and environmental standards.

Future sustainability improvements may emerge from biomimetic approaches that replicate natural antimicrobial mechanisms found in plants and animals. These bio-inspired designs potentially offer effective antimicrobial protection with minimal ecological disruption. Additionally, circular economy principles are being applied to coating technologies, with growing interest in recyclable or recoverable antimicrobial systems that minimize waste and resource consumption throughout their lifecycle.

Traditional antimicrobial coatings often contain heavy metals or persistent chemicals that can accumulate in ecosystems when leached or disposed of improperly. Self-cleaning polymer coatings represent a potential improvement, as they can reduce the need for harsh cleaning chemicals and frequent reapplication. However, comprehensive lifecycle assessments reveal that some polymer formulations may still contribute to microplastic pollution or release potentially harmful compounds during degradation.

Recent advancements have focused on developing biodegradable antimicrobial polymers derived from renewable resources. These bio-based alternatives, including chitosan derivatives and modified cellulose, demonstrate promising antimicrobial efficacy while significantly reducing environmental persistence. Studies indicate that such materials can degrade into non-toxic components within controlled timeframes, minimizing long-term ecological impacts.

Water consumption represents another critical sustainability consideration. Self-cleaning surfaces can substantially reduce water usage in maintenance operations, with some estimates suggesting water savings of 30-50% compared to conventional cleaning regimens. This benefit becomes particularly significant in water-stressed regions and large-scale applications such as healthcare facilities or public transportation systems.

Energy requirements for manufacturing antimicrobial polymer coatings must also be evaluated. Current production methods often involve energy-intensive processes, though innovations in green chemistry and low-temperature polymerization are gradually reducing the carbon footprint associated with these materials. Several manufacturers have reported energy efficiency improvements of 15-25% through optimized production techniques.

Regulatory frameworks worldwide are increasingly emphasizing environmental criteria for antimicrobial products. The European Union's REACH regulations and similar initiatives in North America and Asia have established stricter guidelines for chemical safety and environmental impact. Consequently, research efforts are increasingly directed toward developing antimicrobial coatings that meet both performance requirements and environmental standards.

Future sustainability improvements may emerge from biomimetic approaches that replicate natural antimicrobial mechanisms found in plants and animals. These bio-inspired designs potentially offer effective antimicrobial protection with minimal ecological disruption. Additionally, circular economy principles are being applied to coating technologies, with growing interest in recyclable or recoverable antimicrobial systems that minimize waste and resource consumption throughout their lifecycle.

Healthcare Applications and Regulatory Compliance

Antimicrobial surface coatings with self-cleaning polymers have found significant applications in healthcare settings, where infection control and surface hygiene are paramount concerns. These advanced materials are increasingly being deployed in hospitals, clinics, and long-term care facilities to reduce healthcare-associated infections (HAIs), which affect approximately 1 in 31 hospital patients daily according to CDC data. The implementation of these coatings on high-touch surfaces such as door handles, bed rails, and medical equipment has demonstrated reduction in bacterial colonization by up to 99.9% in clinical trials.

The regulatory landscape governing these antimicrobial coatings is complex and multifaceted. In the United States, such coatings fall under the jurisdiction of multiple agencies, including the FDA for medical devices, the EPA for antimicrobial claims, and the CDC for infection control guidelines. Products making specific claims about preventing infection must undergo rigorous testing protocols established by ASTM International and the Japanese Industrial Standard (JIS) to verify efficacy against relevant pathogens.

European regulatory frameworks, particularly the EU Medical Device Regulation (MDR) and Biocidal Products Regulation (BPR), impose stringent requirements on antimicrobial coatings used in healthcare settings. These regulations mandate comprehensive safety assessments, including biocompatibility testing and evaluation of potential environmental impacts from antimicrobial agents leaching into wastewater systems.

Recent clinical implementations have shown promising results in reducing nosocomial infections. A 2022 study across 17 hospitals demonstrated that rooms with antimicrobial polymer-coated surfaces experienced 36% fewer HAIs compared to control rooms. The economic implications are substantial, with each prevented infection saving approximately $28,400 in additional healthcare costs and reducing average hospital stays by 3.7 days.

The integration of these technologies into healthcare facilities requires careful consideration of durability under intensive cleaning protocols. Self-cleaning polymers must withstand exposure to hospital-grade disinfectants, UV sterilization, and mechanical abrasion from daily use. Current generation coatings maintain antimicrobial efficacy for 12-24 months before requiring reapplication, though newer formulations aim to extend this to 36+ months.

Patient and healthcare worker safety considerations remain paramount in regulatory compliance. Manufacturers must demonstrate that these coatings do not cause skin irritation, respiratory issues, or other adverse effects during prolonged exposure. Additionally, antimicrobial resistance concerns have prompted regulatory bodies to scrutinize the mechanisms of action, favoring physical disruption approaches over traditional biocide release systems that may contribute to resistance development.

The regulatory landscape governing these antimicrobial coatings is complex and multifaceted. In the United States, such coatings fall under the jurisdiction of multiple agencies, including the FDA for medical devices, the EPA for antimicrobial claims, and the CDC for infection control guidelines. Products making specific claims about preventing infection must undergo rigorous testing protocols established by ASTM International and the Japanese Industrial Standard (JIS) to verify efficacy against relevant pathogens.

European regulatory frameworks, particularly the EU Medical Device Regulation (MDR) and Biocidal Products Regulation (BPR), impose stringent requirements on antimicrobial coatings used in healthcare settings. These regulations mandate comprehensive safety assessments, including biocompatibility testing and evaluation of potential environmental impacts from antimicrobial agents leaching into wastewater systems.

Recent clinical implementations have shown promising results in reducing nosocomial infections. A 2022 study across 17 hospitals demonstrated that rooms with antimicrobial polymer-coated surfaces experienced 36% fewer HAIs compared to control rooms. The economic implications are substantial, with each prevented infection saving approximately $28,400 in additional healthcare costs and reducing average hospital stays by 3.7 days.

The integration of these technologies into healthcare facilities requires careful consideration of durability under intensive cleaning protocols. Self-cleaning polymers must withstand exposure to hospital-grade disinfectants, UV sterilization, and mechanical abrasion from daily use. Current generation coatings maintain antimicrobial efficacy for 12-24 months before requiring reapplication, though newer formulations aim to extend this to 36+ months.

Patient and healthcare worker safety considerations remain paramount in regulatory compliance. Manufacturers must demonstrate that these coatings do not cause skin irritation, respiratory issues, or other adverse effects during prolonged exposure. Additionally, antimicrobial resistance concerns have prompted regulatory bodies to scrutinize the mechanisms of action, favoring physical disruption approaches over traditional biocide release systems that may contribute to resistance development.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!