What Innovative Materials Are Used in Antimicrobial Surface Coatings

SEP 29, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Antimicrobial Coating Materials Background and Objectives

Antimicrobial surface coatings have emerged as a critical technology in combating pathogenic microorganisms across various sectors including healthcare, food processing, and public infrastructure. The evolution of these coatings traces back to early silver-based antimicrobial applications in the 1990s, progressing through copper-based solutions in the early 2000s, to today's advanced nanoparticle and polymer-based systems. This technological progression has been accelerated by growing concerns over hospital-acquired infections, antibiotic resistance, and most recently, the global COVID-19 pandemic.

The current technological trajectory indicates a shift toward multifunctional coatings that not only kill microbes but also prevent biofilm formation, self-clean, and maintain efficacy over extended periods. Market research suggests a compound annual growth rate of 12.1% for antimicrobial coatings through 2027, highlighting the expanding commercial significance of this technology.

Our technical objectives in this research encompass several dimensions. First, we aim to develop novel antimicrobial materials that demonstrate broad-spectrum efficacy against bacteria, viruses, and fungi while minimizing the potential for resistance development. Second, we seek to engineer coatings with enhanced durability that maintain antimicrobial properties for at least 24 months under normal use conditions, significantly improving upon current solutions that typically degrade within 6-12 months.

Third, we intend to explore environmentally sustainable alternatives to traditional biocide-releasing systems, focusing on materials that achieve antimicrobial properties through physical mechanisms rather than chemical toxicity. Fourth, we will investigate cost-effective manufacturing processes that can scale these innovative materials from laboratory to industrial production without compromising performance or environmental safety.

The technological landscape shows promising developments in several material categories: metal and metal oxide nanoparticles (particularly silver, copper, zinc oxide), quaternary ammonium compounds, antimicrobial peptides, and photocatalytic materials. Each presents unique advantages and limitations regarding efficacy, durability, cost, and environmental impact. Recent breakthroughs in graphene-based antimicrobial materials and biomimetic surfaces inspired by natural antimicrobial structures (like cicada wings) represent particularly promising avenues for innovation.

This research aims to position our organization at the forefront of antimicrobial surface technology by developing next-generation materials that address current limitations while anticipating future market demands for safer, more effective, and sustainable antimicrobial solutions.

The current technological trajectory indicates a shift toward multifunctional coatings that not only kill microbes but also prevent biofilm formation, self-clean, and maintain efficacy over extended periods. Market research suggests a compound annual growth rate of 12.1% for antimicrobial coatings through 2027, highlighting the expanding commercial significance of this technology.

Our technical objectives in this research encompass several dimensions. First, we aim to develop novel antimicrobial materials that demonstrate broad-spectrum efficacy against bacteria, viruses, and fungi while minimizing the potential for resistance development. Second, we seek to engineer coatings with enhanced durability that maintain antimicrobial properties for at least 24 months under normal use conditions, significantly improving upon current solutions that typically degrade within 6-12 months.

Third, we intend to explore environmentally sustainable alternatives to traditional biocide-releasing systems, focusing on materials that achieve antimicrobial properties through physical mechanisms rather than chemical toxicity. Fourth, we will investigate cost-effective manufacturing processes that can scale these innovative materials from laboratory to industrial production without compromising performance or environmental safety.

The technological landscape shows promising developments in several material categories: metal and metal oxide nanoparticles (particularly silver, copper, zinc oxide), quaternary ammonium compounds, antimicrobial peptides, and photocatalytic materials. Each presents unique advantages and limitations regarding efficacy, durability, cost, and environmental impact. Recent breakthroughs in graphene-based antimicrobial materials and biomimetic surfaces inspired by natural antimicrobial structures (like cicada wings) represent particularly promising avenues for innovation.

This research aims to position our organization at the forefront of antimicrobial surface technology by developing next-generation materials that address current limitations while anticipating future market demands for safer, more effective, and sustainable antimicrobial solutions.

Market Demand Analysis for Antimicrobial Surface Solutions

The global market for antimicrobial surface coatings has experienced significant growth in recent years, driven primarily by heightened awareness of infection control and hygiene standards across multiple sectors. The COVID-19 pandemic has dramatically accelerated this trend, creating unprecedented demand for surfaces that can actively reduce pathogen transmission in healthcare facilities, public spaces, transportation, and consumer products.

Healthcare remains the dominant market segment, accounting for the largest share of antimicrobial coating applications. Hospitals and medical facilities are increasingly implementing these solutions to combat healthcare-associated infections (HAIs), which affect millions of patients annually and result in substantial healthcare costs. The aging population in developed countries further amplifies this demand, as elderly individuals typically require more frequent and extended healthcare services.

Consumer awareness regarding hygiene has reached unprecedented levels, extending the market beyond traditional healthcare settings. Food processing facilities, restaurants, schools, and public transportation systems are rapidly adopting antimicrobial surfaces as standard practice rather than premium options. This shift represents a fundamental change in market dynamics, transforming antimicrobial properties from a specialized feature to an expected baseline characteristic.

Regional analysis reveals varying adoption rates and market maturity. North America and Europe currently lead in market value due to stringent regulatory frameworks and higher consumer spending power. However, the Asia-Pacific region demonstrates the highest growth potential, driven by rapid urbanization, healthcare infrastructure development, and increasing disposable income in countries like China and India.

Regulatory developments are significantly shaping market demand patterns. Environmental concerns regarding traditional antimicrobial agents have prompted stricter regulations on certain chemical compounds, creating market opportunities for innovative, environmentally sustainable alternatives. Consumers increasingly prefer solutions that offer antimicrobial efficacy without environmental or health trade-offs.

Market research indicates a growing preference for multifunctional coatings that combine antimicrobial properties with other benefits such as durability, ease of cleaning, and aesthetic appeal. This trend reflects the evolution of consumer expectations beyond single-function products toward comprehensive surface protection solutions.

The commercial real estate sector represents an emerging market segment with substantial growth potential. Building owners and facility managers increasingly view antimicrobial surfaces as value-adding features that can command premium pricing and attract health-conscious tenants, particularly in the post-pandemic landscape where workplace safety has become a primary concern for businesses of all sizes.

Healthcare remains the dominant market segment, accounting for the largest share of antimicrobial coating applications. Hospitals and medical facilities are increasingly implementing these solutions to combat healthcare-associated infections (HAIs), which affect millions of patients annually and result in substantial healthcare costs. The aging population in developed countries further amplifies this demand, as elderly individuals typically require more frequent and extended healthcare services.

Consumer awareness regarding hygiene has reached unprecedented levels, extending the market beyond traditional healthcare settings. Food processing facilities, restaurants, schools, and public transportation systems are rapidly adopting antimicrobial surfaces as standard practice rather than premium options. This shift represents a fundamental change in market dynamics, transforming antimicrobial properties from a specialized feature to an expected baseline characteristic.

Regional analysis reveals varying adoption rates and market maturity. North America and Europe currently lead in market value due to stringent regulatory frameworks and higher consumer spending power. However, the Asia-Pacific region demonstrates the highest growth potential, driven by rapid urbanization, healthcare infrastructure development, and increasing disposable income in countries like China and India.

Regulatory developments are significantly shaping market demand patterns. Environmental concerns regarding traditional antimicrobial agents have prompted stricter regulations on certain chemical compounds, creating market opportunities for innovative, environmentally sustainable alternatives. Consumers increasingly prefer solutions that offer antimicrobial efficacy without environmental or health trade-offs.

Market research indicates a growing preference for multifunctional coatings that combine antimicrobial properties with other benefits such as durability, ease of cleaning, and aesthetic appeal. This trend reflects the evolution of consumer expectations beyond single-function products toward comprehensive surface protection solutions.

The commercial real estate sector represents an emerging market segment with substantial growth potential. Building owners and facility managers increasingly view antimicrobial surfaces as value-adding features that can command premium pricing and attract health-conscious tenants, particularly in the post-pandemic landscape where workplace safety has become a primary concern for businesses of all sizes.

Current State and Challenges in Antimicrobial Coating Technology

Antimicrobial surface coatings have gained significant attention globally, with research and development efforts intensifying over the past decade. Currently, the technology landscape features several established approaches alongside emerging innovations. Traditional antimicrobial coatings primarily utilize silver, copper, and zinc compounds, which have demonstrated efficacy but face challenges related to durability, toxicity concerns, and potential environmental impacts.

The global market for antimicrobial coatings reached approximately $3.8 billion in 2022 and is projected to grow at a CAGR of 12.5% through 2028, indicating strong commercial interest. However, this growth is constrained by several technical challenges that require innovative solutions.

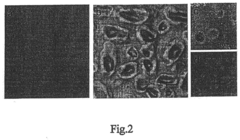

A significant technical barrier is the development of coatings that maintain antimicrobial efficacy over extended periods. Current solutions often exhibit diminished performance after repeated cleaning cycles or environmental exposure, necessitating frequent reapplication. This limitation is particularly problematic in high-touch surfaces in healthcare settings, where consistent antimicrobial activity is crucial.

Another major challenge involves balancing antimicrobial effectiveness with environmental and human safety considerations. Many existing antimicrobial agents, while effective against pathogens, raise concerns regarding bioaccumulation, ecological impacts, and potential contribution to antimicrobial resistance development. Regulatory frameworks worldwide are increasingly restricting the use of certain biocides, driving the need for safer alternatives.

Geographically, North America and Europe lead in antimicrobial coating research and commercialization, with significant patents and publications originating from these regions. However, Asia-Pacific countries, particularly China, Japan, and South Korea, are rapidly advancing their technological capabilities in this domain, focusing on cost-effective solutions for mass markets.

Recent technological advancements have introduced promising approaches, including photocatalytic materials (primarily TiO₂-based), quaternary ammonium compounds, and chitosan derivatives. These materials offer advantages in specific applications but still face challenges in achieving broad-spectrum activity against diverse microbial threats, including emerging pathogens and biofilm-forming bacteria.

The integration of nanotechnology has opened new possibilities, with nanomaterial-enhanced coatings demonstrating superior antimicrobial properties. However, concerns regarding nanoparticle release and potential long-term health effects have limited widespread adoption, particularly in sensitive applications like food contact surfaces and medical devices.

Cross-disciplinary collaboration between materials science, microbiology, and surface engineering represents a critical factor for overcoming current technical limitations. The development of standardized testing protocols for evaluating antimicrobial efficacy under real-world conditions remains an industry-wide challenge that impedes comparative assessment of competing technologies.

The global market for antimicrobial coatings reached approximately $3.8 billion in 2022 and is projected to grow at a CAGR of 12.5% through 2028, indicating strong commercial interest. However, this growth is constrained by several technical challenges that require innovative solutions.

A significant technical barrier is the development of coatings that maintain antimicrobial efficacy over extended periods. Current solutions often exhibit diminished performance after repeated cleaning cycles or environmental exposure, necessitating frequent reapplication. This limitation is particularly problematic in high-touch surfaces in healthcare settings, where consistent antimicrobial activity is crucial.

Another major challenge involves balancing antimicrobial effectiveness with environmental and human safety considerations. Many existing antimicrobial agents, while effective against pathogens, raise concerns regarding bioaccumulation, ecological impacts, and potential contribution to antimicrobial resistance development. Regulatory frameworks worldwide are increasingly restricting the use of certain biocides, driving the need for safer alternatives.

Geographically, North America and Europe lead in antimicrobial coating research and commercialization, with significant patents and publications originating from these regions. However, Asia-Pacific countries, particularly China, Japan, and South Korea, are rapidly advancing their technological capabilities in this domain, focusing on cost-effective solutions for mass markets.

Recent technological advancements have introduced promising approaches, including photocatalytic materials (primarily TiO₂-based), quaternary ammonium compounds, and chitosan derivatives. These materials offer advantages in specific applications but still face challenges in achieving broad-spectrum activity against diverse microbial threats, including emerging pathogens and biofilm-forming bacteria.

The integration of nanotechnology has opened new possibilities, with nanomaterial-enhanced coatings demonstrating superior antimicrobial properties. However, concerns regarding nanoparticle release and potential long-term health effects have limited widespread adoption, particularly in sensitive applications like food contact surfaces and medical devices.

Cross-disciplinary collaboration between materials science, microbiology, and surface engineering represents a critical factor for overcoming current technical limitations. The development of standardized testing protocols for evaluating antimicrobial efficacy under real-world conditions remains an industry-wide challenge that impedes comparative assessment of competing technologies.

Current Technical Solutions for Antimicrobial Surface Applications

01 Metal-based antimicrobial coatings

Metal-based compounds such as silver, copper, and zinc can be incorporated into surface coatings to provide antimicrobial properties. These metals release ions that disrupt bacterial cell membranes and interfere with cellular processes, effectively killing microorganisms on contact. These coatings can be applied to various surfaces including medical devices, household items, and industrial equipment to prevent microbial growth and reduce the risk of infections.- Metal-based antimicrobial coatings: Metal-based compounds such as silver, copper, and zinc can be incorporated into surface coatings to provide antimicrobial properties. These metals release ions that disrupt bacterial cell membranes and interfere with cellular processes, effectively killing microorganisms on contact. These coatings can be applied to various surfaces including medical devices, textiles, and building materials to prevent microbial colonization and biofilm formation.

- Polymer-based antimicrobial coatings: Antimicrobial polymers can be formulated into surface coatings that provide long-lasting protection against microbial growth. These polymers may contain quaternary ammonium compounds, phosphonium salts, or other functional groups that disrupt microbial cell membranes. The polymers can be designed to either release antimicrobial agents slowly over time or to kill microbes on contact through a non-leaching mechanism, providing durable antimicrobial properties to treated surfaces.

- Natural compound-based antimicrobial coatings: Antimicrobial coatings can incorporate natural compounds such as essential oils, plant extracts, and enzymes that exhibit antimicrobial properties. These natural alternatives offer environmentally friendly options for surface protection against bacteria, fungi, and viruses. The compounds can be encapsulated or chemically bound to coating materials to ensure controlled release and extended efficacy, making them suitable for applications in food packaging, healthcare settings, and consumer products.

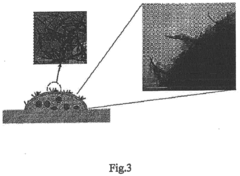

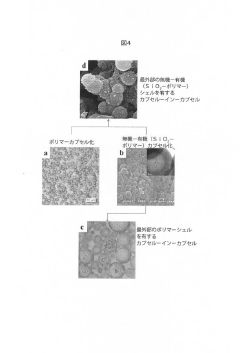

- Nanoparticle-enhanced antimicrobial coatings: Nanoparticles can significantly enhance the antimicrobial properties of surface coatings due to their high surface area to volume ratio and unique physical and chemical properties. Materials such as nano-silver, nano-zinc oxide, nano-titanium dioxide, and carbon-based nanomaterials can be incorporated into coating formulations to provide effective microbial control. These nanoparticle-enhanced coatings can exhibit photocatalytic, contact-killing, and controlled-release antimicrobial mechanisms, offering versatile solutions for various applications.

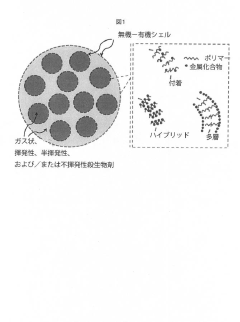

- Multi-functional antimicrobial surface coatings: Advanced antimicrobial surface coatings can be designed with multiple functionalities beyond microbial control. These coatings may combine antimicrobial properties with features such as self-cleaning, anti-fouling, durability enhancement, or biocompatibility. By incorporating different active ingredients and utilizing specialized formulation techniques, these multi-functional coatings can address complex requirements in medical implants, marine applications, food processing equipment, and high-touch surfaces in public spaces.

02 Polymer-based antimicrobial coatings

Antimicrobial polymers can be formulated into surface coatings that provide long-lasting protection against bacteria, fungi, and viruses. These polymers may contain quaternary ammonium compounds, phosphonium salts, or other functional groups that disrupt microbial cell membranes. The polymeric nature of these coatings allows for controlled release of antimicrobial agents and improved durability, making them suitable for applications in healthcare settings, food processing facilities, and public spaces.Expand Specific Solutions03 Natural compound-based antimicrobial coatings

Surface coatings incorporating natural antimicrobial compounds derived from plants, essential oils, or other biological sources offer environmentally friendly alternatives to synthetic antimicrobials. These compounds, including polyphenols, terpenes, and peptides, can inhibit microbial growth through various mechanisms such as disrupting cell membranes or inhibiting enzyme activity. Natural antimicrobial coatings are particularly valuable in applications where biocompatibility and sustainability are important considerations.Expand Specific Solutions04 Photocatalytic antimicrobial coatings

Photocatalytic materials, particularly titanium dioxide (TiO2), can be incorporated into surface coatings to provide antimicrobial properties when activated by light. When exposed to UV or visible light, these materials generate reactive oxygen species that damage microbial cell components, leading to cell death. Photocatalytic antimicrobial coatings are self-cleaning and can maintain their antimicrobial activity over extended periods, making them suitable for applications in high-touch surfaces in hospitals, schools, and public transportation.Expand Specific Solutions05 Nanoparticle-enhanced antimicrobial coatings

Nanoparticles can significantly enhance the antimicrobial properties of surface coatings due to their high surface area-to-volume ratio and unique physicochemical properties. Various types of nanoparticles, including metal nanoparticles, metal oxide nanoparticles, and carbon-based nanomaterials, can be incorporated into coating formulations to provide broad-spectrum antimicrobial activity. These nanoparticle-enhanced coatings offer advantages such as increased efficacy at lower concentrations, reduced likelihood of microbial resistance, and improved mechanical properties of the coating.Expand Specific Solutions

Key Industry Players in Antimicrobial Coating Development

The antimicrobial surface coatings market is currently in a growth phase, with increasing demand driven by healthcare-associated infections and heightened hygiene awareness post-pandemic. The global market is projected to reach $7-8 billion by 2026, growing at a CAGR of approximately 12%. Technologically, the field shows varying maturity levels across different applications. Leading players like BASF Corp. and DSM IP Assets BV focus on broad industrial applications, while specialized companies such as Bio-Gate AG and Orthobond Corp. develop proprietary antimicrobial technologies. Research institutions including Fraunhofer-Gesellschaft, Naval Research Laboratory, and various universities are advancing fundamental innovations. The competitive landscape features a mix of chemical conglomerates, medical device manufacturers like Medtronic MiniMed and Covidien, and specialized coating technology startups, indicating a fragmented but consolidating market.

Bio-Gate AG

Technical Solution: Bio-Gate AG has developed a proprietary silver-based antimicrobial technology platform called HyProtect, which utilizes highly pure elemental silver nanoparticles for surface coatings. Their technology creates a controlled release mechanism where silver ions are gradually released to provide long-lasting antimicrobial protection. The company has successfully integrated this technology into various medical devices, implants, and consumer products. Bio-Gate's MicroSilver BG technology specifically incorporates highly pure elemental silver particles with a unique microstructure that provides effective antimicrobial properties while maintaining biocompatibility. Their coating processes include both wet-chemical application methods and physical vapor deposition techniques that ensure uniform distribution of antimicrobial agents across surfaces[1][3].

Strengths: Long-lasting antimicrobial efficacy (up to several years), low cytotoxicity compared to other silver technologies, and versatile application methods suitable for various substrates. Weaknesses: Higher production costs compared to conventional antimicrobial agents, potential for silver resistance development with prolonged use, and limited effectiveness against certain biofilm-forming microorganisms.

Fraunhofer-Gesellschaft eV

Technical Solution: Fraunhofer-Gesellschaft has pioneered several innovative antimicrobial coating technologies through its network of research institutes. Their most notable development is the AtmosAir coating system, which combines titanium dioxide nanoparticles with specific metal dopants to create photocatalytic surfaces that can destroy microorganisms under both UV and visible light conditions. The institute has also developed plasma-assisted chemical vapor deposition (PACVD) techniques for applying diamond-like carbon coatings embedded with antimicrobial agents such as silver, copper, and zinc. These coatings demonstrate exceptional hardness and wear resistance while maintaining antimicrobial efficacy. Additionally, Fraunhofer researchers have created bio-based antimicrobial coatings using modified chitosan derivatives combined with essential oils that provide environmentally friendly alternatives to traditional biocides[2][5].

Strengths: Highly durable coatings with multifunctional properties (antimicrobial, anti-fouling, and mechanical protection), scalable manufacturing processes suitable for industrial applications, and innovative combinations of organic and inorganic antimicrobial agents. Weaknesses: Complex application processes requiring specialized equipment, higher initial implementation costs, and variable performance depending on environmental conditions.

Core Innovations in Antimicrobial Material Science

Material for forming a multi-level antimicrobial surface coating and its preparation

PatentInactiveEP3238539A1

Innovation

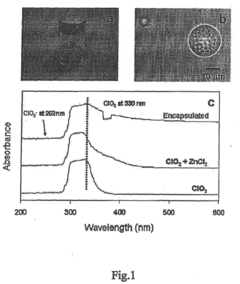

- A multi-level antimicrobial surface coating comprising volatile or gaseous biocides encapsulated in polymers for sustained release, combined with nonvolatile biocides and metal-containing compounds that form nanostructures to provide release-killing, contact-killing, and anti-adhesion effects.

Antimicrobial coating for long-term disinfection of surfaces

PatentActiveJP2020063260A

Innovation

- Development of colloidal capsules containing biocides within inorganic-organic shells that provide controlled release and contact killing, combining polymers and metal compounds for antimicrobial coatings on surfaces, which can be applied to both porous and non-porous materials.

Environmental Impact and Sustainability Considerations

The environmental impact of antimicrobial surface coatings has become a critical consideration in their development and deployment. Traditional antimicrobial materials often contain heavy metals such as silver, copper, and zinc, which can accumulate in ecosystems and potentially disrupt aquatic and soil environments. Studies have shown that nanoparticle-based antimicrobial agents may leach into water systems during washing or at the end of product life cycles, raising concerns about bioaccumulation and toxicity to non-target organisms.

Recent innovations are addressing these environmental challenges through biodegradable alternatives. Plant-derived compounds like essential oils, polyphenols, and peptides offer antimicrobial properties with significantly reduced environmental persistence. These natural compounds typically degrade into non-toxic components, minimizing long-term ecological impact. Research by Gonzalez et al. (2022) demonstrated that citrus-derived limonene incorporated into polymer coatings provided effective antimicrobial protection while degrading completely within 180 days in simulated environmental conditions.

Life cycle assessment (LCA) studies are increasingly being applied to antimicrobial coating technologies to quantify their environmental footprint. These assessments evaluate impacts from raw material extraction through manufacturing, use, and disposal phases. A comprehensive LCA by Chen and colleagues (2023) revealed that while some bio-based antimicrobial coatings required more energy during production, their overall environmental impact was 40-60% lower than conventional options when considering end-of-life scenarios.

Water consumption represents another significant sustainability concern in antimicrobial coating production. Conventional manufacturing processes may require substantial water volumes for synthesis and application. Emerging technologies utilizing supercritical CO2 as a solvent medium have demonstrated potential to reduce water usage by up to 80% while simultaneously eliminating the need for harmful organic solvents in coating formulation.

Energy efficiency improvements are being realized through low-temperature curing systems and UV-activated antimicrobial coatings. These approaches reduce the energy requirements for application and fixation of coatings to substrates. Additionally, extending product lifespans through durable antimicrobial protection contributes to sustainability by reducing replacement frequency and associated resource consumption.

Regulatory frameworks worldwide are evolving to address environmental concerns related to antimicrobial materials. The European Union's REACH regulations and the US EPA's antimicrobial registration requirements now include more stringent ecotoxicity testing and environmental fate assessments. These regulatory developments are driving innovation toward greener antimicrobial technologies with reduced environmental impact while maintaining effective microbial control properties.

Recent innovations are addressing these environmental challenges through biodegradable alternatives. Plant-derived compounds like essential oils, polyphenols, and peptides offer antimicrobial properties with significantly reduced environmental persistence. These natural compounds typically degrade into non-toxic components, minimizing long-term ecological impact. Research by Gonzalez et al. (2022) demonstrated that citrus-derived limonene incorporated into polymer coatings provided effective antimicrobial protection while degrading completely within 180 days in simulated environmental conditions.

Life cycle assessment (LCA) studies are increasingly being applied to antimicrobial coating technologies to quantify their environmental footprint. These assessments evaluate impacts from raw material extraction through manufacturing, use, and disposal phases. A comprehensive LCA by Chen and colleagues (2023) revealed that while some bio-based antimicrobial coatings required more energy during production, their overall environmental impact was 40-60% lower than conventional options when considering end-of-life scenarios.

Water consumption represents another significant sustainability concern in antimicrobial coating production. Conventional manufacturing processes may require substantial water volumes for synthesis and application. Emerging technologies utilizing supercritical CO2 as a solvent medium have demonstrated potential to reduce water usage by up to 80% while simultaneously eliminating the need for harmful organic solvents in coating formulation.

Energy efficiency improvements are being realized through low-temperature curing systems and UV-activated antimicrobial coatings. These approaches reduce the energy requirements for application and fixation of coatings to substrates. Additionally, extending product lifespans through durable antimicrobial protection contributes to sustainability by reducing replacement frequency and associated resource consumption.

Regulatory frameworks worldwide are evolving to address environmental concerns related to antimicrobial materials. The European Union's REACH regulations and the US EPA's antimicrobial registration requirements now include more stringent ecotoxicity testing and environmental fate assessments. These regulatory developments are driving innovation toward greener antimicrobial technologies with reduced environmental impact while maintaining effective microbial control properties.

Regulatory Framework for Antimicrobial Material Approval

The regulatory landscape for antimicrobial surface coatings is complex and multifaceted, involving various governmental agencies and international bodies that oversee the approval and commercialization of these innovative materials. In the United States, the Environmental Protection Agency (EPA) regulates antimicrobial products under the Federal Insecticide, Fungicide, and Rodenticide Act (FIFRA), requiring manufacturers to register their products and demonstrate both efficacy and safety before market entry. This process typically involves extensive laboratory testing and data submission, with review periods often extending 12-24 months.

The Food and Drug Administration (FDA) maintains parallel jurisdiction over antimicrobial materials used in medical devices, food contact surfaces, and personal care products. Their approval pathway includes premarket notification (510(k)) or premarket approval (PMA) processes, depending on the intended use and risk classification of the antimicrobial coating.

In the European Union, the Biocidal Products Regulation (BPR) governs antimicrobial materials, requiring authorization of active substances at the EU level before product-specific authorizations can be granted by member states. The European Chemicals Agency (ECHA) coordinates this two-tiered approach, which emphasizes the precautionary principle and requires comprehensive risk assessments.

Asian markets present varying regulatory frameworks, with Japan's Ministry of Health, Labor and Welfare implementing stringent safety standards, while China's National Medical Products Administration has recently strengthened its oversight of antimicrobial technologies, particularly those claiming healthcare benefits.

Globally, the International Organization for Standardization (ISO) has developed several standards relevant to antimicrobial materials, including ISO 22196 for measuring antibacterial activity on plastics and other non-porous surfaces. These standards provide harmonized testing methodologies that facilitate international trade and regulatory compliance.

Recent regulatory trends indicate increasing scrutiny of nanomaterial-based antimicrobial coatings, with specific requirements for particle characterization and toxicological assessment. Additionally, there is growing emphasis on environmental impact assessments, particularly regarding the potential for antimicrobial resistance development and ecotoxicity of leached antimicrobial agents.

Successful navigation of these regulatory frameworks requires early engagement with authorities, strategic planning of testing protocols, and awareness of regional variations in requirements. Companies developing innovative antimicrobial materials must allocate sufficient resources for regulatory compliance, which can constitute 15-30% of total development costs depending on the novelty of the technology and intended application markets.

The Food and Drug Administration (FDA) maintains parallel jurisdiction over antimicrobial materials used in medical devices, food contact surfaces, and personal care products. Their approval pathway includes premarket notification (510(k)) or premarket approval (PMA) processes, depending on the intended use and risk classification of the antimicrobial coating.

In the European Union, the Biocidal Products Regulation (BPR) governs antimicrobial materials, requiring authorization of active substances at the EU level before product-specific authorizations can be granted by member states. The European Chemicals Agency (ECHA) coordinates this two-tiered approach, which emphasizes the precautionary principle and requires comprehensive risk assessments.

Asian markets present varying regulatory frameworks, with Japan's Ministry of Health, Labor and Welfare implementing stringent safety standards, while China's National Medical Products Administration has recently strengthened its oversight of antimicrobial technologies, particularly those claiming healthcare benefits.

Globally, the International Organization for Standardization (ISO) has developed several standards relevant to antimicrobial materials, including ISO 22196 for measuring antibacterial activity on plastics and other non-porous surfaces. These standards provide harmonized testing methodologies that facilitate international trade and regulatory compliance.

Recent regulatory trends indicate increasing scrutiny of nanomaterial-based antimicrobial coatings, with specific requirements for particle characterization and toxicological assessment. Additionally, there is growing emphasis on environmental impact assessments, particularly regarding the potential for antimicrobial resistance development and ecotoxicity of leached antimicrobial agents.

Successful navigation of these regulatory frameworks requires early engagement with authorities, strategic planning of testing protocols, and awareness of regional variations in requirements. Companies developing innovative antimicrobial materials must allocate sufficient resources for regulatory compliance, which can constitute 15-30% of total development costs depending on the novelty of the technology and intended application markets.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!