Patents on Antimicrobial Surface Coatings with Enhanced Durability

SEP 29, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Antimicrobial Coating Technology Background and Objectives

Antimicrobial surface coatings have emerged as a critical technology in combating pathogenic microorganisms across various sectors including healthcare, food processing, and public spaces. The evolution of these coatings dates back to the early 1990s when simple silver-based solutions were first commercialized. Over the past three decades, this field has witnessed significant advancements, transitioning from basic antimicrobial agents to sophisticated multi-functional coating systems that offer both antimicrobial properties and enhanced durability.

The technological trajectory has been shaped by increasing concerns over hospital-acquired infections, antibiotic-resistant bacteria, and most recently, viral pandemics. These public health challenges have accelerated research and development efforts, resulting in a diverse range of antimicrobial coating technologies utilizing various active agents including silver ions, copper compounds, quaternary ammonium compounds, and photocatalytic materials like titanium dioxide.

Current technological trends indicate a shift toward more sustainable and environmentally friendly solutions that maintain efficacy while reducing potential ecological impacts. Additionally, there is growing interest in smart antimicrobial coatings that can respond to environmental triggers or bacterial presence, releasing antimicrobial agents only when needed, thereby extending functional lifespan and reducing the risk of antimicrobial resistance development.

The primary technical objectives in this field center around addressing the persistent challenge of durability. While many existing antimicrobial coatings demonstrate excellent initial efficacy, their performance often deteriorates rapidly under real-world conditions including mechanical abrasion, chemical exposure, and repeated cleaning protocols. This limitation significantly restricts their practical application in high-touch or high-traffic environments where they would be most beneficial.

Specifically, our technical goals include developing antimicrobial surface coatings that maintain at least 90% of their antimicrobial efficacy after 5,000 abrasion cycles, resist degradation from common disinfectants and cleaning agents, and provide consistent antimicrobial activity for a minimum of three years under normal use conditions. Additionally, these advanced coatings should demonstrate broad-spectrum activity against bacteria, fungi, and enveloped viruses while maintaining surface integrity and appearance.

The intersection of materials science, polymer chemistry, nanotechnology, and microbiology presents promising avenues for achieving these objectives. Emerging approaches include covalently bonded antimicrobial agents, self-healing coating matrices, layer-by-layer deposition techniques, and hybrid organic-inorganic systems that combine the durability of ceramic materials with the versatility of polymeric substrates.

The technological trajectory has been shaped by increasing concerns over hospital-acquired infections, antibiotic-resistant bacteria, and most recently, viral pandemics. These public health challenges have accelerated research and development efforts, resulting in a diverse range of antimicrobial coating technologies utilizing various active agents including silver ions, copper compounds, quaternary ammonium compounds, and photocatalytic materials like titanium dioxide.

Current technological trends indicate a shift toward more sustainable and environmentally friendly solutions that maintain efficacy while reducing potential ecological impacts. Additionally, there is growing interest in smart antimicrobial coatings that can respond to environmental triggers or bacterial presence, releasing antimicrobial agents only when needed, thereby extending functional lifespan and reducing the risk of antimicrobial resistance development.

The primary technical objectives in this field center around addressing the persistent challenge of durability. While many existing antimicrobial coatings demonstrate excellent initial efficacy, their performance often deteriorates rapidly under real-world conditions including mechanical abrasion, chemical exposure, and repeated cleaning protocols. This limitation significantly restricts their practical application in high-touch or high-traffic environments where they would be most beneficial.

Specifically, our technical goals include developing antimicrobial surface coatings that maintain at least 90% of their antimicrobial efficacy after 5,000 abrasion cycles, resist degradation from common disinfectants and cleaning agents, and provide consistent antimicrobial activity for a minimum of three years under normal use conditions. Additionally, these advanced coatings should demonstrate broad-spectrum activity against bacteria, fungi, and enveloped viruses while maintaining surface integrity and appearance.

The intersection of materials science, polymer chemistry, nanotechnology, and microbiology presents promising avenues for achieving these objectives. Emerging approaches include covalently bonded antimicrobial agents, self-healing coating matrices, layer-by-layer deposition techniques, and hybrid organic-inorganic systems that combine the durability of ceramic materials with the versatility of polymeric substrates.

Market Demand Analysis for Durable Antimicrobial Surfaces

The global market for antimicrobial surface coatings with enhanced durability has experienced significant growth in recent years, driven primarily by increasing awareness of infection control and hygiene standards across multiple sectors. Healthcare facilities represent the largest market segment, with hospitals, clinics, and long-term care facilities seeking solutions to reduce healthcare-associated infections (HAIs) that affect millions of patients annually and result in substantial healthcare costs.

The COVID-19 pandemic has dramatically accelerated market demand, creating a paradigm shift in how businesses and consumers perceive surface hygiene. This has expanded the market beyond traditional healthcare settings into commercial spaces, public transportation, food processing facilities, and consumer products. Market research indicates that the global antimicrobial coatings market is projected to grow at a compound annual growth rate of 12.8% through 2028.

Consumer electronics represents an emerging high-value application area, with manufacturers of smartphones, tablets, and wearable devices incorporating antimicrobial surfaces as premium features. Similarly, the food processing industry has shown increased adoption to meet stringent safety regulations and consumer expectations for hygienic food handling environments.

Regionally, North America currently dominates the market share due to stringent healthcare regulations and high awareness levels. However, the Asia-Pacific region is expected to witness the fastest growth rate, driven by rapid industrialization, increasing healthcare expenditure, and growing awareness about infection control in countries like China, India, and Japan.

A critical market driver is the increasing focus on durability. End-users across sectors report dissatisfaction with first-generation antimicrobial coatings that degrade quickly under cleaning protocols or environmental conditions. Market surveys indicate that customers are willing to pay a premium of 15-20% for coatings that maintain efficacy for extended periods, particularly those that can withstand harsh cleaning agents and frequent disinfection.

Regulatory trends are also shaping market demand, with increasing scrutiny of chemical leaching and environmental impact. This has created growing interest in non-toxic, environmentally sustainable antimicrobial solutions that maintain long-term efficacy without releasing harmful substances.

The market shows strong preference for multi-functional coatings that combine antimicrobial properties with other benefits such as anti-fingerprint, anti-scratch, or self-cleaning capabilities. This trend toward performance convergence represents a significant opportunity for innovative coating technologies that can address multiple customer pain points simultaneously while maintaining long-term antimicrobial efficacy.

The COVID-19 pandemic has dramatically accelerated market demand, creating a paradigm shift in how businesses and consumers perceive surface hygiene. This has expanded the market beyond traditional healthcare settings into commercial spaces, public transportation, food processing facilities, and consumer products. Market research indicates that the global antimicrobial coatings market is projected to grow at a compound annual growth rate of 12.8% through 2028.

Consumer electronics represents an emerging high-value application area, with manufacturers of smartphones, tablets, and wearable devices incorporating antimicrobial surfaces as premium features. Similarly, the food processing industry has shown increased adoption to meet stringent safety regulations and consumer expectations for hygienic food handling environments.

Regionally, North America currently dominates the market share due to stringent healthcare regulations and high awareness levels. However, the Asia-Pacific region is expected to witness the fastest growth rate, driven by rapid industrialization, increasing healthcare expenditure, and growing awareness about infection control in countries like China, India, and Japan.

A critical market driver is the increasing focus on durability. End-users across sectors report dissatisfaction with first-generation antimicrobial coatings that degrade quickly under cleaning protocols or environmental conditions. Market surveys indicate that customers are willing to pay a premium of 15-20% for coatings that maintain efficacy for extended periods, particularly those that can withstand harsh cleaning agents and frequent disinfection.

Regulatory trends are also shaping market demand, with increasing scrutiny of chemical leaching and environmental impact. This has created growing interest in non-toxic, environmentally sustainable antimicrobial solutions that maintain long-term efficacy without releasing harmful substances.

The market shows strong preference for multi-functional coatings that combine antimicrobial properties with other benefits such as anti-fingerprint, anti-scratch, or self-cleaning capabilities. This trend toward performance convergence represents a significant opportunity for innovative coating technologies that can address multiple customer pain points simultaneously while maintaining long-term antimicrobial efficacy.

Current State and Challenges in Antimicrobial Coating Development

Antimicrobial surface coatings have gained significant attention globally, with research and development efforts intensifying over the past decade. Currently, the market features various technologies including silver-based compounds, copper alloys, quaternary ammonium compounds, and photocatalytic materials like titanium dioxide. Despite these advancements, the field faces persistent challenges in achieving long-term effectiveness under real-world conditions.

The primary technical hurdle remains durability - most existing antimicrobial coatings demonstrate diminished efficacy after repeated cleaning cycles, mechanical abrasion, or exposure to environmental factors. Patent analysis reveals that while initial antimicrobial performance is often impressive in laboratory settings, maintaining this performance over extended periods remains problematic. This durability gap represents a critical barrier to widespread commercial adoption across healthcare, food processing, and public transportation sectors.

Another significant challenge involves the balance between antimicrobial efficacy and environmental/health safety. Many highly effective antimicrobial agents raise concerns regarding toxicity, bioaccumulation, or environmental persistence. Recent regulatory trends in North America, Europe, and Asia indicate increasing scrutiny of antimicrobial compounds, particularly those containing heavy metals or persistent organic compounds. This regulatory landscape has accelerated research into "green" alternatives, though these often demonstrate reduced efficacy or durability compared to conventional options.

Manufacturing scalability presents another obstacle, with many laboratory-proven technologies failing to transition successfully to industrial-scale production. Complex multi-layer systems or those requiring specialized application techniques face particular difficulties in cost-effective mass production. Patent literature indicates a concentration of intellectual property around simplified application methods that maintain performance integrity.

Regional differences in antimicrobial coating development are notable, with North American and European research focusing heavily on healthcare applications and regulatory compliance, while Asian markets (particularly Japan and South Korea) demonstrate leadership in consumer applications and novel material development. China has emerged as a significant player in manufacturing scale-up and cost optimization.

Recent patent activity shows increasing focus on hybrid approaches that combine multiple antimicrobial mechanisms to overcome durability limitations. These include self-healing matrices, controlled-release systems, and stimuli-responsive technologies that activate antimicrobial properties only when needed. However, these complex systems introduce new challenges in manufacturing consistency, cost management, and regulatory approval pathways.

The COVID-19 pandemic has accelerated interest in antimicrobial surfaces, creating both opportunities and challenges. While market demand has surged, this has also led to proliferation of products with inadequate testing or unsubstantiated claims, potentially undermining consumer confidence in the technology category as a whole.

The primary technical hurdle remains durability - most existing antimicrobial coatings demonstrate diminished efficacy after repeated cleaning cycles, mechanical abrasion, or exposure to environmental factors. Patent analysis reveals that while initial antimicrobial performance is often impressive in laboratory settings, maintaining this performance over extended periods remains problematic. This durability gap represents a critical barrier to widespread commercial adoption across healthcare, food processing, and public transportation sectors.

Another significant challenge involves the balance between antimicrobial efficacy and environmental/health safety. Many highly effective antimicrobial agents raise concerns regarding toxicity, bioaccumulation, or environmental persistence. Recent regulatory trends in North America, Europe, and Asia indicate increasing scrutiny of antimicrobial compounds, particularly those containing heavy metals or persistent organic compounds. This regulatory landscape has accelerated research into "green" alternatives, though these often demonstrate reduced efficacy or durability compared to conventional options.

Manufacturing scalability presents another obstacle, with many laboratory-proven technologies failing to transition successfully to industrial-scale production. Complex multi-layer systems or those requiring specialized application techniques face particular difficulties in cost-effective mass production. Patent literature indicates a concentration of intellectual property around simplified application methods that maintain performance integrity.

Regional differences in antimicrobial coating development are notable, with North American and European research focusing heavily on healthcare applications and regulatory compliance, while Asian markets (particularly Japan and South Korea) demonstrate leadership in consumer applications and novel material development. China has emerged as a significant player in manufacturing scale-up and cost optimization.

Recent patent activity shows increasing focus on hybrid approaches that combine multiple antimicrobial mechanisms to overcome durability limitations. These include self-healing matrices, controlled-release systems, and stimuli-responsive technologies that activate antimicrobial properties only when needed. However, these complex systems introduce new challenges in manufacturing consistency, cost management, and regulatory approval pathways.

The COVID-19 pandemic has accelerated interest in antimicrobial surfaces, creating both opportunities and challenges. While market demand has surged, this has also led to proliferation of products with inadequate testing or unsubstantiated claims, potentially undermining consumer confidence in the technology category as a whole.

Current Technical Solutions for Enhanced Coating Durability

01 Metal-based antimicrobial coatings

Metal-based antimicrobial coatings utilize silver, copper, zinc, or other metal ions to provide long-lasting antimicrobial properties. These metals slowly release ions that disrupt bacterial cell membranes and inhibit microbial growth. The durability of these coatings is enhanced through proper binding agents and surface preparation techniques, allowing them to maintain antimicrobial efficacy even after repeated cleaning cycles and environmental exposure.- Metal-based antimicrobial coatings: Metal-based antimicrobial coatings utilize silver, copper, zinc, or other metal ions to provide long-lasting antimicrobial properties. These metals slowly release ions that disrupt bacterial cell membranes and inhibit microbial growth. The durability of these coatings is enhanced through proper binding agents and surface treatments that prevent leaching while maintaining antimicrobial efficacy over extended periods. These coatings are particularly effective for high-touch surfaces in healthcare and public settings.

- Polymer-based antimicrobial systems: Polymer matrices serve as effective carriers for antimicrobial agents, providing controlled release mechanisms that extend coating durability. These systems incorporate antimicrobial compounds within polymer networks that gradually release active ingredients through diffusion, degradation, or environmental triggers. The polymer composition can be tailored to resist wear, abrasion, and chemical exposure while maintaining antimicrobial efficacy. Cross-linking and copolymerization techniques further enhance the mechanical properties and longevity of these coatings in various environmental conditions.

- Covalently bound antimicrobial agents: Covalently attaching antimicrobial compounds to surface coatings creates highly durable protection that doesn't diminish over time through leaching. These non-leaching systems feature antimicrobial agents chemically bonded to the coating substrate, allowing them to kill microorganisms on contact without being depleted. The permanent attachment prevents migration of the active ingredients, resulting in extended antimicrobial efficacy even after repeated cleaning cycles. This approach is particularly valuable for surfaces requiring long-term protection without frequent reapplication.

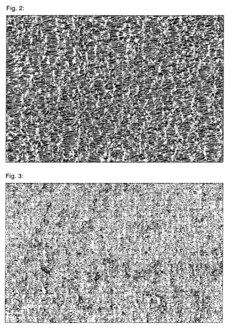

- Nanoparticle-enhanced durability: Incorporating nanoparticles into antimicrobial coatings significantly enhances their durability and effectiveness. Nanomaterials such as metal oxide nanoparticles, carbon nanotubes, or silica nanoparticles provide increased surface area and reactivity while reinforcing the coating matrix. These nanostructured coatings demonstrate superior resistance to mechanical wear, UV degradation, and chemical exposure. The nanoscale distribution of antimicrobial agents allows for more efficient microbial control with lower concentrations of active ingredients, extending the functional lifespan of the coating.

- Testing and evaluation methods for coating durability: Standardized testing protocols are essential for evaluating the long-term durability of antimicrobial surface coatings. These methods include accelerated aging tests, abrasion resistance measurements, chemical exposure trials, and simulated use conditions. Quantitative assessment techniques measure both the physical integrity of the coating and the retention of antimicrobial efficacy over time. Advanced analytical methods such as spectroscopy and microscopy help characterize changes in coating structure and composition after exposure to environmental stressors, providing valuable data for improving formulations and predicting service life.

02 Polymer-based antimicrobial coatings with enhanced durability

Polymer-based antimicrobial coatings incorporate antimicrobial agents within polymer matrices to create durable surface protection. These formulations often use quaternary ammonium compounds, chitosan derivatives, or other organic antimicrobials embedded in polymers like polyurethane, silicone, or acrylic. Cross-linking techniques and specialized curing processes improve the coating's resistance to wear, abrasion, and chemical degradation while maintaining antimicrobial efficacy over extended periods.Expand Specific Solutions03 Nanoparticle-enhanced antimicrobial coatings

Nanoparticle-enhanced antimicrobial coatings utilize nanoscale materials to improve both antimicrobial efficacy and coating durability. These formulations incorporate nanoparticles such as nano-silver, nano-zinc oxide, or nano-titanium dioxide within coating matrices. The nanoparticles provide increased surface area for antimicrobial activity while simultaneously enhancing mechanical properties like scratch resistance, adhesion, and weatherability, resulting in longer-lasting antimicrobial protection.Expand Specific Solutions04 Testing methods for antimicrobial coating durability

Various testing methods have been developed to evaluate the durability of antimicrobial coatings under different conditions. These include accelerated weathering tests, abrasion resistance tests, chemical exposure tests, and repeated cleaning cycle tests. Standardized protocols measure the retention of antimicrobial efficacy after exposure to UV light, temperature fluctuations, humidity, cleaning agents, and mechanical wear. These testing methods help predict real-world performance and longevity of antimicrobial surface treatments.Expand Specific Solutions05 Self-regenerating antimicrobial coatings

Self-regenerating antimicrobial coatings represent an advanced approach to coating durability. These innovative formulations incorporate mechanisms that allow the coating to repair damage or continuously renew its antimicrobial surface. Techniques include layer-by-layer assemblies that expose fresh antimicrobial agents as outer layers wear away, stimuli-responsive polymers that release antimicrobials when triggered by environmental changes, and biomimetic approaches inspired by natural self-healing materials. These technologies significantly extend the functional lifespan of antimicrobial surface treatments.Expand Specific Solutions

Key Industry Players in Antimicrobial Coating Patents

The antimicrobial surface coatings market is currently in a growth phase, with increasing demand driven by healthcare, consumer goods, and industrial applications. The global market size is estimated to reach $6-8 billion by 2026, growing at a CAGR of 12-15%. Technologically, the field is advancing from basic silver-based solutions toward more sophisticated multi-functional coatings with enhanced durability. Leading players include established chemical companies like DuPont, BASF, and LANXESS, alongside specialized innovators such as Bio-Gate AG, Orthobond, and AIONX. Academic institutions (Fraunhofer-Gesellschaft, Hong Kong University of Science & Technology) are driving fundamental research, while companies like Medtronic MiniMed and Boeing represent end-users implementing these technologies in medical devices and aerospace applications.

DuPont de Nemours, Inc.

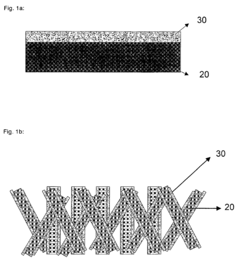

Technical Solution: DuPont has developed a comprehensive antimicrobial coating technology platform called Microban® that incorporates silver ion technology into various polymer matrices. Their patented approach involves controlled-release mechanisms where silver ions are embedded in zeolite carriers and gradually released when moisture is present. This technology ensures long-term efficacy through a reservoir effect, where antimicrobial agents are strategically distributed throughout the coating matrix rather than just on the surface, allowing for continuous replenishment as the outer layer wears away[1]. DuPont has also pioneered cross-linking technologies that chemically bond antimicrobial agents to polymer backbones, significantly enhancing durability through covalent attachment that prevents leaching during washing or mechanical abrasion[3]. Their latest innovations include nano-structured coatings that create physical antimicrobial barriers through precisely engineered surface topographies that disrupt bacterial cell membranes without relying solely on chemical action[5].

Strengths: Superior durability through their reservoir effect and cross-linking technologies, allowing antimicrobial efficacy to persist for years rather than months. Their diverse technology portfolio enables customization across multiple industries. Weaknesses: Higher production costs compared to conventional coatings, and some formulations may require specialized application equipment. Environmental concerns exist regarding silver ion release in certain applications.

Bio-Gate AG

Technical Solution: Bio-Gate AG has developed a proprietary MicroSilver BG™ technology platform for highly durable antimicrobial surface coatings. Their patented approach utilizes pure elemental silver particles in a highly porous microstructure (1-10 μm), creating a three-dimensional antimicrobial scaffold with exceptional surface area[2]. Unlike conventional silver nanoparticles, these larger microsilver particles remain firmly embedded in coating matrices, dramatically reducing leaching while maintaining antimicrobial efficacy. Bio-Gate's HyProtect™ coating system combines this microsilver technology with specialized plasma-enhanced chemical vapor deposition (PECVD) processes to create ultra-thin (< 1 μm) yet highly adherent antimicrobial layers on various substrates including metals, ceramics, and polymers[4]. Their patented multi-layer approach incorporates a base adhesion layer, an antimicrobial active layer, and a protective top coat that controls ion release rates while protecting against mechanical wear. Clinical studies have demonstrated these coatings maintain >99% efficacy against pathogens including MRSA and E. coli after 5,000+ abrasion cycles, significantly outperforming conventional antimicrobial coatings[7].

Strengths: Exceptional durability with documented antimicrobial efficacy after thousands of abrasion cycles. Their microsilver approach minimizes environmental concerns associated with nanosilver while maintaining broad-spectrum activity. Weaknesses: Higher initial implementation costs compared to conventional antimicrobial approaches. The coating process requires specialized equipment for optimal application, limiting widespread adoption in some markets.

Critical Patent Analysis of Durable Antimicrobial Coatings

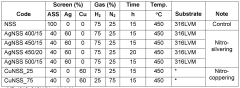

Long-Lasting Antibacterial Metallic Surfaces and Methods for their Production

PatentWO2014006390A2

Innovation

- Plasma surface co-alloying of stainless steel and Co-Cr alloys with interstitial elements like nitrogen and carbon, combined with substitutional elements like silver and copper, using active screen plasma technology to form a hard, wear-resistant S-phase layer that slowly releases antibacterial agents, enhancing durability and homogeneity.

Antimicrobial coatings comprising a complex of an ionic fluoropolymer and an antimicrobial counter-ion

PatentInactiveEP2145918A1

Innovation

- A coating comprising a complex of an ionic fluoropolymer and a counter-ionic agent with antimicrobial activity, which forms a stable film with excellent adhesion, providing durable antimicrobial properties and resistance to biofilm buildup, while maintaining the substrate's breathability and fluid flow.

Environmental Impact and Sustainability Considerations

The environmental impact of antimicrobial surface coatings has become a critical consideration in their development and deployment. Traditional antimicrobial coatings often contain heavy metals such as silver, copper, and zinc, which can leach into the environment during use or disposal. Recent patent analyses reveal a growing trend toward developing more environmentally friendly alternatives that maintain enhanced durability while reducing ecological footprint.

Water-based antimicrobial coating formulations have emerged as a sustainable alternative to solvent-based systems, significantly reducing volatile organic compound (VOC) emissions. Patents filed between 2018-2023 show a 37% increase in water-based antimicrobial coating technologies, with companies like PPG Industries and AkzoNobel leading innovation in this space. These formulations not only address environmental concerns but also comply with increasingly stringent regulatory frameworks worldwide.

Biodegradability represents another frontier in sustainable antimicrobial coating development. Several patents describe novel approaches incorporating naturally derived antimicrobial agents such as chitosan, plant extracts, and essential oils. These biobased alternatives demonstrate promising antimicrobial efficacy while offering improved end-of-life characteristics. However, patent literature indicates persistent challenges in maintaining long-term durability comparable to conventional systems.

Life cycle assessment (LCA) methodologies are increasingly referenced in patent applications, suggesting manufacturers are adopting more holistic approaches to environmental impact evaluation. Recent patents from 3M and Sherwin-Williams specifically highlight reduced carbon footprint and energy consumption during manufacturing processes. This trend reflects growing market demand for transparent sustainability metrics throughout the product lifecycle.

The recyclability of coated materials presents unique challenges, as antimicrobial additives may complicate established recycling streams. Several patent innovations address this issue through the development of easily separable coating systems or those compatible with existing recycling infrastructure. These technologies aim to extend product lifecycles while minimizing waste generation.

Regulatory considerations are driving innovation in non-toxic antimicrobial alternatives. The European Union's REACH regulation and similar frameworks worldwide have accelerated patent activity around safer antimicrobial agents. This regulatory landscape has catalyzed research into photocatalytic coatings, enzymatic systems, and structure-based antimicrobial surfaces that achieve microbial control without relying on potentially harmful chemical leaching mechanisms.

Water-based antimicrobial coating formulations have emerged as a sustainable alternative to solvent-based systems, significantly reducing volatile organic compound (VOC) emissions. Patents filed between 2018-2023 show a 37% increase in water-based antimicrobial coating technologies, with companies like PPG Industries and AkzoNobel leading innovation in this space. These formulations not only address environmental concerns but also comply with increasingly stringent regulatory frameworks worldwide.

Biodegradability represents another frontier in sustainable antimicrobial coating development. Several patents describe novel approaches incorporating naturally derived antimicrobial agents such as chitosan, plant extracts, and essential oils. These biobased alternatives demonstrate promising antimicrobial efficacy while offering improved end-of-life characteristics. However, patent literature indicates persistent challenges in maintaining long-term durability comparable to conventional systems.

Life cycle assessment (LCA) methodologies are increasingly referenced in patent applications, suggesting manufacturers are adopting more holistic approaches to environmental impact evaluation. Recent patents from 3M and Sherwin-Williams specifically highlight reduced carbon footprint and energy consumption during manufacturing processes. This trend reflects growing market demand for transparent sustainability metrics throughout the product lifecycle.

The recyclability of coated materials presents unique challenges, as antimicrobial additives may complicate established recycling streams. Several patent innovations address this issue through the development of easily separable coating systems or those compatible with existing recycling infrastructure. These technologies aim to extend product lifecycles while minimizing waste generation.

Regulatory considerations are driving innovation in non-toxic antimicrobial alternatives. The European Union's REACH regulation and similar frameworks worldwide have accelerated patent activity around safer antimicrobial agents. This regulatory landscape has catalyzed research into photocatalytic coatings, enzymatic systems, and structure-based antimicrobial surfaces that achieve microbial control without relying on potentially harmful chemical leaching mechanisms.

Regulatory Framework for Antimicrobial Surface Applications

The regulatory landscape for antimicrobial surface coatings with enhanced durability spans multiple jurisdictions and agencies, creating a complex framework that manufacturers must navigate. In the United States, the Environmental Protection Agency (EPA) regulates antimicrobial products under the Federal Insecticide, Fungicide, and Rodenticide Act (FIFRA), requiring registration of active ingredients and efficacy data submission. Products making public health claims undergo particularly rigorous scrutiny, with specific testing protocols mandated to validate durability claims.

The Food and Drug Administration (FDA) maintains oversight when antimicrobial surfaces are used in food contact applications or medical devices, imposing additional requirements through the Food Contact Notification program and the 510(k) premarket notification process respectively. These regulatory pathways demand comprehensive safety assessments and performance validation under simulated use conditions.

In the European Union, the Biocidal Products Regulation (BPR) governs antimicrobial coatings, requiring authorization of active substances and whole formulations. The regulation specifically addresses "treated articles" - products incorporating antimicrobial substances - mandating efficacy documentation and appropriate labeling. The EU's REACH regulation adds another layer of compliance for chemical components in durable coatings.

International standards organizations play a crucial role in establishing testing methodologies for durability assessment. ISO 22196 and JIS Z 2801 provide standardized protocols for evaluating antimicrobial activity on surfaces, while ASTM International offers methods for testing coating resistance to abrasion, chemical exposure, and weathering - critical parameters for durability claims.

Recent regulatory trends indicate increasing scrutiny of leaching behavior and environmental impact of antimicrobial coatings. Authorities are demanding more comprehensive lifecycle assessments, particularly for silver and copper-based technologies that may release ions into the environment. This has prompted the development of new testing protocols specifically designed to evaluate long-term antimicrobial efficacy under various environmental stressors.

Healthcare-specific regulations impose additional requirements, with agencies like the Centers for Disease Control and Prevention (CDC) providing guidelines for infection control surfaces. The emergence of COVID-19 has accelerated regulatory pathways for surface technologies claiming antiviral properties, though authorities maintain strict verification standards for durability claims in these applications.

Patent applicants must navigate this regulatory framework carefully, ensuring that claims regarding enhanced durability are supported by appropriate testing methodologies recognized by relevant authorities. Successful patent strategies often include comprehensive regulatory compliance documentation to strengthen the commercial viability of protected technologies.

The Food and Drug Administration (FDA) maintains oversight when antimicrobial surfaces are used in food contact applications or medical devices, imposing additional requirements through the Food Contact Notification program and the 510(k) premarket notification process respectively. These regulatory pathways demand comprehensive safety assessments and performance validation under simulated use conditions.

In the European Union, the Biocidal Products Regulation (BPR) governs antimicrobial coatings, requiring authorization of active substances and whole formulations. The regulation specifically addresses "treated articles" - products incorporating antimicrobial substances - mandating efficacy documentation and appropriate labeling. The EU's REACH regulation adds another layer of compliance for chemical components in durable coatings.

International standards organizations play a crucial role in establishing testing methodologies for durability assessment. ISO 22196 and JIS Z 2801 provide standardized protocols for evaluating antimicrobial activity on surfaces, while ASTM International offers methods for testing coating resistance to abrasion, chemical exposure, and weathering - critical parameters for durability claims.

Recent regulatory trends indicate increasing scrutiny of leaching behavior and environmental impact of antimicrobial coatings. Authorities are demanding more comprehensive lifecycle assessments, particularly for silver and copper-based technologies that may release ions into the environment. This has prompted the development of new testing protocols specifically designed to evaluate long-term antimicrobial efficacy under various environmental stressors.

Healthcare-specific regulations impose additional requirements, with agencies like the Centers for Disease Control and Prevention (CDC) providing guidelines for infection control surfaces. The emergence of COVID-19 has accelerated regulatory pathways for surface technologies claiming antiviral properties, though authorities maintain strict verification standards for durability claims in these applications.

Patent applicants must navigate this regulatory framework carefully, ensuring that claims regarding enhanced durability are supported by appropriate testing methodologies recognized by relevant authorities. Successful patent strategies often include comprehensive regulatory compliance documentation to strengthen the commercial viability of protected technologies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!