Applications of Calorimetry in Biomimetic Material Synthesis

AUG 5, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Biomimetic Calorimetry Background and Objectives

Calorimetry, a fundamental technique in thermal analysis, has emerged as a powerful tool in the field of biomimetic material synthesis. This interdisciplinary approach combines the principles of biology, chemistry, and materials science to create innovative materials inspired by nature. The evolution of calorimetry in this context has been driven by the increasing demand for advanced materials with superior properties and functionalities.

The primary objective of applying calorimetry in biomimetic material synthesis is to understand and replicate the intricate processes observed in biological systems. By measuring heat flow and thermal changes during material formation, researchers can gain valuable insights into the energetics and kinetics of biomimetic reactions. This knowledge is crucial for developing synthetic strategies that mimic natural processes with high precision and efficiency.

Historically, calorimetry has been used extensively in biochemistry and biophysics to study protein folding, enzyme kinetics, and ligand binding. However, its application in biomimetic material synthesis represents a relatively recent development. The adaptation of calorimetric techniques to this field has been facilitated by advancements in instrumentation and data analysis methods, allowing for more sensitive and accurate measurements of thermal events during material formation.

The technological trajectory of calorimetry in biomimetic synthesis has been marked by several key milestones. Early applications focused on simple biomineralization processes, such as calcium carbonate formation inspired by mollusk shells. As the field progressed, more complex systems were explored, including the synthesis of hierarchical structures mimicking bone and nacre. Recent advancements have enabled the study of dynamic, self-assembling systems that emulate the adaptive properties of living organisms.

Current research goals in this area include developing high-throughput calorimetric methods for rapid screening of biomimetic materials, integrating calorimetry with other analytical techniques for comprehensive characterization, and applying machine learning algorithms to interpret complex calorimetric data. These objectives aim to accelerate the discovery and optimization of novel biomimetic materials with applications ranging from medicine to energy storage and environmental remediation.

The future of calorimetry in biomimetic material synthesis is expected to focus on real-time, in situ measurements that capture the dynamic nature of biomimetic processes. This approach will provide unprecedented insights into the formation mechanisms of complex, multi-component materials and enable more precise control over their properties. Additionally, there is a growing interest in applying calorimetric techniques to study the interface between synthetic biomimetic materials and living systems, paving the way for advanced biomedical applications and tissue engineering.

The primary objective of applying calorimetry in biomimetic material synthesis is to understand and replicate the intricate processes observed in biological systems. By measuring heat flow and thermal changes during material formation, researchers can gain valuable insights into the energetics and kinetics of biomimetic reactions. This knowledge is crucial for developing synthetic strategies that mimic natural processes with high precision and efficiency.

Historically, calorimetry has been used extensively in biochemistry and biophysics to study protein folding, enzyme kinetics, and ligand binding. However, its application in biomimetic material synthesis represents a relatively recent development. The adaptation of calorimetric techniques to this field has been facilitated by advancements in instrumentation and data analysis methods, allowing for more sensitive and accurate measurements of thermal events during material formation.

The technological trajectory of calorimetry in biomimetic synthesis has been marked by several key milestones. Early applications focused on simple biomineralization processes, such as calcium carbonate formation inspired by mollusk shells. As the field progressed, more complex systems were explored, including the synthesis of hierarchical structures mimicking bone and nacre. Recent advancements have enabled the study of dynamic, self-assembling systems that emulate the adaptive properties of living organisms.

Current research goals in this area include developing high-throughput calorimetric methods for rapid screening of biomimetic materials, integrating calorimetry with other analytical techniques for comprehensive characterization, and applying machine learning algorithms to interpret complex calorimetric data. These objectives aim to accelerate the discovery and optimization of novel biomimetic materials with applications ranging from medicine to energy storage and environmental remediation.

The future of calorimetry in biomimetic material synthesis is expected to focus on real-time, in situ measurements that capture the dynamic nature of biomimetic processes. This approach will provide unprecedented insights into the formation mechanisms of complex, multi-component materials and enable more precise control over their properties. Additionally, there is a growing interest in applying calorimetric techniques to study the interface between synthetic biomimetic materials and living systems, paving the way for advanced biomedical applications and tissue engineering.

Market Analysis for Biomimetic Materials

The market for biomimetic materials, particularly those synthesized using calorimetry techniques, has shown significant growth in recent years. This expansion is driven by the increasing demand for advanced materials that mimic natural structures and functions across various industries. The global biomimetic materials market is expected to experience robust growth, with applications spanning healthcare, aerospace, automotive, and consumer goods sectors.

In the healthcare industry, biomimetic materials are gaining traction for tissue engineering, drug delivery systems, and medical implants. The ability to create materials that closely resemble natural tissues and organs has opened new possibilities for regenerative medicine and personalized healthcare solutions. This sector represents a substantial portion of the market, with continued investment in research and development fueling further growth.

The aerospace and automotive industries are also key drivers of the biomimetic materials market. These sectors are increasingly adopting biomimetic materials for their lightweight properties, enhanced strength, and improved fuel efficiency. Materials inspired by natural structures, such as shark skin or lotus leaves, are being developed to reduce drag and improve aerodynamics in aircraft and vehicles.

Consumer goods and electronics represent another significant market segment for biomimetic materials. Products ranging from self-cleaning surfaces to advanced adhesives inspired by gecko feet are finding applications in everyday items. The growing consumer awareness of eco-friendly and sustainable products is further boosting the demand for biomimetic materials in this sector.

The market for biomimetic materials synthesized using calorimetry techniques is particularly promising. Calorimetry allows for precise control and monitoring of the synthesis process, enabling the creation of materials with tailored properties. This level of control is crucial for developing high-performance biomimetic materials that can meet the stringent requirements of various industries.

Geographically, North America and Europe currently lead the biomimetic materials market, owing to their strong research infrastructure and technological advancements. However, the Asia-Pacific region is expected to witness the fastest growth, driven by increasing industrialization, government initiatives, and rising investment in research and development activities.

Despite the positive outlook, the market faces challenges such as high development costs and the complexity of scaling up production processes. Overcoming these hurdles will be crucial for the widespread adoption of biomimetic materials across industries. As research continues to advance and manufacturing techniques improve, the market is expected to expand further, offering innovative solutions to complex engineering and design challenges.

In the healthcare industry, biomimetic materials are gaining traction for tissue engineering, drug delivery systems, and medical implants. The ability to create materials that closely resemble natural tissues and organs has opened new possibilities for regenerative medicine and personalized healthcare solutions. This sector represents a substantial portion of the market, with continued investment in research and development fueling further growth.

The aerospace and automotive industries are also key drivers of the biomimetic materials market. These sectors are increasingly adopting biomimetic materials for their lightweight properties, enhanced strength, and improved fuel efficiency. Materials inspired by natural structures, such as shark skin or lotus leaves, are being developed to reduce drag and improve aerodynamics in aircraft and vehicles.

Consumer goods and electronics represent another significant market segment for biomimetic materials. Products ranging from self-cleaning surfaces to advanced adhesives inspired by gecko feet are finding applications in everyday items. The growing consumer awareness of eco-friendly and sustainable products is further boosting the demand for biomimetic materials in this sector.

The market for biomimetic materials synthesized using calorimetry techniques is particularly promising. Calorimetry allows for precise control and monitoring of the synthesis process, enabling the creation of materials with tailored properties. This level of control is crucial for developing high-performance biomimetic materials that can meet the stringent requirements of various industries.

Geographically, North America and Europe currently lead the biomimetic materials market, owing to their strong research infrastructure and technological advancements. However, the Asia-Pacific region is expected to witness the fastest growth, driven by increasing industrialization, government initiatives, and rising investment in research and development activities.

Despite the positive outlook, the market faces challenges such as high development costs and the complexity of scaling up production processes. Overcoming these hurdles will be crucial for the widespread adoption of biomimetic materials across industries. As research continues to advance and manufacturing techniques improve, the market is expected to expand further, offering innovative solutions to complex engineering and design challenges.

Current Calorimetry Techniques in Biomimetics

Calorimetry techniques play a crucial role in the field of biomimetic material synthesis, offering valuable insights into the thermodynamic properties and processes involved. Current calorimetry methods employed in biomimetics can be broadly categorized into three main types: isothermal titration calorimetry (ITC), differential scanning calorimetry (DSC), and microcalorimetry.

Isothermal titration calorimetry is widely used to study biomolecular interactions and binding processes. In biomimetic material synthesis, ITC provides quantitative information on the thermodynamics of molecular recognition events, such as protein-ligand binding or the assembly of supramolecular structures. This technique allows researchers to determine binding affinities, stoichiometry, and thermodynamic parameters like enthalpy and entropy changes.

Differential scanning calorimetry is another powerful tool in biomimetic research, particularly for investigating phase transitions and conformational changes in materials. DSC measures the heat capacity of a sample as a function of temperature, enabling the characterization of thermal properties such as melting points, glass transitions, and crystallization behaviors. In biomimetic material synthesis, DSC is invaluable for studying the thermal stability of biomolecules and the formation of self-assembled structures.

Microcalorimetry techniques, including isothermal microcalorimetry and flow microcalorimetry, offer high sensitivity for measuring small heat changes in biological and biomimetic systems. These methods are particularly useful for monitoring slow processes or reactions with low heat outputs, such as enzyme kinetics or the formation of biomineralized structures. Microcalorimetry allows researchers to study the energetics of biomimetic processes in real-time and under near-physiological conditions.

Recent advancements in calorimetry instrumentation have led to the development of nanocalorimetry techniques, which enable measurements on extremely small sample volumes. This innovation has opened up new possibilities for studying biomimetic processes at the nanoscale, such as the formation of nanostructured materials or the behavior of individual biomolecules.

In addition to these established techniques, researchers are exploring novel calorimetry approaches tailored to biomimetic applications. For instance, the integration of calorimetry with other analytical methods, such as spectroscopy or microscopy, allows for simultaneous measurement of thermal and structural properties. These hyphenated techniques provide a more comprehensive understanding of biomimetic processes and material properties.

Isothermal titration calorimetry is widely used to study biomolecular interactions and binding processes. In biomimetic material synthesis, ITC provides quantitative information on the thermodynamics of molecular recognition events, such as protein-ligand binding or the assembly of supramolecular structures. This technique allows researchers to determine binding affinities, stoichiometry, and thermodynamic parameters like enthalpy and entropy changes.

Differential scanning calorimetry is another powerful tool in biomimetic research, particularly for investigating phase transitions and conformational changes in materials. DSC measures the heat capacity of a sample as a function of temperature, enabling the characterization of thermal properties such as melting points, glass transitions, and crystallization behaviors. In biomimetic material synthesis, DSC is invaluable for studying the thermal stability of biomolecules and the formation of self-assembled structures.

Microcalorimetry techniques, including isothermal microcalorimetry and flow microcalorimetry, offer high sensitivity for measuring small heat changes in biological and biomimetic systems. These methods are particularly useful for monitoring slow processes or reactions with low heat outputs, such as enzyme kinetics or the formation of biomineralized structures. Microcalorimetry allows researchers to study the energetics of biomimetic processes in real-time and under near-physiological conditions.

Recent advancements in calorimetry instrumentation have led to the development of nanocalorimetry techniques, which enable measurements on extremely small sample volumes. This innovation has opened up new possibilities for studying biomimetic processes at the nanoscale, such as the formation of nanostructured materials or the behavior of individual biomolecules.

In addition to these established techniques, researchers are exploring novel calorimetry approaches tailored to biomimetic applications. For instance, the integration of calorimetry with other analytical methods, such as spectroscopy or microscopy, allows for simultaneous measurement of thermal and structural properties. These hyphenated techniques provide a more comprehensive understanding of biomimetic processes and material properties.

Existing Calorimetric Methods for Biomimetics

01 Calorimetry devices and methods

Various devices and methods for calorimetry measurements are developed, including improvements in calorimeter design, heat flow measurement techniques, and temperature control systems. These advancements aim to enhance the accuracy and efficiency of calorimetric analysis in different applications.- Calorimetry measurement devices: Various devices and instruments are designed for calorimetry measurements, including calorimeters and thermal analysis equipment. These devices are used to measure heat transfer, thermal properties, and energy changes in chemical reactions or physical processes. They often incorporate temperature sensors, heat flow meters, and specialized chambers for sample analysis.

- Calorimetry in medical applications: Calorimetry techniques are applied in medical fields for diagnostics, metabolic studies, and patient monitoring. These methods can measure heat production in the human body, assess metabolic rates, and analyze physiological processes. Medical calorimetry devices may be integrated into respiratory systems or wearable technologies for continuous monitoring.

- Calorimetry in material science and chemistry: Calorimetry plays a crucial role in material science and chemistry for characterizing substances, studying phase transitions, and analyzing chemical reactions. Techniques such as differential scanning calorimetry (DSC) and isothermal titration calorimetry (ITC) are used to investigate thermal properties, reaction kinetics, and thermodynamic parameters of various materials and chemical systems.

- Advanced calorimetry data analysis and modeling: Modern calorimetry incorporates advanced data analysis techniques and computational modeling to interpret complex thermal data. This includes the development of algorithms for signal processing, pattern recognition, and machine learning approaches to extract meaningful information from calorimetric measurements. These methods enhance the accuracy and reliability of calorimetry results across various applications.

- Miniaturized and portable calorimetry systems: Advancements in technology have led to the development of miniaturized and portable calorimetry systems. These compact devices enable on-site measurements, real-time monitoring, and field applications of calorimetry. Miniaturized calorimeters often utilize microfluidic technologies, MEMS sensors, and integrated electronic systems to achieve high sensitivity and portability.

02 Calorimetry in medical applications

Calorimetry techniques are applied in medical fields for diagnostics, metabolic rate measurements, and patient monitoring. These applications involve specialized calorimeters designed for use in clinical settings, providing valuable data for healthcare professionals.Expand Specific Solutions03 Micro-calorimetry and nanoscale measurements

Advancements in micro-calorimetry and nanoscale measurement techniques allow for highly sensitive thermal analysis of small samples or processes. These developments enable the study of minute energy changes in various scientific and industrial applications.Expand Specific Solutions04 Calorimetry in material science and chemical analysis

Calorimetry plays a crucial role in material science and chemical analysis, providing insights into material properties, reaction kinetics, and thermodynamic processes. Specialized calorimeters and methods are developed to study various materials and chemical reactions.Expand Specific Solutions05 Automated and high-throughput calorimetry systems

Development of automated and high-throughput calorimetry systems enables rapid and efficient thermal analysis of multiple samples. These systems incorporate advanced robotics, data processing, and control mechanisms to streamline calorimetric measurements in research and industrial settings.Expand Specific Solutions

Key Players in Biomimetic Calorimetry

The field of calorimetry in biomimetic material synthesis is in a growth phase, with increasing market size and technological advancements. The global market for biomimetic materials is projected to expand significantly in the coming years, driven by applications in various sectors. While the technology is maturing, it still offers substantial room for innovation. Key players like Northeastern University, Palo Alto Research Center, and California Institute of Technology are at the forefront of research and development in this area. These institutions, along with companies like Xerox and Malvern Panalytical, are contributing to the advancement of calorimetric techniques in biomimetic synthesis, pushing the boundaries of material science and engineering.

California Institute of Technology

Technical Solution: California Institute of Technology (Caltech) has developed advanced calorimetry techniques for biomimetic material synthesis. Their approach utilizes isothermal titration calorimetry (ITC) to study the thermodynamics of biomineralization processes[1]. This method allows for precise measurement of heat changes during molecular interactions, providing insights into the energetics of biomimetic material formation. Caltech researchers have applied this technique to investigate the formation of calcium carbonate structures inspired by marine organisms[2]. By analyzing the heat released or absorbed during different stages of mineral growth, they can optimize conditions for synthesizing materials with desired properties. Additionally, Caltech has combined calorimetry with in situ atomic force microscopy to observe real-time changes in crystal morphology during biomimetic synthesis[3], enabling a deeper understanding of the relationship between energy changes and structural development in biomimetic materials.

Strengths: High precision in measuring thermodynamic parameters; integration with complementary techniques for comprehensive analysis. Weaknesses: Complex data interpretation; limited to studying processes with measurable heat changes.

President & Fellows of Harvard College

Technical Solution: Harvard University has pioneered the use of differential scanning calorimetry (DSC) in biomimetic material synthesis. Their approach focuses on understanding the phase transitions and thermal behavior of biomimetic polymers and composites[4]. Harvard researchers have developed a method to use DSC data to guide the design of temperature-responsive biomimetic hydrogels that mimic the behavior of natural tissues[5]. By analyzing the heat flow during heating and cooling cycles, they can determine the optimal composition and processing conditions for materials with specific thermal properties. Harvard has also applied calorimetry to study the self-assembly of peptide-based biomimetic materials, using the technique to investigate the energetics of nanostructure formation[6]. This has led to the development of novel biomaterials for tissue engineering and drug delivery applications. Furthermore, Harvard scientists have combined calorimetry with spectroscopic techniques to correlate thermal events with structural changes in biomimetic systems[7], providing a more comprehensive understanding of material behavior.

Strengths: Versatile application across various biomimetic systems; ability to inform material design and processing. Weaknesses: Primarily focused on thermal properties; may overlook other important aspects of biomimetic synthesis.

Innovative Calorimetry Approaches in Biomimetics

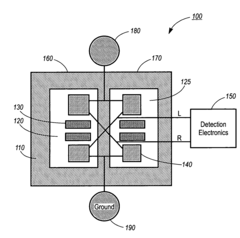

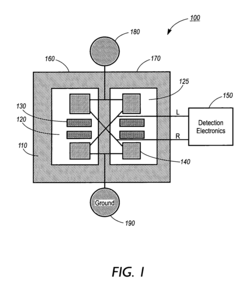

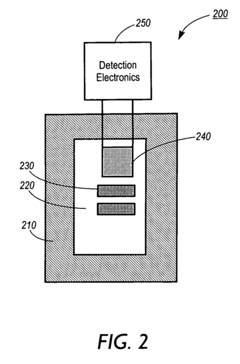

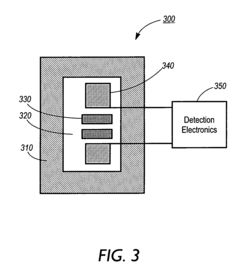

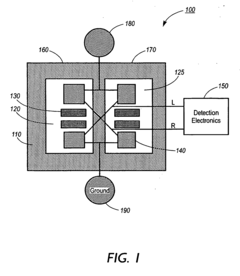

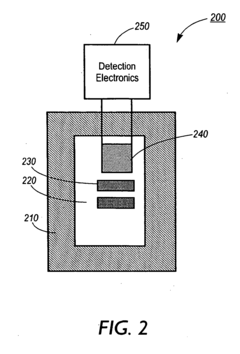

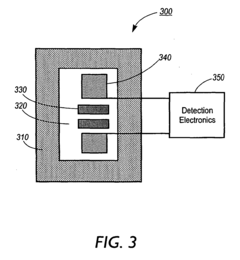

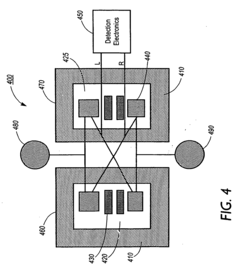

Method for a nanocalorimeter for detecting chemical reactions

PatentInactiveUS7727768B2

Innovation

- A nanocalorimeter system with thermal isolation and equilibration regions that allows for the measurement of enthalpic changes in small sample sizes by merging drops of potentially reactive chemical solutions, using resistive thermometers to detect heat changes, and integrating with detection electronics for high-throughput screening.

Nanocalorimeter apparatus and method for detecting chemical reactions

PatentInactiveEP1351052B1

Innovation

- A nanocalorimeter array with thermal isolation regions and drop merging electrodes allows for the measurement of chemical reactions at low concentrations by merging small drops of potentially reactive solutions and detecting thermal changes, enabling efficient detection of chemical interactions with minimal sample usage.

Environmental Impact of Biomimetic Synthesis

The environmental impact of biomimetic synthesis in the context of calorimetry applications is a crucial aspect to consider as this field continues to advance. Biomimetic material synthesis, inspired by natural processes, often aims to replicate the efficiency and sustainability found in nature. However, it is essential to evaluate the environmental implications of these synthetic processes.

One of the primary environmental benefits of biomimetic synthesis is the potential for reduced energy consumption. By mimicking natural processes that occur at ambient temperatures and pressures, biomimetic approaches can significantly decrease the energy requirements compared to traditional synthetic methods. This reduction in energy usage translates to lower greenhouse gas emissions and a smaller carbon footprint associated with material production.

Furthermore, biomimetic synthesis often employs water-based systems and environmentally benign solvents, aligning with green chemistry principles. This approach minimizes the use of harmful organic solvents and reduces the generation of toxic waste products. Consequently, the environmental impact of waste disposal and potential contamination of water sources is substantially mitigated.

The use of renewable and biodegradable raw materials in biomimetic synthesis contributes to resource conservation and sustainability. Many biomimetic processes utilize abundant natural materials or waste products from other industries, promoting a circular economy approach. This not only reduces the demand for finite resources but also addresses waste management challenges.

However, it is important to note that not all biomimetic synthesis processes are inherently environmentally friendly. Some may require specialized precursors or catalysts that have their own environmental footprint. Additionally, the scalability of certain biomimetic processes may present challenges in terms of resource consumption and waste generation when implemented at an industrial scale.

Life cycle assessments (LCAs) of biomimetic synthesis processes are crucial for comprehensively evaluating their environmental impact. These assessments consider factors such as raw material extraction, energy consumption, waste generation, and end-of-life disposal. By conducting thorough LCAs, researchers and industry professionals can identify areas for improvement and optimize the environmental performance of biomimetic synthesis methods.

As the field of biomimetic material synthesis continues to evolve, there is a growing emphasis on developing processes that not only mimic natural systems but also actively contribute to environmental remediation. Some innovative approaches aim to incorporate waste materials or pollutants as precursors in the synthesis process, effectively turning environmental challenges into opportunities for sustainable material production.

One of the primary environmental benefits of biomimetic synthesis is the potential for reduced energy consumption. By mimicking natural processes that occur at ambient temperatures and pressures, biomimetic approaches can significantly decrease the energy requirements compared to traditional synthetic methods. This reduction in energy usage translates to lower greenhouse gas emissions and a smaller carbon footprint associated with material production.

Furthermore, biomimetic synthesis often employs water-based systems and environmentally benign solvents, aligning with green chemistry principles. This approach minimizes the use of harmful organic solvents and reduces the generation of toxic waste products. Consequently, the environmental impact of waste disposal and potential contamination of water sources is substantially mitigated.

The use of renewable and biodegradable raw materials in biomimetic synthesis contributes to resource conservation and sustainability. Many biomimetic processes utilize abundant natural materials or waste products from other industries, promoting a circular economy approach. This not only reduces the demand for finite resources but also addresses waste management challenges.

However, it is important to note that not all biomimetic synthesis processes are inherently environmentally friendly. Some may require specialized precursors or catalysts that have their own environmental footprint. Additionally, the scalability of certain biomimetic processes may present challenges in terms of resource consumption and waste generation when implemented at an industrial scale.

Life cycle assessments (LCAs) of biomimetic synthesis processes are crucial for comprehensively evaluating their environmental impact. These assessments consider factors such as raw material extraction, energy consumption, waste generation, and end-of-life disposal. By conducting thorough LCAs, researchers and industry professionals can identify areas for improvement and optimize the environmental performance of biomimetic synthesis methods.

As the field of biomimetic material synthesis continues to evolve, there is a growing emphasis on developing processes that not only mimic natural systems but also actively contribute to environmental remediation. Some innovative approaches aim to incorporate waste materials or pollutants as precursors in the synthesis process, effectively turning environmental challenges into opportunities for sustainable material production.

Scalability of Calorimetry-Based Biomimetic Processes

The scalability of calorimetry-based biomimetic processes is a critical factor in determining their potential for industrial applications and large-scale production of biomimetic materials. As research in this field progresses, several key aspects have emerged that influence the ability to scale up these processes effectively.

One of the primary challenges in scaling calorimetry-based biomimetic processes is maintaining precise temperature control and measurement accuracy across larger volumes. Laboratory-scale calorimeters typically work with small sample sizes, but industrial applications require processing much larger quantities of materials. Engineers and researchers are developing innovative solutions to address this issue, such as modular calorimetry systems and advanced heat flow modeling techniques.

Another important consideration is the energy efficiency of scaled-up processes. While calorimetry provides valuable insights into the energetics of biomimetic material synthesis, the energy requirements for maintaining temperature control in large-scale operations can be substantial. Efforts are underway to optimize heat transfer and recovery systems to minimize energy consumption and improve overall process efficiency.

The integration of calorimetry-based processes with other manufacturing techniques is also crucial for successful scalability. Researchers are exploring ways to combine calorimetry with continuous flow reactors, 3D printing technologies, and other advanced manufacturing methods to create more efficient and versatile production systems for biomimetic materials.

Scalability also depends on the availability and cost of raw materials used in biomimetic synthesis. As production volumes increase, ensuring a stable and economically viable supply chain for these materials becomes increasingly important. This has led to research into alternative precursors and more sustainable sourcing strategies for bio-inspired materials.

Regulatory considerations play a significant role in the scalability of calorimetry-based biomimetic processes, particularly for applications in fields such as healthcare and food production. Ensuring compliance with safety and quality standards across larger production scales requires careful process validation and quality control measures.

In conclusion, while challenges exist, ongoing research and technological advancements are steadily improving the scalability of calorimetry-based biomimetic processes. As these hurdles are overcome, the potential for widespread industrial adoption of these techniques for producing advanced biomimetic materials continues to grow.

One of the primary challenges in scaling calorimetry-based biomimetic processes is maintaining precise temperature control and measurement accuracy across larger volumes. Laboratory-scale calorimeters typically work with small sample sizes, but industrial applications require processing much larger quantities of materials. Engineers and researchers are developing innovative solutions to address this issue, such as modular calorimetry systems and advanced heat flow modeling techniques.

Another important consideration is the energy efficiency of scaled-up processes. While calorimetry provides valuable insights into the energetics of biomimetic material synthesis, the energy requirements for maintaining temperature control in large-scale operations can be substantial. Efforts are underway to optimize heat transfer and recovery systems to minimize energy consumption and improve overall process efficiency.

The integration of calorimetry-based processes with other manufacturing techniques is also crucial for successful scalability. Researchers are exploring ways to combine calorimetry with continuous flow reactors, 3D printing technologies, and other advanced manufacturing methods to create more efficient and versatile production systems for biomimetic materials.

Scalability also depends on the availability and cost of raw materials used in biomimetic synthesis. As production volumes increase, ensuring a stable and economically viable supply chain for these materials becomes increasingly important. This has led to research into alternative precursors and more sustainable sourcing strategies for bio-inspired materials.

Regulatory considerations play a significant role in the scalability of calorimetry-based biomimetic processes, particularly for applications in fields such as healthcare and food production. Ensuring compliance with safety and quality standards across larger production scales requires careful process validation and quality control measures.

In conclusion, while challenges exist, ongoing research and technological advancements are steadily improving the scalability of calorimetry-based biomimetic processes. As these hurdles are overcome, the potential for widespread industrial adoption of these techniques for producing advanced biomimetic materials continues to grow.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!