How Calorimetry Aids in Developing Sustainable Concrete

AUG 5, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Calorimetry in Concrete: Background and Objectives

Calorimetry has emerged as a crucial tool in the development of sustainable concrete, marking a significant advancement in the construction industry's efforts to reduce its environmental impact. The evolution of calorimetry in concrete research spans several decades, with its roots tracing back to the mid-20th century when researchers began exploring heat evolution patterns in cement hydration.

The primary objective of employing calorimetry in concrete development is to gain a comprehensive understanding of the complex chemical reactions that occur during cement hydration. This knowledge is instrumental in optimizing concrete mixtures, enhancing durability, and ultimately creating more sustainable construction materials. By precisely measuring the heat released during these reactions, researchers can assess the rate and extent of hydration, providing valuable insights into the concrete's setting and hardening processes.

In recent years, the focus has shifted towards leveraging calorimetry to develop eco-friendly concrete formulations. This aligns with the global push for sustainable construction practices and the urgent need to reduce the carbon footprint of the cement and concrete industry, which accounts for approximately 8% of global CO2 emissions. Calorimetry aids in this endeavor by enabling the evaluation of alternative cementitious materials and supplementary cementitious materials (SCMs) that can partially replace traditional Portland cement.

The technological progression in calorimetry equipment has been remarkable, transitioning from simple adiabatic calorimeters to sophisticated isothermal and semi-adiabatic calorimeters. These advancements have significantly improved the accuracy and reliability of heat measurements, allowing researchers to detect subtle changes in hydration kinetics caused by different concrete compositions or admixtures.

One of the key objectives in utilizing calorimetry for sustainable concrete development is to optimize the use of industrial by-products and waste materials as SCMs. Materials such as fly ash, ground granulated blast furnace slag, and silica fume can be incorporated into concrete mixtures to reduce the cement content while maintaining or even improving performance characteristics. Calorimetry plays a vital role in understanding how these materials interact with cement and affect the overall hydration process.

Furthermore, calorimetry is instrumental in developing low-carbon cements and novel binder systems. By providing real-time data on heat evolution, it allows researchers to fine-tune formulations and assess the effectiveness of various activators and accelerators. This is particularly crucial in the development of alkali-activated materials and geopolymers, which are considered promising alternatives to traditional Portland cement-based concrete.

As we look towards the future, the integration of calorimetry with other advanced analytical techniques, such as X-ray diffraction and thermogravimetric analysis, is expected to provide even more comprehensive insights into concrete behavior. This holistic approach will be essential in addressing the multifaceted challenges of creating truly sustainable concrete solutions that meet the demanding performance requirements of modern construction while minimizing environmental impact.

The primary objective of employing calorimetry in concrete development is to gain a comprehensive understanding of the complex chemical reactions that occur during cement hydration. This knowledge is instrumental in optimizing concrete mixtures, enhancing durability, and ultimately creating more sustainable construction materials. By precisely measuring the heat released during these reactions, researchers can assess the rate and extent of hydration, providing valuable insights into the concrete's setting and hardening processes.

In recent years, the focus has shifted towards leveraging calorimetry to develop eco-friendly concrete formulations. This aligns with the global push for sustainable construction practices and the urgent need to reduce the carbon footprint of the cement and concrete industry, which accounts for approximately 8% of global CO2 emissions. Calorimetry aids in this endeavor by enabling the evaluation of alternative cementitious materials and supplementary cementitious materials (SCMs) that can partially replace traditional Portland cement.

The technological progression in calorimetry equipment has been remarkable, transitioning from simple adiabatic calorimeters to sophisticated isothermal and semi-adiabatic calorimeters. These advancements have significantly improved the accuracy and reliability of heat measurements, allowing researchers to detect subtle changes in hydration kinetics caused by different concrete compositions or admixtures.

One of the key objectives in utilizing calorimetry for sustainable concrete development is to optimize the use of industrial by-products and waste materials as SCMs. Materials such as fly ash, ground granulated blast furnace slag, and silica fume can be incorporated into concrete mixtures to reduce the cement content while maintaining or even improving performance characteristics. Calorimetry plays a vital role in understanding how these materials interact with cement and affect the overall hydration process.

Furthermore, calorimetry is instrumental in developing low-carbon cements and novel binder systems. By providing real-time data on heat evolution, it allows researchers to fine-tune formulations and assess the effectiveness of various activators and accelerators. This is particularly crucial in the development of alkali-activated materials and geopolymers, which are considered promising alternatives to traditional Portland cement-based concrete.

As we look towards the future, the integration of calorimetry with other advanced analytical techniques, such as X-ray diffraction and thermogravimetric analysis, is expected to provide even more comprehensive insights into concrete behavior. This holistic approach will be essential in addressing the multifaceted challenges of creating truly sustainable concrete solutions that meet the demanding performance requirements of modern construction while minimizing environmental impact.

Market Demand for Sustainable Concrete Solutions

The global construction industry is experiencing a significant shift towards sustainable practices, driven by increasing environmental concerns and regulatory pressures. This has created a robust market demand for sustainable concrete solutions, with calorimetry playing a crucial role in their development. The market for green building materials, including sustainable concrete, is projected to reach $523 billion by 2026, growing at a CAGR of 11.8% from 2021 to 2026.

Sustainable concrete solutions are gaining traction due to their potential to reduce the carbon footprint of construction projects. Traditional concrete production accounts for approximately 8% of global CO2 emissions, making it a prime target for sustainability efforts. The demand for sustainable concrete is particularly strong in developed countries, where stringent environmental regulations and green building certifications are driving adoption.

Calorimetry aids in developing sustainable concrete by enabling precise measurements of heat evolution during cement hydration. This information is crucial for optimizing concrete mixtures, reducing cement content, and incorporating supplementary cementitious materials (SCMs) such as fly ash, slag, and silica fume. The use of SCMs can significantly reduce the environmental impact of concrete while maintaining or even improving its performance characteristics.

The construction industry's focus on lifecycle assessment (LCA) and embodied carbon has further boosted the demand for sustainable concrete solutions. Developers, architects, and engineers are increasingly specifying low-carbon concrete mixes in their projects to meet sustainability goals and achieve green building certifications such as LEED, BREEAM, and Green Star.

Government initiatives and policies promoting sustainable construction practices have also contributed to the growing market demand. For instance, the European Union's Circular Economy Action Plan and the United States' proposed Low Embodied Carbon Concrete Leadership Act are creating favorable conditions for the adoption of sustainable concrete solutions.

The COVID-19 pandemic has paradoxically accelerated the shift towards sustainable construction materials, as governments worldwide focus on green recovery plans. This trend is expected to continue, with sustainable concrete playing a pivotal role in rebuilding efforts and infrastructure development projects.

As the demand for sustainable concrete solutions continues to rise, calorimetry's role in their development becomes increasingly critical. The technology enables manufacturers to create innovative, low-carbon concrete formulations that meet both performance and sustainability requirements, positioning it as an essential tool in addressing the market's evolving needs.

Sustainable concrete solutions are gaining traction due to their potential to reduce the carbon footprint of construction projects. Traditional concrete production accounts for approximately 8% of global CO2 emissions, making it a prime target for sustainability efforts. The demand for sustainable concrete is particularly strong in developed countries, where stringent environmental regulations and green building certifications are driving adoption.

Calorimetry aids in developing sustainable concrete by enabling precise measurements of heat evolution during cement hydration. This information is crucial for optimizing concrete mixtures, reducing cement content, and incorporating supplementary cementitious materials (SCMs) such as fly ash, slag, and silica fume. The use of SCMs can significantly reduce the environmental impact of concrete while maintaining or even improving its performance characteristics.

The construction industry's focus on lifecycle assessment (LCA) and embodied carbon has further boosted the demand for sustainable concrete solutions. Developers, architects, and engineers are increasingly specifying low-carbon concrete mixes in their projects to meet sustainability goals and achieve green building certifications such as LEED, BREEAM, and Green Star.

Government initiatives and policies promoting sustainable construction practices have also contributed to the growing market demand. For instance, the European Union's Circular Economy Action Plan and the United States' proposed Low Embodied Carbon Concrete Leadership Act are creating favorable conditions for the adoption of sustainable concrete solutions.

The COVID-19 pandemic has paradoxically accelerated the shift towards sustainable construction materials, as governments worldwide focus on green recovery plans. This trend is expected to continue, with sustainable concrete playing a pivotal role in rebuilding efforts and infrastructure development projects.

As the demand for sustainable concrete solutions continues to rise, calorimetry's role in their development becomes increasingly critical. The technology enables manufacturers to create innovative, low-carbon concrete formulations that meet both performance and sustainability requirements, positioning it as an essential tool in addressing the market's evolving needs.

Current State of Calorimetry in Concrete Research

Calorimetry has become an indispensable tool in concrete research, offering valuable insights into the complex chemical reactions that occur during cement hydration. The current state of calorimetry in concrete research is characterized by advanced technologies and methodologies that enable researchers to precisely measure heat evolution during the setting and hardening processes of concrete mixtures.

Isothermal conduction calorimetry is widely used in the field, allowing for the continuous monitoring of heat release over time. This technique provides detailed information about the kinetics of cement hydration, enabling researchers to optimize concrete mix designs and evaluate the effects of various additives and supplementary cementitious materials on the hydration process.

Differential scanning calorimetry (DSC) is another prominent method employed in concrete research. DSC allows for the investigation of phase transitions and thermal properties of cementitious materials, providing crucial data on the formation of hydration products and the development of microstructures within the concrete matrix.

Advancements in calorimetric instrumentation have led to improved sensitivity and accuracy in measurements. Modern calorimeters can detect subtle changes in heat flow, enabling researchers to study the early stages of hydration and identify critical points in the setting process with unprecedented precision.

The integration of calorimetry with other analytical techniques has expanded its capabilities in concrete research. For instance, combining calorimetry with X-ray diffraction or nuclear magnetic resonance spectroscopy allows for a more comprehensive understanding of the chemical and physical changes occurring during cement hydration.

Researchers are increasingly utilizing calorimetry to investigate the effects of alternative binders and recycled materials on concrete performance. This application is particularly relevant in the development of sustainable concrete, as it helps assess the compatibility and reactivity of various waste materials and industrial by-products used as cement replacements.

Calorimetric studies are also being employed to evaluate the influence of admixtures on concrete properties. By monitoring heat evolution patterns, researchers can optimize dosages of superplasticizers, accelerators, and retarders to achieve desired workability and setting characteristics while minimizing negative impacts on long-term strength and durability.

The current state of calorimetry in concrete research is marked by a shift towards high-throughput screening methods. These approaches allow for the rapid evaluation of multiple concrete formulations, accelerating the development of innovative and sustainable concrete mixtures. Such advancements are crucial in addressing the growing demand for eco-friendly construction materials and practices.

Isothermal conduction calorimetry is widely used in the field, allowing for the continuous monitoring of heat release over time. This technique provides detailed information about the kinetics of cement hydration, enabling researchers to optimize concrete mix designs and evaluate the effects of various additives and supplementary cementitious materials on the hydration process.

Differential scanning calorimetry (DSC) is another prominent method employed in concrete research. DSC allows for the investigation of phase transitions and thermal properties of cementitious materials, providing crucial data on the formation of hydration products and the development of microstructures within the concrete matrix.

Advancements in calorimetric instrumentation have led to improved sensitivity and accuracy in measurements. Modern calorimeters can detect subtle changes in heat flow, enabling researchers to study the early stages of hydration and identify critical points in the setting process with unprecedented precision.

The integration of calorimetry with other analytical techniques has expanded its capabilities in concrete research. For instance, combining calorimetry with X-ray diffraction or nuclear magnetic resonance spectroscopy allows for a more comprehensive understanding of the chemical and physical changes occurring during cement hydration.

Researchers are increasingly utilizing calorimetry to investigate the effects of alternative binders and recycled materials on concrete performance. This application is particularly relevant in the development of sustainable concrete, as it helps assess the compatibility and reactivity of various waste materials and industrial by-products used as cement replacements.

Calorimetric studies are also being employed to evaluate the influence of admixtures on concrete properties. By monitoring heat evolution patterns, researchers can optimize dosages of superplasticizers, accelerators, and retarders to achieve desired workability and setting characteristics while minimizing negative impacts on long-term strength and durability.

The current state of calorimetry in concrete research is marked by a shift towards high-throughput screening methods. These approaches allow for the rapid evaluation of multiple concrete formulations, accelerating the development of innovative and sustainable concrete mixtures. Such advancements are crucial in addressing the growing demand for eco-friendly construction materials and practices.

Existing Calorimetric Methods for Concrete Analysis

01 Energy-efficient calorimetry systems

Development of calorimetry systems that optimize energy consumption and reduce waste. These systems incorporate advanced sensors, improved insulation, and smart control mechanisms to enhance efficiency and minimize environmental impact. The focus is on creating sustainable laboratory practices while maintaining accurate measurements.- Energy-efficient calorimetry systems: Development of calorimetry systems that optimize energy consumption and reduce waste heat. These systems incorporate advanced insulation materials, heat recovery mechanisms, and smart temperature control algorithms to minimize energy loss and improve overall efficiency in calorimetric measurements.

- Sustainable materials in calorimeter construction: Utilization of eco-friendly and recyclable materials in the manufacturing of calorimeters and related equipment. This approach focuses on reducing the environmental impact of calorimetry instruments throughout their lifecycle, from production to disposal, while maintaining high performance and accuracy.

- Integration of renewable energy sources: Incorporation of renewable energy sources, such as solar or wind power, to operate calorimetry systems. This innovation aims to reduce reliance on non-renewable energy sources and decrease the carbon footprint associated with calorimetric research and applications.

- Data-driven optimization for sustainable calorimetry: Implementation of advanced data analytics and machine learning algorithms to optimize calorimetry processes. These techniques enable more efficient experimental design, reduce the number of required measurements, and minimize resource consumption while maintaining or improving the quality of results.

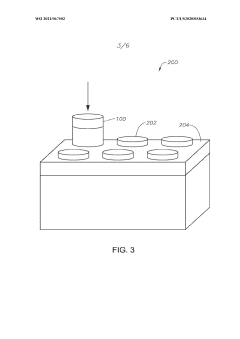

- Miniaturization and portability in calorimetry: Development of compact and portable calorimetry devices that require fewer resources and consume less energy. These innovations enable on-site measurements, reduce transportation needs, and allow for more efficient use of laboratory space, contributing to overall sustainability in calorimetric research and applications.

02 Sustainable materials in calorimeter construction

Utilization of eco-friendly and recyclable materials in the manufacturing of calorimeters. This approach aims to reduce the carbon footprint of calorimetry equipment throughout its lifecycle. Innovations include the use of biodegradable components and materials with lower environmental impact, without compromising the accuracy and reliability of measurements.Expand Specific Solutions03 Integration of renewable energy sources

Incorporation of renewable energy sources to power calorimetry systems. This includes the use of solar panels, wind turbines, or other clean energy technologies to operate calorimeters and associated equipment. The integration aims to reduce reliance on non-renewable energy sources and promote sustainability in laboratory operations.Expand Specific Solutions04 Data-driven optimization for sustainable calorimetry

Implementation of advanced data analytics and machine learning algorithms to optimize calorimetry processes. These systems analyze historical data and real-time measurements to improve efficiency, reduce resource consumption, and minimize waste. The approach enables more sustainable laboratory practices through intelligent resource management and predictive maintenance.Expand Specific Solutions05 Circular economy principles in calorimetry

Application of circular economy concepts to calorimetry equipment and processes. This includes designing calorimeters for easy disassembly and recycling, implementing take-back programs for used equipment, and exploring ways to repurpose or upcycle components. The goal is to minimize waste and maximize resource efficiency throughout the lifecycle of calorimetry systems.Expand Specific Solutions

Key Players in Concrete Calorimetry Technology

The development of sustainable concrete through calorimetry is in an emerging phase, with growing market potential due to increasing environmental concerns. The technology's maturity varies among key players, with established companies like Saudi Arabian Oil Co. and Solidia Technologies leading research efforts. Newer entrants such as Giatec Scientific are introducing innovative IoT and AI-based solutions for concrete testing. Academic institutions, including Southeast University and Wuhan University of Technology, are contributing significantly to advancing the field. The competitive landscape is diverse, featuring collaborations between industry giants, startups, and research institutions, driving progress in sustainable concrete development.

Solidia Technologies, Inc.

Technical Solution: Solidia Technologies has developed a sustainable concrete production process that uses CO2 curing instead of water. Their patented technology employs calorimetry to optimize the curing process and monitor heat evolution during carbonation. This allows for precise control of the reaction kinetics, resulting in reduced curing times and improved product quality. The company's calorimetric approach enables real-time monitoring of the exothermic carbonation reaction, allowing for adjustments to CO2 exposure and curing conditions to achieve optimal strength development and reduced carbon footprint [1][3]. Solidia's process can reduce the carbon footprint of concrete by up to 70% compared to traditional Portland cement concrete.

Strengths: Significantly reduced carbon footprint, faster curing times, and improved product consistency. Weaknesses: Requires specialized equipment and may have higher initial implementation costs.

Giatec Scientific, Inc.

Technical Solution: Giatec Scientific has developed SmartRock, a wireless concrete sensor that utilizes calorimetry principles to monitor concrete curing in real-time. The sensor measures temperature changes within the concrete, which correlates with strength development. By analyzing the heat of hydration curve, SmartRock can predict concrete strength without the need for destructive testing. This technology allows for optimized curing processes, reduced energy consumption, and improved quality control. Giatec's approach integrates calorimetric data with machine learning algorithms to provide accurate strength predictions and maturity calculations, enabling more sustainable concrete practices through reduced overdesign and optimized mix proportions [2][4].

Strengths: Non-destructive testing, real-time monitoring, and data-driven optimization of concrete mixes. Weaknesses: Requires initial investment in sensors and software infrastructure.

Innovative Calorimetry Applications in Concrete Sustainability

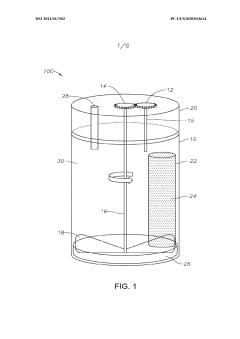

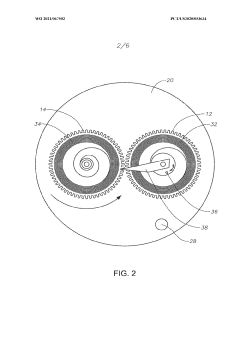

Systems and methods for high temperature, high pressure isothermal calorimetry

PatentWO2021067502A1

Innovation

- A modified ampoule design with a steel lid containing a manually wound mainspring to store mechanical energy for in-situ mixing and stirring of cement and water at high temperatures and pressures, using a glass container for water to prevent cross-heating and ensure uniform mixing.

Method of developing sustainable concrete incorporating coal bottom ash to mitigate carbon footprints.

PatentPendingIN202211071423A

Innovation

- Utilization of coal fly ash as a binder instead of cement to create more environmentally friendly and durable concrete.

- Incorporation of coal bottom ash (CBA) in various types of concrete, including standard, lightweight, self-compacting, and ultra-high-performance concrete.

- Development of an inorganic polymer network using calcium-aluminate-silicate-hydrate molecules, resulting in a more durable concrete compared to traditional cement-based concrete.

Environmental Impact Assessment of Concrete Production

The environmental impact of concrete production is a critical concern in the construction industry, given the material's widespread use and significant carbon footprint. Calorimetry plays a crucial role in assessing and mitigating these impacts by providing valuable insights into the heat generation and chemical reactions during concrete production and curing processes.

One of the primary environmental concerns associated with concrete production is the high energy consumption and carbon dioxide emissions from cement manufacturing. Calorimetry aids in optimizing cement formulations by measuring the heat released during hydration reactions. This information allows researchers to develop more efficient cement blends that require less energy to produce and emit fewer greenhouse gases.

Furthermore, calorimetry enables the evaluation of alternative cementitious materials and supplementary cementitious materials (SCMs) such as fly ash, slag, and silica fume. By analyzing the heat evolution patterns of these materials, researchers can determine their effectiveness in partially replacing traditional cement, thereby reducing the overall environmental impact of concrete production.

The use of calorimetry also contributes to the development of more durable concrete mixtures. By understanding the heat generation and curing processes, engineers can optimize mix designs to enhance long-term performance and reduce the need for frequent repairs or replacements. This increased durability translates to reduced resource consumption and lower environmental impact over the lifecycle of concrete structures.

Additionally, calorimetry aids in assessing the environmental impact of various concrete admixtures and additives. By measuring the heat of hydration in the presence of these substances, researchers can evaluate their effects on cement reactivity and overall concrete performance. This knowledge helps in selecting environmentally friendly additives that improve concrete properties without compromising sustainability goals.

Calorimetry also plays a role in developing low-carbon concrete technologies. By providing detailed information on reaction kinetics and heat evolution, it supports the creation of novel binders and alternative cement formulations that have a lower environmental footprint. This includes geopolymer concretes and other innovative materials that aim to reduce the reliance on traditional Portland cement.

In the context of waste management and circular economy principles, calorimetry assists in evaluating the potential of recycled materials in concrete production. By analyzing the heat generation patterns of concrete mixtures incorporating recycled aggregates or industrial by-products, researchers can optimize their use while maintaining the desired concrete properties. This approach helps reduce landfill waste and promotes the efficient use of resources in the construction industry.

One of the primary environmental concerns associated with concrete production is the high energy consumption and carbon dioxide emissions from cement manufacturing. Calorimetry aids in optimizing cement formulations by measuring the heat released during hydration reactions. This information allows researchers to develop more efficient cement blends that require less energy to produce and emit fewer greenhouse gases.

Furthermore, calorimetry enables the evaluation of alternative cementitious materials and supplementary cementitious materials (SCMs) such as fly ash, slag, and silica fume. By analyzing the heat evolution patterns of these materials, researchers can determine their effectiveness in partially replacing traditional cement, thereby reducing the overall environmental impact of concrete production.

The use of calorimetry also contributes to the development of more durable concrete mixtures. By understanding the heat generation and curing processes, engineers can optimize mix designs to enhance long-term performance and reduce the need for frequent repairs or replacements. This increased durability translates to reduced resource consumption and lower environmental impact over the lifecycle of concrete structures.

Additionally, calorimetry aids in assessing the environmental impact of various concrete admixtures and additives. By measuring the heat of hydration in the presence of these substances, researchers can evaluate their effects on cement reactivity and overall concrete performance. This knowledge helps in selecting environmentally friendly additives that improve concrete properties without compromising sustainability goals.

Calorimetry also plays a role in developing low-carbon concrete technologies. By providing detailed information on reaction kinetics and heat evolution, it supports the creation of novel binders and alternative cement formulations that have a lower environmental footprint. This includes geopolymer concretes and other innovative materials that aim to reduce the reliance on traditional Portland cement.

In the context of waste management and circular economy principles, calorimetry assists in evaluating the potential of recycled materials in concrete production. By analyzing the heat generation patterns of concrete mixtures incorporating recycled aggregates or industrial by-products, researchers can optimize their use while maintaining the desired concrete properties. This approach helps reduce landfill waste and promotes the efficient use of resources in the construction industry.

Regulatory Framework for Sustainable Construction Materials

The regulatory framework for sustainable construction materials plays a crucial role in shaping the development and adoption of eco-friendly concrete solutions. As governments and international organizations increasingly prioritize environmental sustainability, a complex web of regulations, standards, and guidelines has emerged to govern the use of sustainable materials in the construction industry.

At the international level, organizations such as the International Organization for Standardization (ISO) have developed standards like ISO 21930, which provides guidelines for environmental product declarations of construction products. These standards help establish a common language for assessing and communicating the environmental impact of construction materials, including sustainable concrete.

In the European Union, the Construction Products Regulation (CPR) sets out harmonized rules for the marketing of construction products, including requirements for sustainability and environmental performance. The EU has also introduced initiatives like the European Green Deal, which aims to make Europe climate-neutral by 2050 and includes provisions for sustainable construction practices.

In the United States, the Environmental Protection Agency (EPA) has established guidelines for the use of recycled materials in concrete, while the U.S. Green Building Council's LEED certification program incentivizes the use of sustainable construction materials. Individual states have also implemented their own regulations, such as California's Green Building Standards Code (CALGreen), which mandates the use of low-impact materials in construction projects.

Many countries have developed national standards for sustainable concrete, such as the German Sustainable Building Council's (DGNB) certification system or the UK's BRE Environmental Assessment Method (BREEAM). These standards often incorporate lifecycle assessment methodologies to evaluate the environmental impact of construction materials from cradle to grave.

The regulatory landscape also includes industry-led initiatives, such as the Concrete Sustainability Council's certification system, which provides a global responsible sourcing scheme for concrete. These voluntary standards often complement and sometimes exceed governmental regulations, driving innovation in sustainable concrete development.

As calorimetry becomes an increasingly important tool in developing sustainable concrete, regulators are beginning to incorporate its use into testing and certification processes. For instance, some jurisdictions now require calorimetric data as part of the documentation for approving new concrete mixtures, particularly those claiming enhanced sustainability characteristics.

The evolving regulatory framework presents both challenges and opportunities for the concrete industry. While compliance with these regulations can be complex and costly, it also drives innovation and creates market demand for sustainable solutions. As calorimetry continues to demonstrate its value in developing and validating sustainable concrete formulations, it is likely to become an integral part of future regulatory requirements and industry standards.

At the international level, organizations such as the International Organization for Standardization (ISO) have developed standards like ISO 21930, which provides guidelines for environmental product declarations of construction products. These standards help establish a common language for assessing and communicating the environmental impact of construction materials, including sustainable concrete.

In the European Union, the Construction Products Regulation (CPR) sets out harmonized rules for the marketing of construction products, including requirements for sustainability and environmental performance. The EU has also introduced initiatives like the European Green Deal, which aims to make Europe climate-neutral by 2050 and includes provisions for sustainable construction practices.

In the United States, the Environmental Protection Agency (EPA) has established guidelines for the use of recycled materials in concrete, while the U.S. Green Building Council's LEED certification program incentivizes the use of sustainable construction materials. Individual states have also implemented their own regulations, such as California's Green Building Standards Code (CALGreen), which mandates the use of low-impact materials in construction projects.

Many countries have developed national standards for sustainable concrete, such as the German Sustainable Building Council's (DGNB) certification system or the UK's BRE Environmental Assessment Method (BREEAM). These standards often incorporate lifecycle assessment methodologies to evaluate the environmental impact of construction materials from cradle to grave.

The regulatory landscape also includes industry-led initiatives, such as the Concrete Sustainability Council's certification system, which provides a global responsible sourcing scheme for concrete. These voluntary standards often complement and sometimes exceed governmental regulations, driving innovation in sustainable concrete development.

As calorimetry becomes an increasingly important tool in developing sustainable concrete, regulators are beginning to incorporate its use into testing and certification processes. For instance, some jurisdictions now require calorimetric data as part of the documentation for approving new concrete mixtures, particularly those claiming enhanced sustainability characteristics.

The evolving regulatory framework presents both challenges and opportunities for the concrete industry. While compliance with these regulations can be complex and costly, it also drives innovation and creates market demand for sustainable solutions. As calorimetry continues to demonstrate its value in developing and validating sustainable concrete formulations, it is likely to become an integral part of future regulatory requirements and industry standards.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!