The Role of Calorimetry in Efficient Water Treatment Processes

AUG 5, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Calorimetry in Water Treatment: Background and Objectives

Calorimetry, the science of measuring heat transfer during physical and chemical processes, has emerged as a crucial tool in the field of water treatment. The application of calorimetric techniques in water purification processes has a rich history dating back to the early 20th century. As water scarcity and pollution have become increasingly pressing global issues, the need for efficient and sustainable water treatment methods has grown exponentially.

The evolution of calorimetry in water treatment has been marked by significant technological advancements. Early applications primarily focused on basic thermal measurements to monitor treatment processes. However, as the complexity of water contaminants increased, so did the sophistication of calorimetric techniques. The development of high-precision calorimeters and the integration of computer-aided data analysis have revolutionized the field, enabling more accurate and real-time monitoring of treatment processes.

In recent years, the water treatment industry has witnessed a paradigm shift towards more energy-efficient and environmentally friendly solutions. This trend has further amplified the importance of calorimetry in optimizing treatment processes. By providing detailed insights into the energetics of various treatment steps, calorimetric methods have become instrumental in designing more efficient systems that minimize energy consumption and maximize contaminant removal.

The primary objective of incorporating calorimetry in water treatment is to enhance the overall efficiency and effectiveness of purification processes. This encompasses several key goals, including the reduction of energy consumption, improvement of treatment efficacy, and development of more sustainable practices. Calorimetric techniques enable researchers and engineers to gain a deeper understanding of the thermodynamic aspects of water treatment, leading to innovative solutions for persistent challenges in the field.

One of the critical aims is to utilize calorimetry for real-time monitoring and control of treatment processes. By continuously measuring heat changes during various stages of water purification, operators can make informed decisions to optimize system performance. This not only improves the quality of treated water but also contributes to significant energy savings and operational cost reductions.

Furthermore, calorimetry plays a vital role in the development of novel treatment technologies. As researchers explore advanced oxidation processes, membrane filtration techniques, and biological treatment methods, calorimetric data provide invaluable insights into the underlying mechanisms. This knowledge is crucial for scaling up laboratory findings to industrial applications and for fine-tuning existing technologies to meet increasingly stringent water quality standards.

In the broader context of global sustainability goals, the application of calorimetry in water treatment aligns with the United Nations Sustainable Development Goals, particularly those related to clean water and sanitation, and responsible consumption and production. By enabling more efficient use of resources and reducing the environmental impact of water treatment processes, calorimetry contributes to the creation of more sustainable urban and industrial water management systems.

The evolution of calorimetry in water treatment has been marked by significant technological advancements. Early applications primarily focused on basic thermal measurements to monitor treatment processes. However, as the complexity of water contaminants increased, so did the sophistication of calorimetric techniques. The development of high-precision calorimeters and the integration of computer-aided data analysis have revolutionized the field, enabling more accurate and real-time monitoring of treatment processes.

In recent years, the water treatment industry has witnessed a paradigm shift towards more energy-efficient and environmentally friendly solutions. This trend has further amplified the importance of calorimetry in optimizing treatment processes. By providing detailed insights into the energetics of various treatment steps, calorimetric methods have become instrumental in designing more efficient systems that minimize energy consumption and maximize contaminant removal.

The primary objective of incorporating calorimetry in water treatment is to enhance the overall efficiency and effectiveness of purification processes. This encompasses several key goals, including the reduction of energy consumption, improvement of treatment efficacy, and development of more sustainable practices. Calorimetric techniques enable researchers and engineers to gain a deeper understanding of the thermodynamic aspects of water treatment, leading to innovative solutions for persistent challenges in the field.

One of the critical aims is to utilize calorimetry for real-time monitoring and control of treatment processes. By continuously measuring heat changes during various stages of water purification, operators can make informed decisions to optimize system performance. This not only improves the quality of treated water but also contributes to significant energy savings and operational cost reductions.

Furthermore, calorimetry plays a vital role in the development of novel treatment technologies. As researchers explore advanced oxidation processes, membrane filtration techniques, and biological treatment methods, calorimetric data provide invaluable insights into the underlying mechanisms. This knowledge is crucial for scaling up laboratory findings to industrial applications and for fine-tuning existing technologies to meet increasingly stringent water quality standards.

In the broader context of global sustainability goals, the application of calorimetry in water treatment aligns with the United Nations Sustainable Development Goals, particularly those related to clean water and sanitation, and responsible consumption and production. By enabling more efficient use of resources and reducing the environmental impact of water treatment processes, calorimetry contributes to the creation of more sustainable urban and industrial water management systems.

Market Analysis for Calorimetry-Based Water Treatment

The market for calorimetry-based water treatment technologies is experiencing significant growth, driven by increasing global water scarcity and the need for more efficient and sustainable treatment methods. This market segment is part of the broader water treatment industry, which is projected to reach substantial value in the coming years due to rising environmental concerns and stringent regulations.

Calorimetry-based water treatment processes offer unique advantages in terms of energy efficiency and process optimization, making them particularly attractive in industrial and municipal water treatment applications. The technology's ability to precisely measure and control heat transfer during treatment processes allows for more accurate monitoring and adjustment of chemical reactions, leading to improved treatment outcomes and reduced operational costs.

In the industrial sector, calorimetry-based water treatment solutions are gaining traction in industries such as pharmaceuticals, food and beverage, and chemical manufacturing. These industries require high-purity water for their processes and are increasingly adopting advanced treatment technologies to meet stringent quality standards while minimizing energy consumption.

The municipal water treatment sector is also showing growing interest in calorimetry-based solutions, particularly in regions facing water stress and stricter environmental regulations. The technology's potential to optimize disinfection processes, reduce chemical usage, and improve overall treatment efficiency aligns well with the goals of many municipal water authorities seeking to upgrade their infrastructure.

Geographically, North America and Europe are currently leading the adoption of calorimetry-based water treatment technologies, owing to their well-established water treatment infrastructure and strong focus on innovation. However, rapid industrialization and urbanization in Asia-Pacific countries, particularly China and India, are creating significant market opportunities for these advanced treatment solutions.

The market is characterized by a mix of established water treatment companies and specialized technology providers. Key players are investing in research and development to enhance the capabilities of calorimetry-based systems and expand their application range. Collaborations between technology developers and water treatment plant operators are becoming more common, driving further innovation and market growth.

Despite the promising outlook, challenges such as high initial investment costs and the need for specialized expertise in implementing and operating calorimetry-based systems may hinder widespread adoption, particularly in smaller municipalities and developing regions. However, as the technology matures and its benefits become more widely recognized, these barriers are expected to diminish.

Calorimetry-based water treatment processes offer unique advantages in terms of energy efficiency and process optimization, making them particularly attractive in industrial and municipal water treatment applications. The technology's ability to precisely measure and control heat transfer during treatment processes allows for more accurate monitoring and adjustment of chemical reactions, leading to improved treatment outcomes and reduced operational costs.

In the industrial sector, calorimetry-based water treatment solutions are gaining traction in industries such as pharmaceuticals, food and beverage, and chemical manufacturing. These industries require high-purity water for their processes and are increasingly adopting advanced treatment technologies to meet stringent quality standards while minimizing energy consumption.

The municipal water treatment sector is also showing growing interest in calorimetry-based solutions, particularly in regions facing water stress and stricter environmental regulations. The technology's potential to optimize disinfection processes, reduce chemical usage, and improve overall treatment efficiency aligns well with the goals of many municipal water authorities seeking to upgrade their infrastructure.

Geographically, North America and Europe are currently leading the adoption of calorimetry-based water treatment technologies, owing to their well-established water treatment infrastructure and strong focus on innovation. However, rapid industrialization and urbanization in Asia-Pacific countries, particularly China and India, are creating significant market opportunities for these advanced treatment solutions.

The market is characterized by a mix of established water treatment companies and specialized technology providers. Key players are investing in research and development to enhance the capabilities of calorimetry-based systems and expand their application range. Collaborations between technology developers and water treatment plant operators are becoming more common, driving further innovation and market growth.

Despite the promising outlook, challenges such as high initial investment costs and the need for specialized expertise in implementing and operating calorimetry-based systems may hinder widespread adoption, particularly in smaller municipalities and developing regions. However, as the technology matures and its benefits become more widely recognized, these barriers are expected to diminish.

Current Challenges in Calorimetric Water Treatment

Calorimetric water treatment processes face several significant challenges that hinder their widespread adoption and efficiency. One of the primary obstacles is the high energy consumption associated with heating large volumes of water. This energy-intensive nature of calorimetric treatments often leads to increased operational costs and reduced sustainability, making it less attractive for large-scale applications.

Another challenge lies in the precise control of temperature throughout the treatment process. Maintaining uniform heat distribution in large water bodies is technically demanding and often requires sophisticated equipment and monitoring systems. Fluctuations in temperature can lead to inconsistent treatment results, potentially compromising the effectiveness of pathogen inactivation or contaminant removal.

The scalability of calorimetric water treatment systems presents another hurdle. While effective on a small scale, scaling up these processes for municipal or industrial use introduces complexities in system design and operation. Larger systems may face issues with heat loss, thermal efficiency, and the need for more robust infrastructure, all of which can impact the overall performance and cost-effectiveness of the treatment process.

Furthermore, the effectiveness of calorimetric treatments can vary depending on the specific contaminants present in the water. While heat treatment is generally effective against many pathogens, it may be less efficient in removing certain chemical pollutants or dissolved solids. This limitation necessitates the integration of additional treatment methods, potentially complicating the overall process and increasing costs.

The environmental impact of calorimetric water treatment is also a growing concern. The high energy requirements often translate to increased carbon emissions, especially if the energy source is not renewable. This aspect challenges the sustainability credentials of the technology, particularly in an era where environmental considerations are paramount in water treatment solutions.

Lastly, the capital investment required for implementing advanced calorimetric systems can be substantial. The need for specialized heating equipment, insulation, and control systems can make the initial setup costs prohibitive for many water treatment facilities, especially in developing regions where water treatment infrastructure is most needed.

These challenges collectively highlight the need for innovative approaches in calorimetric water treatment. Future developments in this field must focus on enhancing energy efficiency, improving temperature control mechanisms, and developing more cost-effective and environmentally friendly heating methods to overcome these current limitations.

Another challenge lies in the precise control of temperature throughout the treatment process. Maintaining uniform heat distribution in large water bodies is technically demanding and often requires sophisticated equipment and monitoring systems. Fluctuations in temperature can lead to inconsistent treatment results, potentially compromising the effectiveness of pathogen inactivation or contaminant removal.

The scalability of calorimetric water treatment systems presents another hurdle. While effective on a small scale, scaling up these processes for municipal or industrial use introduces complexities in system design and operation. Larger systems may face issues with heat loss, thermal efficiency, and the need for more robust infrastructure, all of which can impact the overall performance and cost-effectiveness of the treatment process.

Furthermore, the effectiveness of calorimetric treatments can vary depending on the specific contaminants present in the water. While heat treatment is generally effective against many pathogens, it may be less efficient in removing certain chemical pollutants or dissolved solids. This limitation necessitates the integration of additional treatment methods, potentially complicating the overall process and increasing costs.

The environmental impact of calorimetric water treatment is also a growing concern. The high energy requirements often translate to increased carbon emissions, especially if the energy source is not renewable. This aspect challenges the sustainability credentials of the technology, particularly in an era where environmental considerations are paramount in water treatment solutions.

Lastly, the capital investment required for implementing advanced calorimetric systems can be substantial. The need for specialized heating equipment, insulation, and control systems can make the initial setup costs prohibitive for many water treatment facilities, especially in developing regions where water treatment infrastructure is most needed.

These challenges collectively highlight the need for innovative approaches in calorimetric water treatment. Future developments in this field must focus on enhancing energy efficiency, improving temperature control mechanisms, and developing more cost-effective and environmentally friendly heating methods to overcome these current limitations.

Existing Calorimetric Water Treatment Solutions

01 Improved calorimeter design for enhanced efficiency

Advanced calorimeter designs incorporate features to improve measurement accuracy and efficiency. These may include optimized heat flow paths, improved insulation, and precise temperature control mechanisms. Such designs aim to minimize heat loss and increase sensitivity, resulting in more accurate and efficient calorimetric measurements.- Improved calorimeter design for enhanced efficiency: Advanced calorimeter designs incorporate features to improve measurement accuracy and efficiency. These may include optimized heat flow paths, improved insulation, and precise temperature control mechanisms. Such designs aim to minimize heat loss and increase sensitivity, resulting in more accurate and efficient calorimetric measurements.

- Integration of advanced sensors and data analysis: Modern calorimetry systems utilize advanced sensors and sophisticated data analysis techniques to enhance efficiency. This may involve the use of high-precision temperature sensors, real-time data processing algorithms, and machine learning approaches for improved data interpretation and analysis, leading to faster and more accurate results.

- Miniaturization and automation of calorimetry systems: The development of miniaturized and automated calorimetry systems has significantly improved efficiency in terms of sample size, throughput, and ease of use. These systems often incorporate microfluidic technologies, automated sample handling, and integrated analysis tools, allowing for rapid and high-throughput measurements with minimal sample volumes.

- Novel calorimetry techniques for specific applications: Specialized calorimetry techniques have been developed to address specific applications, enhancing efficiency in particular fields. These may include differential scanning calorimetry, isothermal titration calorimetry, or flow calorimetry, each optimized for certain types of measurements or sample characteristics, leading to improved efficiency in their respective domains.

- Integration of calorimetry with other analytical methods: Combining calorimetry with complementary analytical techniques has led to increased efficiency in comprehensive sample analysis. This integration may involve coupling calorimeters with spectroscopic methods, chromatography, or other analytical tools, allowing for simultaneous multi-parameter measurements and more efficient data collection and interpretation.

02 Integration of advanced sensors and data analysis

Modern calorimetry systems utilize advanced sensors and sophisticated data analysis techniques to enhance efficiency. This may include the use of high-precision temperature sensors, real-time data processing algorithms, and machine learning approaches for data interpretation. These advancements allow for faster, more accurate measurements and improved overall system performance.Expand Specific Solutions03 Miniaturization and portability of calorimetry devices

The development of miniaturized and portable calorimetry devices has led to increased efficiency in various applications. These compact systems often utilize microfluidic technologies and integrated circuit designs to achieve high-performance measurements in a smaller form factor. This allows for on-site analysis and improved accessibility in fields such as medical diagnostics and environmental monitoring.Expand Specific Solutions04 Automation and robotics in calorimetry

The integration of automation and robotics in calorimetry systems has significantly improved efficiency by reducing human error and increasing throughput. Automated sample handling, preparation, and measurement processes allow for continuous operation and higher sample volumes. This approach is particularly beneficial in high-throughput screening applications and industrial quality control.Expand Specific Solutions05 Novel materials and methods for enhanced heat transfer

Research into novel materials and methods for improved heat transfer has led to advancements in calorimetry efficiency. This includes the development of high-conductivity materials for calorimeter construction, innovative heat sink designs, and the use of phase-change materials for improved thermal management. These approaches contribute to more sensitive and responsive calorimetric measurements.Expand Specific Solutions

Key Players in Calorimetric Water Treatment Industry

The calorimetry market in efficient water treatment processes is in a growth phase, driven by increasing demand for advanced water treatment solutions. The market size is expanding due to rising environmental concerns and stringent regulations. Technologically, the field is advancing rapidly, with key players like Northeastern University, LECO Corp., and The Charles Stark Draper Laboratory leading research and development efforts. Companies such as Saudi Arabian Oil Co. and The Boeing Co. are investing in calorimetry applications for water treatment, indicating its growing importance in industrial processes. Academic institutions like California Institute of Technology and McGill University are contributing to technological advancements, fostering innovation in this sector.

Saudi Arabian Oil Co.

Technical Solution: Saudi Aramco has integrated calorimetry into its water treatment processes for oil and gas operations. The company has developed a high-pressure, high-temperature calorimetric system for studying the thermodynamics of scale formation in produced water treatment[11]. This has led to more effective scale inhibition strategies and reduced operational costs. Aramco has also implemented online calorimetric monitoring in its desalination plants to optimize energy consumption and detect early signs of membrane scaling[12]. Additionally, the company has pioneered the use of calorimetry in conjunction with electrochemical techniques to enhance the efficiency of electrocoagulation processes for oily wastewater treatment[13].

Strengths: Advanced scale formation prevention, optimized desalination processes, and improved electrocoagulation efficiency. Weaknesses: Technologies primarily focused on oil and gas industry applications, potentially limiting broader water treatment applications.

The University of Manchester

Technical Solution: The University of Manchester has made significant advancements in applying calorimetry to water treatment processes. Their research team has developed a novel differential scanning calorimetry (DSC) technique for characterizing the thermal properties of water treatment residuals, which has led to more efficient dewatering and disposal methods[8]. The university has also pioneered the use of isothermal microcalorimetry for studying the kinetics of adsorption processes in water treatment, enabling more precise design of adsorbent materials and treatment systems[9]. Furthermore, they have developed a calorimetric method for real-time monitoring of membrane fouling in water treatment plants, allowing for optimized cleaning cycles and extended membrane life[10].

Strengths: Advanced characterization of treatment residuals, improved adsorbent design, and innovative membrane fouling monitoring. Weaknesses: Some techniques may be too specialized for widespread adoption in municipal water treatment plants.

Core Innovations in Calorimetric Water Treatment

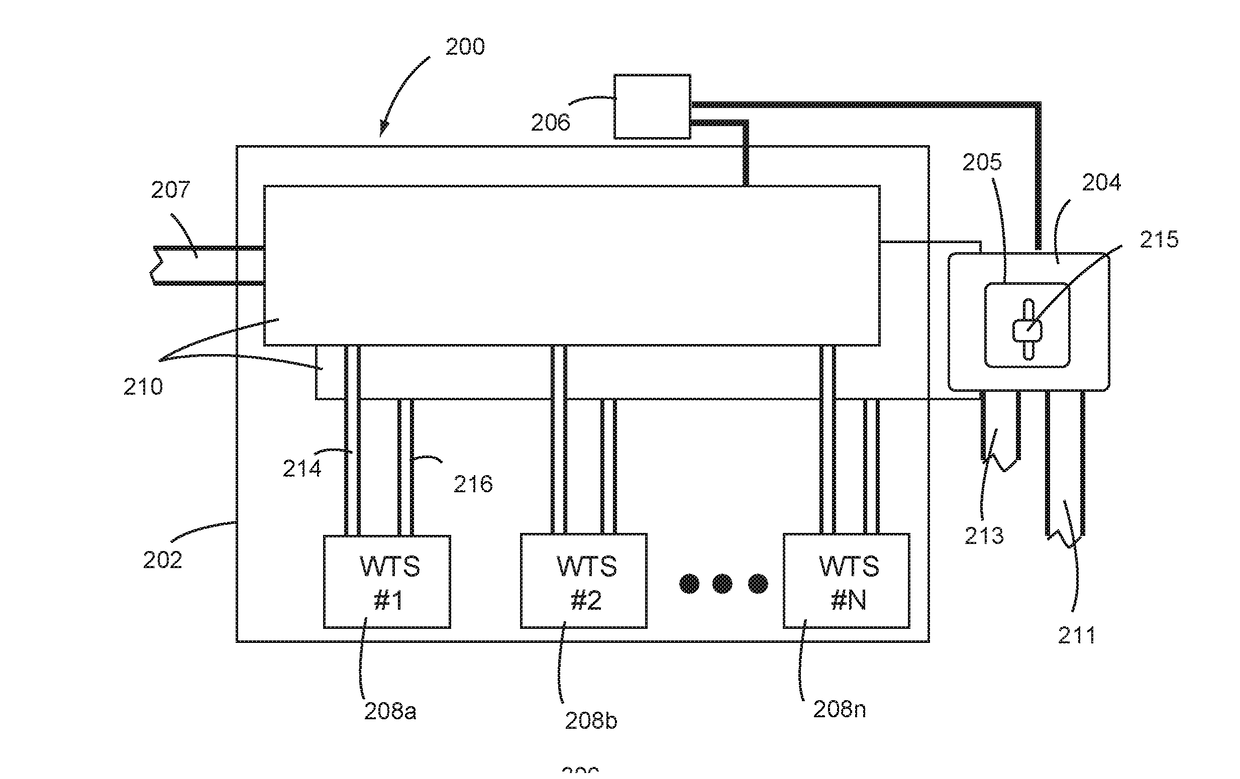

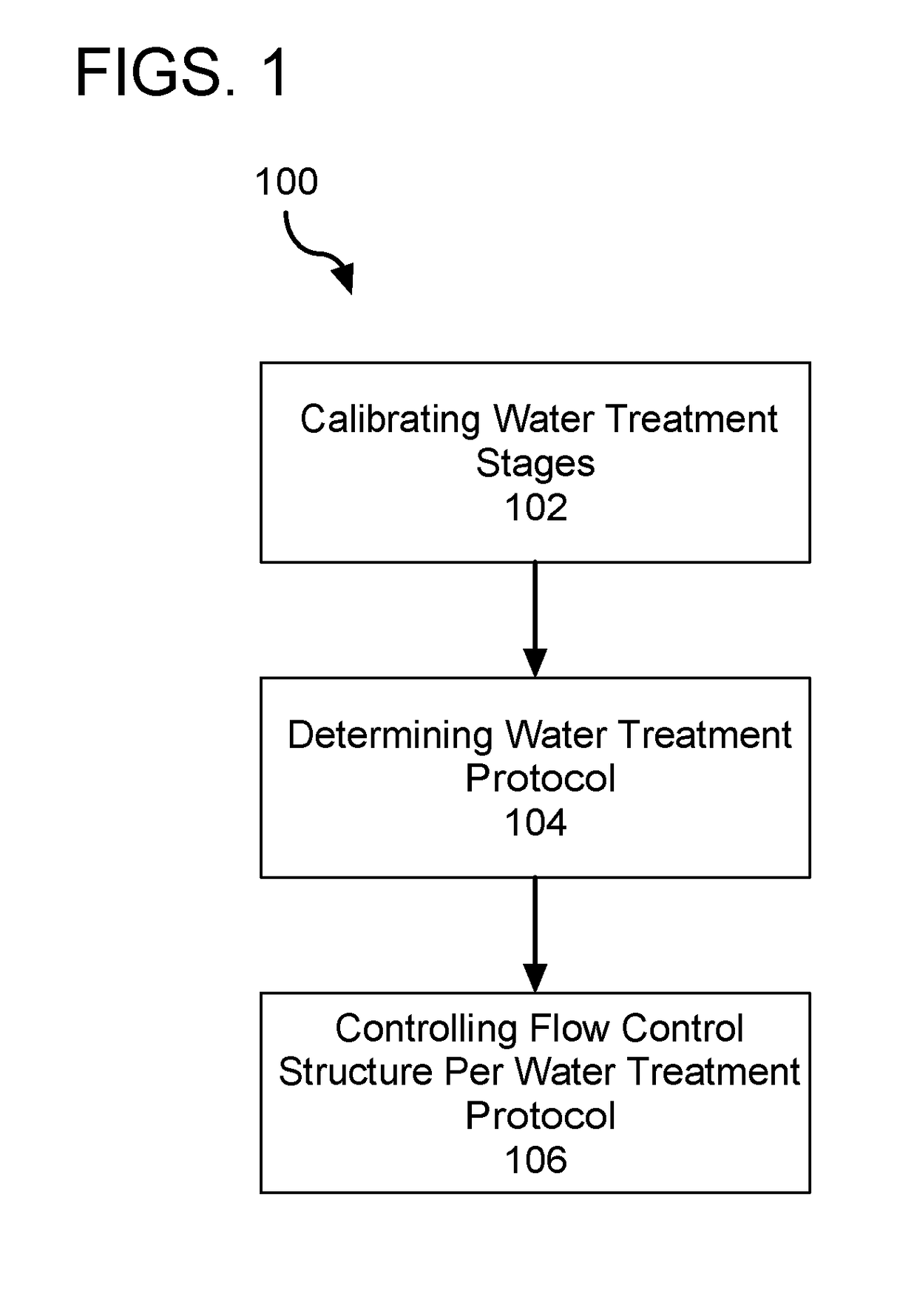

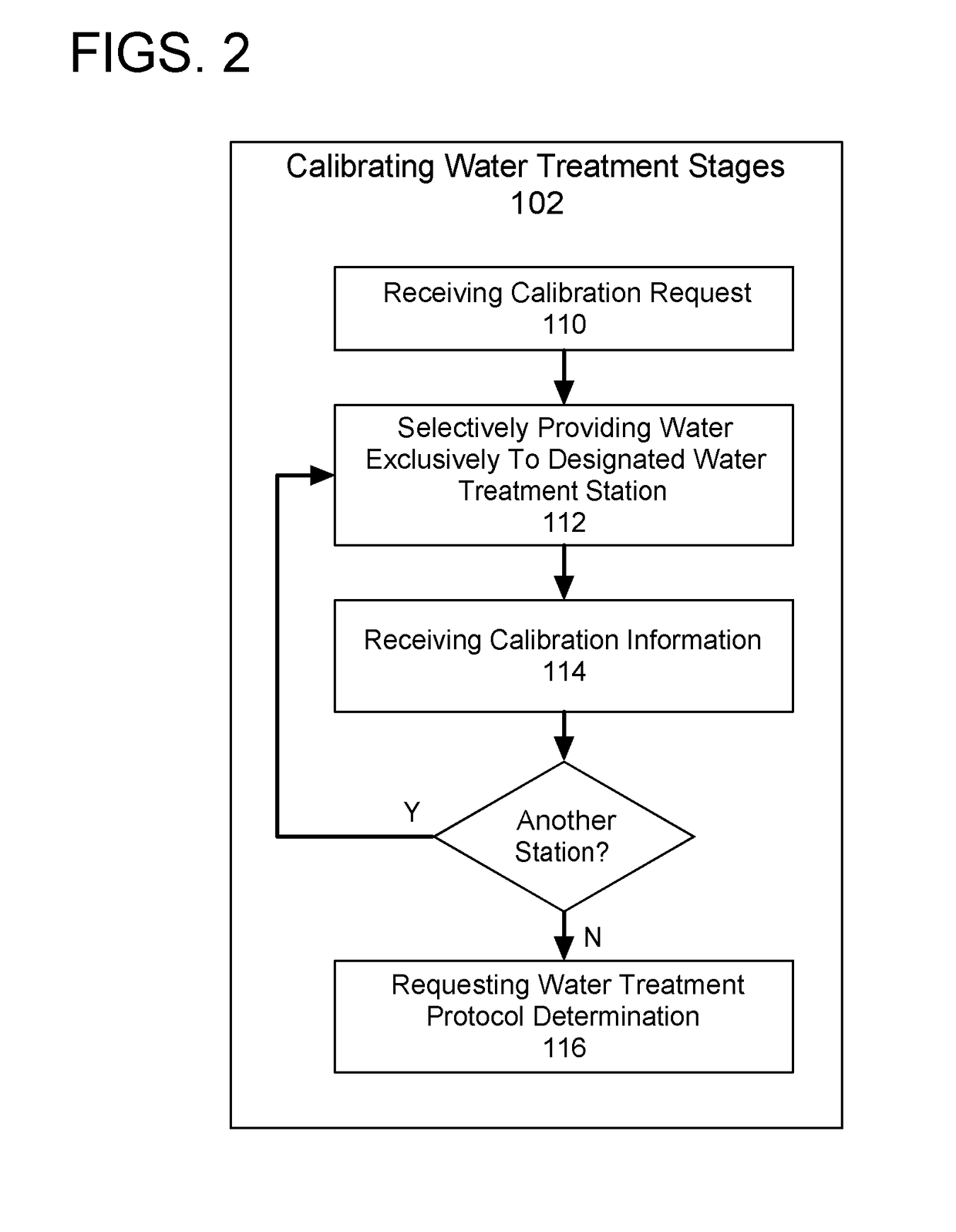

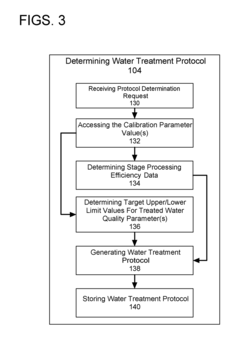

Water treatment method and system providing partial dynamic by-pass of water treatment stages

PatentInactiveUS20170305759A1

Innovation

- Implementing a dynamic bypass system that monitors water quality parameters to adjust treatment stages, allowing partial bypass and recombination of treated and untreated water, thereby conserving power, extending system uptime, and reducing consumable usage.

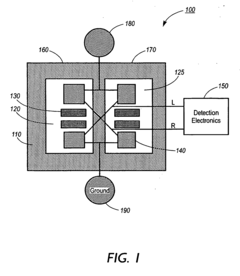

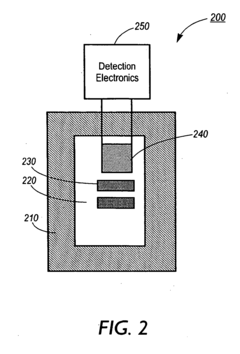

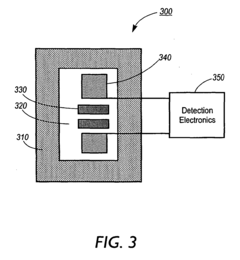

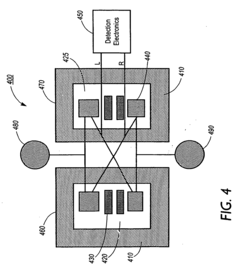

Nanocalorimeter apparatus and method for detecting chemical reactions

PatentInactiveEP1351052B1

Innovation

- A nanocalorimeter array with thermal isolation regions and drop merging electrodes allows for the measurement of chemical reactions at low concentrations by merging small drops of potentially reactive solutions and detecting thermal changes, enabling efficient detection of chemical interactions with minimal sample usage.

Environmental Impact of Calorimetric Water Treatment

Calorimetric water treatment processes have significant environmental implications that warrant careful consideration. These methods, which leverage heat-based techniques for water purification, offer both advantages and challenges from an ecological perspective.

One of the primary environmental benefits of calorimetric water treatment is its potential to reduce chemical usage in water purification. Traditional water treatment often relies heavily on chemical additives, which can have downstream effects on aquatic ecosystems. By utilizing heat-based processes, calorimetric methods can potentially decrease the reliance on these chemicals, thereby minimizing the introduction of artificial compounds into water bodies.

However, the energy requirements of calorimetric water treatment processes present a notable environmental concern. The heating and cooling cycles inherent in these methods can be energy-intensive, potentially leading to increased greenhouse gas emissions if the energy source is not renewable. This aspect underscores the importance of coupling calorimetric water treatment with sustainable energy solutions to truly realize its environmental benefits.

The impact on water quality is another crucial consideration. While calorimetric methods can effectively remove certain contaminants, they may also alter the mineral composition of the treated water. This could have implications for the ecological balance of water bodies receiving the treated effluent, potentially affecting aquatic life and biodiversity.

From a resource conservation standpoint, calorimetric water treatment shows promise. These processes can be designed to recover heat and energy, improving overall efficiency and reducing waste. Additionally, some calorimetric methods may enable the recovery of valuable minerals and compounds from wastewater, contributing to circular economy principles and resource sustainability.

The scalability of calorimetric water treatment also influences its environmental impact. Large-scale implementations could lead to significant reductions in water pollution on a regional or even national level. However, the infrastructure required for such large-scale operations must be carefully planned to minimize land use changes and habitat disruption.

Lastly, the long-term environmental effects of widespread adoption of calorimetric water treatment need to be considered. While immediate benefits in water quality may be observed, the cumulative impact on aquatic ecosystems, energy consumption patterns, and climate change mitigation efforts should be continuously monitored and assessed to ensure that the environmental benefits outweigh any potential drawbacks.

One of the primary environmental benefits of calorimetric water treatment is its potential to reduce chemical usage in water purification. Traditional water treatment often relies heavily on chemical additives, which can have downstream effects on aquatic ecosystems. By utilizing heat-based processes, calorimetric methods can potentially decrease the reliance on these chemicals, thereby minimizing the introduction of artificial compounds into water bodies.

However, the energy requirements of calorimetric water treatment processes present a notable environmental concern. The heating and cooling cycles inherent in these methods can be energy-intensive, potentially leading to increased greenhouse gas emissions if the energy source is not renewable. This aspect underscores the importance of coupling calorimetric water treatment with sustainable energy solutions to truly realize its environmental benefits.

The impact on water quality is another crucial consideration. While calorimetric methods can effectively remove certain contaminants, they may also alter the mineral composition of the treated water. This could have implications for the ecological balance of water bodies receiving the treated effluent, potentially affecting aquatic life and biodiversity.

From a resource conservation standpoint, calorimetric water treatment shows promise. These processes can be designed to recover heat and energy, improving overall efficiency and reducing waste. Additionally, some calorimetric methods may enable the recovery of valuable minerals and compounds from wastewater, contributing to circular economy principles and resource sustainability.

The scalability of calorimetric water treatment also influences its environmental impact. Large-scale implementations could lead to significant reductions in water pollution on a regional or even national level. However, the infrastructure required for such large-scale operations must be carefully planned to minimize land use changes and habitat disruption.

Lastly, the long-term environmental effects of widespread adoption of calorimetric water treatment need to be considered. While immediate benefits in water quality may be observed, the cumulative impact on aquatic ecosystems, energy consumption patterns, and climate change mitigation efforts should be continuously monitored and assessed to ensure that the environmental benefits outweigh any potential drawbacks.

Cost-Benefit Analysis of Calorimetric Water Treatment

The implementation of calorimetric water treatment technologies presents a complex cost-benefit scenario that requires careful analysis. Initial investment costs for calorimetric systems can be substantial, encompassing equipment acquisition, installation, and integration into existing water treatment infrastructure. These upfront expenses may include calorimeters, heat exchangers, and associated control systems, which can represent a significant capital outlay for water treatment facilities.

However, the long-term operational benefits of calorimetric water treatment can offset these initial costs. Energy efficiency is a primary advantage, as calorimetric processes often require less energy input compared to traditional treatment methods. This translates to reduced electricity consumption and lower ongoing operational expenses. Additionally, the precise temperature control afforded by calorimetric techniques can lead to optimized chemical reactions, potentially decreasing the quantity of treatment chemicals required and further reducing costs.

Maintenance costs for calorimetric systems typically fall within an acceptable range, with routine calibration and occasional component replacement being the primary expenses. The durability of modern calorimetric equipment contributes to extended operational lifespans, spreading the initial investment over many years of service.

From a water quality perspective, calorimetric treatment can yield superior results, potentially reducing the need for additional purification steps. This improvement in treatment efficacy can lead to decreased downstream costs and enhanced regulatory compliance, mitigating the risk of fines or penalties associated with substandard water quality.

The scalability of calorimetric systems allows for cost-effective implementation across various facility sizes. Smaller operations may benefit from modular systems that can be expanded as needed, while larger facilities can leverage economies of scale to maximize cost efficiency.

When considering environmental impact, calorimetric water treatment often results in a smaller carbon footprint due to reduced energy consumption and chemical usage. While difficult to quantify directly, this environmental benefit can translate to tangible cost savings through carbon credits or improved public perception, potentially leading to increased business opportunities or community support.

In conclusion, while the initial investment in calorimetric water treatment technology may be substantial, the long-term cost benefits, including reduced energy consumption, optimized chemical usage, and improved water quality, present a compelling case for implementation. A thorough cost-benefit analysis should consider both immediate expenses and long-term savings to accurately assess the financial viability of calorimetric water treatment solutions.

However, the long-term operational benefits of calorimetric water treatment can offset these initial costs. Energy efficiency is a primary advantage, as calorimetric processes often require less energy input compared to traditional treatment methods. This translates to reduced electricity consumption and lower ongoing operational expenses. Additionally, the precise temperature control afforded by calorimetric techniques can lead to optimized chemical reactions, potentially decreasing the quantity of treatment chemicals required and further reducing costs.

Maintenance costs for calorimetric systems typically fall within an acceptable range, with routine calibration and occasional component replacement being the primary expenses. The durability of modern calorimetric equipment contributes to extended operational lifespans, spreading the initial investment over many years of service.

From a water quality perspective, calorimetric treatment can yield superior results, potentially reducing the need for additional purification steps. This improvement in treatment efficacy can lead to decreased downstream costs and enhanced regulatory compliance, mitigating the risk of fines or penalties associated with substandard water quality.

The scalability of calorimetric systems allows for cost-effective implementation across various facility sizes. Smaller operations may benefit from modular systems that can be expanded as needed, while larger facilities can leverage economies of scale to maximize cost efficiency.

When considering environmental impact, calorimetric water treatment often results in a smaller carbon footprint due to reduced energy consumption and chemical usage. While difficult to quantify directly, this environmental benefit can translate to tangible cost savings through carbon credits or improved public perception, potentially leading to increased business opportunities or community support.

In conclusion, while the initial investment in calorimetric water treatment technology may be substantial, the long-term cost benefits, including reduced energy consumption, optimized chemical usage, and improved water quality, present a compelling case for implementation. A thorough cost-benefit analysis should consider both immediate expenses and long-term savings to accurately assess the financial viability of calorimetric water treatment solutions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!