How Calorimetry Optimizes Water-Vapor-Sorbent System Design

AUG 5, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Calorimetry in Sorbent Systems: Background and Objectives

Calorimetry has emerged as a crucial tool in optimizing water-vapor-sorbent system design, playing a pivotal role in addressing global challenges related to energy efficiency and environmental sustainability. The application of calorimetric techniques in this field has evolved significantly over the past few decades, driven by the increasing demand for more effective and eco-friendly cooling and dehumidification solutions.

The primary objective of utilizing calorimetry in sorbent systems is to enhance the performance and efficiency of water vapor adsorption and desorption processes. By providing precise measurements of heat transfer and energy exchange during these processes, calorimetry enables researchers and engineers to gain deeper insights into the thermodynamic behavior of various sorbent materials and system configurations.

Historically, the development of calorimetric methods for studying sorbent systems can be traced back to the mid-20th century. Early research focused on basic calorimetric measurements of adsorption heat, which laid the foundation for more advanced techniques. As technology progressed, so did the sophistication of calorimetric instruments and methodologies, allowing for more accurate and detailed analysis of sorbent-water vapor interactions.

The evolution of calorimetry in this field has been closely tied to advancements in material science and engineering. The discovery and development of novel sorbent materials, such as zeolites, silica gels, and metal-organic frameworks (MOFs), have necessitated more refined calorimetric techniques to characterize their performance accurately. This symbiotic relationship between material development and calorimetric analysis has been a key driver of innovation in water-vapor-sorbent systems.

In recent years, the focus of calorimetric research in sorbent systems has shifted towards addressing specific challenges in system design and optimization. These include improving the energy efficiency of adsorption cooling systems, enhancing the moisture uptake capacity of desiccants, and developing more effective regeneration processes. Calorimetry plays a critical role in these efforts by providing quantitative data on heat of adsorption, kinetics of water uptake, and cyclic stability of sorbent materials.

The current technological landscape demands increasingly sophisticated calorimetric techniques to meet the complex requirements of modern water-vapor-sorbent systems. Researchers are now employing advanced methods such as isothermal titration calorimetry, differential scanning calorimetry, and flow calorimetry to obtain more comprehensive and accurate thermodynamic data. These techniques allow for the investigation of subtle energy changes and kinetic processes that are crucial for optimizing system performance.

Looking ahead, the objectives of calorimetric research in sorbent systems are aligned with broader goals of sustainability and energy efficiency. There is a growing emphasis on developing calorimetric methods that can simulate real-world operating conditions more accurately, enabling better translation of laboratory findings to practical applications. Additionally, there is a push towards integrating calorimetric analysis with other analytical techniques and computational modeling to create more holistic approaches to system design and optimization.

The primary objective of utilizing calorimetry in sorbent systems is to enhance the performance and efficiency of water vapor adsorption and desorption processes. By providing precise measurements of heat transfer and energy exchange during these processes, calorimetry enables researchers and engineers to gain deeper insights into the thermodynamic behavior of various sorbent materials and system configurations.

Historically, the development of calorimetric methods for studying sorbent systems can be traced back to the mid-20th century. Early research focused on basic calorimetric measurements of adsorption heat, which laid the foundation for more advanced techniques. As technology progressed, so did the sophistication of calorimetric instruments and methodologies, allowing for more accurate and detailed analysis of sorbent-water vapor interactions.

The evolution of calorimetry in this field has been closely tied to advancements in material science and engineering. The discovery and development of novel sorbent materials, such as zeolites, silica gels, and metal-organic frameworks (MOFs), have necessitated more refined calorimetric techniques to characterize their performance accurately. This symbiotic relationship between material development and calorimetric analysis has been a key driver of innovation in water-vapor-sorbent systems.

In recent years, the focus of calorimetric research in sorbent systems has shifted towards addressing specific challenges in system design and optimization. These include improving the energy efficiency of adsorption cooling systems, enhancing the moisture uptake capacity of desiccants, and developing more effective regeneration processes. Calorimetry plays a critical role in these efforts by providing quantitative data on heat of adsorption, kinetics of water uptake, and cyclic stability of sorbent materials.

The current technological landscape demands increasingly sophisticated calorimetric techniques to meet the complex requirements of modern water-vapor-sorbent systems. Researchers are now employing advanced methods such as isothermal titration calorimetry, differential scanning calorimetry, and flow calorimetry to obtain more comprehensive and accurate thermodynamic data. These techniques allow for the investigation of subtle energy changes and kinetic processes that are crucial for optimizing system performance.

Looking ahead, the objectives of calorimetric research in sorbent systems are aligned with broader goals of sustainability and energy efficiency. There is a growing emphasis on developing calorimetric methods that can simulate real-world operating conditions more accurately, enabling better translation of laboratory findings to practical applications. Additionally, there is a push towards integrating calorimetric analysis with other analytical techniques and computational modeling to create more holistic approaches to system design and optimization.

Market Analysis for Water Vapor Sorbent Technologies

The water vapor sorbent technology market is experiencing significant growth, driven by increasing demand for energy-efficient and environmentally friendly solutions in various industries. This market encompasses a wide range of applications, including dehumidification, air purification, and water harvesting systems. The global market for water vapor sorbent technologies is expected to expand at a compound annual growth rate (CAGR) of over 6% in the coming years.

One of the primary drivers of market growth is the rising awareness of indoor air quality and its impact on human health. As people spend more time indoors, there is a growing need for effective humidity control and air purification systems in residential, commercial, and industrial settings. This trend has been further accelerated by the COVID-19 pandemic, which has heightened concerns about air quality and the spread of airborne pathogens.

The industrial sector represents a significant portion of the water vapor sorbent technology market. Manufacturing processes, particularly in the pharmaceutical, food and beverage, and electronics industries, require precise humidity control to maintain product quality and operational efficiency. As these industries continue to grow and adopt more stringent quality standards, the demand for advanced water vapor sorbent technologies is expected to increase.

In the commercial sector, the adoption of water vapor sorbent technologies is driven by the need for energy-efficient HVAC systems in office buildings, shopping centers, and healthcare facilities. These technologies can significantly reduce energy consumption and operating costs while improving indoor air quality and occupant comfort.

The residential market for water vapor sorbent technologies is also expanding, particularly in regions with high humidity levels or extreme weather conditions. Homeowners are increasingly investing in dehumidification systems and air purifiers to create healthier living environments and protect their property from moisture-related damage.

Geographically, North America and Europe currently dominate the water vapor sorbent technology market, owing to stringent regulations on indoor air quality and energy efficiency. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, driven by rapid industrialization, urbanization, and increasing awareness of air quality issues in countries like China and India.

The market is characterized by intense competition among key players, including Honeywell International, Munters, and Trane Technologies. These companies are investing heavily in research and development to improve the efficiency and performance of their water vapor sorbent technologies. Innovations in materials science, such as the development of advanced zeolites and metal-organic frameworks (MOFs), are expected to drive further growth and expansion of the market in the coming years.

One of the primary drivers of market growth is the rising awareness of indoor air quality and its impact on human health. As people spend more time indoors, there is a growing need for effective humidity control and air purification systems in residential, commercial, and industrial settings. This trend has been further accelerated by the COVID-19 pandemic, which has heightened concerns about air quality and the spread of airborne pathogens.

The industrial sector represents a significant portion of the water vapor sorbent technology market. Manufacturing processes, particularly in the pharmaceutical, food and beverage, and electronics industries, require precise humidity control to maintain product quality and operational efficiency. As these industries continue to grow and adopt more stringent quality standards, the demand for advanced water vapor sorbent technologies is expected to increase.

In the commercial sector, the adoption of water vapor sorbent technologies is driven by the need for energy-efficient HVAC systems in office buildings, shopping centers, and healthcare facilities. These technologies can significantly reduce energy consumption and operating costs while improving indoor air quality and occupant comfort.

The residential market for water vapor sorbent technologies is also expanding, particularly in regions with high humidity levels or extreme weather conditions. Homeowners are increasingly investing in dehumidification systems and air purifiers to create healthier living environments and protect their property from moisture-related damage.

Geographically, North America and Europe currently dominate the water vapor sorbent technology market, owing to stringent regulations on indoor air quality and energy efficiency. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, driven by rapid industrialization, urbanization, and increasing awareness of air quality issues in countries like China and India.

The market is characterized by intense competition among key players, including Honeywell International, Munters, and Trane Technologies. These companies are investing heavily in research and development to improve the efficiency and performance of their water vapor sorbent technologies. Innovations in materials science, such as the development of advanced zeolites and metal-organic frameworks (MOFs), are expected to drive further growth and expansion of the market in the coming years.

Current Challenges in Sorbent System Design

The design of water-vapor-sorbent systems faces several significant challenges that hinder their widespread adoption and optimal performance. One of the primary issues is the selection of appropriate sorbent materials that can efficiently adsorb and desorb water vapor under varying environmental conditions. The ideal sorbent should possess high water uptake capacity, rapid sorption kinetics, and excellent cyclability, but finding materials that meet all these criteria simultaneously remains a formidable task.

Another critical challenge lies in the thermal management of sorbent systems. During the adsorption process, heat is released, which can lead to a temperature increase in the sorbent bed. This temperature rise can adversely affect the adsorption efficiency, as the process is typically exothermic. Conversely, during desorption, heat needs to be supplied to drive off the adsorbed water vapor, which requires careful energy management to maintain system efficiency.

The design of heat exchangers for effective heat transfer within the sorbent system presents another significant hurdle. Optimizing the heat transfer between the sorbent material and the heat transfer fluid is crucial for maintaining desired temperature profiles and enhancing overall system performance. However, designing heat exchangers that provide uniform heat distribution while minimizing pressure drop and maximizing contact area with the sorbent material is a complex engineering challenge.

Scaling up laboratory-proven sorbent systems to industrial applications introduces additional complications. Issues such as non-uniform flow distribution, channeling effects, and heat and mass transfer limitations become more pronounced at larger scales. These factors can lead to reduced efficiency and increased operational costs in real-world applications.

Furthermore, the long-term stability and durability of sorbent materials under repeated adsorption-desorption cycles remain a concern. Degradation of sorbent performance over time due to factors such as chemical changes, structural collapse, or fouling can significantly impact the system's overall efficiency and lifespan.

The integration of sorbent systems with existing HVAC or industrial processes poses another challenge. Ensuring seamless operation and control strategies that can adapt to varying load conditions and environmental factors is essential for practical implementation. This requires sophisticated control algorithms and robust system designs that can handle fluctuations in temperature, humidity, and flow rates.

Lastly, the economic viability of water-vapor-sorbent systems compared to conventional technologies remains a significant barrier to widespread adoption. The initial capital costs, operational expenses, and potential energy savings must be carefully balanced to make these systems competitive in the market. Overcoming these challenges requires innovative approaches to system design, material science advancements, and improved manufacturing techniques to reduce costs and enhance performance.

Another critical challenge lies in the thermal management of sorbent systems. During the adsorption process, heat is released, which can lead to a temperature increase in the sorbent bed. This temperature rise can adversely affect the adsorption efficiency, as the process is typically exothermic. Conversely, during desorption, heat needs to be supplied to drive off the adsorbed water vapor, which requires careful energy management to maintain system efficiency.

The design of heat exchangers for effective heat transfer within the sorbent system presents another significant hurdle. Optimizing the heat transfer between the sorbent material and the heat transfer fluid is crucial for maintaining desired temperature profiles and enhancing overall system performance. However, designing heat exchangers that provide uniform heat distribution while minimizing pressure drop and maximizing contact area with the sorbent material is a complex engineering challenge.

Scaling up laboratory-proven sorbent systems to industrial applications introduces additional complications. Issues such as non-uniform flow distribution, channeling effects, and heat and mass transfer limitations become more pronounced at larger scales. These factors can lead to reduced efficiency and increased operational costs in real-world applications.

Furthermore, the long-term stability and durability of sorbent materials under repeated adsorption-desorption cycles remain a concern. Degradation of sorbent performance over time due to factors such as chemical changes, structural collapse, or fouling can significantly impact the system's overall efficiency and lifespan.

The integration of sorbent systems with existing HVAC or industrial processes poses another challenge. Ensuring seamless operation and control strategies that can adapt to varying load conditions and environmental factors is essential for practical implementation. This requires sophisticated control algorithms and robust system designs that can handle fluctuations in temperature, humidity, and flow rates.

Lastly, the economic viability of water-vapor-sorbent systems compared to conventional technologies remains a significant barrier to widespread adoption. The initial capital costs, operational expenses, and potential energy savings must be carefully balanced to make these systems competitive in the market. Overcoming these challenges requires innovative approaches to system design, material science advancements, and improved manufacturing techniques to reduce costs and enhance performance.

Existing Calorimetric Methods for Sorbent Optimization

01 Optimization of sorbent materials

Improving the performance of water vapor sorbent systems by optimizing the sorbent materials used. This includes developing new materials with enhanced adsorption capacities, faster kinetics, and improved regeneration properties. The optimization process may involve modifying existing materials or synthesizing novel compounds tailored for specific applications in water vapor sorption.- Optimization of sorbent materials: Improving the performance of water vapor sorbent systems by optimizing the sorbent materials used. This includes developing new materials with enhanced adsorption capacity, faster kinetics, and improved regeneration properties. The optimization process may involve modifying the chemical composition, surface area, and pore structure of the sorbents to increase their efficiency in capturing and releasing water vapor.

- System design and configuration: Enhancing the overall efficiency of water vapor sorbent systems through innovative design and configuration. This includes optimizing the arrangement of sorbent beds, improving heat and mass transfer within the system, and developing novel cyclic processes for adsorption and desorption. The focus is on maximizing the system's capacity to capture and release water vapor while minimizing energy consumption and operational costs.

- Integration with renewable energy sources: Incorporating renewable energy sources to power water vapor sorbent systems, improving their sustainability and reducing operational costs. This approach involves designing systems that can efficiently utilize solar, wind, or waste heat energy for the regeneration of sorbents and other system processes. The integration aims to enhance the overall energy efficiency and environmental performance of the water vapor sorbent systems.

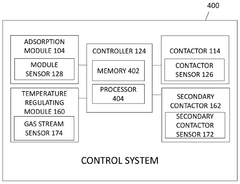

- Control and monitoring systems: Developing advanced control and monitoring systems to optimize the performance of water vapor sorbent systems. This includes implementing smart sensors, data analytics, and machine learning algorithms to continuously monitor and adjust system parameters. The goal is to maintain optimal operating conditions, predict maintenance needs, and maximize water vapor capture efficiency under varying environmental conditions.

- Application-specific optimization: Tailoring water vapor sorbent systems for specific applications such as atmospheric water harvesting, dehumidification, or industrial processes. This involves optimizing system components, sorbent materials, and operational parameters to meet the unique requirements of each application. The focus is on developing specialized solutions that maximize efficiency and performance in diverse operating environments and use cases.

02 System design and configuration

Enhancing the overall efficiency of water vapor sorbent systems through innovative design and configuration. This involves optimizing the arrangement of components, improving heat and mass transfer, and developing more effective regeneration cycles. Advanced system designs may incorporate features such as multi-stage adsorption, heat recovery mechanisms, and intelligent control systems to maximize performance and energy efficiency.Expand Specific Solutions03 Integration with renewable energy sources

Incorporating renewable energy sources to power water vapor sorbent systems, reducing their environmental impact and operational costs. This may include the use of solar thermal energy for regeneration processes, wind power for auxiliary systems, or geothermal energy for heating and cooling. The integration of renewable energy can significantly improve the sustainability and efficiency of water vapor sorbent systems.Expand Specific Solutions04 Advanced control and monitoring systems

Implementing sophisticated control and monitoring systems to optimize the performance of water vapor sorbent systems. This includes the use of sensors, data analytics, and machine learning algorithms to adjust operating parameters in real-time, predict maintenance needs, and maximize overall system efficiency. Advanced control systems can help balance multiple objectives such as energy consumption, water production, and system longevity.Expand Specific Solutions05 Novel applications and system integration

Exploring new applications for water vapor sorbent systems and integrating them with other technologies. This may include combining water vapor sorption with air conditioning systems, developing portable water harvesting devices, or integrating these systems into building envelopes. Novel applications can expand the utility of water vapor sorbent technology and address emerging challenges in water scarcity and energy efficiency.Expand Specific Solutions

Key Players in Calorimetry and Sorbent Industries

The field of calorimetry for optimizing water-vapor-sorbent systems is in a growth phase, with increasing market size driven by energy efficiency demands. The technology is maturing but still evolving, as evidenced by ongoing research at institutions like MIT, University of Florida, and Tianjin University. Companies such as Mitsubishi Electric, Air Products & Chemicals, and DENSO Corp are actively developing applications, indicating a competitive landscape with both academic and industrial players. The market is characterized by a mix of established corporations and specialized firms like Euro Heat Pipes SA, reflecting the technology's broad potential across multiple sectors including HVAC, energy storage, and industrial processes.

Mitsubishi Electric Research Laboratories, Inc.

Technical Solution: Mitsubishi Electric Research Laboratories (MERL) has developed an innovative calorimetry-based approach for optimizing water-vapor-sorbent systems, with a focus on HVAC and refrigeration applications. Their method utilizes advanced modulated differential scanning calorimetry (MDSC) to precisely measure the heat of adsorption and desorption for various sorbent materials[9]. MERL has created a proprietary database of thermodynamic and kinetic data for a wide range of sorbents, which is used in conjunction with machine learning algorithms to predict and optimize system performance. They have also developed a novel micro-calorimetry technique that allows for rapid screening of sorbent materials, significantly reducing the time required for material selection and system optimization[10].

Strengths: Strong integration with Mitsubishi's product development pipeline, extensive experience in HVAC systems, and advanced AI and machine learning capabilities. Weaknesses: Potential limitations in adapting research findings to non-HVAC applications.

Massachusetts Institute of Technology

Technical Solution: MIT has developed advanced calorimetry techniques for optimizing water-vapor-sorbent systems. Their approach involves using high-precision calorimeters to measure the heat of adsorption and desorption in various sorbent materials. They have created a database of thermodynamic properties for different sorbent-water vapor pairs, enabling more accurate system modeling and design[1]. MIT researchers have also developed a novel differential scanning calorimetry method that allows for rapid screening of sorbent materials, significantly reducing the time required for material selection in water-vapor-sorbent systems[2]. This method can measure both the equilibrium and kinetic properties of sorbents, providing crucial data for system optimization.

Strengths: Cutting-edge research facilities, interdisciplinary approach, and strong industry partnerships. Weaknesses: High cost of implementation and potential scalability issues for industrial applications.

Innovative Calorimetric Approaches in Sorbent Design

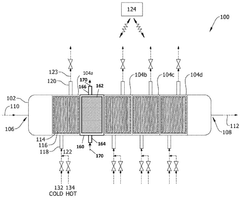

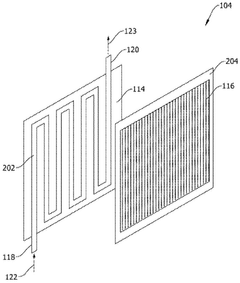

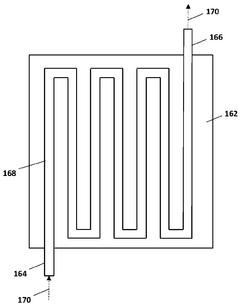

Systems and methods for optimizing carbon dioxide capture using gas stream temperature control

PatentWO2025038132A1

Innovation

- The system employs temperature management of a gas stream channeled through an adsorbent bed with dedicated contactors to optimize the adsorption and desorption of CO2 and water vapor by solid sorbents within adsorption modules.

Water vapor differential minimization systems and methods for gas exchange measurements of aqueous or water saturated samples

PatentActiveUS11761893B2

Innovation

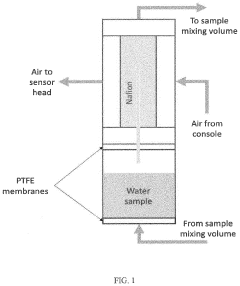

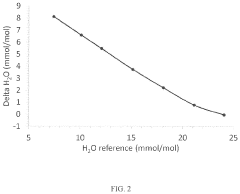

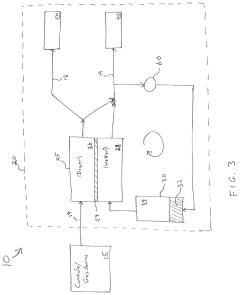

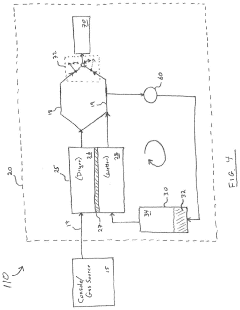

- Incorporating a water vapor selective element, such as a Nafion membrane, to reduce water vapor concentration in the sample air stream and minimize differential between sample and reference streams, thereby reducing measurement errors and preventing condensation by allowing water vapor to equilibrate across the membrane, ensuring accurate CO2 and H2O measurements.

Environmental Impact of Optimized Sorbent Systems

The optimization of water-vapor-sorbent systems through calorimetry has significant environmental implications. These systems, when properly designed and implemented, can contribute to reduced energy consumption and greenhouse gas emissions in various applications, particularly in heating, ventilation, and air conditioning (HVAC) systems.

One of the primary environmental benefits of optimized sorbent systems is their potential to enhance energy efficiency. By accurately measuring and analyzing the heat of adsorption and desorption processes, calorimetry enables the development of more efficient sorbent materials and system designs. This increased efficiency translates to lower energy requirements for dehumidification and cooling processes, resulting in reduced fossil fuel consumption and associated carbon emissions.

Furthermore, optimized sorbent systems can lead to a decrease in the use of conventional refrigerants, many of which have high global warming potential (GWP). By utilizing water as the working fluid, these systems eliminate the need for synthetic refrigerants that contribute to ozone depletion and climate change. This shift towards more environmentally friendly working fluids aligns with global efforts to phase out harmful refrigerants under international agreements such as the Montreal Protocol and the Kigali Amendment.

The improved performance of water-vapor-sorbent systems also has implications for water conservation. By enhancing the efficiency of water vapor capture and release, these systems can reduce water consumption in cooling towers and other HVAC components. This is particularly significant in water-stressed regions where the demand for air conditioning is high.

Additionally, the optimization of sorbent systems through calorimetry can lead to the development of more compact and lightweight HVAC units. This reduction in material usage not only conserves resources but also decreases the environmental impact associated with the manufacturing, transportation, and disposal of HVAC equipment.

The environmental benefits extend to indoor air quality as well. Optimized sorbent systems can more effectively control humidity levels, reducing the risk of mold growth and improving overall air quality. This can lead to healthier indoor environments and potentially reduce the need for chemical treatments and air purification systems.

In the context of sustainable building design, the integration of optimized water-vapor-sorbent systems can contribute to achieving green building certifications such as LEED (Leadership in Energy and Environmental Design). These systems align with the principles of energy efficiency and environmental responsibility that are central to sustainable architecture and urban planning.

One of the primary environmental benefits of optimized sorbent systems is their potential to enhance energy efficiency. By accurately measuring and analyzing the heat of adsorption and desorption processes, calorimetry enables the development of more efficient sorbent materials and system designs. This increased efficiency translates to lower energy requirements for dehumidification and cooling processes, resulting in reduced fossil fuel consumption and associated carbon emissions.

Furthermore, optimized sorbent systems can lead to a decrease in the use of conventional refrigerants, many of which have high global warming potential (GWP). By utilizing water as the working fluid, these systems eliminate the need for synthetic refrigerants that contribute to ozone depletion and climate change. This shift towards more environmentally friendly working fluids aligns with global efforts to phase out harmful refrigerants under international agreements such as the Montreal Protocol and the Kigali Amendment.

The improved performance of water-vapor-sorbent systems also has implications for water conservation. By enhancing the efficiency of water vapor capture and release, these systems can reduce water consumption in cooling towers and other HVAC components. This is particularly significant in water-stressed regions where the demand for air conditioning is high.

Additionally, the optimization of sorbent systems through calorimetry can lead to the development of more compact and lightweight HVAC units. This reduction in material usage not only conserves resources but also decreases the environmental impact associated with the manufacturing, transportation, and disposal of HVAC equipment.

The environmental benefits extend to indoor air quality as well. Optimized sorbent systems can more effectively control humidity levels, reducing the risk of mold growth and improving overall air quality. This can lead to healthier indoor environments and potentially reduce the need for chemical treatments and air purification systems.

In the context of sustainable building design, the integration of optimized water-vapor-sorbent systems can contribute to achieving green building certifications such as LEED (Leadership in Energy and Environmental Design). These systems align with the principles of energy efficiency and environmental responsibility that are central to sustainable architecture and urban planning.

Economic Feasibility of Calorimetry-Optimized Sorbents

The economic feasibility of calorimetry-optimized sorbents in water-vapor-sorbent systems is a critical consideration for their widespread adoption and commercialization. Calorimetry optimization offers significant potential for enhancing system efficiency and reducing operational costs, which can lead to improved economic viability.

One of the primary economic benefits of calorimetry-optimized sorbents is the potential for reduced energy consumption. By precisely measuring and controlling the heat of adsorption and desorption, these systems can operate more efficiently, resulting in lower energy costs over the system's lifetime. This reduction in energy expenditure can translate to substantial savings, particularly for large-scale industrial applications.

Furthermore, calorimetry optimization can lead to increased sorbent longevity and reduced maintenance requirements. By minimizing thermal stress on the sorbent material, the system can experience less degradation over time, potentially extending the operational lifespan of the sorbent. This increased durability can result in lower replacement costs and reduced downtime for maintenance, contributing to improved economic performance.

The initial investment in calorimetry-optimized systems may be higher than traditional water-vapor-sorbent systems due to the additional instrumentation and control mechanisms required. However, the long-term cost savings from improved efficiency and reduced maintenance can offset this initial expense, leading to a favorable return on investment over time.

Market analysis suggests that industries with high energy consumption and strict humidity control requirements, such as pharmaceuticals, food processing, and semiconductor manufacturing, are likely to benefit most from calorimetry-optimized sorbent systems. The potential for energy savings and improved process control in these sectors can justify the higher upfront costs associated with implementing these advanced systems.

Additionally, as environmental regulations become more stringent and energy prices continue to fluctuate, the economic advantages of calorimetry-optimized sorbents are expected to become more pronounced. Companies adopting these technologies may gain a competitive edge through reduced operational costs and improved sustainability profiles.

However, the economic feasibility of these systems can vary depending on factors such as local energy prices, scale of operation, and specific application requirements. A thorough cost-benefit analysis, taking into account both capital expenditure and projected operational savings, is essential for determining the economic viability of implementing calorimetry-optimized sorbent systems in specific industrial contexts.

One of the primary economic benefits of calorimetry-optimized sorbents is the potential for reduced energy consumption. By precisely measuring and controlling the heat of adsorption and desorption, these systems can operate more efficiently, resulting in lower energy costs over the system's lifetime. This reduction in energy expenditure can translate to substantial savings, particularly for large-scale industrial applications.

Furthermore, calorimetry optimization can lead to increased sorbent longevity and reduced maintenance requirements. By minimizing thermal stress on the sorbent material, the system can experience less degradation over time, potentially extending the operational lifespan of the sorbent. This increased durability can result in lower replacement costs and reduced downtime for maintenance, contributing to improved economic performance.

The initial investment in calorimetry-optimized systems may be higher than traditional water-vapor-sorbent systems due to the additional instrumentation and control mechanisms required. However, the long-term cost savings from improved efficiency and reduced maintenance can offset this initial expense, leading to a favorable return on investment over time.

Market analysis suggests that industries with high energy consumption and strict humidity control requirements, such as pharmaceuticals, food processing, and semiconductor manufacturing, are likely to benefit most from calorimetry-optimized sorbent systems. The potential for energy savings and improved process control in these sectors can justify the higher upfront costs associated with implementing these advanced systems.

Additionally, as environmental regulations become more stringent and energy prices continue to fluctuate, the economic advantages of calorimetry-optimized sorbents are expected to become more pronounced. Companies adopting these technologies may gain a competitive edge through reduced operational costs and improved sustainability profiles.

However, the economic feasibility of these systems can vary depending on factors such as local energy prices, scale of operation, and specific application requirements. A thorough cost-benefit analysis, taking into account both capital expenditure and projected operational savings, is essential for determining the economic viability of implementing calorimetry-optimized sorbent systems in specific industrial contexts.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!