Evaluating Electromagnetic Interference Using Calorimeters

AUG 5, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

EMI Calorimetry Background and Objectives

Electromagnetic Interference (EMI) calorimetry has emerged as a critical field in the realm of electromagnetic compatibility (EMC) testing and evaluation. This innovative approach combines the principles of calorimetry with electromagnetic field measurements to provide a more comprehensive and accurate assessment of EMI in various electronic systems and devices.

The development of EMI calorimetry can be traced back to the early 2000s when researchers began exploring alternative methods to traditional EMI testing techniques. These conventional methods, such as conducted and radiated emissions measurements, often fell short in capturing the full spectrum of electromagnetic energy dissipation in complex systems. The need for a more holistic approach led to the integration of calorimetric principles into EMI evaluation.

EMI calorimetry aims to quantify the total electromagnetic energy absorbed by a device under test (DUT) by measuring the heat generated as a result of EMI. This method offers several advantages over traditional EMI testing techniques, including the ability to measure both conducted and radiated emissions simultaneously, improved accuracy in low-frequency measurements, and the capacity to evaluate EMI in systems with multiple sources of electromagnetic energy.

The evolution of EMI calorimetry has been driven by advancements in sensor technology, data acquisition systems, and computational modeling. Early calorimetric setups were relatively simple, utilizing basic temperature sensors and rudimentary heat flow measurements. However, modern EMI calorimeters employ sophisticated thermal imaging cameras, high-precision temperature sensors, and advanced signal processing algorithms to capture and analyze electromagnetic energy dissipation with unprecedented accuracy.

As the field of EMI calorimetry continues to mature, researchers and industry professionals are focusing on several key objectives. One primary goal is to develop standardized testing protocols and calibration procedures to ensure consistency and reproducibility across different laboratories and testing environments. This standardization effort is crucial for the widespread adoption of EMI calorimetry in regulatory compliance testing and product development processes.

Another important objective is to expand the application of EMI calorimetry beyond traditional electronic devices to emerging technologies such as wireless power transfer systems, electric vehicles, and 5G communication infrastructure. These complex systems present unique challenges in terms of EMI evaluation, and calorimetric methods offer promising solutions for comprehensive interference assessment.

Furthermore, researchers are working towards integrating EMI calorimetry with other advanced EMC testing techniques, such as near-field scanning and time-domain analysis, to create more powerful and versatile evaluation tools. This integration aims to provide a more complete picture of electromagnetic interactions within and between electronic systems, ultimately leading to improved design practices and more robust EMC solutions.

The development of EMI calorimetry can be traced back to the early 2000s when researchers began exploring alternative methods to traditional EMI testing techniques. These conventional methods, such as conducted and radiated emissions measurements, often fell short in capturing the full spectrum of electromagnetic energy dissipation in complex systems. The need for a more holistic approach led to the integration of calorimetric principles into EMI evaluation.

EMI calorimetry aims to quantify the total electromagnetic energy absorbed by a device under test (DUT) by measuring the heat generated as a result of EMI. This method offers several advantages over traditional EMI testing techniques, including the ability to measure both conducted and radiated emissions simultaneously, improved accuracy in low-frequency measurements, and the capacity to evaluate EMI in systems with multiple sources of electromagnetic energy.

The evolution of EMI calorimetry has been driven by advancements in sensor technology, data acquisition systems, and computational modeling. Early calorimetric setups were relatively simple, utilizing basic temperature sensors and rudimentary heat flow measurements. However, modern EMI calorimeters employ sophisticated thermal imaging cameras, high-precision temperature sensors, and advanced signal processing algorithms to capture and analyze electromagnetic energy dissipation with unprecedented accuracy.

As the field of EMI calorimetry continues to mature, researchers and industry professionals are focusing on several key objectives. One primary goal is to develop standardized testing protocols and calibration procedures to ensure consistency and reproducibility across different laboratories and testing environments. This standardization effort is crucial for the widespread adoption of EMI calorimetry in regulatory compliance testing and product development processes.

Another important objective is to expand the application of EMI calorimetry beyond traditional electronic devices to emerging technologies such as wireless power transfer systems, electric vehicles, and 5G communication infrastructure. These complex systems present unique challenges in terms of EMI evaluation, and calorimetric methods offer promising solutions for comprehensive interference assessment.

Furthermore, researchers are working towards integrating EMI calorimetry with other advanced EMC testing techniques, such as near-field scanning and time-domain analysis, to create more powerful and versatile evaluation tools. This integration aims to provide a more complete picture of electromagnetic interactions within and between electronic systems, ultimately leading to improved design practices and more robust EMC solutions.

Market Demand for EMI Testing Solutions

The market demand for Electromagnetic Interference (EMI) testing solutions, particularly those utilizing calorimeters, has been steadily growing in recent years. This growth is primarily driven by the increasing complexity of electronic devices and systems, as well as the stringent regulatory requirements across various industries.

In the automotive sector, the rapid adoption of electric and hybrid vehicles has created a significant need for EMI testing solutions. These vehicles incorporate numerous electronic components and high-voltage systems, which can generate substantial electromagnetic interference. As a result, automotive manufacturers are investing heavily in EMI testing equipment, including calorimeter-based solutions, to ensure compliance with safety standards and optimal performance of their vehicles.

The aerospace and defense industries also contribute significantly to the market demand for EMI testing solutions. With the increasing use of advanced avionics and communication systems in aircraft and military equipment, the need for accurate EMI evaluation has become paramount. Calorimeter-based testing methods offer a unique advantage in these applications, as they can provide precise measurements of electromagnetic energy absorption and dissipation in complex systems.

The telecommunications sector, particularly with the ongoing rollout of 5G networks, represents another major driver for EMI testing solutions. As 5G infrastructure requires a dense network of base stations and small cells, ensuring electromagnetic compatibility becomes crucial. Calorimeter-based EMI testing can help identify potential interference issues and optimize the placement and performance of 5G equipment.

In the consumer electronics market, the proliferation of Internet of Things (IoT) devices and wearable technology has led to increased demand for EMI testing solutions. These devices often operate in close proximity to each other and to the human body, making electromagnetic compatibility a critical concern. Calorimeter-based testing methods can provide valuable insights into the interaction between these devices and their environment.

The healthcare industry is another sector driving the demand for advanced EMI testing solutions. Medical devices, particularly implantable and wearable devices, must undergo rigorous EMI testing to ensure patient safety and device reliability. Calorimeter-based testing methods offer a non-invasive approach to evaluate the electromagnetic effects on biological tissues and medical equipment.

As industries continue to innovate and develop more sophisticated electronic systems, the market for EMI testing solutions, including those based on calorimetry, is expected to expand further. This growth is supported by the increasing awareness of electromagnetic compatibility issues and the need for comprehensive testing methodologies to address them effectively.

In the automotive sector, the rapid adoption of electric and hybrid vehicles has created a significant need for EMI testing solutions. These vehicles incorporate numerous electronic components and high-voltage systems, which can generate substantial electromagnetic interference. As a result, automotive manufacturers are investing heavily in EMI testing equipment, including calorimeter-based solutions, to ensure compliance with safety standards and optimal performance of their vehicles.

The aerospace and defense industries also contribute significantly to the market demand for EMI testing solutions. With the increasing use of advanced avionics and communication systems in aircraft and military equipment, the need for accurate EMI evaluation has become paramount. Calorimeter-based testing methods offer a unique advantage in these applications, as they can provide precise measurements of electromagnetic energy absorption and dissipation in complex systems.

The telecommunications sector, particularly with the ongoing rollout of 5G networks, represents another major driver for EMI testing solutions. As 5G infrastructure requires a dense network of base stations and small cells, ensuring electromagnetic compatibility becomes crucial. Calorimeter-based EMI testing can help identify potential interference issues and optimize the placement and performance of 5G equipment.

In the consumer electronics market, the proliferation of Internet of Things (IoT) devices and wearable technology has led to increased demand for EMI testing solutions. These devices often operate in close proximity to each other and to the human body, making electromagnetic compatibility a critical concern. Calorimeter-based testing methods can provide valuable insights into the interaction between these devices and their environment.

The healthcare industry is another sector driving the demand for advanced EMI testing solutions. Medical devices, particularly implantable and wearable devices, must undergo rigorous EMI testing to ensure patient safety and device reliability. Calorimeter-based testing methods offer a non-invasive approach to evaluate the electromagnetic effects on biological tissues and medical equipment.

As industries continue to innovate and develop more sophisticated electronic systems, the market for EMI testing solutions, including those based on calorimetry, is expected to expand further. This growth is supported by the increasing awareness of electromagnetic compatibility issues and the need for comprehensive testing methodologies to address them effectively.

Current EMI Measurement Techniques and Challenges

Electromagnetic Interference (EMI) measurement techniques have evolved significantly over the years, yet they still face numerous challenges in accurately evaluating and quantifying EMI. Current methods primarily rely on antennas, current probes, and spectrum analyzers to detect and measure electromagnetic emissions. These techniques, while widely used, have limitations in terms of sensitivity, frequency range, and spatial resolution.

One of the most common approaches is the use of antennas in anechoic chambers or open area test sites. This method allows for far-field measurements of radiated emissions but can be affected by environmental factors and requires large, expensive facilities. Near-field scanning techniques have gained popularity for their ability to pinpoint EMI sources with higher spatial resolution. However, these methods often require complex post-processing and may not accurately represent far-field emissions.

Current probes are frequently employed to measure conducted emissions on cables and wires. While effective for lower frequency ranges, they struggle with higher frequencies and can introduce measurement errors due to probe positioning and coupling effects. Spectrum analyzers remain a cornerstone of EMI measurement, offering high sensitivity and wide frequency coverage. However, they typically provide only magnitude information, lacking phase data that can be crucial for understanding complex EMI scenarios.

Time-domain techniques, such as time-domain EMI (TDEMI) measurements, have emerged as promising alternatives. These methods offer advantages in measurement speed and the ability to capture transient emissions. However, they often require sophisticated signal processing and may face challenges in accurately representing frequency-domain limits specified in EMC standards.

A significant challenge in current EMI measurement techniques is the difficulty in capturing and analyzing complex, multi-source EMI environments. Many modern electronic systems contain multiple EMI sources operating simultaneously, making it challenging to isolate and characterize individual contributors. Additionally, the increasing use of wireless technologies and higher operating frequencies in electronic devices pushes the limits of traditional measurement equipment.

Another pressing challenge is the need for more accurate and repeatable measurements in the presence of ambient electromagnetic noise. This is particularly problematic in industrial settings or densely populated urban areas where background EMI levels can be high and variable. Shielding and filtering techniques used to mitigate this issue can sometimes introduce their own measurement artifacts.

The integration of EMI measurements with system-level performance evaluation remains a significant challenge. While current techniques can identify EMI sources and levels, correlating these measurements with actual device or system performance degradation is often complex and not well-standardized. This gap hinders the development of more effective EMI mitigation strategies and complicates regulatory compliance processes.

One of the most common approaches is the use of antennas in anechoic chambers or open area test sites. This method allows for far-field measurements of radiated emissions but can be affected by environmental factors and requires large, expensive facilities. Near-field scanning techniques have gained popularity for their ability to pinpoint EMI sources with higher spatial resolution. However, these methods often require complex post-processing and may not accurately represent far-field emissions.

Current probes are frequently employed to measure conducted emissions on cables and wires. While effective for lower frequency ranges, they struggle with higher frequencies and can introduce measurement errors due to probe positioning and coupling effects. Spectrum analyzers remain a cornerstone of EMI measurement, offering high sensitivity and wide frequency coverage. However, they typically provide only magnitude information, lacking phase data that can be crucial for understanding complex EMI scenarios.

Time-domain techniques, such as time-domain EMI (TDEMI) measurements, have emerged as promising alternatives. These methods offer advantages in measurement speed and the ability to capture transient emissions. However, they often require sophisticated signal processing and may face challenges in accurately representing frequency-domain limits specified in EMC standards.

A significant challenge in current EMI measurement techniques is the difficulty in capturing and analyzing complex, multi-source EMI environments. Many modern electronic systems contain multiple EMI sources operating simultaneously, making it challenging to isolate and characterize individual contributors. Additionally, the increasing use of wireless technologies and higher operating frequencies in electronic devices pushes the limits of traditional measurement equipment.

Another pressing challenge is the need for more accurate and repeatable measurements in the presence of ambient electromagnetic noise. This is particularly problematic in industrial settings or densely populated urban areas where background EMI levels can be high and variable. Shielding and filtering techniques used to mitigate this issue can sometimes introduce their own measurement artifacts.

The integration of EMI measurements with system-level performance evaluation remains a significant challenge. While current techniques can identify EMI sources and levels, correlating these measurements with actual device or system performance degradation is often complex and not well-standardized. This gap hinders the development of more effective EMI mitigation strategies and complicates regulatory compliance processes.

Existing Calorimetric EMI Measurement Solutions

01 Electromagnetic shielding for calorimeters

Calorimeters can be protected from electromagnetic interference by implementing shielding techniques. This may involve using conductive materials or specialized coatings to create a barrier that prevents external electromagnetic fields from affecting the sensitive measurements within the calorimeter.- Electromagnetic shielding for calorimeters: Calorimeters can be protected from electromagnetic interference by implementing shielding techniques. This may involve using conductive materials or specialized coatings to create a barrier that prevents external electromagnetic fields from affecting the sensitive measurements of the calorimeter. Such shielding can significantly improve the accuracy and reliability of calorimetric measurements in environments with high electromagnetic noise.

- Grounding and isolation techniques: Proper grounding and isolation techniques are crucial for minimizing electromagnetic interference in calorimeters. This can include the use of dedicated ground planes, isolation transformers, and careful routing of signal and power lines. By implementing effective grounding and isolation strategies, the impact of electromagnetic noise on calorimeter performance can be significantly reduced.

- Digital signal processing for noise reduction: Advanced digital signal processing techniques can be employed to filter out electromagnetic interference in calorimeter measurements. This may involve the use of adaptive filters, noise cancellation algorithms, or frequency domain analysis to separate the desired signal from electromagnetic noise. Such digital processing methods can enhance the signal-to-noise ratio and improve the overall accuracy of calorimetric measurements.

- Electromagnetic compatibility design: Designing calorimeters with electromagnetic compatibility in mind from the outset can help mitigate interference issues. This involves considering factors such as component placement, PCB layout, and cable routing to minimize electromagnetic coupling. By incorporating EMC principles into the design phase, the susceptibility of calorimeters to electromagnetic interference can be significantly reduced.

- Active cancellation of electromagnetic interference: Active cancellation techniques can be implemented to counteract electromagnetic interference in calorimeters. This may involve the use of sensors to detect interfering signals and generate opposing fields to cancel them out. Such active approaches can be particularly effective for dealing with dynamic or unpredictable sources of electromagnetic interference in calorimetric measurements.

02 Grounding and isolation techniques

Proper grounding and isolation methods can be employed to minimize electromagnetic interference in calorimeters. This includes using dedicated ground planes, isolating sensitive components, and implementing effective circuit design techniques to reduce noise and interference.Expand Specific Solutions03 Digital signal processing for interference reduction

Advanced digital signal processing techniques can be used to filter out electromagnetic interference in calorimeter measurements. This may involve implementing algorithms for noise cancellation, adaptive filtering, or other signal processing methods to improve the accuracy of calorimeter readings in the presence of electromagnetic interference.Expand Specific Solutions04 Electromagnetic compatibility testing for calorimeters

Specialized testing procedures and equipment can be used to evaluate the electromagnetic compatibility of calorimeters. This involves subjecting the devices to controlled electromagnetic environments to assess their performance and identify potential vulnerabilities to interference.Expand Specific Solutions05 Design optimization for electromagnetic interference mitigation

Calorimeter designs can be optimized to inherently reduce susceptibility to electromagnetic interference. This may include careful component selection, strategic placement of sensitive elements, and the use of advanced materials or structures that minimize the impact of external electromagnetic fields on measurement accuracy.Expand Specific Solutions

Key Players in EMI Testing Equipment Industry

The field of electromagnetic interference evaluation using calorimeters is in a developing stage, with growing market potential as industries increasingly focus on electromagnetic compatibility. The market size is expanding, driven by stringent regulations and the need for precise measurement techniques. Technologically, the field is advancing, with companies like NTT, Robert Bosch, and Sony leading innovation. These firms are leveraging their expertise in electronics and measurement systems to develop sophisticated calorimetric solutions. Research institutions such as Fraunhofer-Gesellschaft and the Electronics & Telecommunications Research Institute are also contributing significantly to technological advancements. The competitive landscape is characterized by a mix of established electronics giants and specialized measurement equipment providers, indicating a maturing but still evolving market.

Fraunhofer-Gesellschaft eV

Technical Solution: Fraunhofer-Gesellschaft has pioneered a novel approach to EMI evaluation using calorimetric methods combined with advanced signal processing techniques. Their system utilizes an array of micro-calorimeters distributed across the device under test, providing a high-resolution thermal map of EMI-induced heating[2]. This approach allows for precise localization of EMI hotspots and characterization of interference patterns. Fraunhofer's technology incorporates machine learning algorithms to analyze the thermal data, enabling real-time identification of EMI sources and prediction of potential electromagnetic compatibility issues[4]. The system also features adaptive frequency scanning, automatically adjusting its measurement parameters to focus on the most problematic frequency ranges for each specific device or system under test.

Strengths: High-resolution EMI mapping, real-time analysis capabilities, and adaptive measurement techniques. Weaknesses: May require significant computational resources and specialized expertise to operate effectively.

Commissariat à l´énergie atomique et aux énergies Alternatives

Technical Solution: The Commissariat à l'énergie atomique et aux énergies alternatives (CEA) has developed advanced calorimetric techniques for evaluating electromagnetic interference (EMI). Their approach utilizes high-precision calorimeters to measure the heat generated by EMI in electronic components and systems. The CEA's method employs a combination of adiabatic and isothermal calorimetry, allowing for accurate quantification of EMI-induced thermal effects across a wide range of frequencies and power levels[1]. This technique enables researchers to detect even subtle EMI impacts that might be missed by traditional electrical measurement methods. The CEA has also integrated their calorimetric EMI evaluation system with advanced shielding technologies to isolate test subjects from external electromagnetic sources, ensuring highly accurate and reproducible results[3].

Strengths: High precision measurements, ability to detect subtle EMI effects, and integration with advanced shielding technologies. Weaknesses: Potentially complex setup and higher cost compared to traditional EMI evaluation methods.

Core Innovations in Calorimetric EMI Evaluation

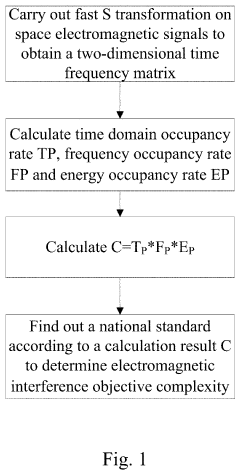

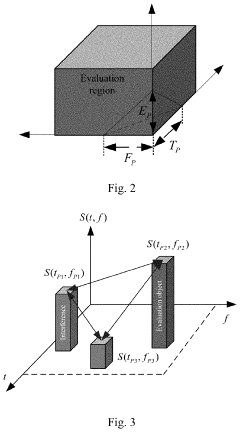

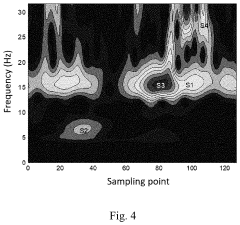

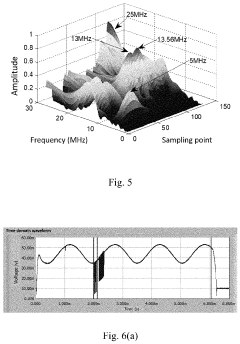

Electromagnetic interference objective complexity evaluation method based on fast S-transformation time-frequency space model

PatentActiveUS10859621B2

Innovation

- The method employs a fast S-transformation time-frequency space model to extract time-frequency characteristic parameters, calculating occupancy rates and determining electromagnetic interference complexity through a product of time, frequency, and energy occupancy rates, allowing for both qualitative and quantitative evaluations.

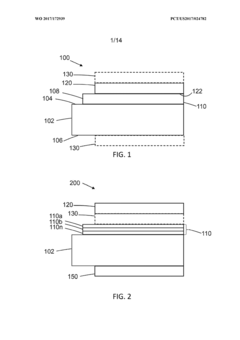

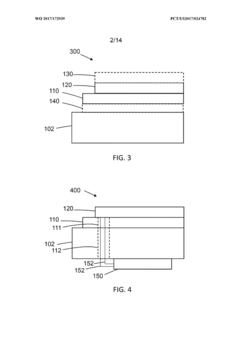

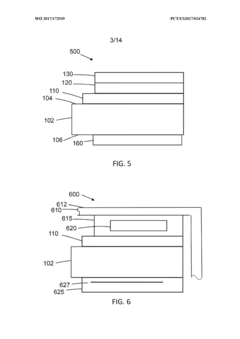

Noise suppressing assemblies

PatentWO2017172939A1

Innovation

- A multi-functional assembly combining a heat spreading layer of compressed exfoliated graphite or graphitized polymers with a magnetic layer for magnetic flux management and EMI shielding, along with an optional conductive mesh for broadband electromagnetic shielding, to enhance power transmission efficiency and thermal management.

EMC Standards and Regulatory Compliance

Electromagnetic Compatibility (EMC) standards and regulatory compliance play a crucial role in ensuring that electronic devices and systems can coexist without causing harmful interference to one another. In the context of evaluating electromagnetic interference using calorimeters, adherence to these standards is paramount for accurate measurements and reliable results.

The International Electrotechnical Commission (IEC) has established several standards relevant to EMC testing, including IEC 61000-4-3 for radiated immunity and IEC 61000-4-6 for conducted immunity. These standards provide guidelines for test setups, measurement procedures, and acceptable limits for electromagnetic emissions and susceptibility.

For calorimetric measurements of electromagnetic interference, specific standards such as IEC 62209-1 and IEC 62209-2 are particularly relevant. These standards address the measurement of human exposure to radio frequency fields from hand-held and body-mounted wireless communication devices, which often employ calorimetric techniques for evaluation.

Regulatory bodies worldwide have adopted these standards or developed their own based on IEC guidelines. In the United States, the Federal Communications Commission (FCC) enforces EMC regulations, while the European Union relies on the CE marking system to ensure compliance with EMC directives.

Compliance with EMC standards involves rigorous testing procedures, including the use of specialized equipment such as anechoic chambers, spectrum analyzers, and calorimeters. These tests aim to verify that devices emit electromagnetic energy within acceptable limits and can withstand interference from external sources without malfunction.

When using calorimeters for EMC evaluation, it is essential to consider the specific requirements outlined in relevant standards. This includes calibration procedures, measurement uncertainties, and reporting formats. Calorimeters must be designed and operated in accordance with these standards to ensure that the results are valid and recognized by regulatory authorities.

Furthermore, as technology evolves, EMC standards are regularly updated to address new challenges and emerging technologies. For instance, the increasing prevalence of wireless devices and the advent of 5G networks have led to revisions in existing standards and the development of new ones to address higher frequency ranges and more complex electromagnetic environments.

Manufacturers and researchers working with calorimeters for EMC evaluation must stay informed about the latest standards and regulatory requirements. This ensures that their testing methodologies remain compliant and that their products meet the necessary criteria for market approval and safe operation in various electromagnetic environments.

The International Electrotechnical Commission (IEC) has established several standards relevant to EMC testing, including IEC 61000-4-3 for radiated immunity and IEC 61000-4-6 for conducted immunity. These standards provide guidelines for test setups, measurement procedures, and acceptable limits for electromagnetic emissions and susceptibility.

For calorimetric measurements of electromagnetic interference, specific standards such as IEC 62209-1 and IEC 62209-2 are particularly relevant. These standards address the measurement of human exposure to radio frequency fields from hand-held and body-mounted wireless communication devices, which often employ calorimetric techniques for evaluation.

Regulatory bodies worldwide have adopted these standards or developed their own based on IEC guidelines. In the United States, the Federal Communications Commission (FCC) enforces EMC regulations, while the European Union relies on the CE marking system to ensure compliance with EMC directives.

Compliance with EMC standards involves rigorous testing procedures, including the use of specialized equipment such as anechoic chambers, spectrum analyzers, and calorimeters. These tests aim to verify that devices emit electromagnetic energy within acceptable limits and can withstand interference from external sources without malfunction.

When using calorimeters for EMC evaluation, it is essential to consider the specific requirements outlined in relevant standards. This includes calibration procedures, measurement uncertainties, and reporting formats. Calorimeters must be designed and operated in accordance with these standards to ensure that the results are valid and recognized by regulatory authorities.

Furthermore, as technology evolves, EMC standards are regularly updated to address new challenges and emerging technologies. For instance, the increasing prevalence of wireless devices and the advent of 5G networks have led to revisions in existing standards and the development of new ones to address higher frequency ranges and more complex electromagnetic environments.

Manufacturers and researchers working with calorimeters for EMC evaluation must stay informed about the latest standards and regulatory requirements. This ensures that their testing methodologies remain compliant and that their products meet the necessary criteria for market approval and safe operation in various electromagnetic environments.

EMI Shielding Materials and Technologies

EMI shielding materials and technologies have evolved significantly in recent years to address the growing challenges of electromagnetic interference in various applications. Traditional metallic shields, such as aluminum and copper, remain widely used due to their high conductivity and effectiveness in reflecting electromagnetic waves. However, the increasing demand for lightweight and flexible shielding solutions has led to the development of innovative materials and composites.

Conductive polymers have emerged as a promising alternative, offering a balance between shielding effectiveness and weight reduction. These materials, such as polypyrrole and polyaniline, can be easily processed and integrated into existing manufacturing processes. Their ability to be tailored for specific frequency ranges makes them particularly attractive for targeted EMI shielding applications.

Carbon-based materials, including graphene and carbon nanotubes, have garnered significant attention due to their exceptional electrical properties and high surface area. These materials can be incorporated into polymer matrices to create lightweight, flexible, and highly effective EMI shielding composites. The unique structure of carbon nanotubes allows for the creation of interconnected conductive networks, enhancing overall shielding performance.

Metamaterials represent a cutting-edge approach to EMI shielding, offering the potential for frequency-selective and even adaptive shielding solutions. These engineered structures can manipulate electromagnetic waves in ways not possible with conventional materials, opening up new possibilities for highly efficient and compact shielding designs.

Multilayer shielding technologies have also gained traction, combining different materials to achieve broadband EMI protection. By strategically layering materials with complementary properties, such as conductive and absorptive layers, these solutions can provide enhanced shielding across a wide frequency spectrum.

Nano-engineered coatings and films have emerged as versatile EMI shielding solutions, offering the ability to apply thin, conformal layers to complex geometries. These coatings can be tailored to provide high shielding effectiveness while maintaining optical transparency, making them ideal for display applications and sensitive electronic devices.

Advancements in manufacturing techniques, such as 3D printing and electrospinning, have enabled the production of intricate shielding structures with optimized geometries. These methods allow for the creation of lightweight, high-performance shields with precisely controlled material distribution and porosity.

As the demand for EMI shielding continues to grow across industries, from consumer electronics to aerospace and healthcare, ongoing research focuses on developing more efficient, sustainable, and cost-effective shielding materials and technologies. The integration of smart materials and active shielding systems represents the next frontier in EMI protection, promising adaptive solutions capable of responding dynamically to changing electromagnetic environments.

Conductive polymers have emerged as a promising alternative, offering a balance between shielding effectiveness and weight reduction. These materials, such as polypyrrole and polyaniline, can be easily processed and integrated into existing manufacturing processes. Their ability to be tailored for specific frequency ranges makes them particularly attractive for targeted EMI shielding applications.

Carbon-based materials, including graphene and carbon nanotubes, have garnered significant attention due to their exceptional electrical properties and high surface area. These materials can be incorporated into polymer matrices to create lightweight, flexible, and highly effective EMI shielding composites. The unique structure of carbon nanotubes allows for the creation of interconnected conductive networks, enhancing overall shielding performance.

Metamaterials represent a cutting-edge approach to EMI shielding, offering the potential for frequency-selective and even adaptive shielding solutions. These engineered structures can manipulate electromagnetic waves in ways not possible with conventional materials, opening up new possibilities for highly efficient and compact shielding designs.

Multilayer shielding technologies have also gained traction, combining different materials to achieve broadband EMI protection. By strategically layering materials with complementary properties, such as conductive and absorptive layers, these solutions can provide enhanced shielding across a wide frequency spectrum.

Nano-engineered coatings and films have emerged as versatile EMI shielding solutions, offering the ability to apply thin, conformal layers to complex geometries. These coatings can be tailored to provide high shielding effectiveness while maintaining optical transparency, making them ideal for display applications and sensitive electronic devices.

Advancements in manufacturing techniques, such as 3D printing and electrospinning, have enabled the production of intricate shielding structures with optimized geometries. These methods allow for the creation of lightweight, high-performance shields with precisely controlled material distribution and porosity.

As the demand for EMI shielding continues to grow across industries, from consumer electronics to aerospace and healthcare, ongoing research focuses on developing more efficient, sustainable, and cost-effective shielding materials and technologies. The integration of smart materials and active shielding systems represents the next frontier in EMI protection, promising adaptive solutions capable of responding dynamically to changing electromagnetic environments.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!