The Impact of Calorimetry on Hydrogen Fuel Cell Development

AUG 5, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Calorimetry in H2 Fuel Cells: Background and Objectives

Calorimetry has played a pivotal role in the development of hydrogen fuel cells, serving as a crucial analytical technique for understanding and optimizing these energy conversion devices. The background of calorimetry in fuel cell research dates back to the early stages of fuel cell development, when researchers sought to quantify the heat generated during electrochemical reactions accurately.

Initially, calorimetric measurements were primarily used to assess the overall efficiency of fuel cells by comparing the electrical energy output to the total energy input from the fuel. As the field progressed, calorimetry evolved into a sophisticated tool for investigating the intricate thermal processes occurring within fuel cells, providing invaluable insights into reaction kinetics, heat management, and material degradation.

The objectives of employing calorimetry in hydrogen fuel cell research have expanded significantly over time. One primary goal is to enhance the overall system efficiency by minimizing heat losses and optimizing thermal management strategies. Calorimetric studies enable researchers to identify hotspots, areas of uneven heat distribution, and potential thermal stress points within the fuel cell stack.

Another critical objective is to improve the durability and longevity of fuel cell components. By utilizing calorimetry to monitor heat generation and dissipation patterns, scientists can better understand the thermal cycling effects on materials, leading to the development of more robust and long-lasting fuel cell designs.

Calorimetry also plays a crucial role in validating theoretical models and simulations of fuel cell behavior. The ability to accurately measure heat flows and temperature distributions allows researchers to refine computational models, thereby accelerating the design and optimization process for new fuel cell configurations.

Furthermore, calorimetric techniques are instrumental in investigating the complex interplay between different fuel cell components, such as the membrane electrode assembly, gas diffusion layers, and bipolar plates. This comprehensive understanding is essential for developing integrated thermal management solutions that address the unique challenges posed by each component.

As hydrogen fuel cells continue to gain prominence in various applications, from automotive to stationary power generation, the role of calorimetry in their development becomes increasingly significant. The technology aims to provide real-time, in-situ measurements of thermal processes during fuel cell operation, enabling more dynamic and responsive control strategies.

In conclusion, the background and objectives of calorimetry in hydrogen fuel cell development underscore its importance as a fundamental analytical tool. By offering detailed insights into thermal phenomena, calorimetry continues to drive innovation in fuel cell technology, paving the way for more efficient, durable, and commercially viable hydrogen-based energy solutions.

Initially, calorimetric measurements were primarily used to assess the overall efficiency of fuel cells by comparing the electrical energy output to the total energy input from the fuel. As the field progressed, calorimetry evolved into a sophisticated tool for investigating the intricate thermal processes occurring within fuel cells, providing invaluable insights into reaction kinetics, heat management, and material degradation.

The objectives of employing calorimetry in hydrogen fuel cell research have expanded significantly over time. One primary goal is to enhance the overall system efficiency by minimizing heat losses and optimizing thermal management strategies. Calorimetric studies enable researchers to identify hotspots, areas of uneven heat distribution, and potential thermal stress points within the fuel cell stack.

Another critical objective is to improve the durability and longevity of fuel cell components. By utilizing calorimetry to monitor heat generation and dissipation patterns, scientists can better understand the thermal cycling effects on materials, leading to the development of more robust and long-lasting fuel cell designs.

Calorimetry also plays a crucial role in validating theoretical models and simulations of fuel cell behavior. The ability to accurately measure heat flows and temperature distributions allows researchers to refine computational models, thereby accelerating the design and optimization process for new fuel cell configurations.

Furthermore, calorimetric techniques are instrumental in investigating the complex interplay between different fuel cell components, such as the membrane electrode assembly, gas diffusion layers, and bipolar plates. This comprehensive understanding is essential for developing integrated thermal management solutions that address the unique challenges posed by each component.

As hydrogen fuel cells continue to gain prominence in various applications, from automotive to stationary power generation, the role of calorimetry in their development becomes increasingly significant. The technology aims to provide real-time, in-situ measurements of thermal processes during fuel cell operation, enabling more dynamic and responsive control strategies.

In conclusion, the background and objectives of calorimetry in hydrogen fuel cell development underscore its importance as a fundamental analytical tool. By offering detailed insights into thermal phenomena, calorimetry continues to drive innovation in fuel cell technology, paving the way for more efficient, durable, and commercially viable hydrogen-based energy solutions.

Market Analysis for H2 Fuel Cell Technologies

The hydrogen fuel cell market has been experiencing significant growth in recent years, driven by the increasing demand for clean energy solutions and the global push towards decarbonization. The market for hydrogen fuel cell technologies is expected to expand rapidly across various sectors, including transportation, stationary power generation, and portable electronics.

In the transportation sector, fuel cell electric vehicles (FCEVs) are gaining traction, particularly in the heavy-duty vehicle segment. Major automotive manufacturers are investing heavily in fuel cell technology, recognizing its potential to complement battery electric vehicles in the transition to zero-emission mobility. The market for fuel cell buses and trucks is projected to grow substantially, as these vehicles offer longer range and faster refueling times compared to their battery-powered counterparts.

The stationary power generation market for hydrogen fuel cells is also showing promise, especially in backup power applications for critical infrastructure such as data centers, hospitals, and telecommunications. As grid reliability becomes increasingly important, fuel cells offer a clean and efficient alternative to traditional diesel generators. Additionally, the use of fuel cells in combined heat and power (CHP) systems for residential and commercial buildings is gaining attention, providing both electricity and thermal energy with high efficiency.

In the portable electronics sector, fuel cells are being explored as a potential replacement for conventional batteries in applications requiring longer operating times and rapid recharging. This includes power sources for drones, remote sensors, and military equipment.

The market growth is supported by increasing government initiatives and funding programs aimed at promoting hydrogen technologies. Many countries have announced ambitious hydrogen strategies, allocating significant resources to develop infrastructure and support research and development in fuel cell technologies.

However, challenges remain in the widespread adoption of hydrogen fuel cells. The high cost of fuel cell systems, limited hydrogen infrastructure, and competition from other clean energy technologies are key factors influencing market dynamics. The cost of hydrogen production, particularly from renewable sources, also plays a crucial role in the overall market development.

Despite these challenges, the market outlook for hydrogen fuel cell technologies remains positive. Advancements in materials science, manufacturing processes, and system integration are expected to drive down costs and improve performance, making fuel cells increasingly competitive with conventional energy technologies. As the global focus on sustainability intensifies, the hydrogen fuel cell market is poised for substantial growth across multiple sectors in the coming years.

In the transportation sector, fuel cell electric vehicles (FCEVs) are gaining traction, particularly in the heavy-duty vehicle segment. Major automotive manufacturers are investing heavily in fuel cell technology, recognizing its potential to complement battery electric vehicles in the transition to zero-emission mobility. The market for fuel cell buses and trucks is projected to grow substantially, as these vehicles offer longer range and faster refueling times compared to their battery-powered counterparts.

The stationary power generation market for hydrogen fuel cells is also showing promise, especially in backup power applications for critical infrastructure such as data centers, hospitals, and telecommunications. As grid reliability becomes increasingly important, fuel cells offer a clean and efficient alternative to traditional diesel generators. Additionally, the use of fuel cells in combined heat and power (CHP) systems for residential and commercial buildings is gaining attention, providing both electricity and thermal energy with high efficiency.

In the portable electronics sector, fuel cells are being explored as a potential replacement for conventional batteries in applications requiring longer operating times and rapid recharging. This includes power sources for drones, remote sensors, and military equipment.

The market growth is supported by increasing government initiatives and funding programs aimed at promoting hydrogen technologies. Many countries have announced ambitious hydrogen strategies, allocating significant resources to develop infrastructure and support research and development in fuel cell technologies.

However, challenges remain in the widespread adoption of hydrogen fuel cells. The high cost of fuel cell systems, limited hydrogen infrastructure, and competition from other clean energy technologies are key factors influencing market dynamics. The cost of hydrogen production, particularly from renewable sources, also plays a crucial role in the overall market development.

Despite these challenges, the market outlook for hydrogen fuel cell technologies remains positive. Advancements in materials science, manufacturing processes, and system integration are expected to drive down costs and improve performance, making fuel cells increasingly competitive with conventional energy technologies. As the global focus on sustainability intensifies, the hydrogen fuel cell market is poised for substantial growth across multiple sectors in the coming years.

Current Calorimetry Techniques in Fuel Cell Research

Calorimetry plays a crucial role in the development and optimization of hydrogen fuel cells. Current calorimetry techniques employed in fuel cell research encompass a wide range of methodologies, each offering unique insights into the thermal behavior and efficiency of these energy conversion devices.

One of the most widely used techniques is isothermal calorimetry, which allows researchers to measure heat generation and consumption under constant temperature conditions. This method is particularly valuable for studying the kinetics of electrochemical reactions within fuel cells, providing detailed information on reaction rates and thermal efficiencies.

Differential scanning calorimetry (DSC) is another essential tool in fuel cell research. DSC enables the investigation of phase transitions, thermal stability, and heat capacity of fuel cell components. This technique is especially useful for analyzing membrane materials and catalyst layers, helping researchers optimize their composition and structure for enhanced performance.

Thermogravimetric analysis (TGA) is often combined with calorimetry to provide a comprehensive understanding of fuel cell materials. TGA measures mass changes as a function of temperature, offering insights into material degradation, water uptake, and thermal stability. When coupled with calorimetry, it allows for the correlation of thermal events with mass changes, providing a more complete picture of fuel cell behavior.

Microcalorimetry has gained prominence in recent years due to its ability to detect minute thermal changes with high precision. This technique is particularly valuable for studying the early stages of catalyst activation and degradation processes, which are critical factors in fuel cell longevity and efficiency.

Flow calorimetry has emerged as a powerful tool for in-situ measurements of operating fuel cells. By integrating calorimetric sensors into fuel cell systems, researchers can monitor heat generation and distribution in real-time, providing valuable data on system efficiency and thermal management strategies.

Advanced imaging techniques, such as infrared thermography, are increasingly being combined with calorimetry to map temperature distributions across fuel cell components. This integration allows for the identification of hotspots and thermal gradients, which can significantly impact fuel cell performance and durability.

Computational modeling and simulation have become indispensable companions to experimental calorimetry. These tools enable researchers to predict thermal behavior, optimize cell designs, and interpret complex calorimetric data. The synergy between experimental and computational approaches has accelerated the development of more efficient and durable fuel cell systems.

As fuel cell technology continues to evolve, calorimetry techniques are becoming more sophisticated and specialized. The development of high-throughput calorimetry methods is enabling faster screening of materials and catalysts, while advances in nanocalorimetry are providing unprecedented insights into the thermal properties of nanoscale fuel cell components.

One of the most widely used techniques is isothermal calorimetry, which allows researchers to measure heat generation and consumption under constant temperature conditions. This method is particularly valuable for studying the kinetics of electrochemical reactions within fuel cells, providing detailed information on reaction rates and thermal efficiencies.

Differential scanning calorimetry (DSC) is another essential tool in fuel cell research. DSC enables the investigation of phase transitions, thermal stability, and heat capacity of fuel cell components. This technique is especially useful for analyzing membrane materials and catalyst layers, helping researchers optimize their composition and structure for enhanced performance.

Thermogravimetric analysis (TGA) is often combined with calorimetry to provide a comprehensive understanding of fuel cell materials. TGA measures mass changes as a function of temperature, offering insights into material degradation, water uptake, and thermal stability. When coupled with calorimetry, it allows for the correlation of thermal events with mass changes, providing a more complete picture of fuel cell behavior.

Microcalorimetry has gained prominence in recent years due to its ability to detect minute thermal changes with high precision. This technique is particularly valuable for studying the early stages of catalyst activation and degradation processes, which are critical factors in fuel cell longevity and efficiency.

Flow calorimetry has emerged as a powerful tool for in-situ measurements of operating fuel cells. By integrating calorimetric sensors into fuel cell systems, researchers can monitor heat generation and distribution in real-time, providing valuable data on system efficiency and thermal management strategies.

Advanced imaging techniques, such as infrared thermography, are increasingly being combined with calorimetry to map temperature distributions across fuel cell components. This integration allows for the identification of hotspots and thermal gradients, which can significantly impact fuel cell performance and durability.

Computational modeling and simulation have become indispensable companions to experimental calorimetry. These tools enable researchers to predict thermal behavior, optimize cell designs, and interpret complex calorimetric data. The synergy between experimental and computational approaches has accelerated the development of more efficient and durable fuel cell systems.

As fuel cell technology continues to evolve, calorimetry techniques are becoming more sophisticated and specialized. The development of high-throughput calorimetry methods is enabling faster screening of materials and catalysts, while advances in nanocalorimetry are providing unprecedented insights into the thermal properties of nanoscale fuel cell components.

Existing Calorimetric Solutions for Fuel Cell Development

01 Calorimetry in medical diagnostics

Calorimetry techniques are applied in medical diagnostics to measure heat production or absorption in biological processes. This can be used for early disease detection, monitoring metabolic rates, and assessing treatment efficacy. Advanced calorimetric devices are being developed to provide non-invasive, real-time measurements of physiological parameters.- Calorimetry in medical diagnostics: Calorimetry techniques are applied in medical diagnostics to measure heat production or absorption in biological processes. This can be used for early disease detection, monitoring metabolic rates, and assessing treatment efficacy. Advanced calorimetric devices are being developed to provide non-invasive, real-time measurements of physiological parameters.

- Calorimetry in material science and engineering: Calorimetry plays a crucial role in material science and engineering for characterizing thermal properties of materials. It is used to study phase transitions, measure heat capacity, and analyze thermal stability. Advanced calorimetric methods are being developed to improve accuracy and sensitivity in material analysis.

- Calorimetry in food and pharmaceutical industries: Calorimetry is widely used in food and pharmaceutical industries for quality control, safety testing, and product development. It helps in determining the shelf life of products, assessing drug stability, and studying the impact of processing conditions on food quality. New calorimetric techniques are being developed to enhance efficiency and accuracy in these applications.

- Advancements in calorimetric instrumentation: Ongoing developments in calorimetric instrumentation focus on improving sensitivity, accuracy, and automation. This includes the integration of advanced sensors, data processing algorithms, and miniaturization of devices. These advancements aim to expand the application range of calorimetry and make it more accessible for various research and industrial applications.

- Environmental and energy applications of calorimetry: Calorimetry is increasingly being applied in environmental monitoring and energy research. It is used to study the thermal properties of renewable energy materials, assess the environmental impact of chemicals, and optimize energy-efficient processes. New calorimetric methods are being developed to address challenges in sustainable development and climate change mitigation.

02 Calorimetry in material science and engineering

Calorimetry plays a crucial role in material science and engineering for characterizing thermal properties of materials. It is used to study phase transitions, measure heat capacity, and analyze thermal stability. Advanced calorimetric methods are being developed to improve accuracy and sensitivity in material analysis.Expand Specific Solutions03 Innovations in calorimetric instrumentation

Recent advancements in calorimetric instrumentation focus on improving sensitivity, accuracy, and automation. New designs incorporate miniaturization, integration with other analytical techniques, and the use of advanced materials. These innovations enable more precise measurements and expand the application range of calorimetry.Expand Specific Solutions04 Calorimetry in environmental and energy studies

Calorimetry is increasingly used in environmental and energy-related research. Applications include studying combustion processes, assessing energy efficiency, and analyzing environmental samples. Calorimetric techniques are being adapted to measure the thermal impact of various industrial processes and to develop more sustainable technologies.Expand Specific Solutions05 Calorimetry in food science and nutrition

Calorimetry has significant impacts in food science and nutrition research. It is used to study food quality, shelf life, and nutritional content. Advanced calorimetric methods are being developed to analyze the thermal properties of food components, assess food safety, and optimize food processing techniques.Expand Specific Solutions

Key Players in H2 Fuel Cell Calorimetry

The development of hydrogen fuel cells is currently in a growth phase, with increasing market size and technological advancements. The global hydrogen fuel cell market is projected to expand significantly in the coming years, driven by environmental concerns and government initiatives. Key players like Toyota Motor Corp., Plug Power, Inc., and FuelCell Energy, Inc. are at the forefront of innovation, investing heavily in research and development. The technology's maturity varies across applications, with automotive and stationary power sectors showing promising progress. Companies such as GM Global Technology Operations LLC and Audi AG are also making strides in fuel cell technology for vehicles. While challenges remain in infrastructure and cost-effectiveness, ongoing research by institutions like the Naval Research Laboratory and universities is accelerating the technology's evolution towards commercial viability.

Toyota Motor Corp.

Technical Solution: Toyota has developed advanced calorimetry techniques for hydrogen fuel cell development, focusing on improving thermal management and efficiency. Their approach involves high-precision calorimetry to measure heat generation and dissipation in fuel cells during operation[1]. This allows for detailed analysis of electrochemical reactions and identification of heat loss points. Toyota's calorimetry system can detect temperature changes as small as 0.01°C, enabling fine-tuning of fuel cell design[3]. They have also implemented in-situ calorimetry in their test vehicles, providing real-time data on fuel cell performance under various driving conditions[5]. This data is used to optimize cooling systems and improve overall fuel cell efficiency, contributing to Toyota's leadership in hydrogen fuel cell vehicles.

Strengths: High precision measurements, real-world data collection, and extensive experience in fuel cell vehicles. Weaknesses: High cost of specialized equipment and potential limitations in scaling up for mass production.

GM Global Technology Operations LLC

Technical Solution: GM has developed a comprehensive calorimetry approach for hydrogen fuel cell development, focusing on both materials characterization and system-level analysis. Their method incorporates differential scanning calorimetry (DSC) to study the thermal properties of fuel cell materials, including membranes and catalysts[2]. GM's calorimetry techniques also extend to full-scale fuel cell stacks, using advanced thermal imaging and flow calorimetry to map heat distribution and identify hotspots[4]. They have reported achieving a 20% improvement in fuel cell efficiency through optimized thermal management based on calorimetric data[6]. GM's approach also includes accelerated stress testing using calorimetry to predict long-term fuel cell durability, a critical factor for commercial viability.

Strengths: Comprehensive approach from materials to full systems, focus on durability testing. Weaknesses: Potential challenges in translating laboratory results to real-world performance.

Innovative Calorimetry Approaches in Fuel Cell Research

Composite material containing perovskite structure oxide, preparation method and application thereof

PatentActiveCN103811772A

Innovation

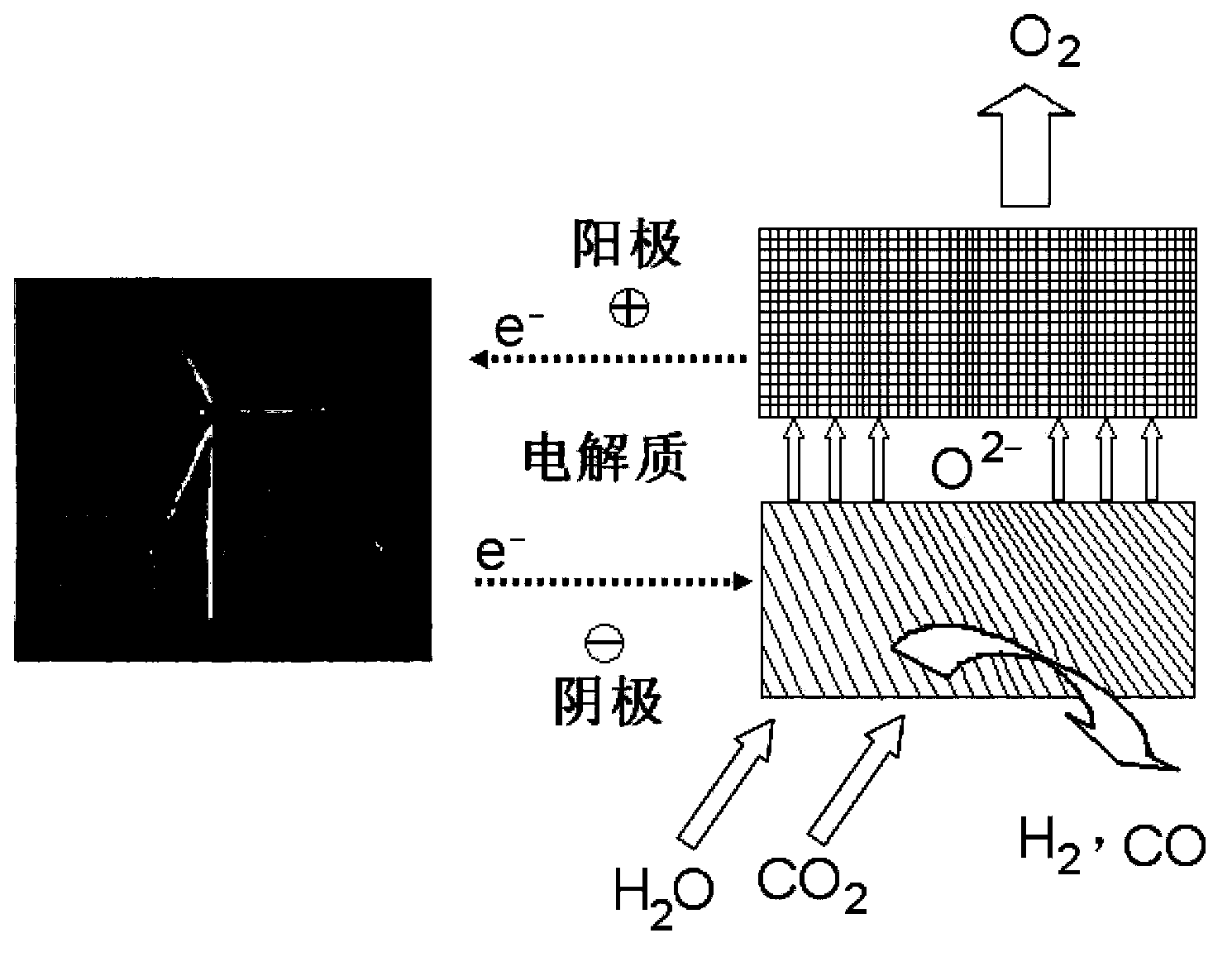

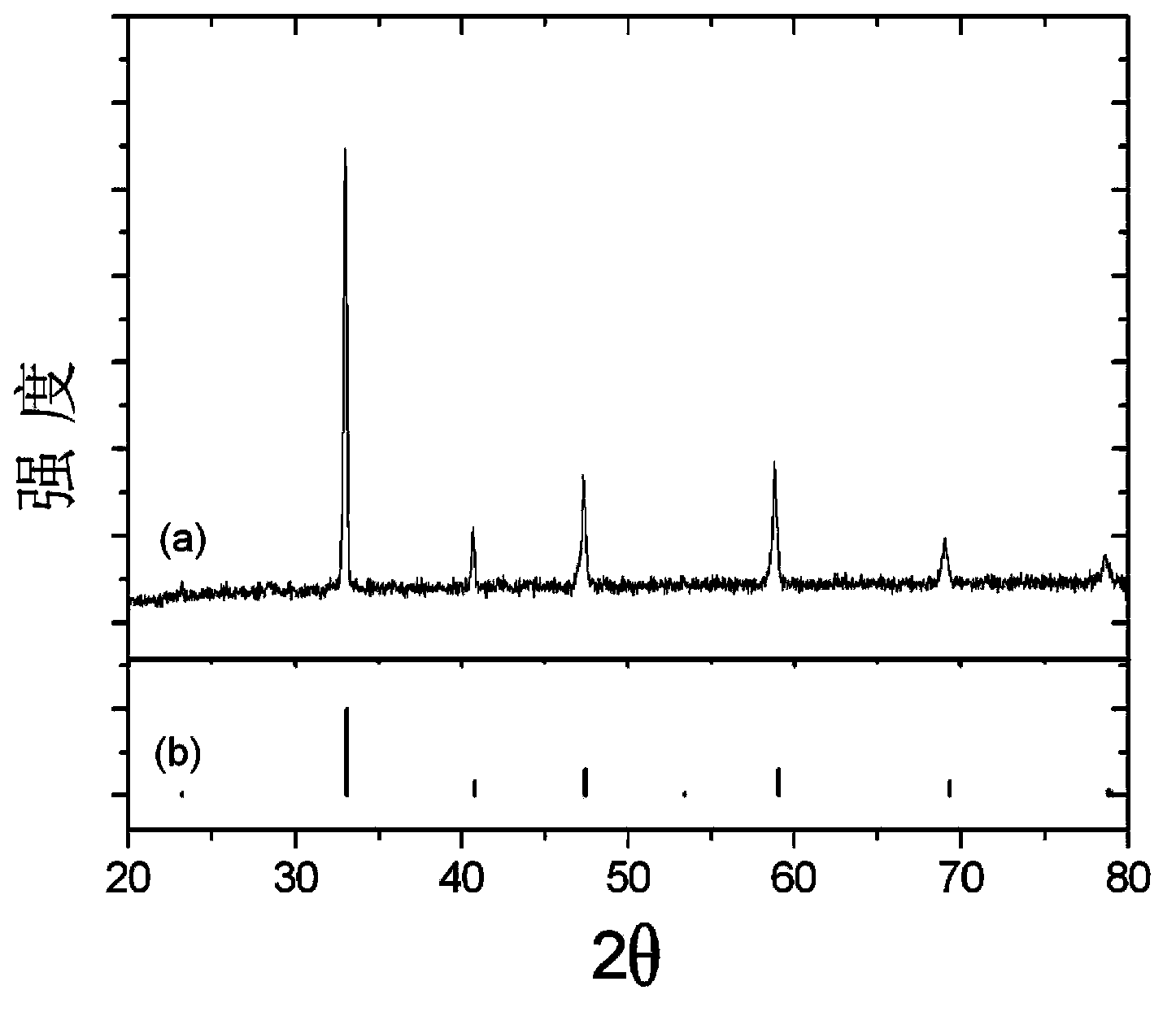

- Composite materials containing perovskite-type structural oxides are used, combined with oxygen ion conductor oxides, through solid-phase methods, sol-gel methods and other preparation methods to form mixed ion conductor materials with high oxygen ion conductivity and electronic conductivity. The cathode of solid oxide fuel cells and the cathode of electrolytic cells improve the chemical compatibility and catalytic activity of materials.

Environmental Impact of H2 Fuel Cell Technologies

The environmental impact of hydrogen fuel cell technologies is a critical consideration in their development and deployment. As the world seeks cleaner energy solutions, hydrogen fuel cells have emerged as a promising alternative to traditional fossil fuel-based systems. However, their environmental footprint must be carefully assessed to ensure they truly contribute to sustainability goals.

One of the primary environmental benefits of hydrogen fuel cells is their potential to reduce greenhouse gas emissions. When hydrogen is produced from renewable sources, such as solar or wind power, the entire fuel cell lifecycle can be nearly carbon-neutral. This aspect is particularly significant in the transportation sector, where fuel cell vehicles can offer zero tailpipe emissions, contributing to improved air quality in urban areas.

Water is the primary byproduct of hydrogen fuel cell operation, which is environmentally benign compared to the emissions from conventional internal combustion engines. This characteristic makes fuel cells particularly attractive for use in sensitive environments or indoor applications where air quality is paramount.

However, the environmental impact of hydrogen fuel cells extends beyond their operational phase. The production of hydrogen itself can have significant environmental implications. Currently, most hydrogen is produced through steam methane reforming, which relies on natural gas and results in carbon dioxide emissions. To truly realize the environmental benefits of fuel cells, there is a pressing need to transition to greener hydrogen production methods, such as electrolysis powered by renewable energy.

The materials used in fuel cell construction also warrant environmental consideration. Platinum, a key catalyst in many fuel cell designs, is a rare and expensive metal with mining practices that can have substantial environmental impacts. Research into alternative catalysts or reduced platinum loading is crucial for improving the overall environmental profile of fuel cell technologies.

End-of-life management and recycling of fuel cell components present both challenges and opportunities. Proper recycling processes can recover valuable materials and minimize waste, but these systems need to be developed and implemented on a large scale as fuel cell adoption increases.

The environmental impact of hydrogen storage and distribution infrastructure must also be considered. While hydrogen itself is clean, the energy-intensive processes of compression or liquefaction for storage and transportation can offset some of the environmental gains if not powered by renewable sources.

In conclusion, while hydrogen fuel cell technologies offer significant potential for reducing environmental impact compared to conventional energy systems, their true sustainability depends on the entire value chain, from hydrogen production to end-of-life management. As the technology matures, ongoing research and development efforts must focus on optimizing each stage of the fuel cell lifecycle to maximize environmental benefits and minimize negative impacts.

One of the primary environmental benefits of hydrogen fuel cells is their potential to reduce greenhouse gas emissions. When hydrogen is produced from renewable sources, such as solar or wind power, the entire fuel cell lifecycle can be nearly carbon-neutral. This aspect is particularly significant in the transportation sector, where fuel cell vehicles can offer zero tailpipe emissions, contributing to improved air quality in urban areas.

Water is the primary byproduct of hydrogen fuel cell operation, which is environmentally benign compared to the emissions from conventional internal combustion engines. This characteristic makes fuel cells particularly attractive for use in sensitive environments or indoor applications where air quality is paramount.

However, the environmental impact of hydrogen fuel cells extends beyond their operational phase. The production of hydrogen itself can have significant environmental implications. Currently, most hydrogen is produced through steam methane reforming, which relies on natural gas and results in carbon dioxide emissions. To truly realize the environmental benefits of fuel cells, there is a pressing need to transition to greener hydrogen production methods, such as electrolysis powered by renewable energy.

The materials used in fuel cell construction also warrant environmental consideration. Platinum, a key catalyst in many fuel cell designs, is a rare and expensive metal with mining practices that can have substantial environmental impacts. Research into alternative catalysts or reduced platinum loading is crucial for improving the overall environmental profile of fuel cell technologies.

End-of-life management and recycling of fuel cell components present both challenges and opportunities. Proper recycling processes can recover valuable materials and minimize waste, but these systems need to be developed and implemented on a large scale as fuel cell adoption increases.

The environmental impact of hydrogen storage and distribution infrastructure must also be considered. While hydrogen itself is clean, the energy-intensive processes of compression or liquefaction for storage and transportation can offset some of the environmental gains if not powered by renewable sources.

In conclusion, while hydrogen fuel cell technologies offer significant potential for reducing environmental impact compared to conventional energy systems, their true sustainability depends on the entire value chain, from hydrogen production to end-of-life management. As the technology matures, ongoing research and development efforts must focus on optimizing each stage of the fuel cell lifecycle to maximize environmental benefits and minimize negative impacts.

Standardization of Calorimetric Measurements in Fuel Cells

Standardization of calorimetric measurements in fuel cells is crucial for advancing hydrogen fuel cell technology and ensuring consistent, reliable performance evaluation across the industry. The lack of uniform measurement protocols has historically hindered progress in fuel cell development, making it challenging to compare results from different research groups and manufacturers.

To address this issue, several international organizations and regulatory bodies have been working towards establishing standardized calorimetric measurement procedures for fuel cells. These efforts aim to create a common framework that researchers and manufacturers can follow, enabling more accurate and reproducible results.

One of the key aspects of standardization is the development of precise calibration methods for calorimetric instruments used in fuel cell testing. This includes defining reference materials and procedures for calibrating heat flow sensors, temperature probes, and other critical components of calorimetric systems.

Another important element of standardization is the establishment of uniform testing conditions and protocols. This involves specifying parameters such as operating temperature ranges, humidity levels, gas flow rates, and pressure conditions under which calorimetric measurements should be conducted. By adhering to these standardized conditions, researchers can ensure that their results are comparable across different laboratories and experimental setups.

The standardization process also addresses the need for consistent data reporting and analysis methods. This includes defining standard units of measurement, data formats, and statistical analysis techniques to be used when presenting calorimetric results. Such uniformity in reporting facilitates easier comparison and interpretation of data from various sources.

Efforts are also being made to standardize the design and construction of calorimetric measurement systems specifically tailored for fuel cell applications. This includes guidelines for thermal insulation, gas handling systems, and electrical connections to minimize measurement errors and ensure consistency across different experimental setups.

As the field of hydrogen fuel cell technology continues to evolve, the standardization of calorimetric measurements will play a vital role in accelerating research and development. It will enable more efficient collaboration between academic institutions, industry partners, and government agencies, ultimately leading to faster commercialization of fuel cell technologies and their widespread adoption in various applications.

To address this issue, several international organizations and regulatory bodies have been working towards establishing standardized calorimetric measurement procedures for fuel cells. These efforts aim to create a common framework that researchers and manufacturers can follow, enabling more accurate and reproducible results.

One of the key aspects of standardization is the development of precise calibration methods for calorimetric instruments used in fuel cell testing. This includes defining reference materials and procedures for calibrating heat flow sensors, temperature probes, and other critical components of calorimetric systems.

Another important element of standardization is the establishment of uniform testing conditions and protocols. This involves specifying parameters such as operating temperature ranges, humidity levels, gas flow rates, and pressure conditions under which calorimetric measurements should be conducted. By adhering to these standardized conditions, researchers can ensure that their results are comparable across different laboratories and experimental setups.

The standardization process also addresses the need for consistent data reporting and analysis methods. This includes defining standard units of measurement, data formats, and statistical analysis techniques to be used when presenting calorimetric results. Such uniformity in reporting facilitates easier comparison and interpretation of data from various sources.

Efforts are also being made to standardize the design and construction of calorimetric measurement systems specifically tailored for fuel cell applications. This includes guidelines for thermal insulation, gas handling systems, and electrical connections to minimize measurement errors and ensure consistency across different experimental setups.

As the field of hydrogen fuel cell technology continues to evolve, the standardization of calorimetric measurements will play a vital role in accelerating research and development. It will enable more efficient collaboration between academic institutions, industry partners, and government agencies, ultimately leading to faster commercialization of fuel cell technologies and their widespread adoption in various applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!