How Calorimetry Refines Biodegradable Polymer Performance Analysis

AUG 5, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Calorimetry in Polymers

Calorimetry has emerged as a powerful analytical technique in the field of polymer science, offering invaluable insights into the thermal properties and behavior of polymers. This method measures the heat exchange between a sample and its environment, providing crucial information about phase transitions, chemical reactions, and structural changes within polymer materials.

In the context of biodegradable polymers, calorimetry plays a pivotal role in refining performance analysis. It enables researchers to study the thermal stability, degradation kinetics, and crystallization behavior of these environmentally friendly materials. By utilizing techniques such as Differential Scanning Calorimetry (DSC) and Isothermal Titration Calorimetry (ITC), scientists can accurately determine key parameters that influence polymer performance and biodegradability.

DSC, in particular, has become an indispensable tool for characterizing biodegradable polymers. It allows for the precise measurement of glass transition temperatures, melting points, and crystallization temperatures. These thermal properties are critical in understanding how the polymer will behave under various environmental conditions and during the degradation process. Furthermore, DSC can reveal information about the polymer's composition, purity, and compatibility with other materials, which are essential factors in optimizing its performance.

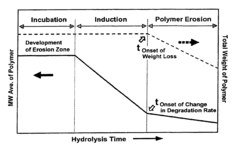

Calorimetry also enables the study of polymer degradation mechanisms. By monitoring the heat flow during controlled degradation experiments, researchers can gain insights into the kinetics and thermodynamics of the breakdown process. This information is crucial for predicting the polymer's lifespan in different environments and for designing materials with tailored degradation rates.

Moreover, calorimetric techniques can be used to investigate the interactions between biodegradable polymers and various additives or fillers. These interactions often play a significant role in enhancing the material's properties, such as mechanical strength, barrier properties, or degradation rate. By quantifying the heat changes associated with these interactions, researchers can optimize formulations and develop more effective composite materials.

In the realm of polymer blends and copolymers, calorimetry provides a means to assess miscibility and phase behavior. This is particularly important for biodegradable polymers, as blending different materials can often lead to improved overall performance. Calorimetric analysis can reveal the presence of separate phases, the degree of mixing, and the impact of composition on thermal properties, all of which are critical for designing high-performance biodegradable materials.

In the context of biodegradable polymers, calorimetry plays a pivotal role in refining performance analysis. It enables researchers to study the thermal stability, degradation kinetics, and crystallization behavior of these environmentally friendly materials. By utilizing techniques such as Differential Scanning Calorimetry (DSC) and Isothermal Titration Calorimetry (ITC), scientists can accurately determine key parameters that influence polymer performance and biodegradability.

DSC, in particular, has become an indispensable tool for characterizing biodegradable polymers. It allows for the precise measurement of glass transition temperatures, melting points, and crystallization temperatures. These thermal properties are critical in understanding how the polymer will behave under various environmental conditions and during the degradation process. Furthermore, DSC can reveal information about the polymer's composition, purity, and compatibility with other materials, which are essential factors in optimizing its performance.

Calorimetry also enables the study of polymer degradation mechanisms. By monitoring the heat flow during controlled degradation experiments, researchers can gain insights into the kinetics and thermodynamics of the breakdown process. This information is crucial for predicting the polymer's lifespan in different environments and for designing materials with tailored degradation rates.

Moreover, calorimetric techniques can be used to investigate the interactions between biodegradable polymers and various additives or fillers. These interactions often play a significant role in enhancing the material's properties, such as mechanical strength, barrier properties, or degradation rate. By quantifying the heat changes associated with these interactions, researchers can optimize formulations and develop more effective composite materials.

In the realm of polymer blends and copolymers, calorimetry provides a means to assess miscibility and phase behavior. This is particularly important for biodegradable polymers, as blending different materials can often lead to improved overall performance. Calorimetric analysis can reveal the presence of separate phases, the degree of mixing, and the impact of composition on thermal properties, all of which are critical for designing high-performance biodegradable materials.

Market Demand Analysis

The market demand for biodegradable polymers has been steadily increasing due to growing environmental concerns and regulatory pressures. Calorimetry, as a refined analytical technique, plays a crucial role in enhancing the performance analysis of these materials, thereby driving market growth and innovation.

The global biodegradable plastics market is experiencing significant expansion, with projections indicating continued growth in the coming years. This surge is primarily attributed to the rising awareness of plastic pollution and the shift towards sustainable alternatives across various industries. Packaging, agriculture, and consumer goods sectors are particularly driving the demand for biodegradable polymers.

Calorimetry's application in biodegradable polymer analysis addresses a critical market need for more accurate and comprehensive performance evaluation. As manufacturers strive to develop polymers with improved degradation rates and mechanical properties, calorimetric techniques offer valuable insights into thermal behavior, degradation kinetics, and material stability. This enhanced understanding enables the production of more efficient and reliable biodegradable products, meeting the evolving demands of environmentally conscious consumers and stringent regulatory standards.

The food packaging industry represents a significant market segment for biodegradable polymers, with calorimetry playing a vital role in ensuring food safety and packaging integrity. As consumers increasingly prefer eco-friendly packaging solutions, the demand for biodegradable polymers that maintain food quality while minimizing environmental impact continues to rise. Calorimetric analysis helps in optimizing polymer formulations to meet these dual requirements effectively.

In the agricultural sector, biodegradable polymers are gaining traction for applications such as mulch films and controlled-release fertilizers. Calorimetry aids in developing polymers with tailored degradation profiles, ensuring optimal nutrient release and soil health. This aligns with the growing trend towards sustainable farming practices and reduced environmental footprint in agriculture.

The medical and pharmaceutical industries also present a promising market for biodegradable polymers, particularly in drug delivery systems and implantable devices. Calorimetric techniques are essential in assessing the biocompatibility and degradation behavior of these materials in physiological conditions, driving innovation in personalized medicine and minimally invasive treatments.

As sustainability becomes a key focus across industries, the demand for advanced analytical tools like calorimetry in biodegradable polymer research and development is expected to grow. This trend is further supported by increasing investments in R&D and collaborations between academic institutions and industry players to develop next-generation biodegradable materials with enhanced performance characteristics.

The global biodegradable plastics market is experiencing significant expansion, with projections indicating continued growth in the coming years. This surge is primarily attributed to the rising awareness of plastic pollution and the shift towards sustainable alternatives across various industries. Packaging, agriculture, and consumer goods sectors are particularly driving the demand for biodegradable polymers.

Calorimetry's application in biodegradable polymer analysis addresses a critical market need for more accurate and comprehensive performance evaluation. As manufacturers strive to develop polymers with improved degradation rates and mechanical properties, calorimetric techniques offer valuable insights into thermal behavior, degradation kinetics, and material stability. This enhanced understanding enables the production of more efficient and reliable biodegradable products, meeting the evolving demands of environmentally conscious consumers and stringent regulatory standards.

The food packaging industry represents a significant market segment for biodegradable polymers, with calorimetry playing a vital role in ensuring food safety and packaging integrity. As consumers increasingly prefer eco-friendly packaging solutions, the demand for biodegradable polymers that maintain food quality while minimizing environmental impact continues to rise. Calorimetric analysis helps in optimizing polymer formulations to meet these dual requirements effectively.

In the agricultural sector, biodegradable polymers are gaining traction for applications such as mulch films and controlled-release fertilizers. Calorimetry aids in developing polymers with tailored degradation profiles, ensuring optimal nutrient release and soil health. This aligns with the growing trend towards sustainable farming practices and reduced environmental footprint in agriculture.

The medical and pharmaceutical industries also present a promising market for biodegradable polymers, particularly in drug delivery systems and implantable devices. Calorimetric techniques are essential in assessing the biocompatibility and degradation behavior of these materials in physiological conditions, driving innovation in personalized medicine and minimally invasive treatments.

As sustainability becomes a key focus across industries, the demand for advanced analytical tools like calorimetry in biodegradable polymer research and development is expected to grow. This trend is further supported by increasing investments in R&D and collaborations between academic institutions and industry players to develop next-generation biodegradable materials with enhanced performance characteristics.

Current Challenges

The field of biodegradable polymer performance analysis faces several significant challenges that hinder the widespread adoption and optimization of these materials. One of the primary obstacles is the lack of standardized testing methods for accurately assessing the degradation rates and environmental impact of biodegradable polymers. This inconsistency in evaluation techniques makes it difficult to compare different materials and establish reliable benchmarks for performance.

Another major challenge lies in the complexity of degradation processes, which can vary significantly depending on environmental conditions. Factors such as temperature, humidity, microbial activity, and pH levels can all influence the degradation rate and pathway of biodegradable polymers. This variability makes it challenging to predict and control the performance of these materials in diverse real-world applications.

The long-term stability and shelf life of biodegradable polymers pose additional concerns. Many of these materials begin to degrade prematurely during storage or use, leading to compromised mechanical properties and reduced functionality. Balancing the need for biodegradability with maintaining desired material properties throughout the product lifecycle remains a significant technical hurdle.

Furthermore, the cost-effectiveness of biodegradable polymers compared to traditional plastics continues to be a limiting factor in their widespread adoption. The production processes for many biodegradable materials are still more expensive and energy-intensive than those for conventional plastics, making it difficult for these eco-friendly alternatives to compete in price-sensitive markets.

The development of accurate and reliable methods for predicting the long-term performance of biodegradable polymers is another critical challenge. Current accelerated aging tests often fail to accurately simulate real-world conditions, leading to discrepancies between laboratory results and actual field performance. This gap in predictive capabilities hampers the design and optimization of biodegradable polymer formulations for specific applications.

Additionally, the environmental impact of degradation byproducts remains a concern. While biodegradable polymers break down more readily than conventional plastics, the potential toxicity and ecological effects of their degradation products are not fully understood. Comprehensive studies on the long-term environmental consequences of these materials are needed to ensure their safety and sustainability.

Lastly, the integration of biodegradable polymers into existing recycling and waste management systems presents logistical and technical challenges. Many current recycling facilities are not equipped to handle biodegradable materials, leading to potential contamination of conventional plastic recycling streams. Developing effective sorting and processing methods for biodegradable polymers within existing waste management infrastructure is crucial for realizing their full environmental benefits.

Another major challenge lies in the complexity of degradation processes, which can vary significantly depending on environmental conditions. Factors such as temperature, humidity, microbial activity, and pH levels can all influence the degradation rate and pathway of biodegradable polymers. This variability makes it challenging to predict and control the performance of these materials in diverse real-world applications.

The long-term stability and shelf life of biodegradable polymers pose additional concerns. Many of these materials begin to degrade prematurely during storage or use, leading to compromised mechanical properties and reduced functionality. Balancing the need for biodegradability with maintaining desired material properties throughout the product lifecycle remains a significant technical hurdle.

Furthermore, the cost-effectiveness of biodegradable polymers compared to traditional plastics continues to be a limiting factor in their widespread adoption. The production processes for many biodegradable materials are still more expensive and energy-intensive than those for conventional plastics, making it difficult for these eco-friendly alternatives to compete in price-sensitive markets.

The development of accurate and reliable methods for predicting the long-term performance of biodegradable polymers is another critical challenge. Current accelerated aging tests often fail to accurately simulate real-world conditions, leading to discrepancies between laboratory results and actual field performance. This gap in predictive capabilities hampers the design and optimization of biodegradable polymer formulations for specific applications.

Additionally, the environmental impact of degradation byproducts remains a concern. While biodegradable polymers break down more readily than conventional plastics, the potential toxicity and ecological effects of their degradation products are not fully understood. Comprehensive studies on the long-term environmental consequences of these materials are needed to ensure their safety and sustainability.

Lastly, the integration of biodegradable polymers into existing recycling and waste management systems presents logistical and technical challenges. Many current recycling facilities are not equipped to handle biodegradable materials, leading to potential contamination of conventional plastic recycling streams. Developing effective sorting and processing methods for biodegradable polymers within existing waste management infrastructure is crucial for realizing their full environmental benefits.

Existing Techniques

01 Improved mechanical properties of biodegradable polymers

Enhancing the mechanical strength, flexibility, and durability of biodegradable polymers through various techniques such as blending, copolymerization, or addition of reinforcing agents. These improvements address the limitations of traditional biodegradable polymers, making them suitable for a wider range of applications.- Improved mechanical properties of biodegradable polymers: Research focuses on enhancing the strength, flexibility, and durability of biodegradable polymers through various methods such as blending, copolymerization, and reinforcement with natural fibers. These improvements aim to make biodegradable polymers more suitable for a wider range of applications, including packaging and medical devices.

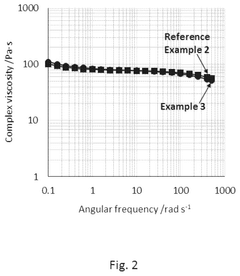

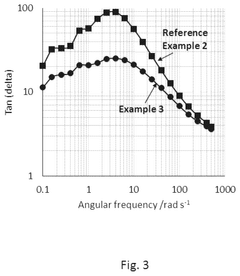

- Thermal stability and processing of biodegradable polymers: Efforts are made to improve the thermal stability and processability of biodegradable polymers, allowing for better performance during manufacturing and use. This includes developing polymers with higher melting points, improved melt strength, and enhanced resistance to thermal degradation.

- Biodegradation rate control and environmental impact: Research focuses on controlling the biodegradation rate of polymers to match specific application requirements while minimizing environmental impact. This involves developing polymers with tailored degradation profiles and studying their breakdown products to ensure they are environmentally benign.

- Functionalization and surface modification of biodegradable polymers: Techniques are developed to modify the surface properties and add functional groups to biodegradable polymers. This enhances their compatibility with other materials, improves their barrier properties, and allows for better control of their interactions with the environment and biological systems.

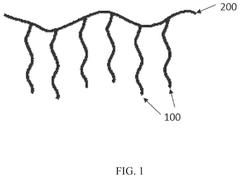

- Novel biodegradable polymer compositions and blends: New biodegradable polymer compositions and blends are developed to combine the desirable properties of different materials. This includes creating polymer alloys, incorporating natural polymers, and developing multi-component systems to achieve improved overall performance and biodegradability.

02 Thermal stability and processing of biodegradable polymers

Developing methods to improve the thermal stability of biodegradable polymers, enabling better processing and wider temperature range applications. This includes techniques to enhance melt strength, reduce thermal degradation during processing, and improve overall heat resistance of the polymers.Expand Specific Solutions03 Biodegradation rate control and environmental impact

Tailoring the biodegradation rate of polymers to suit specific applications while minimizing environmental impact. This involves developing strategies to control the degradation process, ensuring complete breakdown into non-toxic components, and studying the long-term effects on ecosystems.Expand Specific Solutions04 Functionalization and surface modification of biodegradable polymers

Enhancing the performance of biodegradable polymers through functionalization and surface modification techniques. This includes improving properties such as hydrophilicity, adhesion, and biocompatibility, making the polymers suitable for specialized applications in fields like medicine and packaging.Expand Specific Solutions05 Composite materials incorporating biodegradable polymers

Developing composite materials that combine biodegradable polymers with other materials to achieve enhanced performance characteristics. This includes creating bio-based composites, nanocomposites, and hybrid materials that offer improved mechanical, thermal, and barrier properties while maintaining biodegradability.Expand Specific Solutions

Key Industry Players

The calorimetry-based performance analysis of biodegradable polymers is in a growth phase, with increasing market size driven by sustainability demands. The technology's maturity is advancing, as evidenced by research from institutions like Nanjing Tech University and companies such as BASF Corp. and Kingfa Sci. & Tech. Co., Ltd. Major players like DuPont de Nemours, Inc. and ExxonMobil Chemical Patents, Inc. are investing in this field, indicating its strategic importance. The competitive landscape is diverse, with both established chemical companies and specialized biodegradable polymer manufacturers vying for market share. As the technology evolves, collaborations between academia and industry are likely to accelerate innovation and commercialization.

BASF Corp.

Technical Solution: BASF Corp. has developed advanced calorimetry techniques for analyzing biodegradable polymer performance. Their approach utilizes differential scanning calorimetry (DSC) and isothermal microcalorimetry to precisely measure thermal properties and degradation kinetics of biodegradable polymers[1]. This method allows for real-time monitoring of polymer degradation under various environmental conditions, providing insights into degradation rates, mechanisms, and byproduct formation[2]. BASF's calorimetric analysis also incorporates thermogravimetric analysis (TGA) to correlate mass loss with heat flow, offering a comprehensive understanding of the polymer's behavior during biodegradation[3].

Strengths: Precise thermal analysis, real-time degradation monitoring, and comprehensive polymer behavior understanding. Weaknesses: Potentially high equipment costs and complexity in data interpretation for non-experts.

Kingfa Sci. & Tech. Co., Ltd.

Technical Solution: Kingfa has developed a novel calorimetric approach for biodegradable polymer analysis, focusing on polylactic acid (PLA) and its blends. Their method combines differential scanning calorimetry (DSC) with thermogravimetric analysis (TGA) to provide a holistic view of polymer thermal properties and degradation behavior[4]. Kingfa's technique incorporates isothermal crystallization studies to assess the impact of crystallinity on biodegradation rates. Additionally, they have implemented a micro-scale composting setup coupled with calorimetry to simulate real-world degradation conditions, allowing for more accurate predictions of polymer performance in various environments[5].

Strengths: Holistic thermal analysis, focus on practical biodegradation scenarios, and expertise in PLA-based materials. Weaknesses: Potential limitations in analyzing non-PLA biodegradable polymers and scalability of micro-scale composting simulations.

Core Innovations

Method for testing the degradation of polymeric materials

PatentInactiveUS6864090B2

Innovation

- A novel method utilizing Time-of-Flight Secondary Ion Mass Spectrometry (ToF SIMS) to simultaneously determine the surface concentration of a drug and degradation kinetics of biodegradable polymer/drug blend matrices by analyzing high and low mass spectra over time, calculating the rate of oligomer formation and surface drug concentration.

Biodegradable polymer composition with processing aid

PatentPendingUS20250019538A1

Innovation

- Incorporating a processing aid, a reaction product of an acrylate monomer and optionally a copolymerizable monomer, with a weight average molecular weight of at least 20,000 g/mol, into a biodegradable matrix polymer to enhance properties such as maximum tensile elongation and melt strength without compromising optical properties or viscosity.

Regulatory Framework

The regulatory framework surrounding biodegradable polymers and calorimetry analysis plays a crucial role in shaping the development, testing, and application of these materials. As environmental concerns continue to drive the demand for sustainable alternatives to traditional plastics, regulatory bodies worldwide have established guidelines and standards to ensure the safety, efficacy, and environmental impact of biodegradable polymers.

In the United States, the Environmental Protection Agency (EPA) and the Food and Drug Administration (FDA) are the primary regulatory agencies overseeing biodegradable polymers. The EPA focuses on environmental impact assessments and waste management regulations, while the FDA regulates biodegradable polymers used in food packaging and medical devices. These agencies have established specific testing protocols and performance criteria that manufacturers must adhere to when developing and marketing biodegradable polymer products.

The European Union has implemented a comprehensive regulatory framework through the European Committee for Standardization (CEN). The EN 13432 standard, for instance, outlines the requirements for packaging recoverable through composting and biodegradation. This standard specifies the criteria for biodegradability, disintegration during biological treatment, effect on the biological treatment process, and effect on the quality of the resulting compost.

Calorimetry plays a significant role in meeting these regulatory requirements by providing accurate and reliable data on the thermal properties and degradation behavior of biodegradable polymers. Differential Scanning Calorimetry (DSC) and Thermogravimetric Analysis (TGA) are widely accepted techniques for characterizing polymer performance and are often cited in regulatory guidelines.

The International Organization for Standardization (ISO) has developed several standards relevant to biodegradable polymers and calorimetry analysis. ISO 17088, for example, specifies the requirements for compostable plastics, while ISO 11357 outlines the standard methods for DSC analysis of plastics. These international standards help harmonize testing procedures and ensure consistency in polymer performance evaluation across different regions.

Regulatory bodies also emphasize the importance of lifecycle assessments (LCA) for biodegradable polymers. Calorimetry data contributes significantly to these assessments by providing insights into the energy requirements for polymer production and the heat released during degradation. This information is crucial for evaluating the overall environmental impact of biodegradable polymers compared to traditional plastics.

As the field of biodegradable polymers continues to evolve, regulatory frameworks are adapting to incorporate new scientific findings and technological advancements. The integration of calorimetry data into regulatory decision-making processes is becoming increasingly important, as it provides a quantitative basis for assessing polymer performance and environmental impact. This trend underscores the need for continued refinement of calorimetry techniques and standardization of testing protocols to ensure reliable and comparable results across different laboratories and regulatory jurisdictions.

In the United States, the Environmental Protection Agency (EPA) and the Food and Drug Administration (FDA) are the primary regulatory agencies overseeing biodegradable polymers. The EPA focuses on environmental impact assessments and waste management regulations, while the FDA regulates biodegradable polymers used in food packaging and medical devices. These agencies have established specific testing protocols and performance criteria that manufacturers must adhere to when developing and marketing biodegradable polymer products.

The European Union has implemented a comprehensive regulatory framework through the European Committee for Standardization (CEN). The EN 13432 standard, for instance, outlines the requirements for packaging recoverable through composting and biodegradation. This standard specifies the criteria for biodegradability, disintegration during biological treatment, effect on the biological treatment process, and effect on the quality of the resulting compost.

Calorimetry plays a significant role in meeting these regulatory requirements by providing accurate and reliable data on the thermal properties and degradation behavior of biodegradable polymers. Differential Scanning Calorimetry (DSC) and Thermogravimetric Analysis (TGA) are widely accepted techniques for characterizing polymer performance and are often cited in regulatory guidelines.

The International Organization for Standardization (ISO) has developed several standards relevant to biodegradable polymers and calorimetry analysis. ISO 17088, for example, specifies the requirements for compostable plastics, while ISO 11357 outlines the standard methods for DSC analysis of plastics. These international standards help harmonize testing procedures and ensure consistency in polymer performance evaluation across different regions.

Regulatory bodies also emphasize the importance of lifecycle assessments (LCA) for biodegradable polymers. Calorimetry data contributes significantly to these assessments by providing insights into the energy requirements for polymer production and the heat released during degradation. This information is crucial for evaluating the overall environmental impact of biodegradable polymers compared to traditional plastics.

As the field of biodegradable polymers continues to evolve, regulatory frameworks are adapting to incorporate new scientific findings and technological advancements. The integration of calorimetry data into regulatory decision-making processes is becoming increasingly important, as it provides a quantitative basis for assessing polymer performance and environmental impact. This trend underscores the need for continued refinement of calorimetry techniques and standardization of testing protocols to ensure reliable and comparable results across different laboratories and regulatory jurisdictions.

Environmental Impact

The environmental impact of biodegradable polymers is a critical aspect of their performance analysis, and calorimetry plays a significant role in refining this assessment. Biodegradable polymers are designed to decompose naturally in the environment, offering a potential solution to plastic pollution. However, their environmental impact extends beyond mere degradation and encompasses their entire lifecycle.

Calorimetry, as a precise analytical technique, enables researchers to quantify the energy changes associated with the degradation process of biodegradable polymers. This information is crucial for understanding the polymer's interaction with the environment and its overall ecological footprint. By measuring the heat released or absorbed during degradation, calorimetry provides insights into the rate and extent of polymer breakdown under various environmental conditions.

One of the key environmental benefits of biodegradable polymers is their potential to reduce long-term accumulation in ecosystems. Calorimetric analysis helps validate and optimize this attribute by accurately determining the degradation kinetics. This data allows for the prediction of polymer persistence in different environments, such as soil, water, or compost facilities, ensuring that the materials break down within acceptable timeframes.

Moreover, calorimetry aids in assessing the impact of biodegradable polymers on local ecosystems. By analyzing the heat changes during degradation, researchers can infer the potential effects on soil microorganisms, plant growth, and overall ecosystem health. This information is vital for ensuring that the degradation products do not introduce harmful substances or disrupt natural ecological processes.

The carbon footprint of biodegradable polymers is another crucial environmental consideration. Calorimetric techniques can measure the energy required for polymer production and compare it with the energy released during degradation. This comprehensive energy balance helps in evaluating the overall environmental sustainability of these materials throughout their lifecycle.

Additionally, calorimetry contributes to the development of more environmentally friendly biodegradable polymers. By providing detailed thermal data, it enables researchers to fine-tune polymer compositions and structures to achieve optimal degradation profiles while maintaining desired material properties. This optimization process leads to the creation of polymers that not only degrade efficiently but also minimize any negative environmental impacts during their useful life and decomposition.

In conclusion, calorimetry significantly enhances the environmental impact assessment of biodegradable polymers. It provides crucial data on degradation kinetics, ecosystem interactions, and energy balances, enabling a more comprehensive understanding of these materials' ecological implications. This refined analysis supports the development of truly sustainable biodegradable polymers that can effectively address environmental concerns associated with conventional plastics.

Calorimetry, as a precise analytical technique, enables researchers to quantify the energy changes associated with the degradation process of biodegradable polymers. This information is crucial for understanding the polymer's interaction with the environment and its overall ecological footprint. By measuring the heat released or absorbed during degradation, calorimetry provides insights into the rate and extent of polymer breakdown under various environmental conditions.

One of the key environmental benefits of biodegradable polymers is their potential to reduce long-term accumulation in ecosystems. Calorimetric analysis helps validate and optimize this attribute by accurately determining the degradation kinetics. This data allows for the prediction of polymer persistence in different environments, such as soil, water, or compost facilities, ensuring that the materials break down within acceptable timeframes.

Moreover, calorimetry aids in assessing the impact of biodegradable polymers on local ecosystems. By analyzing the heat changes during degradation, researchers can infer the potential effects on soil microorganisms, plant growth, and overall ecosystem health. This information is vital for ensuring that the degradation products do not introduce harmful substances or disrupt natural ecological processes.

The carbon footprint of biodegradable polymers is another crucial environmental consideration. Calorimetric techniques can measure the energy required for polymer production and compare it with the energy released during degradation. This comprehensive energy balance helps in evaluating the overall environmental sustainability of these materials throughout their lifecycle.

Additionally, calorimetry contributes to the development of more environmentally friendly biodegradable polymers. By providing detailed thermal data, it enables researchers to fine-tune polymer compositions and structures to achieve optimal degradation profiles while maintaining desired material properties. This optimization process leads to the creation of polymers that not only degrade efficiently but also minimize any negative environmental impacts during their useful life and decomposition.

In conclusion, calorimetry significantly enhances the environmental impact assessment of biodegradable polymers. It provides crucial data on degradation kinetics, ecosystem interactions, and energy balances, enabling a more comprehensive understanding of these materials' ecological implications. This refined analysis supports the development of truly sustainable biodegradable polymers that can effectively address environmental concerns associated with conventional plastics.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!