Role of Calorimetry in Enhancing Thermal Barrier Coatings

AUG 5, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Calorimetry in TBC: Background and Objectives

Thermal Barrier Coatings (TBCs) have emerged as a critical technology in high-temperature applications, particularly in gas turbine engines. These coatings provide thermal insulation to metallic components, allowing them to operate at higher temperatures and improving overall system efficiency. As the demand for more efficient and durable engines continues to grow, the role of calorimetry in enhancing TBCs has become increasingly significant.

Calorimetry, the science of measuring heat transfer and storage, plays a crucial role in understanding and improving the performance of TBCs. By providing precise measurements of thermal properties, calorimetry enables researchers and engineers to optimize coating compositions, structures, and application methods. This technology has been instrumental in the development of advanced TBCs that can withstand extreme temperatures and harsh operating conditions.

The evolution of calorimetry in TBC research can be traced back to the early days of thermal barrier coating development. Initially, basic calorimetric techniques were used to measure the thermal conductivity of coating materials. As the field progressed, more sophisticated calorimetric methods were developed to analyze the complex heat transfer mechanisms within multi-layered coating systems.

Today, calorimetry is employed at various stages of TBC research and development. From material selection to performance evaluation, calorimetric techniques provide valuable insights into the thermal behavior of coatings. Advanced calorimeters can now measure heat flux, specific heat capacity, and thermal diffusivity with unprecedented accuracy, enabling researchers to fine-tune coating properties for specific applications.

The primary objective of utilizing calorimetry in TBC research is to enhance the thermal insulation properties of the coatings while maintaining their structural integrity and durability. This involves optimizing the composition and microstructure of the ceramic top coat, improving the adhesion between layers, and developing novel coating architectures that can better withstand thermal cycling and mechanical stresses.

Another key goal is to use calorimetric data to develop more accurate predictive models for TBC performance. By combining experimental measurements with computational simulations, researchers aim to create tools that can predict coating behavior under various operating conditions, reducing the need for costly and time-consuming physical testing.

Furthermore, calorimetry is instrumental in exploring new materials and coating designs that push the boundaries of TBC technology. This includes investigating advanced ceramics, nanostructured materials, and functionally graded coatings that offer superior thermal protection and longer service life.

As we look to the future, the role of calorimetry in TBC research is expected to expand further. Emerging technologies such as high-throughput screening and in-situ calorimetry promise to accelerate the discovery and optimization of new coating materials and designs, paving the way for the next generation of thermal barrier coatings.

Calorimetry, the science of measuring heat transfer and storage, plays a crucial role in understanding and improving the performance of TBCs. By providing precise measurements of thermal properties, calorimetry enables researchers and engineers to optimize coating compositions, structures, and application methods. This technology has been instrumental in the development of advanced TBCs that can withstand extreme temperatures and harsh operating conditions.

The evolution of calorimetry in TBC research can be traced back to the early days of thermal barrier coating development. Initially, basic calorimetric techniques were used to measure the thermal conductivity of coating materials. As the field progressed, more sophisticated calorimetric methods were developed to analyze the complex heat transfer mechanisms within multi-layered coating systems.

Today, calorimetry is employed at various stages of TBC research and development. From material selection to performance evaluation, calorimetric techniques provide valuable insights into the thermal behavior of coatings. Advanced calorimeters can now measure heat flux, specific heat capacity, and thermal diffusivity with unprecedented accuracy, enabling researchers to fine-tune coating properties for specific applications.

The primary objective of utilizing calorimetry in TBC research is to enhance the thermal insulation properties of the coatings while maintaining their structural integrity and durability. This involves optimizing the composition and microstructure of the ceramic top coat, improving the adhesion between layers, and developing novel coating architectures that can better withstand thermal cycling and mechanical stresses.

Another key goal is to use calorimetric data to develop more accurate predictive models for TBC performance. By combining experimental measurements with computational simulations, researchers aim to create tools that can predict coating behavior under various operating conditions, reducing the need for costly and time-consuming physical testing.

Furthermore, calorimetry is instrumental in exploring new materials and coating designs that push the boundaries of TBC technology. This includes investigating advanced ceramics, nanostructured materials, and functionally graded coatings that offer superior thermal protection and longer service life.

As we look to the future, the role of calorimetry in TBC research is expected to expand further. Emerging technologies such as high-throughput screening and in-situ calorimetry promise to accelerate the discovery and optimization of new coating materials and designs, paving the way for the next generation of thermal barrier coatings.

Market Analysis for Advanced TBC Technologies

The market for advanced Thermal Barrier Coatings (TBCs) is experiencing significant growth, driven by the increasing demand for high-performance materials in aerospace, power generation, and automotive industries. As engines and turbines operate at higher temperatures to improve efficiency, the need for more effective thermal protection systems becomes critical. This has led to a surge in research and development activities focused on enhancing TBC technologies.

The global TBC market is projected to expand at a steady rate over the next decade, with aerospace applications leading the way. The aviation sector's push for fuel-efficient engines and longer maintenance intervals is a key driver for TBC advancements. Power generation, particularly in gas turbines, represents another major market segment, as energy companies seek to improve plant efficiency and reduce emissions.

Calorimetry plays a crucial role in the development and optimization of advanced TBCs. By providing precise measurements of heat transfer and thermal properties, calorimetric techniques enable researchers and manufacturers to fine-tune coating compositions and structures. This has led to the emergence of new TBC formulations with improved durability, lower thermal conductivity, and enhanced resistance to environmental factors such as oxidation and corrosion.

The automotive industry is also showing increased interest in advanced TBCs, particularly for high-performance and racing applications. As vehicle manufacturers strive to meet stringent emissions standards and improve fuel economy, the use of TBCs in exhaust systems and engine components is gaining traction. This trend is expected to contribute to market growth in the coming years.

Geographically, North America and Europe currently dominate the advanced TBC market, owing to their strong aerospace and power generation sectors. However, the Asia-Pacific region is emerging as a significant player, driven by rapid industrialization and increasing investments in research and development. Countries like China, Japan, and South Korea are actively pursuing TBC technologies to support their growing aerospace and energy industries.

The market landscape is characterized by a mix of established players and innovative startups. Major coating manufacturers and materials science companies are investing heavily in TBC research, often collaborating with academic institutions and government agencies. This has resulted in a competitive environment that fosters innovation and drives continuous improvements in TBC performance.

As environmental regulations become more stringent and the push for energy efficiency intensifies, the demand for advanced TBCs is expected to grow further. The integration of calorimetry in TBC development processes is likely to accelerate, enabling more rapid iterations and optimizations. This synergy between calorimetric techniques and TBC technologies is poised to open new opportunities for market expansion and technological breakthroughs in thermal management solutions across various industries.

The global TBC market is projected to expand at a steady rate over the next decade, with aerospace applications leading the way. The aviation sector's push for fuel-efficient engines and longer maintenance intervals is a key driver for TBC advancements. Power generation, particularly in gas turbines, represents another major market segment, as energy companies seek to improve plant efficiency and reduce emissions.

Calorimetry plays a crucial role in the development and optimization of advanced TBCs. By providing precise measurements of heat transfer and thermal properties, calorimetric techniques enable researchers and manufacturers to fine-tune coating compositions and structures. This has led to the emergence of new TBC formulations with improved durability, lower thermal conductivity, and enhanced resistance to environmental factors such as oxidation and corrosion.

The automotive industry is also showing increased interest in advanced TBCs, particularly for high-performance and racing applications. As vehicle manufacturers strive to meet stringent emissions standards and improve fuel economy, the use of TBCs in exhaust systems and engine components is gaining traction. This trend is expected to contribute to market growth in the coming years.

Geographically, North America and Europe currently dominate the advanced TBC market, owing to their strong aerospace and power generation sectors. However, the Asia-Pacific region is emerging as a significant player, driven by rapid industrialization and increasing investments in research and development. Countries like China, Japan, and South Korea are actively pursuing TBC technologies to support their growing aerospace and energy industries.

The market landscape is characterized by a mix of established players and innovative startups. Major coating manufacturers and materials science companies are investing heavily in TBC research, often collaborating with academic institutions and government agencies. This has resulted in a competitive environment that fosters innovation and drives continuous improvements in TBC performance.

As environmental regulations become more stringent and the push for energy efficiency intensifies, the demand for advanced TBCs is expected to grow further. The integration of calorimetry in TBC development processes is likely to accelerate, enabling more rapid iterations and optimizations. This synergy between calorimetric techniques and TBC technologies is poised to open new opportunities for market expansion and technological breakthroughs in thermal management solutions across various industries.

Current Challenges in Thermal Barrier Coatings

Thermal Barrier Coatings (TBCs) have become an integral component in high-temperature applications, particularly in gas turbine engines. However, as the demand for higher operating temperatures and longer component lifetimes increases, TBCs face several significant challenges that require innovative solutions.

One of the primary challenges is the degradation of TBC performance over time due to thermal cycling and environmental factors. The repeated heating and cooling cycles experienced by TBCs in service lead to thermal fatigue, which can cause cracking, delamination, and eventual spallation of the coating. This degradation not only reduces the thermal protection provided but also exposes the underlying substrate to potentially catastrophic damage.

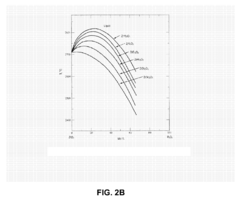

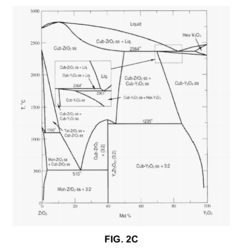

Another critical issue is the limited temperature capability of current TBC materials. While yttria-stabilized zirconia (YSZ) has been the industry standard for decades, its maximum operating temperature is approaching its practical limit. As engine designs push for ever-higher efficiencies, there is an urgent need for new TBC materials that can withstand temperatures beyond 1200°C without compromising their structural integrity or thermal insulation properties.

The complex microstructure of TBCs presents additional challenges. The porous nature of the ceramic top coat, while beneficial for thermal insulation, can also lead to issues such as sintering at high temperatures. This sintering effect can cause densification of the coating, reducing its strain tolerance and thermal insulation effectiveness. Balancing the porosity for optimal thermal performance while maintaining mechanical durability remains a significant challenge.

Oxidation of the bond coat layer is another ongoing concern. The thermally grown oxide (TGO) layer that forms between the bond coat and the ceramic top coat is crucial for coating adhesion. However, excessive TGO growth can lead to stress buildup and eventual coating failure. Controlling the growth rate and morphology of the TGO layer is essential for extending TBC lifetimes.

Furthermore, the increasing use of alternative fuels and the presence of contaminants in operating environments pose new challenges for TBCs. Calcium-magnesium-alumino-silicate (CMAS) infiltration, for instance, can cause severe degradation of the coating structure. Developing TBCs that are resistant to CMAS attack and other environmental contaminants is crucial for ensuring long-term performance in real-world applications.

The integration of sensing capabilities within TBCs for real-time monitoring of coating health and temperature distribution is an emerging challenge. While such functionality could greatly enhance maintenance planning and engine performance optimization, it requires the development of novel materials and coating architectures that can incorporate sensors without compromising the coating's primary protective function.

One of the primary challenges is the degradation of TBC performance over time due to thermal cycling and environmental factors. The repeated heating and cooling cycles experienced by TBCs in service lead to thermal fatigue, which can cause cracking, delamination, and eventual spallation of the coating. This degradation not only reduces the thermal protection provided but also exposes the underlying substrate to potentially catastrophic damage.

Another critical issue is the limited temperature capability of current TBC materials. While yttria-stabilized zirconia (YSZ) has been the industry standard for decades, its maximum operating temperature is approaching its practical limit. As engine designs push for ever-higher efficiencies, there is an urgent need for new TBC materials that can withstand temperatures beyond 1200°C without compromising their structural integrity or thermal insulation properties.

The complex microstructure of TBCs presents additional challenges. The porous nature of the ceramic top coat, while beneficial for thermal insulation, can also lead to issues such as sintering at high temperatures. This sintering effect can cause densification of the coating, reducing its strain tolerance and thermal insulation effectiveness. Balancing the porosity for optimal thermal performance while maintaining mechanical durability remains a significant challenge.

Oxidation of the bond coat layer is another ongoing concern. The thermally grown oxide (TGO) layer that forms between the bond coat and the ceramic top coat is crucial for coating adhesion. However, excessive TGO growth can lead to stress buildup and eventual coating failure. Controlling the growth rate and morphology of the TGO layer is essential for extending TBC lifetimes.

Furthermore, the increasing use of alternative fuels and the presence of contaminants in operating environments pose new challenges for TBCs. Calcium-magnesium-alumino-silicate (CMAS) infiltration, for instance, can cause severe degradation of the coating structure. Developing TBCs that are resistant to CMAS attack and other environmental contaminants is crucial for ensuring long-term performance in real-world applications.

The integration of sensing capabilities within TBCs for real-time monitoring of coating health and temperature distribution is an emerging challenge. While such functionality could greatly enhance maintenance planning and engine performance optimization, it requires the development of novel materials and coating architectures that can incorporate sensors without compromising the coating's primary protective function.

Existing Calorimetric Methods for TBC Enhancement

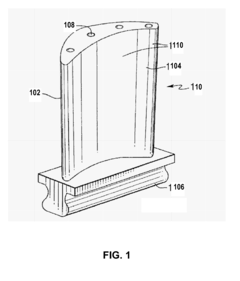

01 Thermal barrier coatings for high-temperature applications

Thermal barrier coatings are applied to components exposed to high temperatures, such as in gas turbine engines. These coatings provide insulation and protection against thermal degradation, improving the durability and performance of the components. Advanced materials and deposition techniques are used to create effective thermal barriers.- Thermal barrier coatings for high-temperature applications: Thermal barrier coatings are applied to components exposed to high temperatures, such as in gas turbine engines. These coatings provide insulation and protection against thermal degradation, improving the durability and efficiency of the components. Advanced materials and deposition techniques are used to create multi-layered coatings with enhanced thermal resistance and mechanical properties.

- Calorimetry techniques for thermal barrier analysis: Calorimetry methods are employed to analyze the thermal properties and performance of thermal barrier materials. These techniques allow for precise measurement of heat flow, thermal conductivity, and specific heat capacity. Advanced calorimetry equipment and procedures are used to evaluate the effectiveness of thermal barriers under various temperature conditions and thermal cycling.

- Nanostructured thermal barrier coatings: Nanostructured materials are incorporated into thermal barrier coatings to enhance their performance. These materials offer improved thermal insulation properties, increased strain tolerance, and better resistance to sintering at high temperatures. Nanostructured coatings can be engineered to have lower thermal conductivity and improved durability compared to conventional coatings.

- Environmental barrier coatings for thermal protection: Environmental barrier coatings are developed to provide both thermal protection and resistance to environmental degradation. These coatings are designed to withstand harsh operating conditions, including high temperatures, oxidation, and corrosive environments. Multi-functional coatings combine thermal barrier properties with resistance to chemical attack and erosion.

- Thermal barrier materials for aerospace applications: Specialized thermal barrier materials are developed for aerospace applications, including spacecraft heat shields and hypersonic vehicle components. These materials are designed to withstand extreme temperatures and thermal gradients encountered during atmospheric reentry or hypersonic flight. Advanced ceramics, composites, and ablative materials are utilized to provide effective thermal protection in aerospace environments.

02 Calorimetry techniques for thermal barrier analysis

Calorimetry methods are employed to analyze the thermal properties and performance of thermal barrier coatings. These techniques help measure heat flow, thermal conductivity, and other critical parameters. Advanced calorimetry equipment and procedures are used to evaluate the effectiveness of thermal barriers under various conditions.Expand Specific Solutions03 Nanostructured thermal barrier coatings

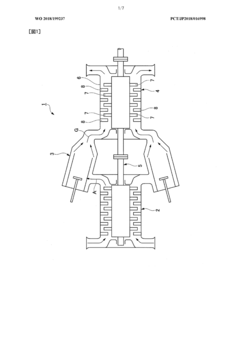

Nanostructured materials are utilized in thermal barrier coatings to enhance their performance. These coatings feature nanoscale structures that provide improved thermal insulation, mechanical properties, and durability. Advanced manufacturing techniques are employed to create nanostructured thermal barriers with optimized properties.Expand Specific Solutions04 Multi-layer thermal barrier systems

Multi-layer thermal barrier systems are designed to provide enhanced protection and performance. These systems consist of multiple layers with different compositions and properties, each serving a specific function. The combination of layers results in improved thermal insulation, adhesion, and resistance to environmental factors.Expand Specific Solutions05 Environmental barrier coatings for thermal protection

Environmental barrier coatings are developed to provide both thermal protection and resistance to environmental factors such as oxidation and corrosion. These coatings are particularly important for components operating in harsh environments. Advanced materials and coating techniques are used to create effective environmental barriers with thermal insulation properties.Expand Specific Solutions

Key Players in TBC and Calorimetry Industries

The competitive landscape for calorimetry in enhancing thermal barrier coatings is characterized by a mature market with significant growth potential. Major players include aerospace giants like RTX Corp., Mitsubishi Heavy Industries, and GE, alongside specialized research institutions such as Beihang University and Xi'an Jiaotong University. The market is driven by increasing demand for advanced thermal protection in aerospace and energy sectors. Technological maturity varies, with established companies focusing on incremental improvements, while research institutions push boundaries in material science and coating techniques. Collaboration between industry and academia is prevalent, fostering innovation and accelerating the development of next-generation thermal barrier coatings.

RTX Corp.

Technical Solution: RTX (formerly United Technologies) utilizes calorimetry extensively in their TBC research, focusing on novel ceramic compositions and nanostructured coatings. They employ both steady-state and transient calorimetry techniques to evaluate coating performance under cyclic thermal conditions. RTX has developed a proprietary calorimetry system that can measure heat flux through TBCs at temperatures up to 1600°C, simulating real engine environments[2]. Their approach includes the use of gadolinium zirconate and other advanced ceramics to achieve lower thermal conductivity and better sintering resistance compared to traditional YSZ coatings[4].

Strengths: Cutting-edge calorimetry equipment, expertise in advanced ceramic materials, strong integration with engine manufacturing. Weaknesses: High equipment costs, potential challenges in scaling up new coating technologies.

Honeywell International Technologies Ltd.

Technical Solution: Honeywell employs calorimetry in developing multi-component TBCs with enhanced durability and thermal performance. Their research focuses on optimizing coating microstructures and compositions using high-throughput calorimetry screening methods. Honeywell has developed a unique calorimetry-based approach to evaluate TBC thermal cycling behavior, allowing for rapid assessment of coating lifetimes under simulated engine conditions[6]. They also utilize calorimetry to study the phase stability and sintering behavior of novel TBC materials, including lanthanum zirconate-based systems[8].

Strengths: Efficient high-throughput screening capabilities, strong focus on coating durability, integrated approach to material development and testing. Weaknesses: Potential limitations in translating laboratory results to full-scale production.

Innovative Calorimetry Techniques for TBCs

Ceramic material and coatings for high temperature service

PatentInactiveEP1772441A1

Innovation

- Development of ultra-pure zirconia and hafnia-based ceramic materials with rare earth oxide stabilizers, such as yttria and ytterbia, to reduce sintering rates and maintain microstructure stability, combined with specific impurity limits to enhance thermal insulation and durability, and application methods like thermal spraying to create coatings with optimized porosity and crack networks.

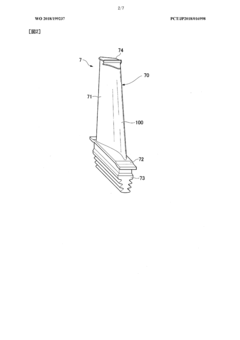

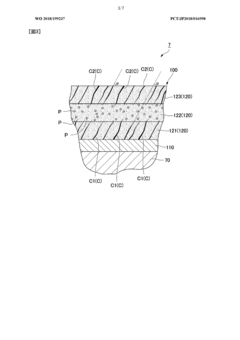

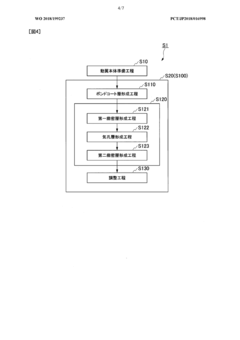

Thermal barrier coating formation method, thermal barrier coating, and high-temperature member

PatentWO2018199237A1

Innovation

- A thermal barrier coating configuration featuring a ceramic layer with a first dense layer, an intermediate pore layer, and a second dense layer, where the intermediate pore layer reduces heat input and the second dense layer enhances erosion resistance, while the porosity and vertical divisions in the layers are strategically optimized to minimize thermal conductivity without compromising erosion resistance.

Environmental Impact of Advanced TBC Technologies

The development of advanced Thermal Barrier Coatings (TBCs) has significant environmental implications, both positive and negative. On the positive side, TBCs contribute to improved energy efficiency in various applications, particularly in gas turbines used for power generation and aerospace propulsion. By allowing engines to operate at higher temperatures, TBCs reduce fuel consumption and consequently lower greenhouse gas emissions. This reduction in carbon footprint aligns with global efforts to combat climate change and meet stringent environmental regulations.

However, the production and application of advanced TBCs also present environmental challenges. The manufacturing process of these coatings often involves energy-intensive methods and the use of rare earth elements, which can have adverse environmental impacts during extraction and processing. The production of yttria-stabilized zirconia (YSZ), a common TBC material, requires mining and refining operations that may lead to habitat disruption and potential soil and water contamination if not properly managed.

Additionally, the disposal of TBC-coated components at the end of their lifecycle poses environmental concerns. The complex nature of these multi-layered coatings makes recycling challenging, potentially contributing to increased waste in landfills. Research into more environmentally friendly coating materials and application techniques is ongoing, with a focus on reducing the reliance on rare earth elements and developing more recyclable coating systems.

The use of calorimetry in TBC research and development offers opportunities for environmental improvement. By providing precise measurements of heat transfer and thermal properties, calorimetry enables the optimization of coating compositions and structures. This optimization can lead to more durable and efficient TBCs, extending the lifespan of coated components and reducing the frequency of replacements, thereby minimizing waste generation.

Furthermore, calorimetric techniques aid in the development of novel TBC materials with enhanced thermal performance. These advancements could potentially reduce the thickness of coatings required for effective thermal insulation, leading to material savings and lighter components. In aerospace applications, lighter components translate to reduced fuel consumption and lower emissions during flight operations.

As environmental regulations become more stringent, the role of calorimetry in TBC development becomes increasingly crucial. It enables researchers to fine-tune coating properties to meet specific environmental performance criteria, such as maximizing heat reflection to minimize cooling requirements in buildings or optimizing thermal management in electric vehicle batteries to enhance their efficiency and lifespan.

However, the production and application of advanced TBCs also present environmental challenges. The manufacturing process of these coatings often involves energy-intensive methods and the use of rare earth elements, which can have adverse environmental impacts during extraction and processing. The production of yttria-stabilized zirconia (YSZ), a common TBC material, requires mining and refining operations that may lead to habitat disruption and potential soil and water contamination if not properly managed.

Additionally, the disposal of TBC-coated components at the end of their lifecycle poses environmental concerns. The complex nature of these multi-layered coatings makes recycling challenging, potentially contributing to increased waste in landfills. Research into more environmentally friendly coating materials and application techniques is ongoing, with a focus on reducing the reliance on rare earth elements and developing more recyclable coating systems.

The use of calorimetry in TBC research and development offers opportunities for environmental improvement. By providing precise measurements of heat transfer and thermal properties, calorimetry enables the optimization of coating compositions and structures. This optimization can lead to more durable and efficient TBCs, extending the lifespan of coated components and reducing the frequency of replacements, thereby minimizing waste generation.

Furthermore, calorimetric techniques aid in the development of novel TBC materials with enhanced thermal performance. These advancements could potentially reduce the thickness of coatings required for effective thermal insulation, leading to material savings and lighter components. In aerospace applications, lighter components translate to reduced fuel consumption and lower emissions during flight operations.

As environmental regulations become more stringent, the role of calorimetry in TBC development becomes increasingly crucial. It enables researchers to fine-tune coating properties to meet specific environmental performance criteria, such as maximizing heat reflection to minimize cooling requirements in buildings or optimizing thermal management in electric vehicle batteries to enhance their efficiency and lifespan.

Cost-Benefit Analysis of Calorimetry in TBC Research

The implementation of calorimetry in thermal barrier coating (TBC) research presents a complex cost-benefit scenario that requires careful analysis. On the cost side, calorimetric equipment and techniques can be expensive to acquire and maintain. High-precision calorimeters, such as differential scanning calorimeters (DSC) or isothermal titration calorimeters (ITC), often come with significant upfront costs, ranging from tens to hundreds of thousands of dollars.

Additionally, the operational expenses, including specialized training for personnel, consumables, and regular calibration, contribute to the ongoing financial investment. The time-intensive nature of calorimetric measurements also factors into the cost equation, as it may extend research timelines and delay product development cycles.

However, the benefits of incorporating calorimetry in TBC research can potentially outweigh these costs. Calorimetry provides crucial data on the thermal properties and behavior of coating materials under various conditions. This information is invaluable for optimizing TBC performance, enhancing durability, and improving overall efficiency of thermal management systems.

The precision and reliability of calorimetric data can lead to more accurate predictions of TBC lifespan and performance in real-world applications. This, in turn, can result in significant cost savings by reducing the frequency of maintenance and replacement of coated components in high-temperature environments, such as gas turbines or aerospace applications.

Furthermore, calorimetry enables researchers to identify and quantify subtle phase transitions and chemical reactions within TBC materials. This level of insight can drive innovation in material design, potentially leading to breakthroughs in coating technology that offer substantial long-term economic benefits.

From a risk management perspective, the comprehensive thermal characterization provided by calorimetry can help prevent costly failures in critical applications. By identifying potential weaknesses or limitations in TBC materials early in the development process, companies can avoid expensive recalls or system failures down the line.

In terms of competitive advantage, organizations that invest in advanced calorimetric techniques may position themselves at the forefront of TBC technology. The ability to develop superior coatings based on detailed thermal analysis can lead to increased market share and premium pricing for high-performance products.

Ultimately, the cost-benefit analysis of calorimetry in TBC research must be evaluated on a case-by-case basis, considering factors such as the scale of operations, specific research objectives, and potential market impact of improved TBC technologies. While the initial investment may be substantial, the long-term benefits in terms of product quality, innovation, and risk mitigation often justify the costs for organizations committed to advancing TBC technology.

Additionally, the operational expenses, including specialized training for personnel, consumables, and regular calibration, contribute to the ongoing financial investment. The time-intensive nature of calorimetric measurements also factors into the cost equation, as it may extend research timelines and delay product development cycles.

However, the benefits of incorporating calorimetry in TBC research can potentially outweigh these costs. Calorimetry provides crucial data on the thermal properties and behavior of coating materials under various conditions. This information is invaluable for optimizing TBC performance, enhancing durability, and improving overall efficiency of thermal management systems.

The precision and reliability of calorimetric data can lead to more accurate predictions of TBC lifespan and performance in real-world applications. This, in turn, can result in significant cost savings by reducing the frequency of maintenance and replacement of coated components in high-temperature environments, such as gas turbines or aerospace applications.

Furthermore, calorimetry enables researchers to identify and quantify subtle phase transitions and chemical reactions within TBC materials. This level of insight can drive innovation in material design, potentially leading to breakthroughs in coating technology that offer substantial long-term economic benefits.

From a risk management perspective, the comprehensive thermal characterization provided by calorimetry can help prevent costly failures in critical applications. By identifying potential weaknesses or limitations in TBC materials early in the development process, companies can avoid expensive recalls or system failures down the line.

In terms of competitive advantage, organizations that invest in advanced calorimetric techniques may position themselves at the forefront of TBC technology. The ability to develop superior coatings based on detailed thermal analysis can lead to increased market share and premium pricing for high-performance products.

Ultimately, the cost-benefit analysis of calorimetry in TBC research must be evaluated on a case-by-case basis, considering factors such as the scale of operations, specific research objectives, and potential market impact of improved TBC technologies. While the initial investment may be substantial, the long-term benefits in terms of product quality, innovation, and risk mitigation often justify the costs for organizations committed to advancing TBC technology.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!