Innovations in Calorimetric Analysis for Graphene-Based Materials

AUG 5, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Graphene Calorimetry Background and Objectives

Graphene, a two-dimensional carbon allotrope, has revolutionized materials science since its isolation in 2004. Its exceptional properties, including high electrical and thermal conductivity, mechanical strength, and optical transparency, have sparked intense research across various fields. In the realm of calorimetric analysis, graphene-based materials present both exciting opportunities and unique challenges.

The evolution of calorimetric techniques for graphene materials has been driven by the need to understand their thermal properties accurately. Traditional calorimetry methods, while effective for bulk materials, often fall short when applied to graphene's atomically thin structure. This limitation has spurred innovations in measurement techniques and instrumentation, leading to the development of specialized calorimetric approaches for nanoscale materials.

The primary objective of calorimetric analysis in graphene research is to quantify and characterize its thermal behavior precisely. This includes measuring specific heat capacity, thermal conductivity, and phase transitions at various temperatures and under different conditions. Understanding these properties is crucial for optimizing graphene's performance in applications ranging from electronics to energy storage and thermal management systems.

Recent advancements in calorimetric analysis for graphene-based materials have focused on overcoming the challenges posed by their unique structure. Researchers have developed ultra-sensitive nanocalorimetry techniques capable of detecting minute thermal changes in graphene samples. These innovations have enabled the study of size-dependent thermal properties and the effects of defects, functionalization, and substrate interactions on graphene's thermal behavior.

The field of graphene calorimetry is rapidly evolving, with emerging trends including the integration of calorimetric measurements with other analytical techniques, such as Raman spectroscopy and scanning probe microscopy. This multi-modal approach allows for a more comprehensive understanding of graphene's thermal properties in relation to its structural and electronic characteristics.

As research progresses, the goals of graphene calorimetry extend beyond basic characterization to include tailoring thermal properties for specific applications. This involves exploring the effects of doping, layering, and composite formation on graphene's thermal behavior. The ultimate aim is to develop graphene-based materials with precisely engineered thermal properties, opening up new possibilities in thermal management, energy conversion, and sensing technologies.

The evolution of calorimetric techniques for graphene materials has been driven by the need to understand their thermal properties accurately. Traditional calorimetry methods, while effective for bulk materials, often fall short when applied to graphene's atomically thin structure. This limitation has spurred innovations in measurement techniques and instrumentation, leading to the development of specialized calorimetric approaches for nanoscale materials.

The primary objective of calorimetric analysis in graphene research is to quantify and characterize its thermal behavior precisely. This includes measuring specific heat capacity, thermal conductivity, and phase transitions at various temperatures and under different conditions. Understanding these properties is crucial for optimizing graphene's performance in applications ranging from electronics to energy storage and thermal management systems.

Recent advancements in calorimetric analysis for graphene-based materials have focused on overcoming the challenges posed by their unique structure. Researchers have developed ultra-sensitive nanocalorimetry techniques capable of detecting minute thermal changes in graphene samples. These innovations have enabled the study of size-dependent thermal properties and the effects of defects, functionalization, and substrate interactions on graphene's thermal behavior.

The field of graphene calorimetry is rapidly evolving, with emerging trends including the integration of calorimetric measurements with other analytical techniques, such as Raman spectroscopy and scanning probe microscopy. This multi-modal approach allows for a more comprehensive understanding of graphene's thermal properties in relation to its structural and electronic characteristics.

As research progresses, the goals of graphene calorimetry extend beyond basic characterization to include tailoring thermal properties for specific applications. This involves exploring the effects of doping, layering, and composite formation on graphene's thermal behavior. The ultimate aim is to develop graphene-based materials with precisely engineered thermal properties, opening up new possibilities in thermal management, energy conversion, and sensing technologies.

Market Demand for Advanced Graphene Analysis

The market demand for advanced graphene analysis, particularly in calorimetric techniques, has been steadily growing in recent years. This surge is primarily driven by the increasing applications of graphene-based materials across various industries, including electronics, energy storage, and biomedical engineering. As these sectors continue to expand their use of graphene, the need for precise and reliable analytical methods becomes paramount.

Calorimetric analysis offers unique insights into the thermal properties and behavior of graphene materials, which are crucial for many applications. For instance, in the development of high-performance batteries and supercapacitors, understanding the heat generation and dissipation characteristics of graphene electrodes is essential for optimizing device efficiency and safety. This has led to a significant demand for advanced calorimetric tools capable of analyzing graphene at nanoscale levels.

The electronics industry, in particular, has shown a strong interest in calorimetric analysis for graphene-based materials. As manufacturers strive to develop smaller, faster, and more energy-efficient devices, the thermal management of graphene components becomes increasingly critical. Calorimetric techniques provide valuable data on heat flow and thermal conductivity, enabling engineers to design more effective cooling solutions and improve overall device performance.

In the field of biomedical engineering, the demand for advanced graphene analysis is driven by the potential applications of graphene in drug delivery systems and biosensors. Calorimetric methods can provide crucial information on the interactions between graphene-based materials and biological systems, helping researchers optimize the design of these innovative medical technologies.

The aerospace and automotive industries are also contributing to the growing market demand for advanced graphene analysis. As these sectors explore the use of graphene composites in lightweight structures and thermal management systems, calorimetric techniques become essential for characterizing material properties and predicting long-term performance under various environmental conditions.

Furthermore, the push towards sustainable and eco-friendly technologies has created new opportunities for graphene-based materials in areas such as water purification and environmental sensing. This has led to an increased demand for analytical tools capable of assessing the thermal behavior and stability of graphene in these applications, further driving the market for advanced calorimetric analysis.

As research and development in graphene-based materials continue to accelerate, the market for specialized analytical tools is expected to expand correspondingly. This trend is likely to foster innovations in calorimetric analysis techniques, leading to the development of more sensitive, accurate, and versatile instruments tailored specifically for graphene and other two-dimensional materials.

Calorimetric analysis offers unique insights into the thermal properties and behavior of graphene materials, which are crucial for many applications. For instance, in the development of high-performance batteries and supercapacitors, understanding the heat generation and dissipation characteristics of graphene electrodes is essential for optimizing device efficiency and safety. This has led to a significant demand for advanced calorimetric tools capable of analyzing graphene at nanoscale levels.

The electronics industry, in particular, has shown a strong interest in calorimetric analysis for graphene-based materials. As manufacturers strive to develop smaller, faster, and more energy-efficient devices, the thermal management of graphene components becomes increasingly critical. Calorimetric techniques provide valuable data on heat flow and thermal conductivity, enabling engineers to design more effective cooling solutions and improve overall device performance.

In the field of biomedical engineering, the demand for advanced graphene analysis is driven by the potential applications of graphene in drug delivery systems and biosensors. Calorimetric methods can provide crucial information on the interactions between graphene-based materials and biological systems, helping researchers optimize the design of these innovative medical technologies.

The aerospace and automotive industries are also contributing to the growing market demand for advanced graphene analysis. As these sectors explore the use of graphene composites in lightweight structures and thermal management systems, calorimetric techniques become essential for characterizing material properties and predicting long-term performance under various environmental conditions.

Furthermore, the push towards sustainable and eco-friendly technologies has created new opportunities for graphene-based materials in areas such as water purification and environmental sensing. This has led to an increased demand for analytical tools capable of assessing the thermal behavior and stability of graphene in these applications, further driving the market for advanced calorimetric analysis.

As research and development in graphene-based materials continue to accelerate, the market for specialized analytical tools is expected to expand correspondingly. This trend is likely to foster innovations in calorimetric analysis techniques, leading to the development of more sensitive, accurate, and versatile instruments tailored specifically for graphene and other two-dimensional materials.

Calorimetric Challenges in Graphene Characterization

Calorimetric analysis of graphene-based materials presents unique challenges due to the material's exceptional thermal properties and two-dimensional structure. The primary difficulty lies in accurately measuring the heat capacity and thermal conductivity of graphene samples, which are often available in limited quantities and exhibit anisotropic behavior.

One of the main obstacles is the ultra-low mass of graphene samples, typically in the microgram range. This necessitates highly sensitive calorimetric instruments capable of detecting minute heat changes. Conventional calorimeters often lack the required sensitivity, leading to potential measurement errors and inconsistencies in reported values.

Another significant challenge is the influence of substrate materials on calorimetric measurements. Graphene is frequently supported on various substrates for practical applications, and separating the thermal contributions of the graphene from those of the substrate can be complex. This issue is particularly pronounced when dealing with few-layer graphene or graphene oxide, where the substrate's thermal properties may dominate the overall measurement.

The anisotropic nature of graphene's thermal properties further complicates calorimetric analysis. Heat conduction in graphene is highly directional, with in-plane thermal conductivity significantly higher than out-of-plane conductivity. Traditional calorimetric techniques may not adequately account for this anisotropy, leading to potential misinterpretations of thermal behavior.

Sample preparation and handling also pose challenges in calorimetric studies of graphene. Ensuring uniform sample distribution, preventing agglomeration, and maintaining sample integrity during measurements are critical factors that can significantly impact the accuracy and reproducibility of results. The high surface area-to-volume ratio of graphene makes it particularly susceptible to environmental contaminants, which can alter its thermal properties.

Moreover, the dynamic nature of graphene's thermal properties under different conditions adds another layer of complexity. Factors such as temperature, pressure, and chemical environment can significantly influence graphene's calorimetric behavior. Developing experimental setups that can precisely control these parameters while maintaining measurement accuracy is a ongoing challenge in the field.

Lastly, the lack of standardized protocols for calorimetric analysis of graphene-based materials hinders direct comparison of results across different studies. Variations in sample preparation methods, measurement techniques, and data analysis approaches contribute to discrepancies in reported thermal properties, making it difficult to establish reliable reference values for graphene and its derivatives.

One of the main obstacles is the ultra-low mass of graphene samples, typically in the microgram range. This necessitates highly sensitive calorimetric instruments capable of detecting minute heat changes. Conventional calorimeters often lack the required sensitivity, leading to potential measurement errors and inconsistencies in reported values.

Another significant challenge is the influence of substrate materials on calorimetric measurements. Graphene is frequently supported on various substrates for practical applications, and separating the thermal contributions of the graphene from those of the substrate can be complex. This issue is particularly pronounced when dealing with few-layer graphene or graphene oxide, where the substrate's thermal properties may dominate the overall measurement.

The anisotropic nature of graphene's thermal properties further complicates calorimetric analysis. Heat conduction in graphene is highly directional, with in-plane thermal conductivity significantly higher than out-of-plane conductivity. Traditional calorimetric techniques may not adequately account for this anisotropy, leading to potential misinterpretations of thermal behavior.

Sample preparation and handling also pose challenges in calorimetric studies of graphene. Ensuring uniform sample distribution, preventing agglomeration, and maintaining sample integrity during measurements are critical factors that can significantly impact the accuracy and reproducibility of results. The high surface area-to-volume ratio of graphene makes it particularly susceptible to environmental contaminants, which can alter its thermal properties.

Moreover, the dynamic nature of graphene's thermal properties under different conditions adds another layer of complexity. Factors such as temperature, pressure, and chemical environment can significantly influence graphene's calorimetric behavior. Developing experimental setups that can precisely control these parameters while maintaining measurement accuracy is a ongoing challenge in the field.

Lastly, the lack of standardized protocols for calorimetric analysis of graphene-based materials hinders direct comparison of results across different studies. Variations in sample preparation methods, measurement techniques, and data analysis approaches contribute to discrepancies in reported thermal properties, making it difficult to establish reliable reference values for graphene and its derivatives.

Current Calorimetric Methods for Graphene Materials

01 Graphene-based calorimetric sensors

Graphene-based materials are utilized in calorimetric sensors for various applications. These sensors leverage the unique thermal and electrical properties of graphene to detect and measure heat changes with high sensitivity. The integration of graphene into calorimetric devices enhances their performance and enables the detection of minute thermal variations.- Graphene-based calorimetric sensors: Graphene-based materials are utilized in calorimetric sensors for various applications. These sensors leverage the unique thermal and electrical properties of graphene to detect and measure heat changes with high sensitivity. The integration of graphene in calorimetric devices enables improved performance and detection capabilities for thermal analysis.

- Thermal analysis methods for graphene materials: Various thermal analysis techniques are employed to characterize graphene-based materials. These methods include differential scanning calorimetry (DSC), thermogravimetric analysis (TGA), and other calorimetric approaches. Such analyses provide insights into the thermal properties, stability, and composition of graphene materials, aiding in their development and application.

- Graphene-enhanced thermal management systems: Graphene-based materials are incorporated into thermal management systems to improve heat dissipation and temperature control. The high thermal conductivity of graphene allows for efficient heat transfer in electronic devices and other applications. Calorimetric analysis is used to evaluate the performance of these graphene-enhanced thermal management solutions.

- Calorimetric analysis of graphene synthesis and modification: Calorimetric techniques are employed to study the synthesis and modification processes of graphene-based materials. These analyses provide information on reaction kinetics, energy changes, and structural transformations during graphene production and functionalization. The results help optimize manufacturing processes and tailor graphene properties for specific applications.

- Graphene-based materials for energy storage applications: Calorimetric analysis is used to evaluate graphene-based materials in energy storage devices such as batteries and supercapacitors. These studies assess the thermal behavior, energy density, and cycling performance of graphene-enhanced energy storage systems. The results guide the development of more efficient and stable energy storage solutions incorporating graphene materials.

02 Thermal analysis of graphene composites

Calorimetric analysis techniques are employed to study the thermal properties of graphene-based composites. These methods provide insights into the heat capacity, thermal conductivity, and phase transitions of graphene materials. The analysis helps in understanding the thermal behavior of graphene composites for various applications, including energy storage and thermal management.Expand Specific Solutions03 Graphene-enhanced calorimetry for material characterization

Graphene-based materials are used to improve calorimetric techniques for characterizing various substances. The high thermal conductivity and large surface area of graphene enable more accurate and sensitive measurements of heat flow and thermal properties. This enhancement allows for better analysis of chemical reactions, phase transitions, and material properties.Expand Specific Solutions04 Calorimetric analysis of graphene synthesis and modification

Calorimetric techniques are applied to study the synthesis and modification processes of graphene-based materials. These methods provide valuable information about the energetics of graphene formation, functionalization, and doping. The analysis helps optimize production methods and assess the quality and properties of the resulting graphene materials.Expand Specific Solutions05 Graphene-based microcalorimetry devices

Graphene is incorporated into microcalorimetry devices for high-precision thermal measurements. The exceptional thermal properties of graphene allow for the development of ultra-sensitive calorimeters capable of detecting extremely small heat changes. These devices find applications in fields such as biochemistry, materials science, and pharmaceutical research.Expand Specific Solutions

Key Players in Graphene Analysis Industry

The field of calorimetric analysis for graphene-based materials is in a dynamic growth phase, characterized by increasing market size and evolving technological maturity. The competitive landscape is diverse, with academic institutions like Zhejiang University, Rice University, and IIT Guwahati leading research efforts alongside industry players such as NEC Corp. and Applied Graphene Materials UK Ltd. The market is driven by the growing demand for advanced materials in various sectors, including electronics and energy storage. While the technology is progressing rapidly, it is still in the early stages of commercialization, with companies like Changxing Dexi Technology Co., Ltd. and C2CNT LLC working on scaling up production and application development.

Zhejiang University

Technical Solution: Zhejiang University has developed innovative calorimetric analysis techniques for graphene-based materials, focusing on the integration of multiple analytical methods. Their approach combines differential scanning calorimetry (DSC) with thermogravimetric analysis (TGA) and evolved gas analysis (EGA) to provide a comprehensive thermal characterization of graphene materials[7]. This multi-modal analysis allows for simultaneous measurement of heat flow, mass changes, and gas evolution during thermal processes. Zhejiang University has also implemented fast scanning calorimetry (FSC) techniques, enabling the study of rapid thermal transitions in graphene that are not observable with conventional DSC. Additionally, they have developed a novel isothermal titration calorimetry (ITC) method to investigate the interactions between graphene and various molecules or nanoparticles[8].

Strengths: Comprehensive multi-modal analysis, ability to study rapid thermal transitions. Weaknesses: Complex data interpretation, may require specialized software for analysis.

William Marsh Rice University

Technical Solution: Rice University has pioneered advanced calorimetric techniques for analyzing graphene-based materials. Their research team has developed a novel approach using nanocalorimetry, which allows for ultra-sensitive measurements of heat capacity and thermal conductivity of graphene at the nanoscale. This method employs microelectromechanical systems (MEMS) based sensors to detect minute thermal changes in graphene samples[2]. Rice University's innovation also includes the use of modulated temperature differential scanning calorimetry (MTDSC) to separate reversible and non-reversible thermal events in graphene materials, providing insights into their structural and chemical properties[4]. Additionally, they have integrated Raman spectroscopy with calorimetric analysis to correlate thermal behavior with graphene's molecular structure.

Strengths: Highly sensitive nanoscale measurements, ability to distinguish between different types of thermal events. Weaknesses: Complex experimental setup, may be limited to small sample sizes.

Innovative Calorimetric Approaches for Graphene

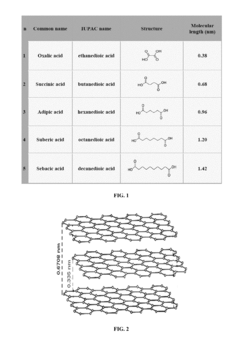

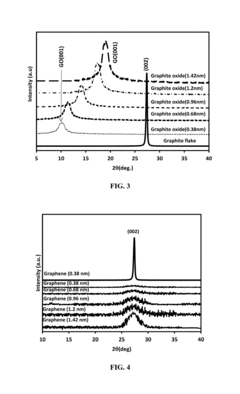

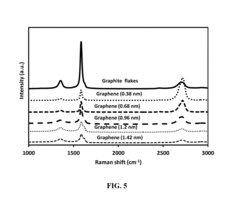

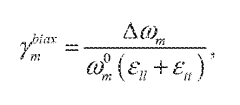

Method for producing graphene with a controllable number of layers

PatentActiveUS20170203968A1

Innovation

- A method involving the intercalation of graphite with dicarboxylic acids of varying molecular chain lengths followed by microwave irradiation and exfoliation in an alcohol solution to produce graphene nanosheets with controlled thickness and purity, allowing for the production of monolayer, bilayer, or multilayer graphene.

Method and system for graphene formation

PatentWO2014110446A2

Innovation

- A one-step plasma-enhanced chemical vapor deposition (PECVD) process at low temperature, using a hydrogen and nitrogen plasma with methane, to grow high-quality, large-area graphene on copper substrates, balancing carbon deposition and etching to achieve smooth surfaces and reduced strain.

Standardization of Graphene Calorimetric Analysis

The standardization of graphene calorimetric analysis is crucial for ensuring consistent and reliable measurements across different research groups and industrial applications. Currently, there is a lack of universally accepted protocols for calorimetric analysis of graphene-based materials, leading to discrepancies in reported results and difficulties in comparing data from various sources.

To address this issue, several key aspects of the standardization process need to be considered. Firstly, sample preparation methods must be standardized to ensure uniformity in the graphene materials being analyzed. This includes establishing guidelines for the synthesis, purification, and handling of graphene samples, as well as defining acceptable ranges for key parameters such as flake size, layer thickness, and defect density.

Secondly, measurement procedures and instrumentation specifications need to be standardized. This involves defining the optimal temperature ranges, heating rates, and atmosphere conditions for calorimetric analysis of graphene materials. Additionally, calibration procedures for calorimetry equipment should be established to ensure accuracy and reproducibility of results across different laboratories.

Data analysis and reporting methods also require standardization. This includes establishing protocols for baseline correction, peak identification, and quantification of thermal events. Furthermore, a standardized format for reporting calorimetric data should be developed, including essential metadata such as sample characteristics, experimental conditions, and data processing methods.

Interlaboratory comparisons and round-robin tests are essential for validating the proposed standardization methods. These collaborative efforts will help identify potential sources of variability and refine the protocols to achieve better consistency across different research groups and facilities.

The development of reference materials specifically designed for graphene calorimetric analysis is another crucial aspect of standardization. These materials should have well-characterized thermal properties and serve as benchmarks for calibrating instruments and validating measurement procedures.

Lastly, the standardization process should be an ongoing effort, with regular reviews and updates to incorporate new developments in graphene synthesis, characterization techniques, and calorimetric instrumentation. This will ensure that the standards remain relevant and continue to meet the evolving needs of the graphene research and industry communities.

To address this issue, several key aspects of the standardization process need to be considered. Firstly, sample preparation methods must be standardized to ensure uniformity in the graphene materials being analyzed. This includes establishing guidelines for the synthesis, purification, and handling of graphene samples, as well as defining acceptable ranges for key parameters such as flake size, layer thickness, and defect density.

Secondly, measurement procedures and instrumentation specifications need to be standardized. This involves defining the optimal temperature ranges, heating rates, and atmosphere conditions for calorimetric analysis of graphene materials. Additionally, calibration procedures for calorimetry equipment should be established to ensure accuracy and reproducibility of results across different laboratories.

Data analysis and reporting methods also require standardization. This includes establishing protocols for baseline correction, peak identification, and quantification of thermal events. Furthermore, a standardized format for reporting calorimetric data should be developed, including essential metadata such as sample characteristics, experimental conditions, and data processing methods.

Interlaboratory comparisons and round-robin tests are essential for validating the proposed standardization methods. These collaborative efforts will help identify potential sources of variability and refine the protocols to achieve better consistency across different research groups and facilities.

The development of reference materials specifically designed for graphene calorimetric analysis is another crucial aspect of standardization. These materials should have well-characterized thermal properties and serve as benchmarks for calibrating instruments and validating measurement procedures.

Lastly, the standardization process should be an ongoing effort, with regular reviews and updates to incorporate new developments in graphene synthesis, characterization techniques, and calorimetric instrumentation. This will ensure that the standards remain relevant and continue to meet the evolving needs of the graphene research and industry communities.

Environmental Impact of Graphene Calorimetry

The environmental impact of graphene calorimetry is a crucial aspect to consider as this innovative technology gains prominence in materials science and engineering. While graphene-based materials offer significant advantages in terms of performance and efficiency, their production and analysis processes may have both positive and negative environmental implications.

One of the primary environmental benefits of graphene calorimetry is its potential to improve energy efficiency in various applications. By enabling more accurate and sensitive thermal measurements, this technology can lead to the development of more energy-efficient materials and devices. This, in turn, could contribute to reduced energy consumption and lower greenhouse gas emissions across multiple industries.

However, the production of graphene itself raises environmental concerns. The most common method of graphene synthesis, chemical vapor deposition (CVD), involves the use of high temperatures and potentially harmful chemicals. These processes can result in significant energy consumption and the generation of hazardous waste. As graphene calorimetry becomes more widespread, the demand for graphene production may increase, potentially exacerbating these environmental issues.

Water usage is another environmental factor to consider in graphene calorimetry. Some graphene production methods require substantial amounts of water, which could strain local water resources in areas where water scarcity is a concern. Additionally, the disposal of wastewater from graphene production processes may introduce contaminants into aquatic ecosystems if not properly treated.

The use of graphene in calorimetric analysis may also have implications for waste management. While graphene is theoretically recyclable, the current recycling infrastructure is not well-equipped to handle graphene-based materials. As these materials become more prevalent in scientific and industrial applications, there is a risk of increased electronic waste if proper recycling methods are not developed and implemented.

On a positive note, the high sensitivity and precision of graphene calorimetry could lead to more efficient use of resources in research and development. By providing more accurate thermal data, this technology may reduce the need for repetitive experiments, thereby minimizing waste generation and resource consumption in laboratory settings.

The long-term environmental effects of graphene nanoparticles released into the environment during production or disposal are not yet fully understood. There are concerns about their potential impact on ecosystems and human health, which necessitates further research and the development of appropriate safety protocols for handling and disposing of graphene-based materials used in calorimetric analysis.

One of the primary environmental benefits of graphene calorimetry is its potential to improve energy efficiency in various applications. By enabling more accurate and sensitive thermal measurements, this technology can lead to the development of more energy-efficient materials and devices. This, in turn, could contribute to reduced energy consumption and lower greenhouse gas emissions across multiple industries.

However, the production of graphene itself raises environmental concerns. The most common method of graphene synthesis, chemical vapor deposition (CVD), involves the use of high temperatures and potentially harmful chemicals. These processes can result in significant energy consumption and the generation of hazardous waste. As graphene calorimetry becomes more widespread, the demand for graphene production may increase, potentially exacerbating these environmental issues.

Water usage is another environmental factor to consider in graphene calorimetry. Some graphene production methods require substantial amounts of water, which could strain local water resources in areas where water scarcity is a concern. Additionally, the disposal of wastewater from graphene production processes may introduce contaminants into aquatic ecosystems if not properly treated.

The use of graphene in calorimetric analysis may also have implications for waste management. While graphene is theoretically recyclable, the current recycling infrastructure is not well-equipped to handle graphene-based materials. As these materials become more prevalent in scientific and industrial applications, there is a risk of increased electronic waste if proper recycling methods are not developed and implemented.

On a positive note, the high sensitivity and precision of graphene calorimetry could lead to more efficient use of resources in research and development. By providing more accurate thermal data, this technology may reduce the need for repetitive experiments, thereby minimizing waste generation and resource consumption in laboratory settings.

The long-term environmental effects of graphene nanoparticles released into the environment during production or disposal are not yet fully understood. There are concerns about their potential impact on ecosystems and human health, which necessitates further research and the development of appropriate safety protocols for handling and disposing of graphene-based materials used in calorimetric analysis.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!