Calorimeter Designs for Improved Detection of Trace Gases

AUG 5, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Calorimeter Technology Evolution and Objectives

Calorimeter technology has undergone significant evolution since its inception, driven by the growing need for precise detection of trace gases in various applications. The development of calorimeters can be traced back to the late 18th century, with notable advancements occurring throughout the 20th and 21st centuries. Initially used for measuring heat in chemical reactions, calorimeters have since been adapted for gas detection, particularly in environmental monitoring, industrial processes, and scientific research.

The primary objective of modern calorimeter designs for trace gas detection is to achieve higher sensitivity, selectivity, and reliability while minimizing interference from other gases or environmental factors. This goal has led to the integration of advanced materials, sophisticated electronics, and innovative detection mechanisms. The evolution of calorimeter technology has been marked by a shift from simple heat measurement devices to complex systems incorporating multiple sensors and data processing capabilities.

One of the key trends in calorimeter development has been the miniaturization of devices, enabling portable and field-deployable solutions. This trend aligns with the increasing demand for real-time, on-site gas analysis in various industries. Concurrently, there has been a focus on improving the detection limits of calorimeters, allowing for the identification of gases at ever-lower concentrations, often in the parts per billion (ppb) range or lower.

The integration of calorimetric techniques with other analytical methods, such as spectroscopy and chromatography, has emerged as a significant area of research. This interdisciplinary approach aims to overcome the limitations of individual techniques and provide more comprehensive gas analysis capabilities. Additionally, the advent of nanotechnology has opened new avenues for enhancing calorimeter performance, particularly in terms of sensor design and material selection.

Recent technological objectives in calorimeter design include the development of multi-gas detection systems capable of simultaneously analyzing multiple trace gases, the implementation of artificial intelligence and machine learning algorithms for improved data interpretation, and the creation of networked sensor arrays for wide-area monitoring. These advancements are crucial for addressing complex environmental challenges, enhancing industrial safety, and supporting cutting-edge scientific research.

As we look towards the future, the objectives for calorimeter technology in trace gas detection are likely to focus on further improving sensitivity and selectivity, reducing power consumption and cost, and enhancing durability and reliability in diverse operating conditions. The integration of calorimeters with Internet of Things (IoT) platforms and cloud-based data analytics is expected to play a significant role in expanding their applications and capabilities.

The primary objective of modern calorimeter designs for trace gas detection is to achieve higher sensitivity, selectivity, and reliability while minimizing interference from other gases or environmental factors. This goal has led to the integration of advanced materials, sophisticated electronics, and innovative detection mechanisms. The evolution of calorimeter technology has been marked by a shift from simple heat measurement devices to complex systems incorporating multiple sensors and data processing capabilities.

One of the key trends in calorimeter development has been the miniaturization of devices, enabling portable and field-deployable solutions. This trend aligns with the increasing demand for real-time, on-site gas analysis in various industries. Concurrently, there has been a focus on improving the detection limits of calorimeters, allowing for the identification of gases at ever-lower concentrations, often in the parts per billion (ppb) range or lower.

The integration of calorimetric techniques with other analytical methods, such as spectroscopy and chromatography, has emerged as a significant area of research. This interdisciplinary approach aims to overcome the limitations of individual techniques and provide more comprehensive gas analysis capabilities. Additionally, the advent of nanotechnology has opened new avenues for enhancing calorimeter performance, particularly in terms of sensor design and material selection.

Recent technological objectives in calorimeter design include the development of multi-gas detection systems capable of simultaneously analyzing multiple trace gases, the implementation of artificial intelligence and machine learning algorithms for improved data interpretation, and the creation of networked sensor arrays for wide-area monitoring. These advancements are crucial for addressing complex environmental challenges, enhancing industrial safety, and supporting cutting-edge scientific research.

As we look towards the future, the objectives for calorimeter technology in trace gas detection are likely to focus on further improving sensitivity and selectivity, reducing power consumption and cost, and enhancing durability and reliability in diverse operating conditions. The integration of calorimeters with Internet of Things (IoT) platforms and cloud-based data analytics is expected to play a significant role in expanding their applications and capabilities.

Market Analysis for Trace Gas Detection

The market for trace gas detection technologies has been experiencing significant growth in recent years, driven by increasing environmental concerns, stringent regulations, and the need for improved safety measures across various industries. The global trace gas detection market is expected to continue its upward trajectory, with a compound annual growth rate (CAGR) projected to be in the high single digits over the next five years.

Key industries driving the demand for advanced trace gas detection technologies include environmental monitoring, industrial safety, automotive emissions control, and healthcare. Environmental monitoring applications are particularly crucial, as governments worldwide implement stricter air quality standards and emissions regulations. This has led to a surge in demand for high-precision, real-time monitoring systems capable of detecting even minute concentrations of harmful gases.

In the industrial sector, there is a growing emphasis on workplace safety and process optimization. Industries such as oil and gas, chemical manufacturing, and semiconductor production require advanced trace gas detection systems to ensure worker safety and maintain product quality. The automotive industry is another significant market driver, as manufacturers seek to comply with increasingly stringent emissions standards and develop more efficient engine technologies.

The healthcare sector presents a promising growth opportunity for trace gas detection technologies. Applications in breath analysis for disease diagnosis and monitoring are gaining traction, with potential for non-invasive detection of various medical conditions. This emerging field is attracting substantial research and development investments.

Geographically, North America and Europe currently dominate the trace gas detection market, owing to their stringent environmental regulations and well-established industrial bases. However, the Asia-Pacific region is expected to witness the fastest growth, driven by rapid industrialization, increasing environmental awareness, and government initiatives to combat air pollution in countries like China and India.

Technological advancements in calorimeter designs for improved trace gas detection are likely to reshape the competitive landscape. Innovations that offer higher sensitivity, faster response times, and improved selectivity will be key differentiators in the market. Additionally, there is a growing demand for portable and miniaturized detection systems, particularly for field applications and personal safety devices.

The market is characterized by a mix of established players and innovative start-ups. Major companies are investing heavily in research and development to maintain their competitive edge, while new entrants are focusing on niche applications and disruptive technologies. Collaborations between industry players and research institutions are becoming increasingly common, accelerating the pace of innovation in the field.

Key industries driving the demand for advanced trace gas detection technologies include environmental monitoring, industrial safety, automotive emissions control, and healthcare. Environmental monitoring applications are particularly crucial, as governments worldwide implement stricter air quality standards and emissions regulations. This has led to a surge in demand for high-precision, real-time monitoring systems capable of detecting even minute concentrations of harmful gases.

In the industrial sector, there is a growing emphasis on workplace safety and process optimization. Industries such as oil and gas, chemical manufacturing, and semiconductor production require advanced trace gas detection systems to ensure worker safety and maintain product quality. The automotive industry is another significant market driver, as manufacturers seek to comply with increasingly stringent emissions standards and develop more efficient engine technologies.

The healthcare sector presents a promising growth opportunity for trace gas detection technologies. Applications in breath analysis for disease diagnosis and monitoring are gaining traction, with potential for non-invasive detection of various medical conditions. This emerging field is attracting substantial research and development investments.

Geographically, North America and Europe currently dominate the trace gas detection market, owing to their stringent environmental regulations and well-established industrial bases. However, the Asia-Pacific region is expected to witness the fastest growth, driven by rapid industrialization, increasing environmental awareness, and government initiatives to combat air pollution in countries like China and India.

Technological advancements in calorimeter designs for improved trace gas detection are likely to reshape the competitive landscape. Innovations that offer higher sensitivity, faster response times, and improved selectivity will be key differentiators in the market. Additionally, there is a growing demand for portable and miniaturized detection systems, particularly for field applications and personal safety devices.

The market is characterized by a mix of established players and innovative start-ups. Major companies are investing heavily in research and development to maintain their competitive edge, while new entrants are focusing on niche applications and disruptive technologies. Collaborations between industry players and research institutions are becoming increasingly common, accelerating the pace of innovation in the field.

Current Challenges in Calorimetric Gas Sensing

Calorimetric gas sensing technology faces several significant challenges that hinder its widespread adoption and effectiveness in detecting trace gases. One of the primary obstacles is the limited sensitivity of current calorimetric sensors, particularly when dealing with extremely low concentrations of target gases. This sensitivity issue is often exacerbated by the presence of interfering gases in complex mixtures, making it difficult to accurately identify and quantify specific trace gases of interest.

Another major challenge lies in the thermal management of calorimetric sensors. The precise control of temperature is crucial for accurate measurements, yet maintaining stable thermal conditions in varying environmental settings remains problematic. Fluctuations in ambient temperature can significantly impact sensor performance, leading to reduced accuracy and reliability in real-world applications.

The response time of calorimetric gas sensors is another area of concern. Many current designs exhibit relatively slow response times, limiting their usefulness in scenarios that require rapid detection and analysis of gas concentrations. This sluggish response is often due to the time required for heat transfer and thermal equilibrium to be established within the sensor system.

Power consumption presents a further challenge, especially for portable or remote sensing applications. Traditional calorimetric sensors often require substantial energy to maintain the necessary operating temperatures, which can be a significant drawback in battery-powered devices or in situations where long-term, unattended operation is required.

Selectivity remains a persistent issue in calorimetric gas sensing. Many sensors struggle to differentiate between gases with similar thermal properties, leading to false positives or inaccurate concentration measurements. This lack of selectivity is particularly problematic in industrial environments or atmospheric monitoring, where multiple gases may be present simultaneously.

Miniaturization of calorimetric sensors while maintaining performance is another ongoing challenge. As demand grows for compact, integrated sensing solutions, reducing the size of calorimetric sensors without compromising their sensitivity or accuracy has proven difficult. This challenge is closely tied to issues of thermal management and power consumption in smaller form factors.

Lastly, the long-term stability and calibration of calorimetric gas sensors pose significant challenges. Sensor drift over time can lead to decreased accuracy and reliability, necessitating frequent recalibration. Developing sensors that maintain consistent performance over extended periods, especially in harsh or variable environments, remains a key area of focus for researchers and engineers in the field.

Another major challenge lies in the thermal management of calorimetric sensors. The precise control of temperature is crucial for accurate measurements, yet maintaining stable thermal conditions in varying environmental settings remains problematic. Fluctuations in ambient temperature can significantly impact sensor performance, leading to reduced accuracy and reliability in real-world applications.

The response time of calorimetric gas sensors is another area of concern. Many current designs exhibit relatively slow response times, limiting their usefulness in scenarios that require rapid detection and analysis of gas concentrations. This sluggish response is often due to the time required for heat transfer and thermal equilibrium to be established within the sensor system.

Power consumption presents a further challenge, especially for portable or remote sensing applications. Traditional calorimetric sensors often require substantial energy to maintain the necessary operating temperatures, which can be a significant drawback in battery-powered devices or in situations where long-term, unattended operation is required.

Selectivity remains a persistent issue in calorimetric gas sensing. Many sensors struggle to differentiate between gases with similar thermal properties, leading to false positives or inaccurate concentration measurements. This lack of selectivity is particularly problematic in industrial environments or atmospheric monitoring, where multiple gases may be present simultaneously.

Miniaturization of calorimetric sensors while maintaining performance is another ongoing challenge. As demand grows for compact, integrated sensing solutions, reducing the size of calorimetric sensors without compromising their sensitivity or accuracy has proven difficult. This challenge is closely tied to issues of thermal management and power consumption in smaller form factors.

Lastly, the long-term stability and calibration of calorimetric gas sensors pose significant challenges. Sensor drift over time can lead to decreased accuracy and reliability, necessitating frequent recalibration. Developing sensors that maintain consistent performance over extended periods, especially in harsh or variable environments, remains a key area of focus for researchers and engineers in the field.

State-of-the-Art Calorimeter Designs

01 Calorimeter design and structure

Various designs and structures of calorimeters are used for detection purposes. These include specialized chambers, sensors, and components that enhance the accuracy and efficiency of heat measurement. Innovations in calorimeter design focus on improving sensitivity, reducing interference, and optimizing thermal insulation for precise measurements.- Calorimeter design and structure: Various designs and structures of calorimeters are used for detection purposes. These include specialized chambers, sensors, and materials to accurately measure heat changes. Improvements in design focus on enhancing sensitivity, accuracy, and reliability of measurements.

- Temperature measurement techniques: Different temperature measurement techniques are employed in calorimeter detection. These may include thermocouples, thermistors, or other temperature-sensitive elements. Advanced methods aim to improve precision and reduce response time for more accurate heat detection.

- Data processing and analysis: Calorimeter detection systems incorporate sophisticated data processing and analysis methods. These may include signal processing algorithms, calibration techniques, and software for interpreting heat measurements. Advanced systems may use machine learning or artificial intelligence for improved accuracy and automation.

- Application-specific calorimeter designs: Calorimeters are designed for specific applications such as medical diagnostics, material analysis, or industrial processes. These specialized designs may incorporate features tailored to the particular field of use, such as sample handling mechanisms or integration with other analytical techniques.

- Calibration and standardization methods: Accurate calorimeter detection relies on proper calibration and standardization methods. These may include the use of reference materials, calibration protocols, and techniques to account for environmental factors. Improved methods aim to enhance the reliability and comparability of measurements across different instruments and conditions.

02 Temperature measurement and control

Calorimeter detection systems incorporate advanced temperature measurement and control mechanisms. These include high-precision thermocouples, thermistors, and temperature sensors that enable accurate monitoring of heat changes. Some designs feature temperature stabilization systems to maintain constant conditions during measurements.Expand Specific Solutions03 Data processing and analysis

Modern calorimeter detection systems employ sophisticated data processing and analysis techniques. This includes real-time data acquisition, signal processing algorithms, and software for interpreting calorimetric data. Advanced systems may incorporate machine learning or artificial intelligence for improved accuracy and automated analysis.Expand Specific Solutions04 Specialized calorimeter applications

Calorimeters are adapted for specific applications in various fields. These include biomedical calorimeters for metabolic studies, nanocalorimeters for small-scale measurements, and high-pressure calorimeters for industrial processes. Specialized designs cater to unique requirements in fields such as materials science, pharmaceuticals, and environmental monitoring.Expand Specific Solutions05 Calibration and standardization techniques

Ensuring accuracy in calorimeter detection requires robust calibration and standardization methods. This involves the use of reference materials, standardized procedures, and calibration devices. Some innovations focus on automated calibration systems and methods to minimize human error and improve reproducibility of measurements across different calorimeter setups.Expand Specific Solutions

Key Players in Calorimetric Sensor Industry

The market for improved calorimeter designs for trace gas detection is in a growth phase, driven by increasing environmental concerns and regulatory requirements. The global market size is expanding, with projections indicating significant growth in the coming years. Technologically, the field is advancing rapidly, with companies like Tokyo Gas Co., Ltd. and Smiths Detection Ltd. leading innovation in sensor technologies. Palo Alto Research Center LLC and Xerox Holdings Corp. are contributing cutting-edge research in materials and detection methods. Academic institutions such as Xi'an Jiaotong University and North Carolina State University are also playing crucial roles in advancing the fundamental science. The involvement of major industrial players like Mitsubishi Heavy Industries, Ltd. and Agilent Technologies, Inc. suggests the technology is maturing and moving towards wider commercial application.

Smiths Detection Ltd.

Technical Solution: Smiths Detection has innovated in calorimeter design for trace gas detection with a focus on portability and robustness for field applications. Their approach combines miniaturized calorimetric sensors with advanced signal processing techniques. The company has developed a multi-channel calorimeter array that can simultaneously detect and quantify multiple trace gases in complex environments[2]. This system utilizes differential thermal analysis to minimize environmental interference and improve detection limits. Smiths Detection's calorimeters also incorporate machine learning algorithms for real-time pattern recognition, enabling rapid identification of gas mixtures and potential threats[4]. The design includes ruggedized components for operation in harsh conditions, making it suitable for security and environmental monitoring applications.

Strengths: Portable, rugged design suitable for field use, multi-gas detection capability. Weaknesses: May have lower sensitivity compared to lab-based systems, and potentially higher power consumption due to robust design.

Agilent Technologies, Inc.

Technical Solution: Agilent Technologies has developed advanced calorimeter designs for improved trace gas detection, focusing on high-sensitivity and rapid response times. Their approach utilizes micro-fabricated thermal sensors combined with innovative gas flow management systems. This design allows for detection of trace gases at parts-per-billion levels with response times in the order of seconds[1]. The system incorporates a reference channel for real-time background compensation, enhancing accuracy in complex gas mixtures. Agilent's calorimeters also feature integrated microfluidics for precise sample handling and a proprietary data processing algorithm that enhances signal-to-noise ratios, enabling detection of ultra-low concentrations of target gases[3].

Strengths: High sensitivity, fast response times, and ability to detect multiple gases simultaneously. Weaknesses: Potentially higher cost due to advanced technology and may require specialized training for operation and maintenance.

Innovative Calorimetric Detection Methods

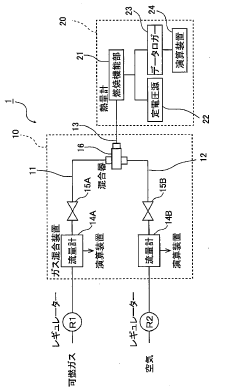

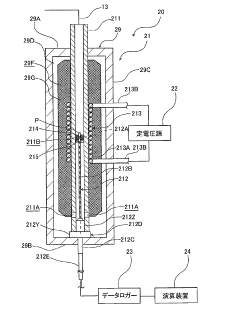

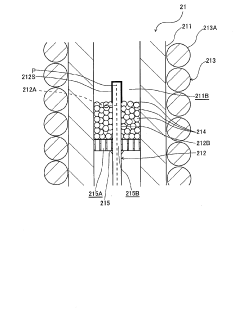

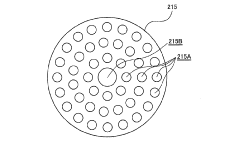

Calorimeter

PatentActiveJP2023030921A

Innovation

- A calorimeter design featuring a tubular member with a granular catalyst layer around the temperature measuring junction, a heating unit, and a stopper member to promote combustion reactions and suppress unburned gas passage while maintaining low pressure loss.

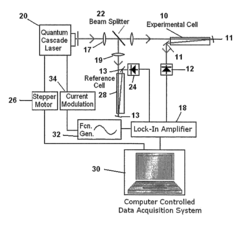

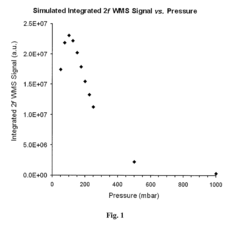

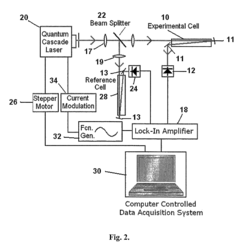

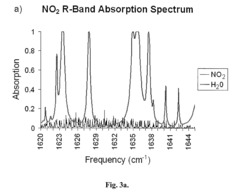

Method and apparatus for trace gas detection using integrated wavelength modulated spectra across multiple lines

PatentInactiveUS8395777B2

Innovation

- The implementation of wavelength modulation spectroscopy with a tunable laser, integrating the absolute value of spectra across multiple absorption lines, enhances sensitivity by several orders of magnitude by utilizing a sinusoidal frequency modulation and lock-in amplifier techniques, allowing for precise detection of trace gas species like NO2.

Environmental Impact of Trace Gas Detection

The detection of trace gases using advanced calorimeter designs has significant environmental implications, both in terms of monitoring and mitigating environmental issues. These improved detection methods enable more accurate and sensitive measurements of trace gases in the atmosphere, which is crucial for understanding and addressing various environmental challenges.

One of the primary environmental impacts of enhanced trace gas detection is in the field of climate change research. Greenhouse gases, such as carbon dioxide, methane, and nitrous oxide, are present in the atmosphere in trace amounts but have a substantial impact on global warming. Improved calorimeter designs allow for more precise quantification of these gases, enabling scientists to better understand their sources, sinks, and overall atmospheric concentrations. This information is vital for developing accurate climate models and informing policy decisions aimed at reducing greenhouse gas emissions.

In the realm of air quality management, advanced trace gas detection techniques contribute to more effective monitoring of pollutants. Volatile organic compounds (VOCs), nitrogen oxides, and other harmful gases can be detected at lower concentrations, allowing for earlier identification of potential health hazards and more timely implementation of mitigation strategies. This capability is particularly valuable in urban areas and industrial zones where air quality is a significant concern.

The environmental impact extends to ecosystem monitoring as well. Trace gas detection plays a crucial role in assessing the health of forests, wetlands, and other natural habitats. For instance, measuring trace amounts of isoprene and other biogenic volatile organic compounds emitted by plants can provide insights into ecosystem stress and biodiversity changes. This information is essential for conservation efforts and understanding the broader impacts of climate change on natural systems.

In the field of agriculture, improved trace gas detection techniques contribute to more sustainable farming practices. By accurately measuring trace gases emitted from soil and crops, farmers can optimize fertilizer use, reduce greenhouse gas emissions from agricultural activities, and improve overall crop management. This not only benefits the environment but also enhances agricultural productivity and efficiency.

Furthermore, advanced calorimeter designs for trace gas detection have applications in environmental forensics and pollution source identification. The ability to detect and analyze minute quantities of gases can help pinpoint the origins of pollutants, aiding in regulatory enforcement and environmental remediation efforts. This capability is particularly valuable in cases of industrial accidents, illegal dumping, or other environmental violations.

In conclusion, the environmental impact of improved trace gas detection through advanced calorimeter designs is far-reaching and multifaceted. From climate change research to air quality management, ecosystem monitoring, and sustainable agriculture, these technologies play a crucial role in our understanding and stewardship of the environment. As detection capabilities continue to advance, we can expect even greater contributions to environmental science and policy-making in the future.

One of the primary environmental impacts of enhanced trace gas detection is in the field of climate change research. Greenhouse gases, such as carbon dioxide, methane, and nitrous oxide, are present in the atmosphere in trace amounts but have a substantial impact on global warming. Improved calorimeter designs allow for more precise quantification of these gases, enabling scientists to better understand their sources, sinks, and overall atmospheric concentrations. This information is vital for developing accurate climate models and informing policy decisions aimed at reducing greenhouse gas emissions.

In the realm of air quality management, advanced trace gas detection techniques contribute to more effective monitoring of pollutants. Volatile organic compounds (VOCs), nitrogen oxides, and other harmful gases can be detected at lower concentrations, allowing for earlier identification of potential health hazards and more timely implementation of mitigation strategies. This capability is particularly valuable in urban areas and industrial zones where air quality is a significant concern.

The environmental impact extends to ecosystem monitoring as well. Trace gas detection plays a crucial role in assessing the health of forests, wetlands, and other natural habitats. For instance, measuring trace amounts of isoprene and other biogenic volatile organic compounds emitted by plants can provide insights into ecosystem stress and biodiversity changes. This information is essential for conservation efforts and understanding the broader impacts of climate change on natural systems.

In the field of agriculture, improved trace gas detection techniques contribute to more sustainable farming practices. By accurately measuring trace gases emitted from soil and crops, farmers can optimize fertilizer use, reduce greenhouse gas emissions from agricultural activities, and improve overall crop management. This not only benefits the environment but also enhances agricultural productivity and efficiency.

Furthermore, advanced calorimeter designs for trace gas detection have applications in environmental forensics and pollution source identification. The ability to detect and analyze minute quantities of gases can help pinpoint the origins of pollutants, aiding in regulatory enforcement and environmental remediation efforts. This capability is particularly valuable in cases of industrial accidents, illegal dumping, or other environmental violations.

In conclusion, the environmental impact of improved trace gas detection through advanced calorimeter designs is far-reaching and multifaceted. From climate change research to air quality management, ecosystem monitoring, and sustainable agriculture, these technologies play a crucial role in our understanding and stewardship of the environment. As detection capabilities continue to advance, we can expect even greater contributions to environmental science and policy-making in the future.

Calibration and Standardization Protocols

Calibration and standardization protocols play a crucial role in ensuring the accuracy and reliability of calorimeter designs for improved detection of trace gases. These protocols establish a systematic approach to maintain consistency across measurements and enable comparability between different instruments and laboratories.

The calibration process for calorimeters typically involves the use of certified reference materials (CRMs) with known concentrations of target trace gases. These CRMs are carefully prepared and characterized to provide a reliable baseline for instrument calibration. The calibration procedure often includes multiple concentration levels to cover the expected range of measurements in real-world applications.

Standardization protocols for calorimeter designs encompass various aspects of the measurement process. These include sample preparation techniques, instrument setup procedures, and data analysis methods. By adhering to standardized protocols, researchers and technicians can minimize variability and ensure reproducibility of results across different laboratories and experimental setups.

One key aspect of calibration and standardization is the establishment of traceability to international standards. This involves linking the measurements obtained from calorimeters to recognized primary standards, such as those maintained by national metrology institutes. Traceability ensures that the results are comparable on a global scale and can be reliably used for regulatory compliance and scientific research.

Quality control measures are an integral part of calibration and standardization protocols. These may include regular performance checks using control samples, participation in interlaboratory comparison studies, and the implementation of statistical process control techniques. Such measures help identify and correct any drift or inconsistencies in instrument performance over time.

The development and implementation of calibration and standardization protocols often involve collaboration between instrument manufacturers, regulatory bodies, and scientific organizations. This collaborative approach ensures that the protocols are comprehensive, practical, and aligned with the latest advancements in calorimeter technology and trace gas detection methods.

As calorimeter designs continue to evolve, calibration and standardization protocols must adapt accordingly. This may involve the incorporation of new reference materials, updated data processing algorithms, or revised measurement procedures to account for improved sensitivity and specificity in trace gas detection. Regular review and revision of these protocols are essential to keep pace with technological advancements and changing regulatory requirements.

The calibration process for calorimeters typically involves the use of certified reference materials (CRMs) with known concentrations of target trace gases. These CRMs are carefully prepared and characterized to provide a reliable baseline for instrument calibration. The calibration procedure often includes multiple concentration levels to cover the expected range of measurements in real-world applications.

Standardization protocols for calorimeter designs encompass various aspects of the measurement process. These include sample preparation techniques, instrument setup procedures, and data analysis methods. By adhering to standardized protocols, researchers and technicians can minimize variability and ensure reproducibility of results across different laboratories and experimental setups.

One key aspect of calibration and standardization is the establishment of traceability to international standards. This involves linking the measurements obtained from calorimeters to recognized primary standards, such as those maintained by national metrology institutes. Traceability ensures that the results are comparable on a global scale and can be reliably used for regulatory compliance and scientific research.

Quality control measures are an integral part of calibration and standardization protocols. These may include regular performance checks using control samples, participation in interlaboratory comparison studies, and the implementation of statistical process control techniques. Such measures help identify and correct any drift or inconsistencies in instrument performance over time.

The development and implementation of calibration and standardization protocols often involve collaboration between instrument manufacturers, regulatory bodies, and scientific organizations. This collaborative approach ensures that the protocols are comprehensive, practical, and aligned with the latest advancements in calorimeter technology and trace gas detection methods.

As calorimeter designs continue to evolve, calibration and standardization protocols must adapt accordingly. This may involve the incorporation of new reference materials, updated data processing algorithms, or revised measurement procedures to account for improved sensitivity and specificity in trace gas detection. Regular review and revision of these protocols are essential to keep pace with technological advancements and changing regulatory requirements.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!