Applications Of Model Predictive Control In Smart Manufacturing

SEP 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

MPC Technology Evolution in Manufacturing

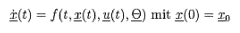

Model Predictive Control (MPC) has undergone significant evolution in manufacturing environments since its initial industrial applications in the 1970s. The technology's journey began with basic process control applications in petrochemical industries, where its ability to handle multivariable systems with constraints provided clear advantages over traditional PID controllers.

The 1980s marked the first generation of MPC in manufacturing, characterized by linear models and centralized computing architectures. During this period, MPC was primarily implemented in large-scale continuous processes where the economic benefits could justify the substantial implementation costs and computational requirements.

A paradigm shift occurred in the 1990s with the development of more efficient algorithms and increased computing power, enabling faster solution times and broader applications. This second generation of MPC technology expanded beyond process industries into discrete manufacturing, particularly in automotive and aerospace sectors where precision control became increasingly critical.

The early 2000s witnessed the integration of nonlinear models into MPC frameworks, allowing for more accurate representation of complex manufacturing processes. This advancement, coupled with distributed computing architectures, facilitated the implementation of MPC in more dynamic production environments with faster response requirements.

The emergence of Industry 4.0 in the 2010s catalyzed the next evolutionary phase of MPC in manufacturing. Cloud computing and edge processing capabilities enabled real-time optimization across entire production lines rather than isolated unit operations. This period also saw the development of robust MPC formulations that could better handle uncertainties in manufacturing processes.

Most recently, the integration of machine learning techniques with traditional MPC frameworks has created hybrid approaches that combine first-principles models with data-driven components. These adaptive MPC systems can continuously improve their performance through operational data, addressing one of the historical limitations of model-based approaches—the degradation of performance as processes evolve over time.

The miniaturization of computing hardware and advances in optimization algorithms have democratized MPC technology, making it accessible to smaller manufacturing operations. Modern implementations now feature user-friendly interfaces and automated model identification tools that significantly reduce the expertise required for deployment.

Looking at the trajectory, MPC technology in manufacturing has evolved from a specialized tool requiring significant expertise to an increasingly standardized approach embedded in modern automation systems. This evolution reflects broader trends in manufacturing technology toward more intelligent, adaptive, and interconnected systems capable of responding to the increasing complexity and variability of modern production environments.

The 1980s marked the first generation of MPC in manufacturing, characterized by linear models and centralized computing architectures. During this period, MPC was primarily implemented in large-scale continuous processes where the economic benefits could justify the substantial implementation costs and computational requirements.

A paradigm shift occurred in the 1990s with the development of more efficient algorithms and increased computing power, enabling faster solution times and broader applications. This second generation of MPC technology expanded beyond process industries into discrete manufacturing, particularly in automotive and aerospace sectors where precision control became increasingly critical.

The early 2000s witnessed the integration of nonlinear models into MPC frameworks, allowing for more accurate representation of complex manufacturing processes. This advancement, coupled with distributed computing architectures, facilitated the implementation of MPC in more dynamic production environments with faster response requirements.

The emergence of Industry 4.0 in the 2010s catalyzed the next evolutionary phase of MPC in manufacturing. Cloud computing and edge processing capabilities enabled real-time optimization across entire production lines rather than isolated unit operations. This period also saw the development of robust MPC formulations that could better handle uncertainties in manufacturing processes.

Most recently, the integration of machine learning techniques with traditional MPC frameworks has created hybrid approaches that combine first-principles models with data-driven components. These adaptive MPC systems can continuously improve their performance through operational data, addressing one of the historical limitations of model-based approaches—the degradation of performance as processes evolve over time.

The miniaturization of computing hardware and advances in optimization algorithms have democratized MPC technology, making it accessible to smaller manufacturing operations. Modern implementations now feature user-friendly interfaces and automated model identification tools that significantly reduce the expertise required for deployment.

Looking at the trajectory, MPC technology in manufacturing has evolved from a specialized tool requiring significant expertise to an increasingly standardized approach embedded in modern automation systems. This evolution reflects broader trends in manufacturing technology toward more intelligent, adaptive, and interconnected systems capable of responding to the increasing complexity and variability of modern production environments.

Smart Manufacturing Market Demand Analysis

The global smart manufacturing market is experiencing unprecedented growth, driven by the increasing demand for efficient, flexible, and sustainable production systems. According to recent market research, the smart manufacturing market is projected to reach $506.33 billion by 2027, growing at a CAGR of 12.4% from 2020. This remarkable expansion is fueled by several key factors that highlight the critical need for advanced control technologies like Model Predictive Control (MPC).

Manufacturing industries worldwide are facing intensifying pressure to optimize production processes while minimizing resource consumption. This has created a substantial demand for sophisticated control systems that can handle complex, multi-variable processes with constraints - precisely where MPC excels. The automotive sector, for instance, has shown particular interest in MPC applications, with major manufacturers implementing these systems to improve production efficiency by approximately 15-20% while reducing energy consumption.

The pharmaceutical and chemical industries represent another significant market segment for MPC technology. These sectors require precise process control to ensure product quality and regulatory compliance. Market analysis indicates that pharmaceutical manufacturers implementing MPC-based solutions have reported up to 30% reduction in batch-to-batch variability, directly translating to improved product consistency and reduced waste.

Energy efficiency has emerged as a primary driver for MPC adoption in smart manufacturing. With industrial operations accounting for roughly one-third of global energy consumption, manufacturers are increasingly seeking technologies that can optimize energy usage. MPC systems have demonstrated the ability to reduce energy consumption by 10-25% across various manufacturing processes, creating both economic and environmental benefits that align with global sustainability initiatives.

The Industry 4.0 paradigm has significantly amplified market demand for MPC technologies. As manufacturers integrate IoT devices, big data analytics, and cloud computing into their operations, the need for advanced control algorithms capable of processing this wealth of information has grown exponentially. Market surveys indicate that over 65% of large manufacturers plan to implement some form of predictive control within their smart factory initiatives in the next five years.

Regional analysis reveals that while North America and Europe currently lead in MPC adoption, the Asia-Pacific region is expected to witness the highest growth rate, with China and India making substantial investments in smart manufacturing technologies. This geographic shift is creating new market opportunities for MPC solution providers who can address the specific needs of rapidly industrializing economies.

Manufacturing industries worldwide are facing intensifying pressure to optimize production processes while minimizing resource consumption. This has created a substantial demand for sophisticated control systems that can handle complex, multi-variable processes with constraints - precisely where MPC excels. The automotive sector, for instance, has shown particular interest in MPC applications, with major manufacturers implementing these systems to improve production efficiency by approximately 15-20% while reducing energy consumption.

The pharmaceutical and chemical industries represent another significant market segment for MPC technology. These sectors require precise process control to ensure product quality and regulatory compliance. Market analysis indicates that pharmaceutical manufacturers implementing MPC-based solutions have reported up to 30% reduction in batch-to-batch variability, directly translating to improved product consistency and reduced waste.

Energy efficiency has emerged as a primary driver for MPC adoption in smart manufacturing. With industrial operations accounting for roughly one-third of global energy consumption, manufacturers are increasingly seeking technologies that can optimize energy usage. MPC systems have demonstrated the ability to reduce energy consumption by 10-25% across various manufacturing processes, creating both economic and environmental benefits that align with global sustainability initiatives.

The Industry 4.0 paradigm has significantly amplified market demand for MPC technologies. As manufacturers integrate IoT devices, big data analytics, and cloud computing into their operations, the need for advanced control algorithms capable of processing this wealth of information has grown exponentially. Market surveys indicate that over 65% of large manufacturers plan to implement some form of predictive control within their smart factory initiatives in the next five years.

Regional analysis reveals that while North America and Europe currently lead in MPC adoption, the Asia-Pacific region is expected to witness the highest growth rate, with China and India making substantial investments in smart manufacturing technologies. This geographic shift is creating new market opportunities for MPC solution providers who can address the specific needs of rapidly industrializing economies.

MPC Implementation Challenges in Industry 4.0

Despite the promising potential of Model Predictive Control (MPC) in smart manufacturing environments, its implementation within Industry 4.0 frameworks presents several significant challenges. The computational complexity of MPC algorithms remains a primary obstacle, particularly when dealing with high-dimensional systems common in modern manufacturing facilities. Real-time execution requirements often conflict with the intensive calculations needed for accurate predictions and optimizations, creating a fundamental tension between model fidelity and computational feasibility.

Data quality and availability represent another critical challenge. MPC systems require reliable, high-frequency data streams to function effectively. In manufacturing environments, sensor degradation, communication delays, and data inconsistencies can severely impact model performance. The heterogeneous nature of manufacturing equipment, often spanning different generations of technology, further complicates data integration efforts.

Model development and maintenance demand significant expertise and resources. Creating accurate dynamic models that capture complex manufacturing processes requires specialized knowledge in both process engineering and control theory. These models must be continuously updated to account for equipment wear, material variations, and process drift—a requirement that many organizations struggle to meet due to resource constraints.

Integration with existing control systems presents substantial technical hurdles. Legacy automation systems typically operate on different protocols and timescales than modern MPC implementations. This architectural mismatch necessitates complex middleware solutions and careful system design to ensure seamless operation without disrupting production.

The economic justification for MPC implementation remains challenging for many manufacturers. While the technology promises efficiency improvements and quality gains, quantifying these benefits in advance proves difficult. The initial investment in hardware, software, and expertise is substantial, creating a barrier particularly for small and medium-sized enterprises with limited capital resources.

Workforce adaptation represents a human-centered challenge that is often underestimated. Transitioning from traditional control approaches to advanced MPC systems requires significant retraining of operational staff and the development of new maintenance procedures. Resistance to change and skill gaps can significantly impede successful implementation.

Cybersecurity concerns have grown increasingly prominent as manufacturing systems become more connected. MPC systems, with their reliance on networked sensors and computational resources, present expanded attack surfaces that must be secured against increasingly sophisticated threats while maintaining operational performance.

Data quality and availability represent another critical challenge. MPC systems require reliable, high-frequency data streams to function effectively. In manufacturing environments, sensor degradation, communication delays, and data inconsistencies can severely impact model performance. The heterogeneous nature of manufacturing equipment, often spanning different generations of technology, further complicates data integration efforts.

Model development and maintenance demand significant expertise and resources. Creating accurate dynamic models that capture complex manufacturing processes requires specialized knowledge in both process engineering and control theory. These models must be continuously updated to account for equipment wear, material variations, and process drift—a requirement that many organizations struggle to meet due to resource constraints.

Integration with existing control systems presents substantial technical hurdles. Legacy automation systems typically operate on different protocols and timescales than modern MPC implementations. This architectural mismatch necessitates complex middleware solutions and careful system design to ensure seamless operation without disrupting production.

The economic justification for MPC implementation remains challenging for many manufacturers. While the technology promises efficiency improvements and quality gains, quantifying these benefits in advance proves difficult. The initial investment in hardware, software, and expertise is substantial, creating a barrier particularly for small and medium-sized enterprises with limited capital resources.

Workforce adaptation represents a human-centered challenge that is often underestimated. Transitioning from traditional control approaches to advanced MPC systems requires significant retraining of operational staff and the development of new maintenance procedures. Resistance to change and skill gaps can significantly impede successful implementation.

Cybersecurity concerns have grown increasingly prominent as manufacturing systems become more connected. MPC systems, with their reliance on networked sensors and computational resources, present expanded attack surfaces that must be secured against increasingly sophisticated threats while maintaining operational performance.

Current MPC Architectures for Manufacturing Systems

01 Industrial Process Control Applications

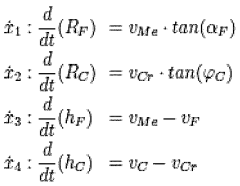

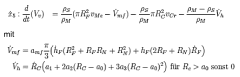

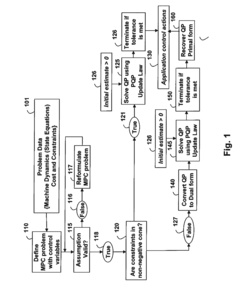

Model Predictive Control (MPC) is widely implemented in industrial processes to optimize operations while maintaining system constraints. These applications include manufacturing systems, chemical processes, and production lines where the controller predicts future behavior based on dynamic models. The MPC algorithm calculates optimal control actions by minimizing cost functions while considering operational constraints, resulting in improved efficiency and reduced energy consumption.- Industrial Process Control Applications: Model Predictive Control (MPC) is widely applied in industrial processes to optimize operations and improve efficiency. These systems use mathematical models to predict future behavior of processes and calculate optimal control actions. MPC algorithms can handle complex constraints and multiple variables simultaneously, making them particularly valuable in manufacturing, chemical processing, and energy production where precise control is critical for product quality and operational safety.

- Advanced Vehicle Control Systems: Model Predictive Control is increasingly implemented in automotive applications for enhanced vehicle performance and safety. These systems predict vehicle behavior based on current states and environmental inputs to optimize driving parameters. Applications include adaptive cruise control, lane-keeping assistance, collision avoidance, and powertrain management. The predictive nature allows vehicles to anticipate changes in driving conditions and respond proactively rather than reactively.

- Energy Management and Optimization: Model Predictive Control techniques are employed in energy systems to optimize resource utilization and reduce consumption. These controllers predict energy demands and environmental conditions to balance supply and demand efficiently. Applications include building climate control, renewable energy integration, grid management, and industrial energy optimization. The predictive capabilities allow systems to anticipate peak demands, weather changes, and other factors affecting energy consumption.

- Machine Learning Enhanced MPC: Integration of machine learning with Model Predictive Control creates more adaptive and robust control systems. These hybrid approaches use data-driven methods to improve model accuracy and controller performance over time. Machine learning algorithms can identify patterns, adapt to changing conditions, and optimize control parameters automatically. This combination is particularly valuable in complex systems where traditional modeling approaches may be insufficient or where system dynamics change over time.

- Distributed and Networked MPC Systems: Distributed Model Predictive Control architectures enable coordination across multiple subsystems while maintaining local control capabilities. These approaches divide complex control problems into manageable components that communicate and coordinate actions. Applications include large-scale industrial processes, smart grids, water distribution networks, and multi-agent robotic systems. Distributed MPC offers advantages in scalability, fault tolerance, and reduced computational burden compared to centralized approaches.

02 Energy Management Systems

MPC techniques are applied to energy management systems to optimize power consumption and distribution. These controllers predict energy demands and adjust operations accordingly, balancing supply and demand while considering constraints such as grid limitations and renewable energy availability. The predictive nature allows for proactive energy management rather than reactive control, resulting in more efficient resource utilization and reduced operational costs in building management systems and power grids.Expand Specific Solutions03 Autonomous Vehicle Control

Model Predictive Control provides advanced control strategies for autonomous vehicles by predicting vehicle dynamics and optimizing trajectory planning. The controller continuously recalculates optimal paths based on current state and environmental conditions, allowing vehicles to navigate complex scenarios while adhering to safety constraints. This application enables smoother vehicle operation, improved fuel efficiency, and enhanced collision avoidance capabilities in autonomous driving systems.Expand Specific Solutions04 Machine Learning Integration with MPC

Recent developments combine machine learning techniques with Model Predictive Control to create more adaptive and robust control systems. These hybrid approaches use data-driven models to improve prediction accuracy and system identification while maintaining the constraint-handling capabilities of traditional MPC. The integration allows controllers to adapt to changing conditions, handle uncertainties, and improve performance through continuous learning from operational data.Expand Specific Solutions05 Distributed and Networked MPC Systems

Distributed Model Predictive Control architectures enable control of large-scale interconnected systems by dividing the control problem into smaller, manageable subsystems. These networked controllers coordinate their actions while respecting local constraints and objectives, making them suitable for applications like smart grids, water distribution networks, and multi-agent robotic systems. The distributed approach reduces computational complexity while maintaining system-wide performance and robustness to local failures.Expand Specific Solutions

Leading MPC Solution Providers and Competitors

Model Predictive Control (MPC) in smart manufacturing is currently in a growth phase, with the market expected to expand significantly due to increasing industrial automation demands. The global market size is projected to reach several billion dollars by 2025, driven by Industry 4.0 initiatives. Technologically, MPC solutions are maturing rapidly with varying levels of sophistication across providers. Industry leaders like Siemens AG, ABB Group, and Honeywell International demonstrate advanced implementation capabilities, while Rockwell Automation and Emerson (Fisher-Rosemount) offer robust industrial-grade solutions. Academic institutions including Tsinghua University and Zhejiang University are contributing significant research advancements. Companies like AspenTech and Tokyo Electron are developing specialized applications for process industries, indicating the technology's expanding practical applications across manufacturing sectors.

Rockwell Automation Technologies, Inc.

Technical Solution: Rockwell Automation has pioneered advanced MPC solutions through their FactoryTalk Analytics and PlantPAx platforms specifically designed for smart manufacturing environments. Their technology implements a distributed MPC architecture that enables coordinated control across multiple production units while maintaining local autonomy. Rockwell's approach incorporates economic objectives directly into the control formulation, allowing manufacturers to optimize production based on real-time market conditions and energy costs[2]. Their MPC implementation features adaptive modeling capabilities that automatically detect and respond to process changes, reducing the need for frequent model maintenance. The system utilizes high-fidelity nonlinear models when necessary while employing computationally efficient linear approximations where appropriate, balancing accuracy with performance[4]. Rockwell has integrated their MPC technology with augmented reality interfaces that provide operators with intuitive visualization of complex process relationships and predicted future states, enhancing operational decision-making[7]. Case studies across food and beverage, pharmaceutical, and discrete manufacturing sectors have demonstrated 10-25% improvements in throughput and 15-30% reductions in quality variability[6].

Strengths: Rockwell's MPC solutions excel in scalability and integration with brownfield environments, making them particularly suitable for phased implementation in existing facilities. Their user-centric design reduces the learning curve for operators transitioning to advanced control strategies. Weaknesses: Their solutions may require significant computational resources for complex applications, and the initial model development process can be time-consuming compared to some competing approaches.

ABB Group

Technical Solution: ABB Group has developed sophisticated MPC technology through their ABB Ability™ Advanced Process Control platform specifically tailored for smart manufacturing applications. Their approach implements a hybrid MPC framework that combines first-principles models with data-driven techniques, enabling robust performance even with incomplete process knowledge. ABB's MPC solution features distributed optimization algorithms that decompose complex manufacturing systems into manageable subsystems while maintaining global coordination through iterative information exchange[3]. The technology incorporates explicit MPC formulations for time-critical applications, pre-computing control solutions offline to enable millisecond-level response times during operation. ABB has pioneered the integration of MPC with soft sensors that provide virtual measurements of difficult-to-measure quality parameters, enabling real-time quality control in previously challenging applications[5]. Their implementation includes automated model adaptation mechanisms that detect process changes and trigger model updates, ensuring sustained performance over equipment lifecycle. Case studies in pulp and paper, metals processing, and chemical manufacturing have demonstrated energy consumption reductions of 5-15% and quality variability improvements of 20-40%[8].

Strengths: ABB's MPC solutions demonstrate exceptional robustness to process disturbances and model uncertainties, making them well-suited for challenging manufacturing environments with complex dynamics. Their technology offers industry-specific templates that accelerate implementation and reduce engineering costs. Weaknesses: The hybrid modeling approach may require more extensive initial configuration compared to purely data-driven alternatives, and integration with non-ABB control systems sometimes requires additional engineering effort.

Key Patents and Algorithms in Industrial MPC

Model predictive control of the zone-melting process

PatentWO2014033212A1

Innovation

- Implementing model predictive control, which involves influencing manipulated variables such as generator power, rod speed, and crystal velocity based on measured and predicted system states to minimize deviations from target values, while considering system and manipulated variable constraints.

Method for Solving Control Problems

PatentInactiveUS20120150324A1

Innovation

- The introduction of parallel quadratic programming (PQP) methods, which utilize a multiplicative fixpoint approach based on Karush-Kuhn-Tucker conditions, allowing for provable convergence and full parallelism on multiprocessor machines, including GPUs, and offering speed advantages even on serial computers.

ROI Analysis of MPC Implementation

Implementing Model Predictive Control (MPC) in smart manufacturing environments requires substantial initial investment, yet offers significant returns when properly deployed. Financial analysis indicates that MPC implementations typically achieve ROI within 6-24 months, depending on the scale and complexity of manufacturing operations. This accelerated payback period stems from multiple value streams that MPC technology unlocks across production processes.

Primary financial benefits derive from production optimization capabilities, with documented efficiency improvements ranging from 2-5% in general manufacturing to 10-15% in process-intensive industries. These efficiency gains translate directly to reduced operational costs through decreased energy consumption (typically 5-15% reduction), optimized raw material utilization (3-8% improvement), and extended equipment lifespan due to smoother operation profiles.

Quality improvements represent another substantial ROI driver, as MPC's predictive capabilities reduce process variability by 30-50% in most implementations. This reduction in variability correlates with 15-25% fewer quality defects, minimizing costly rework and scrap while enhancing product consistency. The financial impact becomes particularly significant in high-value manufacturing sectors where each defective unit represents substantial lost revenue.

Maintenance economics also factor prominently in ROI calculations. Predictive maintenance capabilities enabled by MPC reduce unplanned downtime by 30-45% in typical implementations. This translates to approximately 10-20% lower maintenance costs while simultaneously increasing overall equipment effectiveness (OEE) by 3-7 percentage points. The compound effect of these improvements accelerates ROI realization.

Labor utilization improvements further enhance financial returns, as MPC systems reduce operator intervention requirements by 15-30%. This allows redeployment of skilled personnel to higher-value activities while decreasing overtime costs associated with process disruptions. In facilities operating multiple shifts, these labor efficiencies compound significantly.

Risk mitigation benefits, though more challenging to quantify, contribute substantially to ROI calculations. MPC implementations demonstrate 40-60% reductions in process-related safety incidents and regulatory compliance violations. The avoided costs of these incidents—including potential regulatory penalties, legal liabilities, and production interruptions—represent significant value that should be incorporated into comprehensive ROI analyses.

Primary financial benefits derive from production optimization capabilities, with documented efficiency improvements ranging from 2-5% in general manufacturing to 10-15% in process-intensive industries. These efficiency gains translate directly to reduced operational costs through decreased energy consumption (typically 5-15% reduction), optimized raw material utilization (3-8% improvement), and extended equipment lifespan due to smoother operation profiles.

Quality improvements represent another substantial ROI driver, as MPC's predictive capabilities reduce process variability by 30-50% in most implementations. This reduction in variability correlates with 15-25% fewer quality defects, minimizing costly rework and scrap while enhancing product consistency. The financial impact becomes particularly significant in high-value manufacturing sectors where each defective unit represents substantial lost revenue.

Maintenance economics also factor prominently in ROI calculations. Predictive maintenance capabilities enabled by MPC reduce unplanned downtime by 30-45% in typical implementations. This translates to approximately 10-20% lower maintenance costs while simultaneously increasing overall equipment effectiveness (OEE) by 3-7 percentage points. The compound effect of these improvements accelerates ROI realization.

Labor utilization improvements further enhance financial returns, as MPC systems reduce operator intervention requirements by 15-30%. This allows redeployment of skilled personnel to higher-value activities while decreasing overtime costs associated with process disruptions. In facilities operating multiple shifts, these labor efficiencies compound significantly.

Risk mitigation benefits, though more challenging to quantify, contribute substantially to ROI calculations. MPC implementations demonstrate 40-60% reductions in process-related safety incidents and regulatory compliance violations. The avoided costs of these incidents—including potential regulatory penalties, legal liabilities, and production interruptions—represent significant value that should be incorporated into comprehensive ROI analyses.

Cybersecurity Considerations for MPC Systems

As Model Predictive Control (MPC) systems become increasingly integrated into smart manufacturing environments, cybersecurity considerations have emerged as critical factors for successful implementation. Manufacturing facilities deploying MPC solutions face unique security challenges due to the convergence of operational technology (OT) and information technology (IT) systems. The sensitive nature of production data, proprietary algorithms, and potential impact on physical processes make MPC systems attractive targets for cyber threats.

The attack surface of MPC implementations spans multiple layers, including sensors, controllers, communication networks, and computational infrastructure. Threat actors may attempt to compromise system integrity through data manipulation, potentially altering sensor readings or control parameters that could lead to suboptimal production outcomes or safety incidents. More sophisticated attacks might target the mathematical models underpinning MPC systems, introducing subtle modifications that remain difficult to detect while degrading performance over time.

Communication vulnerabilities present particular concerns in distributed MPC architectures where controllers exchange information across factory networks. Without proper encryption and authentication mechanisms, these data flows become vulnerable to man-in-the-middle attacks or unauthorized interception. The real-time requirements of manufacturing processes further complicate security implementations, as traditional IT security measures may introduce unacceptable latency.

Risk assessment frameworks specifically tailored for MPC deployments must consider both the likelihood of various attack vectors and their potential impact on production operations. Critical considerations include the resilience of control algorithms to corrupted inputs, fallback mechanisms during security incidents, and strategies for secure model updates that protect intellectual property while enabling continuous improvement.

Defense-in-depth approaches have proven effective for MPC security, implementing multiple protective layers including network segmentation, encrypted communications, anomaly detection systems, and secure access controls. Advanced implementations incorporate security-aware MPC formulations that can detect and mitigate certain classes of attacks through mathematical constraints or robust optimization techniques.

Regulatory compliance adds another dimension to MPC cybersecurity, with frameworks such as IEC 62443 for industrial automation and control systems providing guidance for secure implementations. Organizations must balance security requirements with operational needs, developing comprehensive policies that address both technical controls and human factors through regular security training and incident response planning.

Human-machine interfaces for MPC systems require particular attention, as they often serve as both critical control points and potential security vulnerabilities. Implementing principle of least privilege access controls and comprehensive audit logging helps mitigate insider threats while maintaining operational flexibility.

The attack surface of MPC implementations spans multiple layers, including sensors, controllers, communication networks, and computational infrastructure. Threat actors may attempt to compromise system integrity through data manipulation, potentially altering sensor readings or control parameters that could lead to suboptimal production outcomes or safety incidents. More sophisticated attacks might target the mathematical models underpinning MPC systems, introducing subtle modifications that remain difficult to detect while degrading performance over time.

Communication vulnerabilities present particular concerns in distributed MPC architectures where controllers exchange information across factory networks. Without proper encryption and authentication mechanisms, these data flows become vulnerable to man-in-the-middle attacks or unauthorized interception. The real-time requirements of manufacturing processes further complicate security implementations, as traditional IT security measures may introduce unacceptable latency.

Risk assessment frameworks specifically tailored for MPC deployments must consider both the likelihood of various attack vectors and their potential impact on production operations. Critical considerations include the resilience of control algorithms to corrupted inputs, fallback mechanisms during security incidents, and strategies for secure model updates that protect intellectual property while enabling continuous improvement.

Defense-in-depth approaches have proven effective for MPC security, implementing multiple protective layers including network segmentation, encrypted communications, anomaly detection systems, and secure access controls. Advanced implementations incorporate security-aware MPC formulations that can detect and mitigate certain classes of attacks through mathematical constraints or robust optimization techniques.

Regulatory compliance adds another dimension to MPC cybersecurity, with frameworks such as IEC 62443 for industrial automation and control systems providing guidance for secure implementations. Organizations must balance security requirements with operational needs, developing comprehensive policies that address both technical controls and human factors through regular security training and incident response planning.

Human-machine interfaces for MPC systems require particular attention, as they often serve as both critical control points and potential security vulnerabilities. Implementing principle of least privilege access controls and comprehensive audit logging helps mitigate insider threats while maintaining operational flexibility.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!