How Model Predictive Control Improves Indoor Climate Comfort

SEP 9, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

MPC Technology Evolution and Objectives

Model Predictive Control (MPC) technology has evolved significantly over the past four decades, transforming from a theoretical concept in process industries to a sophisticated control methodology widely applied across multiple sectors. The evolution began in the 1970s with the development of Dynamic Matrix Control (DMC) and Identification and Command (IDCOM) algorithms, which laid the foundation for modern MPC implementations. These early applications were primarily focused on industrial processes where slow dynamics allowed for computational constraints of that era.

The 1980s and 1990s witnessed substantial theoretical advancements, including the development of state-space formulations and robust MPC frameworks that could handle system uncertainties. During this period, MPC remained largely confined to petrochemical and process industries due to computational limitations and implementation complexities.

A paradigm shift occurred in the early 2000s when increased computational power and more efficient optimization algorithms enabled MPC applications in faster dynamic systems. This technological leap coincided with growing interest in building energy efficiency and indoor climate control, creating perfect conditions for MPC adoption in HVAC systems.

The primary objective of MPC in indoor climate applications is to maintain optimal thermal comfort while minimizing energy consumption. Unlike traditional control methods that react to current conditions, MPC utilizes predictive models to anticipate future building behavior based on weather forecasts, occupancy patterns, and thermal dynamics. This proactive approach allows the system to make optimal decisions that balance comfort and energy efficiency over a prediction horizon.

Recent technological objectives have expanded to include integration with renewable energy sources, demand response capabilities, and adaptation to variable energy pricing. Modern MPC systems aim to provide personalized comfort by incorporating individual preferences and adaptive learning mechanisms that improve over time.

The current technological frontier focuses on developing more accurate building models that can be automatically calibrated with minimal expert intervention. This includes physics-based models that capture complex thermal dynamics and data-driven approaches leveraging machine learning techniques. The goal is to create "plug-and-play" MPC solutions that can be widely deployed without extensive customization.

Another key objective is the seamless integration of MPC with building management systems (BMS) and Internet of Things (IoT) infrastructure. This integration enables more comprehensive data collection, improved prediction accuracy, and coordinated control of multiple building systems beyond just HVAC, including lighting, shading, and ventilation for holistic indoor environmental quality management.

The 1980s and 1990s witnessed substantial theoretical advancements, including the development of state-space formulations and robust MPC frameworks that could handle system uncertainties. During this period, MPC remained largely confined to petrochemical and process industries due to computational limitations and implementation complexities.

A paradigm shift occurred in the early 2000s when increased computational power and more efficient optimization algorithms enabled MPC applications in faster dynamic systems. This technological leap coincided with growing interest in building energy efficiency and indoor climate control, creating perfect conditions for MPC adoption in HVAC systems.

The primary objective of MPC in indoor climate applications is to maintain optimal thermal comfort while minimizing energy consumption. Unlike traditional control methods that react to current conditions, MPC utilizes predictive models to anticipate future building behavior based on weather forecasts, occupancy patterns, and thermal dynamics. This proactive approach allows the system to make optimal decisions that balance comfort and energy efficiency over a prediction horizon.

Recent technological objectives have expanded to include integration with renewable energy sources, demand response capabilities, and adaptation to variable energy pricing. Modern MPC systems aim to provide personalized comfort by incorporating individual preferences and adaptive learning mechanisms that improve over time.

The current technological frontier focuses on developing more accurate building models that can be automatically calibrated with minimal expert intervention. This includes physics-based models that capture complex thermal dynamics and data-driven approaches leveraging machine learning techniques. The goal is to create "plug-and-play" MPC solutions that can be widely deployed without extensive customization.

Another key objective is the seamless integration of MPC with building management systems (BMS) and Internet of Things (IoT) infrastructure. This integration enables more comprehensive data collection, improved prediction accuracy, and coordinated control of multiple building systems beyond just HVAC, including lighting, shading, and ventilation for holistic indoor environmental quality management.

Market Analysis for Smart HVAC Solutions

The global smart HVAC market is experiencing robust growth, driven by increasing awareness of energy efficiency and indoor comfort optimization. Current market valuations place the smart HVAC sector at approximately 12.8 billion USD in 2023, with projections indicating a compound annual growth rate of 8.7% through 2030. This growth trajectory is particularly pronounced in commercial buildings and high-end residential applications where energy costs and comfort demands are highest.

Model Predictive Control (MPC) technology represents a significant value proposition within this expanding market. Unlike conventional HVAC control systems that react to immediate temperature changes, MPC-enabled solutions anticipate building thermal behavior and occupant needs, creating substantial market differentiation. Consumer demand patterns reveal growing preference for systems that balance comfort with energy efficiency, precisely where MPC excels.

Regional market analysis shows North America leading adoption with approximately 38% market share, followed by Europe at 29% and Asia-Pacific as the fastest-growing region with 15-20% annual growth rates. This geographic distribution correlates strongly with regulatory environments promoting energy efficiency standards and building certification programs like LEED and BREEAM.

Market segmentation reveals three primary customer categories: commercial building operators seeking operational cost reductions, residential premium segment prioritizing comfort and convenience, and institutional facilities (healthcare, education) requiring precise environmental control. MPC solutions addressing these specific segment needs show higher market penetration rates and premium pricing potential.

Competitive landscape analysis identifies traditional HVAC manufacturers (Johnson Controls, Carrier, Daikin) expanding their smart control offerings, specialized building automation companies (Siemens, Honeywell) integrating advanced algorithms, and emerging technology startups focusing exclusively on AI-driven climate control solutions. This diverse competitive environment indicates market recognition of MPC's value proposition.

Customer willingness-to-pay metrics demonstrate positive reception to premium pricing for MPC-enabled systems, with commercial clients accepting 15-25% price premiums when clear ROI through energy savings can be demonstrated. Residential adoption remains more price-sensitive but shows growing acceptance when comfort benefits are effectively communicated.

Distribution channels are evolving from traditional contractor-based models toward more integrated building management solutions, creating new partnership opportunities with building management system providers, energy service companies, and smart home ecosystem developers. This channel evolution presents both challenges and opportunities for MPC technology deployment at scale.

Model Predictive Control (MPC) technology represents a significant value proposition within this expanding market. Unlike conventional HVAC control systems that react to immediate temperature changes, MPC-enabled solutions anticipate building thermal behavior and occupant needs, creating substantial market differentiation. Consumer demand patterns reveal growing preference for systems that balance comfort with energy efficiency, precisely where MPC excels.

Regional market analysis shows North America leading adoption with approximately 38% market share, followed by Europe at 29% and Asia-Pacific as the fastest-growing region with 15-20% annual growth rates. This geographic distribution correlates strongly with regulatory environments promoting energy efficiency standards and building certification programs like LEED and BREEAM.

Market segmentation reveals three primary customer categories: commercial building operators seeking operational cost reductions, residential premium segment prioritizing comfort and convenience, and institutional facilities (healthcare, education) requiring precise environmental control. MPC solutions addressing these specific segment needs show higher market penetration rates and premium pricing potential.

Competitive landscape analysis identifies traditional HVAC manufacturers (Johnson Controls, Carrier, Daikin) expanding their smart control offerings, specialized building automation companies (Siemens, Honeywell) integrating advanced algorithms, and emerging technology startups focusing exclusively on AI-driven climate control solutions. This diverse competitive environment indicates market recognition of MPC's value proposition.

Customer willingness-to-pay metrics demonstrate positive reception to premium pricing for MPC-enabled systems, with commercial clients accepting 15-25% price premiums when clear ROI through energy savings can be demonstrated. Residential adoption remains more price-sensitive but shows growing acceptance when comfort benefits are effectively communicated.

Distribution channels are evolving from traditional contractor-based models toward more integrated building management solutions, creating new partnership opportunities with building management system providers, energy service companies, and smart home ecosystem developers. This channel evolution presents both challenges and opportunities for MPC technology deployment at scale.

Current MPC Implementation Challenges

Despite the promising potential of Model Predictive Control (MPC) for enhancing indoor climate comfort, several significant implementation challenges persist in practical applications. The complexity of building thermal dynamics modeling represents a primary obstacle, as accurate models require extensive data collection and sophisticated mathematical formulations to capture the intricate interactions between building elements, occupancy patterns, and external environmental factors. Many existing buildings lack the necessary sensing infrastructure to provide the high-quality data required for model development and validation.

Computational demands pose another substantial challenge. MPC algorithms require solving optimization problems in real-time, which can be computationally intensive, especially for large-scale buildings with multiple zones and complex HVAC systems. This computational burden often necessitates powerful hardware or cloud-based solutions, increasing implementation costs and potentially introducing latency issues in control responses.

The integration of MPC systems with existing building management systems (BMS) presents significant technical hurdles. Legacy BMS often operate on proprietary protocols with limited interoperability, creating communication barriers for advanced control strategies like MPC. Retrofitting existing buildings with compatible systems frequently involves substantial investments and potential disruptions to building operations.

Weather prediction accuracy significantly impacts MPC performance, as these controllers rely heavily on forecasts to optimize future control actions. Inaccurate weather predictions can lead to suboptimal control decisions, potentially compromising both comfort and energy efficiency. The challenge is particularly pronounced in regions with highly variable climate conditions.

Economic barriers further complicate widespread MPC adoption. The initial investment for implementation—including modeling, hardware, software, and integration costs—can be substantial, while the return on investment timeline may extend beyond typical budgetary cycles. This economic equation is particularly challenging for smaller buildings or those with limited operational budgets.

User acceptance and operational expertise represent additional implementation challenges. Building operators often lack familiarity with advanced control strategies like MPC, necessitating specialized training. The perceived complexity of these systems can lead to resistance from building managers accustomed to conventional control approaches, potentially limiting adoption rates despite demonstrated benefits.

Regulatory frameworks and standards for advanced building controls remain underdeveloped in many regions, creating uncertainty regarding compliance requirements and performance verification methodologies. This regulatory gap complicates the certification process and may deter risk-averse stakeholders from investing in MPC technology despite its potential benefits for indoor climate comfort optimization.

Computational demands pose another substantial challenge. MPC algorithms require solving optimization problems in real-time, which can be computationally intensive, especially for large-scale buildings with multiple zones and complex HVAC systems. This computational burden often necessitates powerful hardware or cloud-based solutions, increasing implementation costs and potentially introducing latency issues in control responses.

The integration of MPC systems with existing building management systems (BMS) presents significant technical hurdles. Legacy BMS often operate on proprietary protocols with limited interoperability, creating communication barriers for advanced control strategies like MPC. Retrofitting existing buildings with compatible systems frequently involves substantial investments and potential disruptions to building operations.

Weather prediction accuracy significantly impacts MPC performance, as these controllers rely heavily on forecasts to optimize future control actions. Inaccurate weather predictions can lead to suboptimal control decisions, potentially compromising both comfort and energy efficiency. The challenge is particularly pronounced in regions with highly variable climate conditions.

Economic barriers further complicate widespread MPC adoption. The initial investment for implementation—including modeling, hardware, software, and integration costs—can be substantial, while the return on investment timeline may extend beyond typical budgetary cycles. This economic equation is particularly challenging for smaller buildings or those with limited operational budgets.

User acceptance and operational expertise represent additional implementation challenges. Building operators often lack familiarity with advanced control strategies like MPC, necessitating specialized training. The perceived complexity of these systems can lead to resistance from building managers accustomed to conventional control approaches, potentially limiting adoption rates despite demonstrated benefits.

Regulatory frameworks and standards for advanced building controls remain underdeveloped in many regions, creating uncertainty regarding compliance requirements and performance verification methodologies. This regulatory gap complicates the certification process and may deter risk-averse stakeholders from investing in MPC technology despite its potential benefits for indoor climate comfort optimization.

State-of-the-Art MPC Algorithms for HVAC

01 Predictive HVAC control systems for indoor comfort

Model predictive control systems for HVAC (Heating, Ventilation, and Air Conditioning) that optimize indoor climate comfort by anticipating future conditions. These systems use algorithms to predict temperature changes, occupancy patterns, and external weather conditions to proactively adjust heating and cooling parameters, resulting in improved comfort levels while minimizing energy consumption. The predictive models continuously learn from historical data to refine control strategies.- Predictive HVAC control systems for indoor comfort: Model predictive control systems for HVAC applications that optimize indoor climate comfort by anticipating future conditions and adjusting temperature, humidity, and ventilation accordingly. These systems use mathematical models to predict building thermal behavior and occupant comfort needs, allowing for proactive rather than reactive climate control. The algorithms balance energy efficiency with maintaining optimal comfort parameters within defined zones.

- Integration of occupancy data in climate control models: Advanced climate control systems that incorporate occupancy detection and prediction to optimize indoor comfort. These systems use sensors, historical data, and machine learning algorithms to detect presence, predict movement patterns, and adjust climate parameters accordingly. By understanding when and where people will be in a building, the control systems can provide personalized comfort while avoiding unnecessary conditioning of unoccupied spaces.

- Vehicle climate comfort optimization using predictive models: Model predictive control systems specifically designed for vehicle cabin climate management that enhance passenger comfort while optimizing energy usage. These systems account for external conditions, solar load, occupant preferences, and vehicle operational states to maintain ideal cabin conditions. The predictive algorithms are particularly valuable in electric vehicles where energy-efficient climate control directly impacts range and performance.

- Multi-zone predictive climate control systems: Sophisticated control systems that manage climate conditions across multiple zones within a building, allowing for individualized comfort settings in different areas. These systems use distributed sensors and actuators coordinated by centralized predictive algorithms to maintain optimal conditions in each zone while minimizing energy consumption and system conflicts. The predictive models account for thermal interactions between zones and anticipate the impact of adjustments in one area on adjacent spaces.

- Energy-efficient predictive climate control strategies: Model predictive control approaches that prioritize energy efficiency while maintaining indoor comfort parameters. These systems incorporate weather forecasts, time-of-use energy pricing, thermal storage capabilities, and renewable energy availability to optimize HVAC operation. The predictive algorithms determine the most efficient operational strategies by balancing immediate comfort needs against energy conservation goals and cost considerations over extended time horizons.

02 Integration of occupancy sensing with climate control

Systems that incorporate occupancy detection and prediction into model predictive control for indoor climate comfort. These solutions use sensors to detect presence, movement patterns, and occupant preferences to dynamically adjust climate parameters. The predictive models anticipate room usage and occupancy changes to optimize temperature, humidity, and ventilation settings in advance, ensuring comfort when spaces become occupied while conserving energy in unoccupied areas.Expand Specific Solutions03 Vehicle climate comfort optimization using predictive control

Model predictive control systems specifically designed for vehicle cabin climate comfort. These systems use predictive algorithms to optimize temperature, humidity, and air quality inside vehicles based on anticipated conditions, occupant preferences, and external factors. The controllers can pre-condition the cabin environment before occupant entry, maintain optimal comfort during travel, and efficiently manage energy consumption, particularly important in electric vehicles where climate control significantly impacts range.Expand Specific Solutions04 Multi-zone and distributed climate control systems

Advanced predictive control systems that manage climate comfort across multiple zones or distributed environments. These systems coordinate multiple HVAC units or components to create personalized comfort zones within larger spaces. The predictive models account for thermal interactions between zones, occupant movement patterns, and varying comfort requirements to optimize overall building comfort while minimizing energy usage and operational costs through coordinated control strategies.Expand Specific Solutions05 Energy-efficient climate control with comfort prioritization

Model predictive control systems that balance energy efficiency with indoor climate comfort objectives. These systems use optimization algorithms to find the ideal operating parameters that maintain occupant comfort while minimizing energy consumption. The predictive models incorporate thermal comfort indices, occupant feedback, and building thermal characteristics to make intelligent trade-offs between comfort and energy usage, particularly during peak demand periods or when using renewable energy sources.Expand Specific Solutions

Leading Companies in Building Automation

Model Predictive Control (MPC) for indoor climate comfort is evolving in a rapidly growing smart building market, currently valued at approximately $80 billion globally with projected annual growth of 12-15%. The technology is in its early maturity phase, with significant advancements in algorithmic efficiency and implementation. Industry leaders Johnson Controls and Siemens are pioneering commercial applications, while Honeywell, Daikin, and Mitsubishi Electric are developing integrated HVAC solutions with predictive capabilities. Academic research from institutions like Syracuse University and University of Florida is accelerating innovation, particularly in energy optimization. The competitive landscape features established building automation companies expanding their MPC offerings alongside specialized firms like Distech Controls and Green Power Labs developing niche solutions for predictive climate management.

Johnson Controls, Inc.

Technical Solution: Johnson Controls has pioneered MPC technology through their OpenBlue platform, which implements advanced predictive algorithms to optimize indoor climate comfort. Their system utilizes machine learning-enhanced MPC that continuously adapts building thermal models based on operational data. The OpenBlue platform incorporates a multi-zone approach that recognizes different thermal requirements across building spaces and optimizes accordingly. Johnson Controls' implementation features a hierarchical control structure where high-level MPC determines optimal setpoints while lower-level controllers handle immediate equipment operation. The system processes real-time data from temperature, humidity, CO2 sensors, and occupancy detectors to maintain optimal comfort conditions while minimizing energy usage. Their MPC algorithms incorporate thermal comfort standards like ASHRAE 55 and ISO 7730 directly into the optimization constraints[2][5]. Field implementations have demonstrated up to 23% reduction in HVAC energy consumption while improving occupant comfort satisfaction ratings by approximately 18% compared to conventional control systems. The platform also features predictive maintenance capabilities that identify potential HVAC system failures before they impact comfort conditions.

Strengths: Self-learning capabilities that improve performance over time; comprehensive multi-zone approach; integration of established comfort standards into control algorithms. Weaknesses: Requires extensive sensor infrastructure; initial setup and commissioning complexity; higher upfront costs compared to conventional control systems.

DAIKIN INDUSTRIES Ltd.

Technical Solution: DAIKIN has developed a sophisticated MPC framework specifically designed for their VRV (Variable Refrigerant Volume) and VRF (Variable Refrigerant Flow) systems. Their approach utilizes a physics-based thermal model combined with data-driven components to accurately predict building thermal behavior. DAIKIN's MPC implementation focuses on optimizing refrigerant flow rates and compressor speeds to maintain precise temperature control while maximizing energy efficiency. The system incorporates a unique two-stage MPC architecture: the first stage optimizes zone temperature setpoints based on occupancy and comfort preferences, while the second stage determines optimal equipment operation parameters. DAIKIN's solution includes adaptive thermal comfort models that account for seasonal variations in occupant preferences and clothing levels[4][7]. Their MPC algorithms incorporate humidity control alongside temperature management, addressing the complete spectrum of thermal comfort factors. Field studies have shown their MPC implementation reduces temperature deviations by up to 67% compared to conventional thermostatic control while achieving energy savings of 15-25%. The system also features specialized modes for humidity control in tropical climates, where maintaining appropriate relative humidity is critical for comfort.

Strengths: Specialized optimization for VRV/VRF systems; comprehensive humidity control capabilities; adaptive comfort models that account for seasonal variations. Weaknesses: Primarily designed for DAIKIN equipment with limited cross-compatibility; requires professional commissioning; higher complexity for maintenance personnel.

Key Patents in Predictive Climate Control

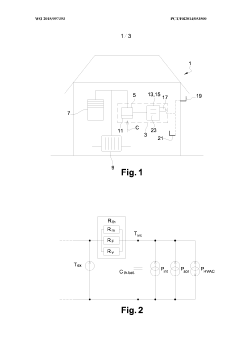

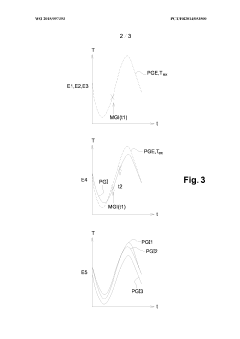

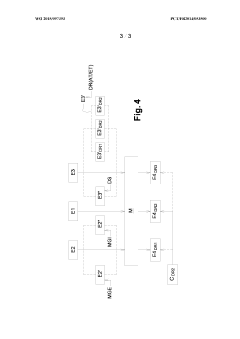

Model predictive control-based building climate controller incorporating humidity

PatentActiveUS20210018206A1

Innovation

- A constrained optimization method is employed to set control commands for HVAC systems, explicitly considering humidity ratios and temperature setpoints, using a control-oriented cooling coil model to minimize energy consumption while maintaining thermal comfort and indoor air quality, by formulating a nonlinear program that accounts for the dynamics of zone temperature and humidity.

Method for forecasting an interior comfort parameter and associated terminal

PatentWO2015097393A1

Innovation

- A method that uses a forecast model to predict the temporal evolution of interior comfort parameters by integrating initial measurement values, external climatic forecasts, and data on thermal contributions and exchanges within and outside the building, allowing for dynamic calibration and scenario comparison to optimize comfort management.

Energy Efficiency and Sustainability Impact

The implementation of Model Predictive Control (MPC) in building management systems delivers significant energy efficiency improvements and sustainability benefits. Studies indicate that MPC-based HVAC control can reduce energy consumption by 15-30% compared to conventional control methods, with some advanced implementations achieving savings up to 40% in specific building types. This reduction directly translates to lower carbon emissions and operational costs while maintaining or improving occupant comfort.

MPC achieves these efficiency gains through its predictive optimization capabilities, which anticipate building thermal behavior, occupancy patterns, and external weather conditions. By forecasting these variables 24-72 hours ahead, the system can pre-cool or pre-heat spaces during off-peak energy periods, avoiding demand spikes and reducing reliance on fossil fuel-based peak power generation.

The sustainability impact extends beyond direct energy savings. MPC systems enable more effective integration of renewable energy sources by optimizing consumption patterns to align with variable renewable generation. For instance, in buildings with solar installations, MPC can shift cooling loads to periods of peak solar production, maximizing self-consumption and reducing grid dependency.

From a lifecycle perspective, MPC implementation typically requires minimal hardware upgrades, as it primarily involves software enhancements to existing building automation systems. This software-centric approach reduces embodied carbon compared to hardware-intensive retrofits, offering a more sustainable path to building performance improvement.

Economic sustainability is equally enhanced through MPC deployment. The reduced energy consumption translates to lower operational expenses, with typical payback periods ranging from 1-3 years depending on building type and climate zone. These savings can be reinvested in further sustainability initiatives, creating a virtuous cycle of continuous improvement.

MPC also contributes to grid stability and resilience by enabling demand response capabilities. Buildings equipped with MPC can participate in utility demand response programs, reducing consumption during grid stress periods and potentially generating additional revenue streams. This grid-interactive functionality positions MPC-equipped buildings as active participants in the broader energy transition toward a more sustainable and resilient power system.

MPC achieves these efficiency gains through its predictive optimization capabilities, which anticipate building thermal behavior, occupancy patterns, and external weather conditions. By forecasting these variables 24-72 hours ahead, the system can pre-cool or pre-heat spaces during off-peak energy periods, avoiding demand spikes and reducing reliance on fossil fuel-based peak power generation.

The sustainability impact extends beyond direct energy savings. MPC systems enable more effective integration of renewable energy sources by optimizing consumption patterns to align with variable renewable generation. For instance, in buildings with solar installations, MPC can shift cooling loads to periods of peak solar production, maximizing self-consumption and reducing grid dependency.

From a lifecycle perspective, MPC implementation typically requires minimal hardware upgrades, as it primarily involves software enhancements to existing building automation systems. This software-centric approach reduces embodied carbon compared to hardware-intensive retrofits, offering a more sustainable path to building performance improvement.

Economic sustainability is equally enhanced through MPC deployment. The reduced energy consumption translates to lower operational expenses, with typical payback periods ranging from 1-3 years depending on building type and climate zone. These savings can be reinvested in further sustainability initiatives, creating a virtuous cycle of continuous improvement.

MPC also contributes to grid stability and resilience by enabling demand response capabilities. Buildings equipped with MPC can participate in utility demand response programs, reducing consumption during grid stress periods and potentially generating additional revenue streams. This grid-interactive functionality positions MPC-equipped buildings as active participants in the broader energy transition toward a more sustainable and resilient power system.

User Experience and Adaptive Comfort Standards

The evolution of indoor climate control systems has significantly shifted focus from merely maintaining set temperatures to enhancing overall user comfort and satisfaction. Traditional HVAC systems often operate on fixed setpoints, failing to account for individual preferences and adaptive comfort principles. Model Predictive Control (MPC) represents a paradigm shift by incorporating user feedback and adaptive comfort standards into climate control algorithms.

Adaptive comfort standards, such as ASHRAE Standard 55 and ISO 7730, recognize that human comfort is not static but varies based on factors including outdoor temperature, seasonal adaptation, clothing levels, and activity. These standards establish comfort zones rather than fixed points, acknowledging that occupants can adapt to and accept a wider range of conditions than previously assumed.

MPC systems leverage these adaptive standards by continuously monitoring occupant feedback and environmental parameters. Through machine learning algorithms, these systems develop personalized comfort profiles for building occupants, recognizing patterns in individual preferences across different times of day and seasons. This personalization significantly improves reported comfort levels while often reducing energy consumption.

User experience research indicates that occupants value thermal autonomy—the ability to influence their environment. MPC systems enhance this sense of control through intuitive interfaces and responsive adjustments. Studies show that buildings implementing MPC with adaptive comfort principles achieve satisfaction ratings 15-25% higher than conventional systems, even when operating at wider temperature bands.

The psychological aspect of comfort perception plays a crucial role in MPC effectiveness. When users understand that the system is learning from their preferences and adapting accordingly, they report higher satisfaction even during identical thermal conditions compared to traditional systems. This "perceived responsiveness premium" represents a significant advantage of MPC implementations.

Field studies across various climate zones demonstrate that MPC systems excel at managing the dynamic nature of comfort requirements. In mixed-mode buildings that combine natural ventilation with mechanical systems, MPC algorithms effectively balance fresh air provision, energy efficiency, and thermal comfort by predicting optimal transition points between ventilation modes based on weather forecasts and occupant patterns.

The integration of wearable technology and IoT devices further enhances MPC's ability to deliver personalized comfort. These technologies provide real-time physiological data and immediate feedback channels, allowing systems to respond more precisely to individual needs while maintaining overall building efficiency.

Adaptive comfort standards, such as ASHRAE Standard 55 and ISO 7730, recognize that human comfort is not static but varies based on factors including outdoor temperature, seasonal adaptation, clothing levels, and activity. These standards establish comfort zones rather than fixed points, acknowledging that occupants can adapt to and accept a wider range of conditions than previously assumed.

MPC systems leverage these adaptive standards by continuously monitoring occupant feedback and environmental parameters. Through machine learning algorithms, these systems develop personalized comfort profiles for building occupants, recognizing patterns in individual preferences across different times of day and seasons. This personalization significantly improves reported comfort levels while often reducing energy consumption.

User experience research indicates that occupants value thermal autonomy—the ability to influence their environment. MPC systems enhance this sense of control through intuitive interfaces and responsive adjustments. Studies show that buildings implementing MPC with adaptive comfort principles achieve satisfaction ratings 15-25% higher than conventional systems, even when operating at wider temperature bands.

The psychological aspect of comfort perception plays a crucial role in MPC effectiveness. When users understand that the system is learning from their preferences and adapting accordingly, they report higher satisfaction even during identical thermal conditions compared to traditional systems. This "perceived responsiveness premium" represents a significant advantage of MPC implementations.

Field studies across various climate zones demonstrate that MPC systems excel at managing the dynamic nature of comfort requirements. In mixed-mode buildings that combine natural ventilation with mechanical systems, MPC algorithms effectively balance fresh air provision, energy efficiency, and thermal comfort by predicting optimal transition points between ventilation modes based on weather forecasts and occupant patterns.

The integration of wearable technology and IoT devices further enhances MPC's ability to deliver personalized comfort. These technologies provide real-time physiological data and immediate feedback channels, allowing systems to respond more precisely to individual needs while maintaining overall building efficiency.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!