How Model Predictive Control Enables Fault-Tolerant Systems

SEP 9, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

MPC Technology Evolution and Fault-Tolerance Objectives

Model Predictive Control (MPC) has evolved significantly since its inception in the 1970s, transforming from a theoretical concept to a practical control methodology widely implemented across various industries. The evolution of MPC technology can be traced through several distinct phases, each marked by significant advancements in computational capabilities and algorithmic sophistication.

Initially, MPC was primarily applied in petrochemical processes due to their slow dynamics, which accommodated the computational limitations of early implementations. The 1980s witnessed the development of Dynamic Matrix Control (DMC) and Quadratic Dynamic Matrix Control (QDMC), which laid the foundation for modern MPC applications. These early implementations were characterized by linear models and relatively simple constraint handling mechanisms.

The 1990s marked a significant leap forward with the introduction of state-space formulations and explicit handling of constraints, enabling MPC to address more complex control scenarios. This period also saw the emergence of nonlinear MPC variants, expanding the methodology's applicability to systems with inherent nonlinearities.

In recent years, MPC has undergone further refinement with the development of robust and stochastic MPC formulations, specifically designed to handle uncertainties and disturbances. These advancements have been crucial in positioning MPC as a viable approach for fault-tolerant control systems, where reliability under adverse conditions is paramount.

The integration of fault-tolerance objectives into MPC frameworks represents a natural evolution of the technology. Fault-tolerant systems aim to maintain acceptable performance levels even when components fail or operate abnormally. MPC's inherent predictive nature and constraint-handling capabilities make it particularly well-suited for this purpose.

The primary objectives of fault-tolerant MPC systems include maintaining system stability during fault conditions, minimizing performance degradation when faults occur, and ensuring safe operation throughout the control process. These objectives are achieved through various mechanisms, including fault detection and isolation (FDI), reconfigurable control strategies, and adaptive model updating.

Modern fault-tolerant MPC implementations often incorporate real-time fault diagnosis capabilities, allowing the controller to detect anomalies and adjust its control strategy accordingly. This may involve switching between different control models or reconfiguring the control architecture to bypass faulty components.

The evolution of MPC in fault-tolerant applications has been driven by increasing demands for system reliability in critical applications such as aerospace, automotive, and industrial process control. As computational resources continue to expand and algorithmic innovations emerge, MPC is expected to play an increasingly central role in the development of resilient control systems capable of maintaining performance even under adverse conditions.

Initially, MPC was primarily applied in petrochemical processes due to their slow dynamics, which accommodated the computational limitations of early implementations. The 1980s witnessed the development of Dynamic Matrix Control (DMC) and Quadratic Dynamic Matrix Control (QDMC), which laid the foundation for modern MPC applications. These early implementations were characterized by linear models and relatively simple constraint handling mechanisms.

The 1990s marked a significant leap forward with the introduction of state-space formulations and explicit handling of constraints, enabling MPC to address more complex control scenarios. This period also saw the emergence of nonlinear MPC variants, expanding the methodology's applicability to systems with inherent nonlinearities.

In recent years, MPC has undergone further refinement with the development of robust and stochastic MPC formulations, specifically designed to handle uncertainties and disturbances. These advancements have been crucial in positioning MPC as a viable approach for fault-tolerant control systems, where reliability under adverse conditions is paramount.

The integration of fault-tolerance objectives into MPC frameworks represents a natural evolution of the technology. Fault-tolerant systems aim to maintain acceptable performance levels even when components fail or operate abnormally. MPC's inherent predictive nature and constraint-handling capabilities make it particularly well-suited for this purpose.

The primary objectives of fault-tolerant MPC systems include maintaining system stability during fault conditions, minimizing performance degradation when faults occur, and ensuring safe operation throughout the control process. These objectives are achieved through various mechanisms, including fault detection and isolation (FDI), reconfigurable control strategies, and adaptive model updating.

Modern fault-tolerant MPC implementations often incorporate real-time fault diagnosis capabilities, allowing the controller to detect anomalies and adjust its control strategy accordingly. This may involve switching between different control models or reconfiguring the control architecture to bypass faulty components.

The evolution of MPC in fault-tolerant applications has been driven by increasing demands for system reliability in critical applications such as aerospace, automotive, and industrial process control. As computational resources continue to expand and algorithmic innovations emerge, MPC is expected to play an increasingly central role in the development of resilient control systems capable of maintaining performance even under adverse conditions.

Market Demand for Resilient Control Systems

The market for resilient control systems has experienced significant growth in recent years, driven by increasing complexity in industrial processes and heightened awareness of system reliability requirements. Industries such as manufacturing, energy, transportation, and healthcare are increasingly demanding fault-tolerant control solutions that can maintain operational continuity despite component failures or unexpected disturbances.

Research indicates that the global market for advanced control systems with fault-tolerance capabilities is projected to grow at a compound annual growth rate of 8.2% through 2028. This growth is particularly pronounced in critical infrastructure sectors where system failures can result in substantial economic losses, safety hazards, or environmental damage.

The automotive industry represents one of the largest market segments for resilient control systems, particularly with the rise of autonomous vehicles where system reliability is paramount. Model Predictive Control (MPC) solutions that can adapt to sensor failures or actuator malfunctions while maintaining vehicle stability are becoming essential components in advanced driver assistance systems and autonomous driving platforms.

In the energy sector, power generation and distribution systems require increasingly sophisticated fault-tolerant control mechanisms to maintain grid stability despite fluctuating renewable energy inputs and potential component failures. MPC-based solutions that can predict and compensate for these variations while maintaining system performance are seeing strong demand growth.

Process industries, including chemical manufacturing, oil refining, and pharmaceutical production, constitute another significant market segment. These industries operate complex, interconnected systems where failures can cascade rapidly, making predictive and fault-tolerant control systems essential for operational safety and efficiency.

The aerospace sector demonstrates perhaps the most stringent requirements for fault-tolerant control systems. Aircraft flight control systems incorporating MPC algorithms capable of reconfiguring control strategies in real-time following component failures represent a high-value market segment with stringent certification requirements.

Healthcare applications, particularly in medical devices and automated drug delivery systems, are emerging as a growth area for resilient control technologies. Patient safety considerations drive demand for systems that can detect and compensate for malfunctions while maintaining therapeutic effectiveness.

Market analysis reveals that end-users are increasingly willing to invest in more sophisticated control solutions when presented with clear evidence of improved system reliability and reduced downtime costs. The return on investment for implementing MPC-based fault-tolerant systems is typically realized through reduced maintenance costs, extended equipment life, and avoidance of costly unplanned shutdowns.

Research indicates that the global market for advanced control systems with fault-tolerance capabilities is projected to grow at a compound annual growth rate of 8.2% through 2028. This growth is particularly pronounced in critical infrastructure sectors where system failures can result in substantial economic losses, safety hazards, or environmental damage.

The automotive industry represents one of the largest market segments for resilient control systems, particularly with the rise of autonomous vehicles where system reliability is paramount. Model Predictive Control (MPC) solutions that can adapt to sensor failures or actuator malfunctions while maintaining vehicle stability are becoming essential components in advanced driver assistance systems and autonomous driving platforms.

In the energy sector, power generation and distribution systems require increasingly sophisticated fault-tolerant control mechanisms to maintain grid stability despite fluctuating renewable energy inputs and potential component failures. MPC-based solutions that can predict and compensate for these variations while maintaining system performance are seeing strong demand growth.

Process industries, including chemical manufacturing, oil refining, and pharmaceutical production, constitute another significant market segment. These industries operate complex, interconnected systems where failures can cascade rapidly, making predictive and fault-tolerant control systems essential for operational safety and efficiency.

The aerospace sector demonstrates perhaps the most stringent requirements for fault-tolerant control systems. Aircraft flight control systems incorporating MPC algorithms capable of reconfiguring control strategies in real-time following component failures represent a high-value market segment with stringent certification requirements.

Healthcare applications, particularly in medical devices and automated drug delivery systems, are emerging as a growth area for resilient control technologies. Patient safety considerations drive demand for systems that can detect and compensate for malfunctions while maintaining therapeutic effectiveness.

Market analysis reveals that end-users are increasingly willing to invest in more sophisticated control solutions when presented with clear evidence of improved system reliability and reduced downtime costs. The return on investment for implementing MPC-based fault-tolerant systems is typically realized through reduced maintenance costs, extended equipment life, and avoidance of costly unplanned shutdowns.

Current MPC Fault-Tolerance Capabilities and Limitations

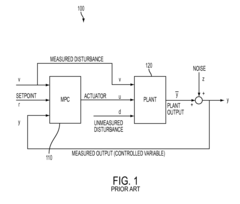

Model Predictive Control (MPC) has emerged as a powerful framework for fault-tolerant control systems, offering significant capabilities while still facing certain limitations. Current MPC implementations demonstrate remarkable robustness in handling system uncertainties and disturbances through their inherent feedback mechanism and receding horizon approach. This allows systems to continuously adapt to changing conditions and recover from minor faults without explicit fault detection mechanisms.

One of the primary strengths of MPC in fault tolerance lies in its constraint-handling capabilities. Modern MPC algorithms can explicitly incorporate both hard constraints (physical limitations) and soft constraints (performance objectives) into the control formulation. When faults occur, these constraints can be dynamically adjusted to maintain safe operation, effectively creating an adaptive operating envelope that prevents catastrophic failures.

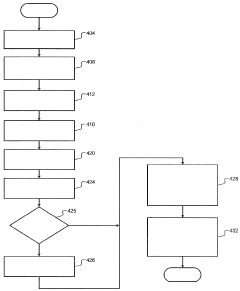

Active fault-tolerant MPC implementations typically integrate fault detection and isolation (FDI) modules that work in conjunction with the controller. These systems can identify faults in real-time and reconfigure the control strategy accordingly. The reconfiguration may involve adjusting the internal model, modifying constraints, or switching between different pre-designed control laws. This approach has shown particular success in aerospace, process control, and automotive applications.

Passive fault-tolerant MPC designs, conversely, aim to maintain acceptable performance without explicit fault detection. These controllers are designed with sufficient robustness margins to accommodate anticipated fault scenarios. Robust MPC formulations that account for bounded uncertainties and disturbances fall into this category, offering resilience against a predefined set of fault conditions without requiring real-time reconfiguration.

Despite these capabilities, current MPC fault-tolerant systems face several limitations. Computational complexity remains a significant challenge, particularly for systems requiring fast response times. The optimization problems solved at each time step can become computationally intensive, especially when incorporating fault scenarios and reconfiguration logic, potentially limiting application in resource-constrained environments.

Model uncertainty presents another substantial limitation. MPC performance is heavily dependent on the accuracy of the underlying system model. When faults occur that fundamentally alter system dynamics beyond what was anticipated in the model design, performance can degrade significantly. This is particularly problematic for complex systems where comprehensive fault modeling is impractical.

Additionally, most current implementations struggle with handling multiple simultaneous faults or cascading failure scenarios. The exponential growth in possible fault combinations makes comprehensive fault coverage computationally prohibitive, forcing designers to focus on the most probable or critical fault scenarios while potentially leaving the system vulnerable to unforeseen combinations of failures.

One of the primary strengths of MPC in fault tolerance lies in its constraint-handling capabilities. Modern MPC algorithms can explicitly incorporate both hard constraints (physical limitations) and soft constraints (performance objectives) into the control formulation. When faults occur, these constraints can be dynamically adjusted to maintain safe operation, effectively creating an adaptive operating envelope that prevents catastrophic failures.

Active fault-tolerant MPC implementations typically integrate fault detection and isolation (FDI) modules that work in conjunction with the controller. These systems can identify faults in real-time and reconfigure the control strategy accordingly. The reconfiguration may involve adjusting the internal model, modifying constraints, or switching between different pre-designed control laws. This approach has shown particular success in aerospace, process control, and automotive applications.

Passive fault-tolerant MPC designs, conversely, aim to maintain acceptable performance without explicit fault detection. These controllers are designed with sufficient robustness margins to accommodate anticipated fault scenarios. Robust MPC formulations that account for bounded uncertainties and disturbances fall into this category, offering resilience against a predefined set of fault conditions without requiring real-time reconfiguration.

Despite these capabilities, current MPC fault-tolerant systems face several limitations. Computational complexity remains a significant challenge, particularly for systems requiring fast response times. The optimization problems solved at each time step can become computationally intensive, especially when incorporating fault scenarios and reconfiguration logic, potentially limiting application in resource-constrained environments.

Model uncertainty presents another substantial limitation. MPC performance is heavily dependent on the accuracy of the underlying system model. When faults occur that fundamentally alter system dynamics beyond what was anticipated in the model design, performance can degrade significantly. This is particularly problematic for complex systems where comprehensive fault modeling is impractical.

Additionally, most current implementations struggle with handling multiple simultaneous faults or cascading failure scenarios. The exponential growth in possible fault combinations makes comprehensive fault coverage computationally prohibitive, forcing designers to focus on the most probable or critical fault scenarios while potentially leaving the system vulnerable to unforeseen combinations of failures.

Contemporary MPC Fault-Tolerance Implementation Strategies

01 Fault detection and diagnosis in MPC systems

Model Predictive Control systems can be enhanced with fault detection and diagnosis capabilities to identify abnormalities in system operation. These methods typically involve monitoring the difference between predicted and actual system behavior, using statistical analysis to detect deviations that indicate potential faults. Once detected, diagnostic algorithms classify the type and severity of the fault, enabling appropriate corrective actions to maintain system performance despite the presence of faults.- Fault-tolerant MPC for industrial process control: Model Predictive Control (MPC) systems can be designed with fault-tolerance capabilities for industrial processes. These systems incorporate fault detection and isolation mechanisms that identify abnormalities in sensors, actuators, or system components. When faults are detected, the control algorithm automatically reconfigures to maintain system stability and performance. This approach ensures continuous operation of critical industrial processes even when components fail, minimizing downtime and preventing potential safety hazards.

- Robust MPC algorithms for handling system uncertainties: Advanced robust MPC algorithms are designed to handle system uncertainties and disturbances that could lead to fault conditions. These algorithms incorporate uncertainty models and constraints to ensure control stability even when the system deviates from expected behavior. By considering worst-case scenarios during the optimization process, robust MPC can maintain performance despite model inaccuracies, parameter variations, or external disturbances, effectively providing a form of passive fault tolerance without requiring explicit fault detection.

- Distributed fault-tolerant MPC architectures: Distributed architectures for fault-tolerant MPC involve multiple controllers working together in a coordinated manner. If one controller fails, others can compensate to maintain system stability. These systems often employ redundancy and voting mechanisms to ensure reliable operation. The distributed approach allows for scalability in complex systems while providing resilience against both local and system-wide failures. Communication protocols between controllers are designed to be robust against network issues, ensuring consistent control performance.

- Self-healing and adaptive MPC systems: Self-healing MPC systems can automatically adapt their control strategies when faults occur. These systems use machine learning and adaptive algorithms to update their internal models based on real-time data, allowing them to compensate for degraded performance caused by faults. The control parameters are continuously optimized to maintain desired system behavior despite changing conditions. This approach is particularly valuable in complex systems where manual reconfiguration would be impractical or too slow to prevent system failure.

- Fault prediction and preventive control strategies: Predictive fault-tolerant MPC systems incorporate prognostic capabilities to anticipate potential failures before they occur. By analyzing patterns in system data, these controllers can identify degradation trends and take preemptive action to prevent faults from developing into failures. The control strategy may gradually adjust operation to reduce stress on vulnerable components or schedule maintenance interventions at optimal times. This proactive approach minimizes unexpected downtime and extends the operational life of system components while maintaining performance objectives.

02 Reconfigurable MPC for fault-tolerant control

Reconfigurable Model Predictive Control strategies adapt control parameters and objectives in real-time when faults occur. These systems dynamically modify their control structure, constraints, or prediction models to accommodate component failures or degradation. By reconfiguring the control strategy based on the current system state and fault conditions, these approaches maintain stability and performance even when parts of the system are compromised, ensuring continuous operation despite faults.Expand Specific Solutions03 Robust MPC design for handling uncertainties and disturbances

Robust Model Predictive Control designs incorporate uncertainty models and disturbance rejection capabilities to maintain system stability and performance under fault conditions. These approaches explicitly account for model uncertainties, external disturbances, and potential component failures in the control design. By considering worst-case scenarios and implementing appropriate safety margins in the control constraints, robust MPC provides fault-tolerance without requiring explicit fault detection mechanisms.Expand Specific Solutions04 Distributed and hierarchical fault-tolerant MPC architectures

Distributed and hierarchical Model Predictive Control architectures enhance fault tolerance by dividing control responsibilities among multiple controllers. These systems implement local control actions while coordinating through a hierarchical structure or peer-to-peer communication. If one controller fails, others can compensate or take over its responsibilities, preventing system-wide failure. This approach is particularly valuable in large-scale systems where component redundancy and graceful degradation are essential for maintaining critical functions during partial failures.Expand Specific Solutions05 Machine learning integration with MPC for adaptive fault tolerance

Integration of machine learning techniques with Model Predictive Control creates adaptive fault-tolerant systems that can learn from historical fault data and improve response to similar situations. These systems use neural networks, reinforcement learning, or other AI methods to predict potential faults before they occur, optimize control parameters in real-time, and adapt to changing system conditions. The learning capabilities enable the control system to continuously improve its fault tolerance strategies based on operational experience and evolving system dynamics.Expand Specific Solutions

Leading Organizations in Fault-Tolerant MPC Research

Model Predictive Control (MPC) for fault-tolerant systems is evolving rapidly in a growing market estimated to reach significant expansion by 2030. The technology is transitioning from early adoption to mainstream implementation across critical infrastructure and industrial applications. Leading players like Mitsubishi Electric, OMRON, ABB Group, and Honeywell demonstrate advanced maturity in commercial applications, while Toyota, Nissan, and Caterpillar are pioneering automotive and heavy machinery implementations. Academic institutions including Beihang University and National University of Defense Technology are driving theoretical advancements. Emerging players like PassiveLogic and oPRO.ai are introducing AI-enhanced MPC solutions, while established software providers such as AspenTech and NVIDIA are integrating MPC into comprehensive control platforms, creating a competitive landscape balanced between industrial incumbents and technology innovators.

Mitsubishi Electric Corp.

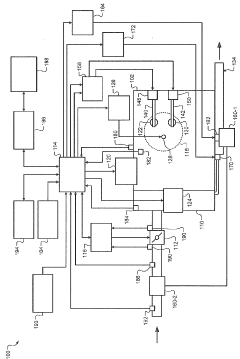

Technical Solution: Mitsubishi Electric has pioneered a fault-tolerant MPC framework specifically designed for critical infrastructure and manufacturing systems. Their approach combines traditional MPC with fault detection and isolation (FDI) techniques using a hierarchical control structure. At the core of their solution is a robust MPC algorithm that explicitly accounts for model uncertainties and disturbances, allowing the controller to maintain stability even when the system deviates from nominal conditions. Mitsubishi's implementation features adaptive constraint handling that automatically adjusts control limits based on detected system capabilities after fault occurrence. The system employs multiple redundant models running in parallel to cross-validate predictions and detect model-plant mismatches that might indicate faults. Their solution also incorporates a fault accommodation mechanism that reconfigures control objectives and constraints in real-time, enabling continued operation under degraded conditions rather than triggering emergency shutdowns.

Strengths: Exceptional reliability in mission-critical applications; sophisticated fault detection algorithms with very low false alarm rates; seamless degradation management that prioritizes essential functions. Weaknesses: Higher implementation complexity requiring specialized expertise; significant computational overhead that may necessitate dedicated control hardware for large-scale systems.

Toyota Motor Corp.

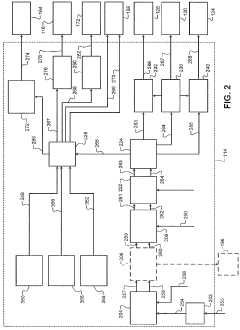

Technical Solution: Toyota has developed a sophisticated fault-tolerant MPC framework primarily focused on automotive applications but with broader industrial applications. Their approach centers on a distributed MPC architecture where multiple controllers coordinate through a hierarchical structure, providing inherent redundancy. Toyota's implementation features a robust MPC formulation that explicitly accounts for parametric uncertainties and external disturbances, maintaining stability even under significant model-plant mismatch. The system incorporates real-time fault detection algorithms that analyze residuals between predicted and measured outputs to identify anomalies. Upon fault detection, the control system automatically reconfigures by adjusting constraints, reweighting objectives, or activating backup control paths. Toyota's solution also includes a novel predictive maintenance component that uses the MPC's internal models to estimate component wear and degradation, scheduling maintenance before faults occur. Their implementation has been extensively validated in vehicle stability control systems, powertrain management, and autonomous driving technologies.

Strengths: Exceptional performance in safety-critical applications; highly optimized computational efficiency suitable for embedded systems; extensive real-world validation across millions of vehicles. Weaknesses: Highly specialized for automotive applications, requiring significant adaptation for other industries; proprietary implementation details that limit academic collaboration and knowledge sharing.

Key Innovations in Robust MPC Algorithms

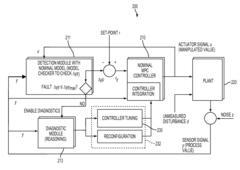

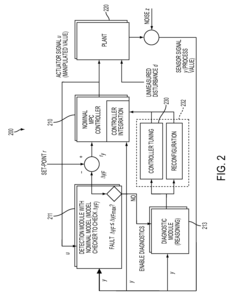

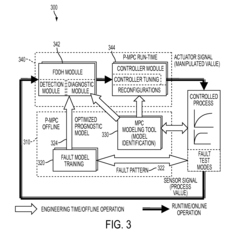

System and method for fault prognostics enhanced MPC framework

PatentInactiveUS9134713B2

Innovation

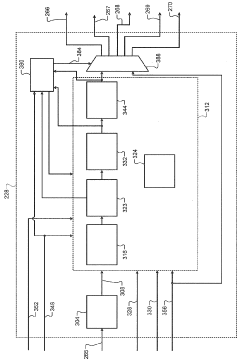

- A prognostics-enhanced MPC framework that incorporates online fault detection, diagnosis, and handling functions, using a nominal system model to determine predicted process outputs and adjust controller parameters or reconfigure the system model based on internal or external faults, optimizing control performance by minimizing system faults and incorporating prognostic information into the cost function.

Fault diagnostic systems and methods for model predictive control

PatentActiveUS9378594B2

Innovation

- A model predictive control (MPC) module identifies and selects target values for engine actuators based on cost analysis and predetermined ranges, while a fault diagnostic module diagnoses issues in the MPC module and adjusts control strategies accordingly, ensuring accurate torque control and rapid response.

Safety Standards and Certification Requirements

The implementation of Model Predictive Control (MPC) in fault-tolerant systems necessitates adherence to rigorous safety standards and certification requirements across various industries. In safety-critical domains such as aerospace, automotive, and industrial automation, regulatory frameworks establish minimum safety thresholds that must be met before deployment.

ISO 26262, the international standard for functional safety in automotive systems, provides a comprehensive framework for implementing MPC in vehicle control systems. It mandates Automotive Safety Integrity Levels (ASIL) ranging from A to D, with D representing the highest safety requirements. MPC-based fault-tolerant systems typically require ASIL C or D certification, demanding extensive verification and validation processes including formal methods to prove system stability under fault conditions.

For aerospace applications, DO-178C (Software Considerations in Airborne Systems) and DO-254 (Hardware Considerations in Airborne Systems) establish certification guidelines with Design Assurance Levels (DAL) from E to A. MPC implementations in flight control systems generally require DAL A or B certification, necessitating comprehensive testing of fault detection, isolation, and recovery mechanisms under various operational scenarios.

In industrial settings, IEC 61508 (Functional Safety of Electrical/Electronic/Programmable Electronic Safety-related Systems) defines Safety Integrity Levels (SIL) from 1 to 4. MPC-based fault-tolerant control systems in process industries typically require SIL 2 or SIL 3 certification, focusing on systematic capability and hardware safety integrity.

Recent regulatory developments have introduced specific requirements for predictive algorithms in safety-critical systems. The European Union Aviation Safety Agency (EASA) has published guidelines for machine learning applications in aviation, which apply to advanced MPC implementations. Similarly, the FDA has established regulatory pathways for software as a medical device (SaMD), affecting MPC applications in medical equipment.

Certification processes for MPC-based fault-tolerant systems typically involve extensive documentation of requirements, design specifications, verification results, and validation testing. This includes demonstrating that the system can maintain safe operation despite sensor failures, actuator malfunctions, or computational errors. Formal verification techniques are increasingly required to mathematically prove that the MPC algorithm maintains stability and performance under specified fault conditions.

ISO 26262, the international standard for functional safety in automotive systems, provides a comprehensive framework for implementing MPC in vehicle control systems. It mandates Automotive Safety Integrity Levels (ASIL) ranging from A to D, with D representing the highest safety requirements. MPC-based fault-tolerant systems typically require ASIL C or D certification, demanding extensive verification and validation processes including formal methods to prove system stability under fault conditions.

For aerospace applications, DO-178C (Software Considerations in Airborne Systems) and DO-254 (Hardware Considerations in Airborne Systems) establish certification guidelines with Design Assurance Levels (DAL) from E to A. MPC implementations in flight control systems generally require DAL A or B certification, necessitating comprehensive testing of fault detection, isolation, and recovery mechanisms under various operational scenarios.

In industrial settings, IEC 61508 (Functional Safety of Electrical/Electronic/Programmable Electronic Safety-related Systems) defines Safety Integrity Levels (SIL) from 1 to 4. MPC-based fault-tolerant control systems in process industries typically require SIL 2 or SIL 3 certification, focusing on systematic capability and hardware safety integrity.

Recent regulatory developments have introduced specific requirements for predictive algorithms in safety-critical systems. The European Union Aviation Safety Agency (EASA) has published guidelines for machine learning applications in aviation, which apply to advanced MPC implementations. Similarly, the FDA has established regulatory pathways for software as a medical device (SaMD), affecting MPC applications in medical equipment.

Certification processes for MPC-based fault-tolerant systems typically involve extensive documentation of requirements, design specifications, verification results, and validation testing. This includes demonstrating that the system can maintain safe operation despite sensor failures, actuator malfunctions, or computational errors. Formal verification techniques are increasingly required to mathematically prove that the MPC algorithm maintains stability and performance under specified fault conditions.

Economic Impact of Fault-Tolerant Control Systems

The economic impact of fault-tolerant control systems enabled by Model Predictive Control (MPC) extends far beyond technical improvements, creating substantial financial benefits across multiple industries. In manufacturing sectors, these systems significantly reduce unplanned downtime, which typically costs industrial manufacturers an estimated $50 billion annually. By implementing MPC-based fault-tolerant systems, companies have reported downtime reductions of 15-35%, directly translating to millions in saved production costs.

The return on investment for fault-tolerant MPC systems is particularly compelling in process industries such as chemical manufacturing, oil refining, and power generation. Case studies from major petrochemical facilities indicate that advanced fault-tolerant control systems deliver payback periods of 3-18 months, with ongoing annual benefits representing 2-5% of operating costs. These savings primarily derive from maintaining optimal production conditions even when sensors or actuators experience partial failures.

Energy efficiency improvements represent another significant economic benefit. Fault-tolerant MPC systems maintain optimal operation despite component degradation, resulting in 5-15% energy consumption reductions in complex industrial processes. In the power generation sector alone, this translates to hundreds of millions in annual savings while simultaneously reducing carbon emissions, potentially avoiding carbon taxation costs in regulated markets.

Insurance and liability considerations further enhance the economic case for these systems. Companies implementing comprehensive fault-tolerant control architectures often qualify for reduced insurance premiums due to decreased operational risk profiles. The risk mitigation value becomes particularly evident in high-consequence industries where failures can result in catastrophic financial impacts through environmental damage, regulatory penalties, or litigation.

From a capital expenditure perspective, fault-tolerant MPC systems extend equipment lifespan by reducing stress during fault conditions. This postponement of replacement investments represents significant capital preservation, with studies indicating 15-25% extensions in useful life for critical industrial assets. Additionally, these systems enable more precise predictive maintenance scheduling, optimizing maintenance expenditures while minimizing production impacts.

The competitive advantage gained through operational resilience also carries substantial economic value. Organizations implementing advanced fault-tolerant control systems demonstrate greater production stability during supply chain disruptions, allowing them to maintain market commitments when competitors face operational challenges. This reliability premium often translates to preferred supplier status and the ability to command price premiums in markets where consistent delivery is highly valued.

The return on investment for fault-tolerant MPC systems is particularly compelling in process industries such as chemical manufacturing, oil refining, and power generation. Case studies from major petrochemical facilities indicate that advanced fault-tolerant control systems deliver payback periods of 3-18 months, with ongoing annual benefits representing 2-5% of operating costs. These savings primarily derive from maintaining optimal production conditions even when sensors or actuators experience partial failures.

Energy efficiency improvements represent another significant economic benefit. Fault-tolerant MPC systems maintain optimal operation despite component degradation, resulting in 5-15% energy consumption reductions in complex industrial processes. In the power generation sector alone, this translates to hundreds of millions in annual savings while simultaneously reducing carbon emissions, potentially avoiding carbon taxation costs in regulated markets.

Insurance and liability considerations further enhance the economic case for these systems. Companies implementing comprehensive fault-tolerant control architectures often qualify for reduced insurance premiums due to decreased operational risk profiles. The risk mitigation value becomes particularly evident in high-consequence industries where failures can result in catastrophic financial impacts through environmental damage, regulatory penalties, or litigation.

From a capital expenditure perspective, fault-tolerant MPC systems extend equipment lifespan by reducing stress during fault conditions. This postponement of replacement investments represents significant capital preservation, with studies indicating 15-25% extensions in useful life for critical industrial assets. Additionally, these systems enable more precise predictive maintenance scheduling, optimizing maintenance expenditures while minimizing production impacts.

The competitive advantage gained through operational resilience also carries substantial economic value. Organizations implementing advanced fault-tolerant control systems demonstrate greater production stability during supply chain disruptions, allowing them to maintain market commitments when competitors face operational challenges. This reliability premium often translates to preferred supplier status and the ability to command price premiums in markets where consistent delivery is highly valued.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!