How Model Predictive Control Supports Sustainable Manufacturing

SEP 9, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

MPC Technology Evolution and Sustainability Goals

Model Predictive Control (MPC) has evolved significantly since its inception in the 1970s, transforming from a theoretical concept to a practical industrial control strategy. Initially developed for oil refineries and petrochemical plants, MPC has undergone several generations of development, each addressing limitations of previous iterations while expanding capabilities and application domains.

The first generation of MPC algorithms in the 1970s focused on basic process control with limited computational resources. By the 1990s, second-generation MPC incorporated more sophisticated mathematical models and constraint handling, enabling more precise control of complex industrial processes. The 2000s saw third-generation MPC systems with improved robustness, adaptive capabilities, and integration with optimization techniques.

Today's fourth-generation MPC represents a convergence with sustainability objectives, featuring real-time energy optimization, emissions reduction capabilities, and integration with renewable energy systems. This evolution aligns perfectly with the manufacturing sector's increasing focus on environmental sustainability, resource efficiency, and regulatory compliance.

The sustainability goals driving modern MPC development include significant reductions in energy consumption, with targets often exceeding 15-20% improvement over conventional control systems. Carbon footprint reduction has become a central objective, with MPC systems designed to minimize greenhouse gas emissions while maintaining production efficiency. Water conservation and waste reduction are increasingly incorporated into MPC frameworks, supporting circular economy principles.

Manufacturing facilities worldwide are adopting sustainability metrics that MPC directly supports, including Overall Equipment Effectiveness (OEE), Energy Performance Indicators (EnPIs), and Environmental, Social, and Governance (ESG) criteria. These metrics are now being embedded into MPC objective functions, creating control systems that inherently optimize for sustainability.

Recent technological advancements enabling this sustainability-focused evolution include cloud computing infrastructure for handling complex MPC calculations, edge computing for distributed control architectures, and machine learning integration for predictive maintenance and adaptive control. The development of digital twins has further enhanced MPC's capabilities by providing virtual environments for testing and optimizing control strategies before implementation.

Looking forward, MPC technology is expected to continue evolving toward fully autonomous sustainable manufacturing systems, with increasing integration of artificial intelligence, broader scope of optimization objectives, and seamless coordination across entire supply chains. This trajectory positions MPC as a cornerstone technology for Industry 4.0 and the sustainable manufacturing revolution.

The first generation of MPC algorithms in the 1970s focused on basic process control with limited computational resources. By the 1990s, second-generation MPC incorporated more sophisticated mathematical models and constraint handling, enabling more precise control of complex industrial processes. The 2000s saw third-generation MPC systems with improved robustness, adaptive capabilities, and integration with optimization techniques.

Today's fourth-generation MPC represents a convergence with sustainability objectives, featuring real-time energy optimization, emissions reduction capabilities, and integration with renewable energy systems. This evolution aligns perfectly with the manufacturing sector's increasing focus on environmental sustainability, resource efficiency, and regulatory compliance.

The sustainability goals driving modern MPC development include significant reductions in energy consumption, with targets often exceeding 15-20% improvement over conventional control systems. Carbon footprint reduction has become a central objective, with MPC systems designed to minimize greenhouse gas emissions while maintaining production efficiency. Water conservation and waste reduction are increasingly incorporated into MPC frameworks, supporting circular economy principles.

Manufacturing facilities worldwide are adopting sustainability metrics that MPC directly supports, including Overall Equipment Effectiveness (OEE), Energy Performance Indicators (EnPIs), and Environmental, Social, and Governance (ESG) criteria. These metrics are now being embedded into MPC objective functions, creating control systems that inherently optimize for sustainability.

Recent technological advancements enabling this sustainability-focused evolution include cloud computing infrastructure for handling complex MPC calculations, edge computing for distributed control architectures, and machine learning integration for predictive maintenance and adaptive control. The development of digital twins has further enhanced MPC's capabilities by providing virtual environments for testing and optimizing control strategies before implementation.

Looking forward, MPC technology is expected to continue evolving toward fully autonomous sustainable manufacturing systems, with increasing integration of artificial intelligence, broader scope of optimization objectives, and seamless coordination across entire supply chains. This trajectory positions MPC as a cornerstone technology for Industry 4.0 and the sustainable manufacturing revolution.

Market Demand for Sustainable Manufacturing Solutions

The global market for sustainable manufacturing solutions is experiencing unprecedented growth, driven by increasing environmental regulations, consumer demand for eco-friendly products, and corporate sustainability commitments. According to recent industry analyses, the sustainable manufacturing market is projected to reach $320 billion by 2025, with a compound annual growth rate of approximately 8.7% from 2020 to 2025. This growth trajectory underscores the critical importance of technologies like Model Predictive Control (MPC) that enable manufacturers to optimize their operations for sustainability.

Manufacturing industries worldwide are facing mounting pressure to reduce their environmental footprint while maintaining productivity and profitability. A 2022 survey by the World Economic Forum revealed that 78% of manufacturing executives consider sustainability initiatives as essential to their competitive strategy, up from 57% in 2018. This shift in corporate priorities has created substantial demand for advanced control systems that can minimize resource consumption and emissions.

Energy efficiency represents a primary driver for MPC adoption in sustainable manufacturing. Industrial processes account for approximately 24% of global energy consumption, with significant inefficiencies in many traditional manufacturing operations. The International Energy Agency estimates that implementing advanced control technologies like MPC could reduce industrial energy consumption by 15-20%, translating to billions in cost savings and substantial carbon emission reductions.

Water conservation presents another critical market need that MPC addresses effectively. In water-intensive industries such as food processing, textiles, and chemicals, optimizing water usage through predictive control systems can reduce consumption by up to 30%. With water scarcity affecting manufacturing operations in many regions globally, solutions that enhance water efficiency command premium market positioning.

Waste reduction capabilities of MPC systems align perfectly with circular economy initiatives gaining momentum across manufacturing sectors. The Ellen MacArthur Foundation reports that transitioning to circular economy models could generate $4.5 trillion in economic benefits by 2030. MPC's ability to optimize production parameters to minimize scrap, rework, and defects positions it as an enabling technology for this transition.

Regulatory compliance represents a significant market driver for MPC adoption. Manufacturing facilities face increasingly stringent environmental regulations worldwide, with non-compliance resulting in substantial financial penalties and operational disruptions. Advanced control systems that help maintain operations within regulatory parameters while optimizing production efficiency offer compelling value propositions to manufacturers navigating complex compliance landscapes.

The market demand for MPC in sustainable manufacturing varies by industry sector, with process industries (chemicals, oil and gas, pulp and paper) showing the highest adoption rates currently. However, discrete manufacturing sectors including automotive, electronics, and consumer goods are rapidly increasing their implementation of advanced control technologies as sustainability becomes a strategic imperative across all manufacturing domains.

Manufacturing industries worldwide are facing mounting pressure to reduce their environmental footprint while maintaining productivity and profitability. A 2022 survey by the World Economic Forum revealed that 78% of manufacturing executives consider sustainability initiatives as essential to their competitive strategy, up from 57% in 2018. This shift in corporate priorities has created substantial demand for advanced control systems that can minimize resource consumption and emissions.

Energy efficiency represents a primary driver for MPC adoption in sustainable manufacturing. Industrial processes account for approximately 24% of global energy consumption, with significant inefficiencies in many traditional manufacturing operations. The International Energy Agency estimates that implementing advanced control technologies like MPC could reduce industrial energy consumption by 15-20%, translating to billions in cost savings and substantial carbon emission reductions.

Water conservation presents another critical market need that MPC addresses effectively. In water-intensive industries such as food processing, textiles, and chemicals, optimizing water usage through predictive control systems can reduce consumption by up to 30%. With water scarcity affecting manufacturing operations in many regions globally, solutions that enhance water efficiency command premium market positioning.

Waste reduction capabilities of MPC systems align perfectly with circular economy initiatives gaining momentum across manufacturing sectors. The Ellen MacArthur Foundation reports that transitioning to circular economy models could generate $4.5 trillion in economic benefits by 2030. MPC's ability to optimize production parameters to minimize scrap, rework, and defects positions it as an enabling technology for this transition.

Regulatory compliance represents a significant market driver for MPC adoption. Manufacturing facilities face increasingly stringent environmental regulations worldwide, with non-compliance resulting in substantial financial penalties and operational disruptions. Advanced control systems that help maintain operations within regulatory parameters while optimizing production efficiency offer compelling value propositions to manufacturers navigating complex compliance landscapes.

The market demand for MPC in sustainable manufacturing varies by industry sector, with process industries (chemicals, oil and gas, pulp and paper) showing the highest adoption rates currently. However, discrete manufacturing sectors including automotive, electronics, and consumer goods are rapidly increasing their implementation of advanced control technologies as sustainability becomes a strategic imperative across all manufacturing domains.

Current State and Challenges of MPC in Manufacturing

Model Predictive Control (MPC) has gained significant traction in manufacturing environments over the past decade, yet its implementation for sustainable manufacturing presents a complex landscape of achievements and obstacles. Currently, MPC deployment varies considerably across different manufacturing sectors, with process industries such as petrochemical, pulp and paper, and food processing demonstrating more mature implementations compared to discrete manufacturing sectors.

The technological infrastructure supporting MPC in manufacturing has evolved substantially, with modern systems leveraging high-performance computing, cloud resources, and advanced sensing technologies. However, a significant challenge remains in the integration of these systems with legacy equipment and outdated control architectures that still dominate many manufacturing facilities, particularly in small and medium enterprises.

Data quality and availability represent another critical challenge for effective MPC implementation. While the theoretical foundations of MPC require accurate process models and real-time data, manufacturing environments often struggle with sensor reliability, data inconsistency, and insufficient historical data for model training. This gap between theoretical requirements and practical realities creates substantial implementation barriers.

From a geographical perspective, MPC adoption shows notable regional disparities. Advanced manufacturing hubs in North America, Western Europe, and East Asia lead in implementation, while developing regions lag significantly. This disparity is further exacerbated by the shortage of skilled professionals capable of designing, implementing, and maintaining MPC systems across global manufacturing operations.

Sustainability-focused MPC applications face additional technical hurdles. Current systems often prioritize traditional manufacturing metrics like productivity and quality over sustainability indicators. The integration of environmental impact metrics, energy efficiency parameters, and waste reduction goals into MPC objective functions remains technically challenging and inconsistently implemented.

Computational complexity presents another significant barrier, particularly for large-scale manufacturing systems with numerous variables and constraints. Real-time optimization requirements for sustainable manufacturing often push against the boundaries of current computational capabilities, necessitating trade-offs between model accuracy and execution speed.

Regulatory frameworks and standards for sustainable manufacturing control systems remain fragmented globally, creating uncertainty for technology developers and adopters. The lack of standardized approaches for measuring and validating sustainability improvements achieved through MPC implementation further complicates technology adoption decisions and return-on-investment calculations.

The technological infrastructure supporting MPC in manufacturing has evolved substantially, with modern systems leveraging high-performance computing, cloud resources, and advanced sensing technologies. However, a significant challenge remains in the integration of these systems with legacy equipment and outdated control architectures that still dominate many manufacturing facilities, particularly in small and medium enterprises.

Data quality and availability represent another critical challenge for effective MPC implementation. While the theoretical foundations of MPC require accurate process models and real-time data, manufacturing environments often struggle with sensor reliability, data inconsistency, and insufficient historical data for model training. This gap between theoretical requirements and practical realities creates substantial implementation barriers.

From a geographical perspective, MPC adoption shows notable regional disparities. Advanced manufacturing hubs in North America, Western Europe, and East Asia lead in implementation, while developing regions lag significantly. This disparity is further exacerbated by the shortage of skilled professionals capable of designing, implementing, and maintaining MPC systems across global manufacturing operations.

Sustainability-focused MPC applications face additional technical hurdles. Current systems often prioritize traditional manufacturing metrics like productivity and quality over sustainability indicators. The integration of environmental impact metrics, energy efficiency parameters, and waste reduction goals into MPC objective functions remains technically challenging and inconsistently implemented.

Computational complexity presents another significant barrier, particularly for large-scale manufacturing systems with numerous variables and constraints. Real-time optimization requirements for sustainable manufacturing often push against the boundaries of current computational capabilities, necessitating trade-offs between model accuracy and execution speed.

Regulatory frameworks and standards for sustainable manufacturing control systems remain fragmented globally, creating uncertainty for technology developers and adopters. The lack of standardized approaches for measuring and validating sustainability improvements achieved through MPC implementation further complicates technology adoption decisions and return-on-investment calculations.

Current MPC Frameworks for Energy Optimization

01 Energy-efficient MPC for sustainable industrial processes

Model Predictive Control (MPC) strategies are implemented to optimize energy consumption in industrial processes, contributing to sustainability goals. These systems continuously monitor and adjust process parameters to minimize energy usage while maintaining production efficiency. Advanced algorithms predict future states and calculate optimal control actions that balance operational requirements with energy conservation, resulting in reduced carbon footprint and improved sustainability metrics.- Energy-efficient MPC for sustainable industrial processes: Model Predictive Control (MPC) strategies are implemented to optimize energy consumption in industrial processes, contributing to sustainability goals. These systems continuously monitor and adjust process parameters to minimize energy usage while maintaining production efficiency. Advanced algorithms predict future states and calculate optimal control actions that balance operational requirements with energy conservation, resulting in reduced carbon footprint and improved sustainability metrics for manufacturing facilities.

- MPC for renewable energy integration and management: Model Predictive Control frameworks are developed specifically for integrating and managing renewable energy sources in power systems. These controllers optimize the utilization of intermittent renewable resources by predicting energy generation patterns and coordinating with energy storage systems. The predictive capabilities allow for smoother integration of solar, wind, and other sustainable energy sources into existing grids, maximizing renewable energy utilization while maintaining grid stability and reducing reliance on fossil fuels.

- Sustainable water resource management using MPC: Model Predictive Control systems are applied to water resource management to enhance sustainability. These systems optimize water distribution networks, wastewater treatment processes, and irrigation systems by predicting demand patterns and environmental conditions. The controllers balance water conservation goals with service requirements, reducing energy consumption in pumping operations while ensuring adequate water supply. This approach leads to more efficient use of water resources and reduced environmental impact of water management infrastructure.

- MPC for sustainable building climate control: Advanced Model Predictive Control strategies are implemented in building management systems to achieve sustainable climate control. These systems incorporate weather forecasts, occupancy patterns, and thermal models to optimize heating, ventilation, and air conditioning operations. By anticipating future conditions and constraints, the controllers minimize energy consumption while maintaining occupant comfort. This approach significantly reduces the carbon footprint of buildings while potentially integrating with renewable energy sources and responding to dynamic energy pricing.

- Sustainable transportation and logistics optimization via MPC: Model Predictive Control frameworks are designed for optimizing transportation and logistics systems with sustainability objectives. These controllers manage fleet operations, route planning, and energy consumption in vehicles by predicting traffic conditions, demand patterns, and energy availability. For electric and autonomous vehicles, MPC systems balance range limitations with operational requirements while minimizing environmental impact. The predictive capabilities enable more efficient use of transportation resources, reduced emissions, and integration with sustainable energy infrastructure.

02 MPC for renewable energy integration and management

Model Predictive Control frameworks are designed specifically for integrating and managing renewable energy sources in power systems. These control systems optimize the utilization of intermittent renewable resources by predicting energy generation patterns and coordinating with energy storage systems. The predictive capabilities allow for smoother integration of solar, wind, and other sustainable energy sources into existing power grids, enhancing overall system stability while maximizing the use of clean energy.Expand Specific Solutions03 Sustainable water resource management using MPC

Model Predictive Control techniques are applied to water distribution and treatment systems to enhance sustainability. These systems optimize water usage, treatment processes, and distribution networks by predicting demand patterns and environmental conditions. The control algorithms balance water quality requirements, energy consumption, and resource conservation, leading to more efficient use of water resources and reduced environmental impact of water management operations.Expand Specific Solutions04 MPC for sustainable building climate control

Advanced Model Predictive Control systems are implemented in building management to achieve sustainable climate control. These systems incorporate weather forecasts, occupancy patterns, and thermal dynamics to optimize heating, ventilation, and air conditioning operations. By predicting future conditions and calculating optimal control strategies, these systems significantly reduce energy consumption while maintaining occupant comfort, contributing to greener building operations and reduced environmental impact.Expand Specific Solutions05 Sustainable transportation and logistics optimization via MPC

Model Predictive Control frameworks are developed for transportation systems to enhance sustainability in mobility and logistics. These control systems optimize route planning, vehicle operations, and traffic flow by predicting demand patterns and environmental conditions. The algorithms balance efficiency, timeliness, and environmental impact considerations, resulting in reduced emissions, lower fuel consumption, and more sustainable transportation networks across various modes of transport.Expand Specific Solutions

Key Industry Players and Solution Providers

Model Predictive Control (MPC) is emerging as a pivotal technology in sustainable manufacturing, currently transitioning from early adoption to mainstream implementation. The global market for MPC in manufacturing is expanding rapidly, projected to reach significant scale as industries prioritize energy efficiency and emissions reduction. Technologically, MPC solutions are maturing with varying levels of sophistication across providers. Industry leaders like Siemens AG, ABB Group, and Rockwell Automation offer comprehensive MPC platforms with advanced capabilities, while companies such as Mitsubishi Electric, Bosch, and OMRON are developing specialized applications. Academic institutions including Zhejiang University and Central South University are contributing fundamental research, while newer entrants like PassiveLogic are introducing innovative approaches. The convergence of MPC with AI and digital twin technologies is accelerating adoption across diverse manufacturing sectors.

Siemens AG

Technical Solution: Siemens has developed advanced Model Predictive Control (MPC) solutions integrated within their SIMATIC PCS 7 Advanced Process Control suite. Their approach combines traditional MPC with AI-driven predictive analytics to optimize manufacturing processes in real-time. The system continuously monitors multiple process variables, predicts future states, and adjusts control parameters to maintain optimal operation while minimizing energy consumption and waste. Siemens' MPC implementation includes specialized modules for energy optimization that can reduce energy usage by up to 30% in industrial settings. Their technology incorporates digital twin capabilities, allowing manufacturers to simulate process changes before implementation, reducing commissioning time by approximately 40% compared to traditional control methods[1]. Siemens has successfully deployed these solutions across various industries including chemical processing, steel manufacturing, and power generation, with documented case studies showing 15-25% reduction in carbon emissions while maintaining or improving production quality[3].

Strengths: Comprehensive integration with existing industrial automation systems; proven energy reduction capabilities; robust digital twin simulation capabilities. Weaknesses: Higher initial implementation costs compared to conventional control systems; requires significant process expertise for optimal configuration; may need substantial computational resources for complex manufacturing environments.

Rockwell Automation Technologies, Inc.

Technical Solution: Rockwell Automation has developed a sophisticated Model Predictive Control framework within their FactoryTalk OptomizeIT suite specifically designed for sustainable manufacturing. Their MPC technology employs multi-variable predictive algorithms that simultaneously manage hundreds of process variables and constraints while optimizing for energy efficiency and resource utilization. The system features adaptive modeling capabilities that continuously refine process models based on real-time data, ensuring optimal performance even as equipment ages or process conditions change. Rockwell's implementation includes specialized sustainability metrics that track carbon footprint, water usage, and waste generation in real-time, allowing manufacturers to balance production goals with environmental targets. Their MPC solution has demonstrated energy savings of 5-15% in continuous process industries while reducing quality variations by up to 40%[2]. The platform includes scenario planning tools that enable manufacturers to evaluate the environmental impact of different production strategies before implementation, supporting more sustainable decision-making across the enterprise[4].

Strengths: Seamless integration with existing Rockwell control systems; user-friendly interface requiring less specialized knowledge; strong focus on sustainability metrics beyond just energy. Weaknesses: More limited application in highly complex chemical processes compared to competitors; requires significant historical data for optimal performance; higher subscription costs for cloud-based deployment options.

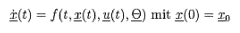

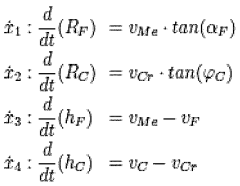

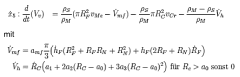

Core Algorithms and Mathematical Foundations

Model predictive control of the zone-melting process

PatentWO2014033212A1

Innovation

- Implementing model predictive control, which involves influencing manipulated variables such as generator power, rod speed, and crystal velocity based on measured and predicted system states to minimize deviations from target values, while considering system and manipulated variable constraints.

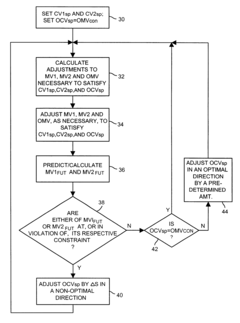

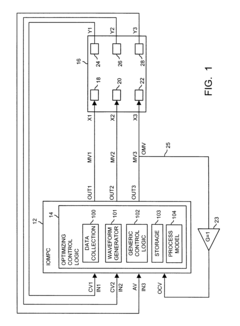

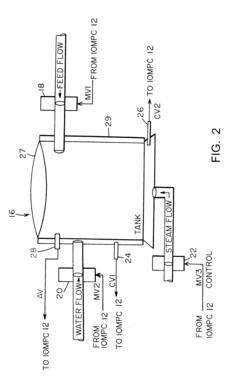

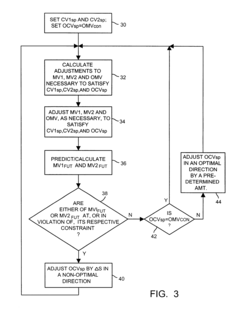

Integrated optimal model predictive control in a process control system

PatentInactiveUS6721609B1

Innovation

- A multi-input/multi-output logic controller with a feedback path and setpoint adjustment unit that monitors and adjusts process outputs to prevent constraint limit violations, using a model predictive controller to optimize process inputs and maintain desired setpoints while avoiding physical constraint limits.

Regulatory Compliance and Environmental Standards

The regulatory landscape for manufacturing operations continues to evolve with increasing emphasis on environmental sustainability. Model Predictive Control (MPC) systems offer manufacturers a sophisticated approach to meet and exceed regulatory requirements while optimizing production processes. Current environmental regulations, including the Paris Agreement, EU Emissions Trading System, and various national carbon reduction targets, impose strict limitations on industrial emissions and resource consumption that manufacturers must navigate.

MPC technology enables precise compliance with these regulations through its predictive capabilities. By forecasting process behaviors and optimizing control actions in advance, MPC systems can maintain operations within regulatory thresholds for emissions, waste generation, and resource utilization. This proactive approach significantly reduces the risk of non-compliance penalties and operational shutdowns that could result from regulatory violations.

ISO 14001 and ISO 50001 standards for environmental management and energy efficiency respectively have become increasingly important benchmarks for manufacturing operations. MPC implementations directly support certification requirements by providing the necessary monitoring, control, and documentation capabilities. The systematic optimization approach of MPC aligns perfectly with these standards' emphasis on continuous improvement in environmental performance.

Regional variations in environmental regulations present significant challenges for global manufacturers. MPC systems offer adaptability through reconfigurable constraint parameters that can be adjusted to meet different regulatory requirements across various operating locations. This flexibility eliminates the need for separate control systems for different regions, reducing implementation costs while ensuring universal compliance.

Beyond mere compliance, MPC enables manufacturers to pursue more ambitious sustainability goals. The technology's ability to optimize multiple objectives simultaneously allows companies to balance production targets with environmental performance metrics. This capability positions manufacturers to achieve certification under emerging standards for carbon neutrality and circular economy principles, providing competitive advantages in increasingly environmentally conscious markets.

The documentation capabilities inherent in MPC systems provide another significant regulatory advantage. These systems continuously log operational data, control actions, and performance metrics, creating comprehensive audit trails that simplify regulatory reporting and verification processes. This transparency builds trust with regulatory bodies and can streamline inspection procedures, reducing administrative burden on manufacturing operations.

MPC technology enables precise compliance with these regulations through its predictive capabilities. By forecasting process behaviors and optimizing control actions in advance, MPC systems can maintain operations within regulatory thresholds for emissions, waste generation, and resource utilization. This proactive approach significantly reduces the risk of non-compliance penalties and operational shutdowns that could result from regulatory violations.

ISO 14001 and ISO 50001 standards for environmental management and energy efficiency respectively have become increasingly important benchmarks for manufacturing operations. MPC implementations directly support certification requirements by providing the necessary monitoring, control, and documentation capabilities. The systematic optimization approach of MPC aligns perfectly with these standards' emphasis on continuous improvement in environmental performance.

Regional variations in environmental regulations present significant challenges for global manufacturers. MPC systems offer adaptability through reconfigurable constraint parameters that can be adjusted to meet different regulatory requirements across various operating locations. This flexibility eliminates the need for separate control systems for different regions, reducing implementation costs while ensuring universal compliance.

Beyond mere compliance, MPC enables manufacturers to pursue more ambitious sustainability goals. The technology's ability to optimize multiple objectives simultaneously allows companies to balance production targets with environmental performance metrics. This capability positions manufacturers to achieve certification under emerging standards for carbon neutrality and circular economy principles, providing competitive advantages in increasingly environmentally conscious markets.

The documentation capabilities inherent in MPC systems provide another significant regulatory advantage. These systems continuously log operational data, control actions, and performance metrics, creating comprehensive audit trails that simplify regulatory reporting and verification processes. This transparency builds trust with regulatory bodies and can streamline inspection procedures, reducing administrative burden on manufacturing operations.

ROI Analysis and Implementation Considerations

Implementing Model Predictive Control (MPC) in manufacturing environments requires careful consideration of both financial returns and practical implementation factors. The ROI analysis for MPC in sustainable manufacturing typically shows payback periods ranging from 6 to 24 months, depending on the scale and complexity of operations. Energy consumption reductions of 10-30% are commonly reported across various manufacturing sectors, with particularly strong results in energy-intensive industries such as chemical processing, pulp and paper, and metals production.

Capital expenditure for MPC implementation varies significantly based on the existing infrastructure. Facilities with modern DCS (Distributed Control Systems) and robust sensor networks may require investments of $50,000-$150,000 for software and integration, while those needing substantial hardware upgrades might face costs exceeding $500,000. These figures must be weighed against operational savings, which often include reduced energy costs, decreased raw material waste, and improved product quality leading to fewer rejects.

Beyond direct financial returns, MPC implementation delivers significant sustainability benefits that may be monetized through carbon credits, compliance with environmental regulations, and enhanced brand value. Studies indicate that manufacturers implementing advanced control strategies like MPC can reduce their carbon footprint by 5-15% while maintaining or improving production output.

Implementation considerations must address several critical factors for successful MPC deployment. Technical infrastructure requirements include sufficient computational resources, reliable real-time data acquisition systems, and robust communication networks. The existing control system architecture must be evaluated for compatibility with MPC algorithms, as retrofitting older systems may present integration challenges.

Workforce considerations represent another crucial implementation factor. Staff training needs typically range from basic operational awareness for plant operators to advanced modeling skills for engineering teams. Organizations should budget for 40-80 hours of initial training per technical staff member, with ongoing support during the first 3-6 months of operation.

Phased implementation approaches often yield better results than facility-wide deployments. Starting with pilot projects in high-impact areas allows organizations to demonstrate value, refine implementation methodologies, and build internal expertise before expanding. This approach typically reduces project risk while accelerating time-to-value for initial investments.

Capital expenditure for MPC implementation varies significantly based on the existing infrastructure. Facilities with modern DCS (Distributed Control Systems) and robust sensor networks may require investments of $50,000-$150,000 for software and integration, while those needing substantial hardware upgrades might face costs exceeding $500,000. These figures must be weighed against operational savings, which often include reduced energy costs, decreased raw material waste, and improved product quality leading to fewer rejects.

Beyond direct financial returns, MPC implementation delivers significant sustainability benefits that may be monetized through carbon credits, compliance with environmental regulations, and enhanced brand value. Studies indicate that manufacturers implementing advanced control strategies like MPC can reduce their carbon footprint by 5-15% while maintaining or improving production output.

Implementation considerations must address several critical factors for successful MPC deployment. Technical infrastructure requirements include sufficient computational resources, reliable real-time data acquisition systems, and robust communication networks. The existing control system architecture must be evaluated for compatibility with MPC algorithms, as retrofitting older systems may present integration challenges.

Workforce considerations represent another crucial implementation factor. Staff training needs typically range from basic operational awareness for plant operators to advanced modeling skills for engineering teams. Organizations should budget for 40-80 hours of initial training per technical staff member, with ongoing support during the first 3-6 months of operation.

Phased implementation approaches often yield better results than facility-wide deployments. Starting with pilot projects in high-impact areas allows organizations to demonstrate value, refine implementation methodologies, and build internal expertise before expanding. This approach typically reduces project risk while accelerating time-to-value for initial investments.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!