Model Predictive Control For Next-Generation Robotics

SEP 9, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

MPC Robotics Background and Objectives

Model Predictive Control (MPC) has emerged as a transformative technology in robotics control systems over the past three decades. Originally developed for process industries in the 1970s, MPC has evolved significantly with advances in computational capabilities, making it increasingly viable for real-time robotic applications that demand high performance under complex constraints.

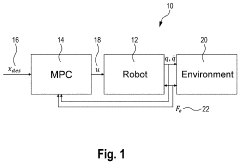

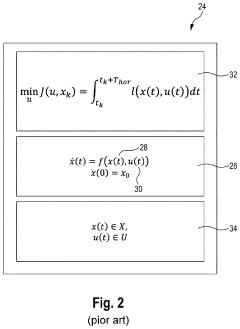

The fundamental principle of MPC involves predicting system behavior over a finite time horizon, optimizing control actions based on these predictions, and implementing only the first step of the calculated sequence before recalculating at the next time step. This receding horizon approach provides remarkable adaptability to changing conditions and constraints, making it particularly valuable for next-generation robotics operating in dynamic environments.

Recent technological advancements have catalyzed MPC's transition from theoretical frameworks to practical implementations in robotics. The exponential growth in computing power, development of more efficient optimization algorithms, and breakthroughs in system identification techniques have collectively addressed historical barriers to MPC adoption in high-speed robotic applications.

The primary objective of MPC in next-generation robotics is to enable autonomous systems that can operate with human-like adaptability while maintaining strict performance guarantees. This includes achieving precise motion control under uncertainty, managing complex dynamic constraints, and optimizing multiple competing objectives simultaneously - capabilities essential for robots working alongside humans in unstructured environments.

Current research focuses on several key technical goals: reducing computational complexity to enable microsecond-level control loops, developing robust MPC formulations that maintain stability despite model inaccuracies, and creating learning-based MPC approaches that can adapt to changing system dynamics or environmental conditions.

The evolution of MPC in robotics reflects broader industry trends toward more autonomous, versatile robotic systems capable of safe human-robot collaboration. As manufacturing, healthcare, logistics, and service sectors increasingly adopt advanced robotics, the demand for sophisticated control methodologies that can guarantee performance while adapting to real-world complexity continues to grow.

Looking forward, the trajectory of MPC development aims to bridge the gap between theoretical capabilities and practical implementations, with particular emphasis on computational efficiency, robustness to uncertainty, and seamless integration with artificial intelligence techniques. The ultimate goal remains creating control systems that enable robots to achieve unprecedented levels of autonomy, safety, and performance in increasingly complex and unpredictable real-world scenarios.

The fundamental principle of MPC involves predicting system behavior over a finite time horizon, optimizing control actions based on these predictions, and implementing only the first step of the calculated sequence before recalculating at the next time step. This receding horizon approach provides remarkable adaptability to changing conditions and constraints, making it particularly valuable for next-generation robotics operating in dynamic environments.

Recent technological advancements have catalyzed MPC's transition from theoretical frameworks to practical implementations in robotics. The exponential growth in computing power, development of more efficient optimization algorithms, and breakthroughs in system identification techniques have collectively addressed historical barriers to MPC adoption in high-speed robotic applications.

The primary objective of MPC in next-generation robotics is to enable autonomous systems that can operate with human-like adaptability while maintaining strict performance guarantees. This includes achieving precise motion control under uncertainty, managing complex dynamic constraints, and optimizing multiple competing objectives simultaneously - capabilities essential for robots working alongside humans in unstructured environments.

Current research focuses on several key technical goals: reducing computational complexity to enable microsecond-level control loops, developing robust MPC formulations that maintain stability despite model inaccuracies, and creating learning-based MPC approaches that can adapt to changing system dynamics or environmental conditions.

The evolution of MPC in robotics reflects broader industry trends toward more autonomous, versatile robotic systems capable of safe human-robot collaboration. As manufacturing, healthcare, logistics, and service sectors increasingly adopt advanced robotics, the demand for sophisticated control methodologies that can guarantee performance while adapting to real-world complexity continues to grow.

Looking forward, the trajectory of MPC development aims to bridge the gap between theoretical capabilities and practical implementations, with particular emphasis on computational efficiency, robustness to uncertainty, and seamless integration with artificial intelligence techniques. The ultimate goal remains creating control systems that enable robots to achieve unprecedented levels of autonomy, safety, and performance in increasingly complex and unpredictable real-world scenarios.

Market Analysis for MPC-Enabled Robotics

The global market for MPC-enabled robotics is experiencing significant growth, driven by increasing demand for advanced automation solutions across various industries. The market size for industrial robots incorporating MPC technology was valued at approximately $5.2 billion in 2022 and is projected to reach $12.7 billion by 2028, representing a compound annual growth rate (CAGR) of 16.1%. This growth trajectory significantly outpaces the broader robotics market, which is growing at around 10% annually.

Manufacturing remains the dominant sector for MPC-enabled robotics, accounting for nearly 45% of the total market share. Within manufacturing, automotive and electronics industries are the primary adopters, leveraging MPC's capabilities for precise motion control and optimization in complex assembly processes. The automotive sector alone represents a $1.8 billion market for MPC robotics solutions.

Healthcare is emerging as the fastest-growing vertical market, with a projected CAGR of 22.3% through 2028. Surgical robots utilizing MPC for enhanced precision and safety are driving this growth, with the market for MPC-enabled surgical systems expected to double in the next five years.

Regional analysis reveals that Asia-Pacific currently leads the market with a 38% share, followed by North America (32%) and Europe (24%). China, Japan, and South Korea are the key contributors in the Asia-Pacific region, while the United States dominates the North American market. However, Europe is showing the fastest adoption rate for advanced MPC robotics in specialized manufacturing and healthcare applications.

Customer demand patterns indicate a strong preference for robots with adaptive capabilities and real-time optimization features. End-users are increasingly prioritizing systems that can handle dynamic environments and unpredictable variables—precisely where MPC technology excels. Market surveys indicate that 67% of industrial automation decision-makers consider predictive control capabilities as "very important" or "critical" in their robotics investment decisions.

The market is also witnessing a shift toward robotics-as-a-service (RaaS) business models, which is lowering the entry barriers for small and medium enterprises to adopt MPC-enabled robotics. This subscription-based approach is expected to expand the addressable market by 30% over the next three years.

Key market challenges include the high initial implementation costs of MPC systems and the technical expertise required for deployment and maintenance. These factors are particularly limiting adoption in small-scale operations and emerging markets, creating a potential opportunity gap that simplified MPC solutions could address.

Manufacturing remains the dominant sector for MPC-enabled robotics, accounting for nearly 45% of the total market share. Within manufacturing, automotive and electronics industries are the primary adopters, leveraging MPC's capabilities for precise motion control and optimization in complex assembly processes. The automotive sector alone represents a $1.8 billion market for MPC robotics solutions.

Healthcare is emerging as the fastest-growing vertical market, with a projected CAGR of 22.3% through 2028. Surgical robots utilizing MPC for enhanced precision and safety are driving this growth, with the market for MPC-enabled surgical systems expected to double in the next five years.

Regional analysis reveals that Asia-Pacific currently leads the market with a 38% share, followed by North America (32%) and Europe (24%). China, Japan, and South Korea are the key contributors in the Asia-Pacific region, while the United States dominates the North American market. However, Europe is showing the fastest adoption rate for advanced MPC robotics in specialized manufacturing and healthcare applications.

Customer demand patterns indicate a strong preference for robots with adaptive capabilities and real-time optimization features. End-users are increasingly prioritizing systems that can handle dynamic environments and unpredictable variables—precisely where MPC technology excels. Market surveys indicate that 67% of industrial automation decision-makers consider predictive control capabilities as "very important" or "critical" in their robotics investment decisions.

The market is also witnessing a shift toward robotics-as-a-service (RaaS) business models, which is lowering the entry barriers for small and medium enterprises to adopt MPC-enabled robotics. This subscription-based approach is expected to expand the addressable market by 30% over the next three years.

Key market challenges include the high initial implementation costs of MPC systems and the technical expertise required for deployment and maintenance. These factors are particularly limiting adoption in small-scale operations and emerging markets, creating a potential opportunity gap that simplified MPC solutions could address.

MPC Technology Status and Challenges

Model Predictive Control (MPC) technology has reached a significant level of maturity in industrial applications, yet its implementation in next-generation robotics presents unique challenges. Currently, MPC algorithms are widely deployed in process industries where system dynamics change relatively slowly. However, the robotics domain demands real-time computation capabilities that can handle complex, nonlinear dynamics with millisecond-level response times.

The global landscape of MPC development shows concentrated expertise in North America, Europe, and increasingly in East Asia. Research institutions in the United States and Germany lead fundamental algorithm development, while Japan and South Korea focus on hardware-optimized implementations. China has recently made substantial investments in applied MPC research specifically targeting autonomous systems and robotics.

A primary technical challenge facing MPC in robotics is computational complexity. Traditional MPC formulations require solving optimization problems that scale poorly with prediction horizon length and system complexity. This becomes particularly problematic for robots with many degrees of freedom operating in dynamic environments. Recent benchmarks indicate that even state-of-the-art solvers struggle to maintain consistent sub-10ms solution times for humanoid robots with 30+ degrees of freedom.

Another significant hurdle is model accuracy. MPC performance fundamentally depends on the quality of the predictive model. Robots operating in unstructured environments encounter varying surface conditions, unexpected disturbances, and changing payloads that are difficult to model precisely. Current system identification techniques often fail to capture these complex interactions adequately, leading to performance degradation.

Robustness to uncertainty represents another critical challenge. While robust MPC formulations exist, they typically introduce additional computational burden or conservatism that limits performance. Finding the optimal balance between robustness and performance remains an open research question, particularly for safety-critical robotic applications.

Hardware limitations further constrain MPC implementation. Energy-efficient embedded systems with limited computational resources struggle to execute complex MPC algorithms in real-time. This creates a significant barrier for deploying advanced control strategies on autonomous mobile robots with restricted power budgets.

Integration challenges also persist between MPC and other robotic subsystems. Seamless coordination between perception, planning, and control layers requires careful interface design and information flow management. Current architectures often suffer from communication bottlenecks that introduce delays incompatible with MPC's predictive capabilities.

Despite these challenges, recent advances in specialized hardware accelerators, algorithmic improvements like automatic code generation, and learning-based approaches show promising directions for overcoming current limitations and enabling widespread adoption of MPC in next-generation robotics.

The global landscape of MPC development shows concentrated expertise in North America, Europe, and increasingly in East Asia. Research institutions in the United States and Germany lead fundamental algorithm development, while Japan and South Korea focus on hardware-optimized implementations. China has recently made substantial investments in applied MPC research specifically targeting autonomous systems and robotics.

A primary technical challenge facing MPC in robotics is computational complexity. Traditional MPC formulations require solving optimization problems that scale poorly with prediction horizon length and system complexity. This becomes particularly problematic for robots with many degrees of freedom operating in dynamic environments. Recent benchmarks indicate that even state-of-the-art solvers struggle to maintain consistent sub-10ms solution times for humanoid robots with 30+ degrees of freedom.

Another significant hurdle is model accuracy. MPC performance fundamentally depends on the quality of the predictive model. Robots operating in unstructured environments encounter varying surface conditions, unexpected disturbances, and changing payloads that are difficult to model precisely. Current system identification techniques often fail to capture these complex interactions adequately, leading to performance degradation.

Robustness to uncertainty represents another critical challenge. While robust MPC formulations exist, they typically introduce additional computational burden or conservatism that limits performance. Finding the optimal balance between robustness and performance remains an open research question, particularly for safety-critical robotic applications.

Hardware limitations further constrain MPC implementation. Energy-efficient embedded systems with limited computational resources struggle to execute complex MPC algorithms in real-time. This creates a significant barrier for deploying advanced control strategies on autonomous mobile robots with restricted power budgets.

Integration challenges also persist between MPC and other robotic subsystems. Seamless coordination between perception, planning, and control layers requires careful interface design and information flow management. Current architectures often suffer from communication bottlenecks that introduce delays incompatible with MPC's predictive capabilities.

Despite these challenges, recent advances in specialized hardware accelerators, algorithmic improvements like automatic code generation, and learning-based approaches show promising directions for overcoming current limitations and enabling widespread adoption of MPC in next-generation robotics.

Current MPC Implementation Approaches

01 Industrial process control applications

Model Predictive Control (MPC) is widely applied in industrial processes to optimize operations and improve efficiency. These systems use dynamic models to predict future behavior and calculate optimal control actions. MPC algorithms can handle complex constraints and multiple variables simultaneously, making them suitable for manufacturing, chemical processing, and other industrial applications where precise control is critical for product quality and operational efficiency.- Industrial Process Control Applications: Model Predictive Control (MPC) is widely applied in industrial processes to optimize operations and improve efficiency. These systems use mathematical models to predict future behavior of processes and calculate optimal control actions. MPC algorithms can handle complex constraints and multiple variables simultaneously, making them suitable for manufacturing, chemical processing, and energy production systems where precise control is critical for product quality and operational safety.

- Advanced Vehicle Control Systems: Model Predictive Control is increasingly implemented in automotive applications for enhanced vehicle performance and safety. These systems predict vehicle behavior based on current states and environmental conditions to optimize driving parameters. MPC algorithms enable adaptive cruise control, lane-keeping assistance, and collision avoidance by continuously calculating optimal trajectories while respecting vehicle dynamics constraints and safety requirements.

- Energy Management Optimization: Model Predictive Control provides significant advantages in energy management systems by optimizing resource allocation and consumption patterns. These controllers predict energy demand and supply conditions to minimize costs while maintaining performance requirements. MPC frameworks are particularly valuable in smart grid applications, building climate control, and renewable energy integration where they balance multiple objectives including efficiency, comfort, and environmental impact.

- Machine Learning Enhanced MPC: Integration of machine learning techniques with Model Predictive Control creates more adaptive and robust control systems. These hybrid approaches use data-driven methods to improve model accuracy and controller performance over time. Neural networks and other AI techniques help overcome limitations of traditional MPC by handling model uncertainties, nonlinearities, and changing operating conditions without requiring explicit mathematical formulations.

- Distributed and Networked MPC Systems: Distributed Model Predictive Control architectures enable coordination among multiple interconnected subsystems while maintaining computational efficiency. These frameworks divide complex control problems into smaller, manageable components that communicate to achieve global optimization objectives. Networked MPC systems are particularly valuable in large-scale applications such as water distribution networks, traffic management, and multi-agent robotic systems where centralized control would be computationally prohibitive.

02 Energy management and optimization

Model Predictive Control strategies are implemented in energy systems to optimize consumption, reduce costs, and enhance sustainability. These controllers predict energy demands and adjust operations accordingly, balancing multiple objectives such as minimizing energy usage while maintaining comfort or production requirements. The predictive capability allows the system to anticipate changes in conditions or demands and proactively adjust control parameters for optimal performance.Expand Specific Solutions03 Advanced automotive control systems

In automotive applications, Model Predictive Control enables sophisticated vehicle management systems that enhance performance, safety, and fuel efficiency. These controllers can predict vehicle behavior under various conditions and optimize engine operation, transmission shifting, and other vehicle systems. The predictive nature allows for smoother transitions between operating states and better handling of complex driving scenarios, particularly in autonomous or semi-autonomous vehicles.Expand Specific Solutions04 Machine learning integration with MPC

The integration of machine learning techniques with Model Predictive Control creates more adaptive and robust control systems. These hybrid approaches use data-driven methods to improve model accuracy and controller performance over time. Machine learning algorithms can identify patterns in system behavior, adapt to changing conditions, and optimize control parameters automatically, reducing the need for manual tuning and enabling more responsive control in complex or changing environments.Expand Specific Solutions05 Distributed and networked MPC systems

Distributed Model Predictive Control architectures enable coordination among multiple controllers in large-scale systems. These approaches divide control problems into manageable subsystems while maintaining overall system performance and stability. Networked MPC systems can handle communication delays and data loss while coordinating actions across physically separated components. This distributed approach is particularly valuable for large infrastructure systems, smart grids, and interconnected industrial processes where centralized control would be impractical.Expand Specific Solutions

Leading Companies in MPC Robotics

Model Predictive Control (MPC) for next-generation robotics is currently in a growth phase, with the market expected to expand significantly as industries adopt advanced control systems for autonomous operations. The global market size for MPC in robotics is projected to reach several billion dollars by 2025, driven by applications in manufacturing, healthcare, and autonomous vehicles. Technologically, MPC is maturing rapidly with companies like Google, NVIDIA, and Toyota leading innovation in AI-integrated predictive control algorithms. Research institutions including Northwestern Polytechnical University and the Institute of Automation Chinese Academy of Sciences are advancing theoretical frameworks, while industrial players such as Siemens, Bosch, and Mitsubishi Electric are implementing practical applications in industrial robotics. YASKAWA and Honda Research Institute are focusing on human-robot interaction capabilities, positioning MPC as a critical technology for collaborative robotics environments.

Google LLC

Technical Solution: Google's approach to Model Predictive Control (MPC) for robotics leverages their expertise in machine learning and computational resources. Their framework combines traditional MPC with deep learning to create adaptive controllers that can handle complex, non-linear dynamics. Google's solution implements a hierarchical control structure where high-level planning is separated from low-level execution, allowing for real-time adaptation. Their system uses learned dynamics models that continuously improve through operational data, enabling robots to handle previously unseen scenarios. Google has also developed specialized hardware accelerators that can solve MPC optimization problems in milliseconds, critical for dynamic environments. Their implementation includes robust state estimation techniques that fuse multiple sensor inputs to maintain accurate environmental awareness even with noisy or partial observations. Google's MPC approach has been successfully deployed in various robotic applications, from manipulation tasks to locomotion systems, demonstrating significant improvements in precision and adaptability compared to traditional control methods.

Strengths: Exceptional computational resources and AI expertise allow for complex model implementation; strong integration with other Google technologies like TensorFlow and Cloud services. Weaknesses: Solutions may be computationally intensive and require significant resources; potential dependency on Google's ecosystem limiting standalone deployments.

NVIDIA Corp.

Technical Solution: NVIDIA's Model Predictive Control solution for robotics centers around their GPU-accelerated computing platform, which enables real-time processing of complex optimization problems inherent in MPC implementations. Their Isaac robotics platform incorporates MPC algorithms that leverage parallel computing capabilities to solve multiple trajectory optimizations simultaneously. NVIDIA's approach uses their CUDA architecture to accelerate the matrix operations required for MPC, achieving computation speeds up to 10x faster than CPU-based solutions. Their framework includes physics-based simulation environments where controllers can be trained and tested before deployment to physical robots. NVIDIA has developed specialized tensor cores in their GPUs that accelerate the deep learning components often integrated with modern MPC implementations. Their solution incorporates differentiable MPC layers that can be embedded within neural networks, allowing end-to-end training of perception and control systems. NVIDIA's robotics stack provides pre-built MPC components that handle various constraints and cost functions common in robotic applications, from collision avoidance to energy efficiency optimization, making advanced control accessible to robotics developers without requiring expertise in optimization theory.

Strengths: Unparalleled GPU acceleration capabilities provide real-time performance for complex MPC computations; comprehensive development ecosystem with simulation tools. Weaknesses: Hardware dependency on NVIDIA GPUs may increase implementation costs; optimization primarily focused on their hardware architecture which may limit flexibility.

Key MPC Algorithms and Frameworks

Robot Control Using Model-Predictive Interaction

PatentInactiveUS20210138652A1

Innovation

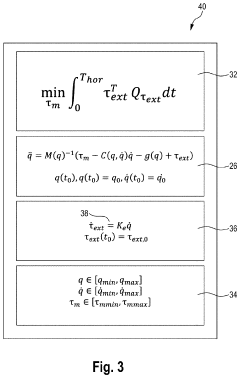

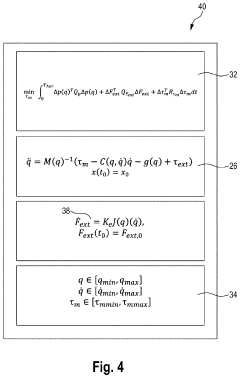

- The method integrates interaction dynamics into model predictive control, allowing for the consideration of forces that arise during human-robot interaction, enabling a unified approach for yield, force, and motion control through an optimization problem that weights interaction forces and adapts to different applications.

System and methods for pixel based model predictive control

PatentWO2019222597A1

Innovation

- Training a latent robot dynamics model using pixel-based data with an encoder, latent transition function, and decoder, combined with a reward function, to enable model predictive control and few-shot learning for robotic tasks, allowing the robot to plan actions in latent space without generating images.

Real-time Computing Requirements

Model Predictive Control (MPC) implementation in next-generation robotics faces significant real-time computing challenges that must be addressed to achieve optimal performance. The computational complexity of MPC algorithms typically scales cubically with the prediction horizon and state dimensions, creating substantial demands on processing resources. For advanced robotic systems operating in dynamic environments, these calculations must be completed within millisecond timeframes to maintain control stability and responsiveness.

Current robotic platforms implementing MPC require specialized hardware configurations to meet these stringent timing requirements. High-performance computing units such as multi-core CPUs with clock speeds exceeding 3.5 GHz or dedicated GPUs with parallel processing capabilities have become standard components in research-grade robotic systems. Field-programmable gate arrays (FPGAs) are increasingly deployed for time-critical MPC implementations, offering deterministic computation times through hardware acceleration of specific mathematical operations.

Memory bandwidth presents another critical constraint, as MPC algorithms require rapid access to state information, constraint parameters, and optimization variables. The data transfer between memory and processing units can become a bottleneck, particularly in systems with distributed control architectures. High-speed cache hierarchies and optimized memory management strategies are essential to minimize latency during critical control cycles.

Power consumption emerges as a significant consideration for autonomous robotic platforms. The computational intensity of MPC algorithms can rapidly deplete battery reserves, limiting operational duration. Energy-efficient computing architectures, including heterogeneous computing platforms that dynamically allocate computational tasks between high-performance and low-power processors based on control demands, are being developed to address this challenge.

Real-time operating systems (RTOS) play a crucial role in ensuring deterministic execution of MPC algorithms. These specialized operating systems provide guaranteed scheduling of control tasks, minimizing jitter and ensuring consistent sampling intervals. Examples include QNX, VxWorks, and real-time Linux variants, which offer sub-millisecond task switching capabilities and priority-based preemption mechanisms essential for maintaining control stability.

The integration of specialized hardware accelerators for matrix operations, particularly those optimized for the quadratic programming solvers common in MPC implementations, represents a promising approach to meeting real-time requirements while managing power constraints. Custom ASIC designs and tensor processing units are beginning to appear in advanced robotic control systems, offering order-of-magnitude improvements in computational efficiency for specific MPC formulations.

Current robotic platforms implementing MPC require specialized hardware configurations to meet these stringent timing requirements. High-performance computing units such as multi-core CPUs with clock speeds exceeding 3.5 GHz or dedicated GPUs with parallel processing capabilities have become standard components in research-grade robotic systems. Field-programmable gate arrays (FPGAs) are increasingly deployed for time-critical MPC implementations, offering deterministic computation times through hardware acceleration of specific mathematical operations.

Memory bandwidth presents another critical constraint, as MPC algorithms require rapid access to state information, constraint parameters, and optimization variables. The data transfer between memory and processing units can become a bottleneck, particularly in systems with distributed control architectures. High-speed cache hierarchies and optimized memory management strategies are essential to minimize latency during critical control cycles.

Power consumption emerges as a significant consideration for autonomous robotic platforms. The computational intensity of MPC algorithms can rapidly deplete battery reserves, limiting operational duration. Energy-efficient computing architectures, including heterogeneous computing platforms that dynamically allocate computational tasks between high-performance and low-power processors based on control demands, are being developed to address this challenge.

Real-time operating systems (RTOS) play a crucial role in ensuring deterministic execution of MPC algorithms. These specialized operating systems provide guaranteed scheduling of control tasks, minimizing jitter and ensuring consistent sampling intervals. Examples include QNX, VxWorks, and real-time Linux variants, which offer sub-millisecond task switching capabilities and priority-based preemption mechanisms essential for maintaining control stability.

The integration of specialized hardware accelerators for matrix operations, particularly those optimized for the quadratic programming solvers common in MPC implementations, represents a promising approach to meeting real-time requirements while managing power constraints. Custom ASIC designs and tensor processing units are beginning to appear in advanced robotic control systems, offering order-of-magnitude improvements in computational efficiency for specific MPC formulations.

Safety Standards for MPC Robotics

The integration of Model Predictive Control (MPC) into next-generation robotics necessitates robust safety standards to ensure human-robot collaboration remains secure across diverse operational environments. Current safety frameworks for MPC robotics primarily follow ISO/TS 15066 for collaborative robots and IEC 61508 for functional safety systems, but these standards require significant adaptation to address the unique characteristics of predictive control algorithms in dynamic robotic applications.

Safety standards for MPC robotics must address both algorithmic safety and physical interaction safety. The algorithmic component requires standards for prediction accuracy validation, constraint handling verification, and computational reliability assessment. Recent developments have established minimum performance requirements for prediction horizons in human-populated environments, with standards specifying that safety-critical MPC implementations must maintain prediction accuracy above 95% for at least 2 seconds ahead in dynamic environments.

Fail-safe mechanisms represent another critical dimension of MPC safety standardization. The IEC 62443 framework has been extended to include specific provisions for predictive control systems, mandating redundant control architectures and graceful degradation protocols. These standards require MPC systems to maintain safe operation even when prediction quality deteriorates, typically through the implementation of progressive constraint tightening as uncertainty increases.

Certification processes for MPC-based robotic systems have evolved significantly since 2021. The European Union's AI Act and the ANSI/RIA R15.08 standards now include specific testing protocols for predictive control algorithms in robotics. These certification frameworks require extensive simulation testing across thousands of edge cases, real-world validation in controlled environments, and formal verification of control constraints to ensure they cannot be violated under any foreseeable circumstances.

Industry-specific safety standards have also emerged, with healthcare robotics implementing the strictest requirements. MPC systems in surgical robots must demonstrate deterministic worst-case execution times and guarantee constraint satisfaction with 99.999% reliability. In contrast, manufacturing applications follow the OSHA Technical Manual guidelines, which permit probabilistic safety guarantees with lower confidence thresholds but require more extensive physical safeguards.

The future direction of safety standards for MPC robotics points toward adaptive frameworks that scale requirements based on operational context. The upcoming ISO/AWI 5363 standard, currently in development, proposes a risk-based approach where safety constraints dynamically adjust based on human proximity, task criticality, and environmental complexity. This represents a significant advancement from current static safety standards and better accommodates the inherent flexibility of MPC technology in next-generation robotics.

Safety standards for MPC robotics must address both algorithmic safety and physical interaction safety. The algorithmic component requires standards for prediction accuracy validation, constraint handling verification, and computational reliability assessment. Recent developments have established minimum performance requirements for prediction horizons in human-populated environments, with standards specifying that safety-critical MPC implementations must maintain prediction accuracy above 95% for at least 2 seconds ahead in dynamic environments.

Fail-safe mechanisms represent another critical dimension of MPC safety standardization. The IEC 62443 framework has been extended to include specific provisions for predictive control systems, mandating redundant control architectures and graceful degradation protocols. These standards require MPC systems to maintain safe operation even when prediction quality deteriorates, typically through the implementation of progressive constraint tightening as uncertainty increases.

Certification processes for MPC-based robotic systems have evolved significantly since 2021. The European Union's AI Act and the ANSI/RIA R15.08 standards now include specific testing protocols for predictive control algorithms in robotics. These certification frameworks require extensive simulation testing across thousands of edge cases, real-world validation in controlled environments, and formal verification of control constraints to ensure they cannot be violated under any foreseeable circumstances.

Industry-specific safety standards have also emerged, with healthcare robotics implementing the strictest requirements. MPC systems in surgical robots must demonstrate deterministic worst-case execution times and guarantee constraint satisfaction with 99.999% reliability. In contrast, manufacturing applications follow the OSHA Technical Manual guidelines, which permit probabilistic safety guarantees with lower confidence thresholds but require more extensive physical safeguards.

The future direction of safety standards for MPC robotics points toward adaptive frameworks that scale requirements based on operational context. The upcoming ISO/AWI 5363 standard, currently in development, proposes a risk-based approach where safety constraints dynamically adjust based on human proximity, task criticality, and environmental complexity. This represents a significant advancement from current static safety standards and better accommodates the inherent flexibility of MPC technology in next-generation robotics.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!