Model Predictive Control In Human-Centric Automation

SEP 9, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

MPC Technology Background and Objectives

Model Predictive Control (MPC) has evolved significantly since its inception in the 1970s, initially developed for process industries where its ability to handle complex, multivariable systems with constraints proved invaluable. The technology has undergone substantial transformation, from theoretical frameworks to practical implementations across diverse sectors, with human-centric automation emerging as a frontier application area in recent years.

The evolution of MPC in human-centric contexts represents a paradigm shift from traditional automation approaches that often treated humans as external elements to the control system. Modern MPC frameworks increasingly recognize humans as integral components within the control loop, necessitating models that account for human behavior, preferences, and limitations. This integration has been accelerated by advances in computational capabilities, allowing for real-time implementation of increasingly sophisticated predictive models.

Current technological trajectories indicate a convergence of MPC with artificial intelligence and machine learning techniques, enabling more accurate prediction of human intentions and responses. This convergence facilitates adaptive control strategies that can dynamically adjust to individual human characteristics and changing environmental conditions, representing a significant advancement from earlier static approaches.

The primary objective of MPC in human-centric automation is to develop control systems that can seamlessly collaborate with humans, enhancing human capabilities while respecting human autonomy and decision-making authority. This involves creating predictive models that can anticipate human actions, preferences, and limitations with sufficient accuracy to enable effective human-machine collaboration.

Secondary objectives include improving system safety through predictive risk assessment and mitigation, enhancing operational efficiency by optimizing the division of tasks between humans and automated systems, and increasing user acceptance through responsive and intuitive interaction paradigms. These objectives collectively contribute to the overarching goal of creating automation systems that augment human capabilities rather than replacing them.

Technical challenges being addressed include developing accurate models of human behavior under various conditions, implementing computationally efficient algorithms for real-time prediction and control, and designing robust systems that can handle the inherent unpredictability of human actions. The field is also exploring ethical considerations related to human autonomy, privacy, and the appropriate balance of control between humans and automated systems.

The anticipated trajectory for MPC in human-centric automation points toward increasingly personalized systems that can adapt to individual users, context-aware controllers that can interpret and respond to complex situations, and collaborative frameworks that enable fluid handovers of control between humans and automated systems based on dynamic assessment of capabilities and needs.

The evolution of MPC in human-centric contexts represents a paradigm shift from traditional automation approaches that often treated humans as external elements to the control system. Modern MPC frameworks increasingly recognize humans as integral components within the control loop, necessitating models that account for human behavior, preferences, and limitations. This integration has been accelerated by advances in computational capabilities, allowing for real-time implementation of increasingly sophisticated predictive models.

Current technological trajectories indicate a convergence of MPC with artificial intelligence and machine learning techniques, enabling more accurate prediction of human intentions and responses. This convergence facilitates adaptive control strategies that can dynamically adjust to individual human characteristics and changing environmental conditions, representing a significant advancement from earlier static approaches.

The primary objective of MPC in human-centric automation is to develop control systems that can seamlessly collaborate with humans, enhancing human capabilities while respecting human autonomy and decision-making authority. This involves creating predictive models that can anticipate human actions, preferences, and limitations with sufficient accuracy to enable effective human-machine collaboration.

Secondary objectives include improving system safety through predictive risk assessment and mitigation, enhancing operational efficiency by optimizing the division of tasks between humans and automated systems, and increasing user acceptance through responsive and intuitive interaction paradigms. These objectives collectively contribute to the overarching goal of creating automation systems that augment human capabilities rather than replacing them.

Technical challenges being addressed include developing accurate models of human behavior under various conditions, implementing computationally efficient algorithms for real-time prediction and control, and designing robust systems that can handle the inherent unpredictability of human actions. The field is also exploring ethical considerations related to human autonomy, privacy, and the appropriate balance of control between humans and automated systems.

The anticipated trajectory for MPC in human-centric automation points toward increasingly personalized systems that can adapt to individual users, context-aware controllers that can interpret and respond to complex situations, and collaborative frameworks that enable fluid handovers of control between humans and automated systems based on dynamic assessment of capabilities and needs.

Human-Centric Automation Market Analysis

The human-centric automation market is experiencing significant growth driven by the increasing need for collaborative systems that enhance human capabilities rather than replace them. Current market valuations indicate that the global human-centric automation sector reached approximately 25 billion USD in 2022, with projections suggesting a compound annual growth rate of 18-20% through 2030. This growth trajectory is particularly pronounced in manufacturing, healthcare, and service industries where human-machine collaboration delivers the highest value.

Market demand is primarily fueled by three key factors: workforce demographic shifts, increasing complexity of production processes, and heightened focus on workplace safety and ergonomics. As aging workforces become prevalent in developed economies, human-centric automation solutions that augment worker capabilities are becoming essential for maintaining productivity levels while reducing physical strain on employees.

Regional analysis reveals distinct market characteristics across different geographies. North America currently leads in market share at approximately 38%, driven by early adoption in advanced manufacturing and healthcare sectors. Europe follows at 32%, with particularly strong implementation in automotive and precision manufacturing industries where human expertise remains irreplaceable but can be significantly enhanced through predictive control systems.

The Asia-Pacific region represents the fastest-growing market segment with 24% annual growth, primarily led by Japan, South Korea, and increasingly China, where labor shortages and quality demands are accelerating adoption. These markets show particular interest in Model Predictive Control (MPC) systems that can adapt to human operator behaviors and preferences in real-time.

Industry-specific demand patterns indicate that manufacturing currently accounts for 45% of market applications, with automotive and electronics subsectors showing the highest implementation rates. Healthcare applications represent 22% of the market, with surgical assistance and rehabilitation systems demonstrating the most promising growth potential for MPC technologies.

Customer requirements analysis reveals a clear shift toward systems offering greater adaptability and personalization. End-users increasingly demand automation solutions that can learn from human operators, predict their intentions, and adjust parameters accordingly. This represents a significant departure from traditional automation approaches and aligns perfectly with the capabilities of advanced MPC frameworks in human-centric applications.

Market barriers include high implementation costs, integration challenges with legacy systems, and concerns regarding data privacy when human behavioral patterns are monitored and analyzed. Additionally, regulatory frameworks governing human-machine collaboration are still evolving in many jurisdictions, creating uncertainty that may temporarily slow adoption rates in certain sectors.

Market demand is primarily fueled by three key factors: workforce demographic shifts, increasing complexity of production processes, and heightened focus on workplace safety and ergonomics. As aging workforces become prevalent in developed economies, human-centric automation solutions that augment worker capabilities are becoming essential for maintaining productivity levels while reducing physical strain on employees.

Regional analysis reveals distinct market characteristics across different geographies. North America currently leads in market share at approximately 38%, driven by early adoption in advanced manufacturing and healthcare sectors. Europe follows at 32%, with particularly strong implementation in automotive and precision manufacturing industries where human expertise remains irreplaceable but can be significantly enhanced through predictive control systems.

The Asia-Pacific region represents the fastest-growing market segment with 24% annual growth, primarily led by Japan, South Korea, and increasingly China, where labor shortages and quality demands are accelerating adoption. These markets show particular interest in Model Predictive Control (MPC) systems that can adapt to human operator behaviors and preferences in real-time.

Industry-specific demand patterns indicate that manufacturing currently accounts for 45% of market applications, with automotive and electronics subsectors showing the highest implementation rates. Healthcare applications represent 22% of the market, with surgical assistance and rehabilitation systems demonstrating the most promising growth potential for MPC technologies.

Customer requirements analysis reveals a clear shift toward systems offering greater adaptability and personalization. End-users increasingly demand automation solutions that can learn from human operators, predict their intentions, and adjust parameters accordingly. This represents a significant departure from traditional automation approaches and aligns perfectly with the capabilities of advanced MPC frameworks in human-centric applications.

Market barriers include high implementation costs, integration challenges with legacy systems, and concerns regarding data privacy when human behavioral patterns are monitored and analyzed. Additionally, regulatory frameworks governing human-machine collaboration are still evolving in many jurisdictions, creating uncertainty that may temporarily slow adoption rates in certain sectors.

Current MPC Implementation Challenges

Despite the proven effectiveness of Model Predictive Control (MPC) in human-centric automation systems, several significant implementation challenges persist. The computational complexity of MPC algorithms remains a primary obstacle, particularly in real-time applications where human interaction requires rapid response. Current implementations often struggle with the optimization problem's computational burden, leading to latency issues that can compromise the seamless integration of human and automated systems.

The requirement for accurate system models presents another substantial challenge. Human behavior is inherently variable and difficult to model mathematically, resulting in prediction uncertainties that can undermine MPC performance. Current approaches often rely on simplified human models that fail to capture the full complexity of human decision-making processes, intentions, and reactions to automated systems.

Robustness concerns further complicate MPC implementation in human-centric contexts. Environmental disturbances, sensor noise, and human unpredictability can lead to significant deviations from predicted outcomes. Many existing MPC frameworks lack sufficient robustness guarantees when operating in dynamic environments with human participants, potentially leading to safety concerns or suboptimal performance.

The balance between computational efficiency and control performance represents a persistent trade-off. Simplified MPC formulations may execute faster but sacrifice prediction accuracy and control quality. Conversely, more sophisticated algorithms that better account for human factors often demand excessive computational resources, limiting their practical application in consumer-grade systems or resource-constrained environments.

Integration challenges with existing infrastructure also impede widespread adoption. Many current industrial and consumer systems were not designed with advanced control algorithms in mind, creating compatibility issues when implementing MPC solutions. Legacy systems often lack the necessary sensing capabilities, computational resources, or communication protocols required for effective MPC deployment in human-interactive scenarios.

Tuning and parameter selection for MPC controllers remains largely heuristic and application-specific. The multitude of design parameters—prediction horizon, control horizon, weighting matrices, and constraint formulations—creates a vast design space that is difficult to navigate systematically. This challenge is amplified in human-centric applications where the optimal parameter configuration may vary based on individual human characteristics and preferences.

Finally, validation and verification methodologies for human-centric MPC systems remain underdeveloped. Current testing approaches struggle to comprehensively evaluate system performance across the full spectrum of potential human-automation interaction scenarios, limiting confidence in system reliability and safety in real-world deployments.

The requirement for accurate system models presents another substantial challenge. Human behavior is inherently variable and difficult to model mathematically, resulting in prediction uncertainties that can undermine MPC performance. Current approaches often rely on simplified human models that fail to capture the full complexity of human decision-making processes, intentions, and reactions to automated systems.

Robustness concerns further complicate MPC implementation in human-centric contexts. Environmental disturbances, sensor noise, and human unpredictability can lead to significant deviations from predicted outcomes. Many existing MPC frameworks lack sufficient robustness guarantees when operating in dynamic environments with human participants, potentially leading to safety concerns or suboptimal performance.

The balance between computational efficiency and control performance represents a persistent trade-off. Simplified MPC formulations may execute faster but sacrifice prediction accuracy and control quality. Conversely, more sophisticated algorithms that better account for human factors often demand excessive computational resources, limiting their practical application in consumer-grade systems or resource-constrained environments.

Integration challenges with existing infrastructure also impede widespread adoption. Many current industrial and consumer systems were not designed with advanced control algorithms in mind, creating compatibility issues when implementing MPC solutions. Legacy systems often lack the necessary sensing capabilities, computational resources, or communication protocols required for effective MPC deployment in human-interactive scenarios.

Tuning and parameter selection for MPC controllers remains largely heuristic and application-specific. The multitude of design parameters—prediction horizon, control horizon, weighting matrices, and constraint formulations—creates a vast design space that is difficult to navigate systematically. This challenge is amplified in human-centric applications where the optimal parameter configuration may vary based on individual human characteristics and preferences.

Finally, validation and verification methodologies for human-centric MPC systems remain underdeveloped. Current testing approaches struggle to comprehensively evaluate system performance across the full spectrum of potential human-automation interaction scenarios, limiting confidence in system reliability and safety in real-world deployments.

Human-Machine Interaction Control Frameworks

01 Industrial Process Control Applications

Model Predictive Control (MPC) is widely applied in industrial processes to optimize operations and improve efficiency. These systems use mathematical models to predict future behavior of processes and calculate optimal control actions. MPC algorithms can handle complex constraints and multiple variables simultaneously, making them particularly valuable in manufacturing, chemical processing, and energy production where precise control is critical for product quality and operational safety.- Industrial process control applications: Model Predictive Control (MPC) is widely applied in industrial processes to optimize operations and improve efficiency. These systems use mathematical models to predict future behavior of processes and calculate optimal control actions. MPC algorithms can handle complex constraints and multiple variables simultaneously, making them suitable for manufacturing, chemical processing, and other industrial applications where precise control is critical.

- Energy management and optimization: MPC techniques are implemented in energy management systems to optimize consumption, reduce costs, and enhance sustainability. These controllers predict energy demands and adjust operations accordingly, balancing efficiency with performance requirements. Applications include building climate control, power grid management, and renewable energy integration, where the predictive capabilities help manage intermittent energy sources and varying demand patterns.

- Automotive and transportation systems: In automotive applications, MPC algorithms enhance vehicle performance, safety, and efficiency. These controllers optimize engine operation, transmission shifting, and vehicle dynamics by predicting future states based on current conditions and driver inputs. Advanced driver assistance systems and autonomous vehicles particularly benefit from MPC's ability to handle multiple objectives simultaneously while respecting physical constraints and safety requirements.

- Machine learning integration with MPC: Modern MPC implementations increasingly incorporate machine learning techniques to enhance model accuracy and adaptability. These hybrid approaches combine traditional model-based control with data-driven methods to improve performance in complex or changing environments. Neural networks and other AI techniques help identify system dynamics that are difficult to model mathematically, allowing the controller to adapt to changing conditions or system degradation over time.

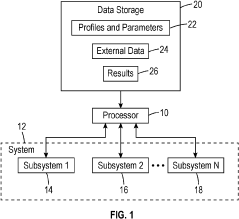

- Distributed and networked MPC systems: Distributed MPC architectures enable control of large-scale interconnected systems by dividing the control problem into smaller, manageable subsystems that communicate with each other. This approach improves scalability, robustness, and computational efficiency compared to centralized control. Applications include smart grids, water distribution networks, and large industrial complexes where multiple subsystems must coordinate while maintaining local autonomy and respecting communication constraints.

02 Advanced Vehicle Control Systems

Model Predictive Control is increasingly implemented in automotive applications for enhanced vehicle performance and safety. These systems predict vehicle behavior based on current states and environmental conditions to optimize driving parameters. MPC algorithms enable more precise control of engine performance, transmission systems, and autonomous driving functions. The predictive nature allows vehicles to anticipate changes in road conditions or traffic patterns and adjust accordingly, improving fuel efficiency and reducing emissions.Expand Specific Solutions03 Energy Management and Optimization

Model Predictive Control provides significant advantages in energy management systems by optimizing resource allocation and consumption patterns. These controllers can predict energy demands based on historical data and external factors such as weather conditions. MPC algorithms help balance supply and demand in power grids, manage renewable energy integration, and optimize building climate control systems. The approach enables more efficient energy use while maintaining desired performance levels and accommodating constraints like equipment limitations.Expand Specific Solutions04 Adaptive and Learning-Based MPC

Advanced implementations of Model Predictive Control incorporate adaptive learning capabilities to improve performance over time. These systems can update their internal models based on observed system responses, enabling them to adapt to changing conditions or system degradation. Machine learning techniques are increasingly integrated with MPC to enhance prediction accuracy and control robustness. This approach is particularly valuable in systems with uncertain parameters or those operating in variable environments where traditional fixed models might be insufficient.Expand Specific Solutions05 Distributed and Networked MPC Systems

Distributed Model Predictive Control architectures enable coordination of multiple interconnected subsystems while maintaining computational efficiency. These approaches divide complex control problems into smaller, more manageable components that can operate semi-independently while still achieving global optimization objectives. Networked MPC systems can handle communication delays and data loss while maintaining stability and performance. This architecture is particularly valuable for large-scale applications such as smart grids, water distribution networks, and manufacturing facilities with multiple interacting processes.Expand Specific Solutions

Leading MPC Solution Providers

Model Predictive Control in Human-Centric Automation is currently in a growth phase, with the market expected to reach significant expansion due to increasing demand for intelligent control systems. The competitive landscape features established automotive players like Toyota, Nissan, and ZF Friedrichshafen developing human-machine interfaces, alongside technology giants such as NVIDIA and NEC providing computational platforms. Industrial automation leaders including Honeywell, Mitsubishi Electric, and Fisher-Rosemount are integrating MPC into human-collaborative systems. The technology is approaching maturity in certain applications but remains evolving in complex human-interaction scenarios, with research institutions like Beijing Institute of Technology and Shanghai Jiao Tong University advancing theoretical frameworks while companies focus on practical implementations.

NVIDIA Corp.

Technical Solution: NVIDIA has developed advanced Model Predictive Control (MPC) frameworks specifically designed for human-centric automation systems. Their approach integrates GPU-accelerated computing with deep learning to enable real-time MPC implementations that can adapt to human behaviors. NVIDIA's DRIVE platform incorporates MPC algorithms that predict human intentions and adjust vehicle control accordingly, creating a more natural human-machine interaction. The company's Isaac robotics platform also leverages MPC for collaborative robots that work alongside humans in manufacturing environments. NVIDIA's technology enables processing complex optimization problems in milliseconds rather than seconds, allowing for responsive human-machine collaboration. Their MPC implementations utilize parallel computing architectures to solve multiple prediction scenarios simultaneously, enabling the system to anticipate various human actions and respond appropriately.

Strengths: Superior computational power through GPU acceleration enables complex real-time MPC implementations; comprehensive software stack integration with AI frameworks enhances human behavior prediction. Weaknesses: High hardware requirements may increase implementation costs; dependency on substantial training data for human behavior modeling may limit effectiveness in novel situations.

Fisher-Rosemount Systems, Inc.

Technical Solution: Fisher-Rosemount (now part of Emerson) has developed DeltaV Predict, an advanced MPC platform specifically designed for human-centric process automation. Their approach focuses on making complex MPC technology accessible to human operators through intuitive interfaces and transparent decision-making processes. The DeltaV Predict system incorporates human-in-the-loop MPC algorithms that continuously optimize processes while allowing operator intervention and adjustment. Their technology includes adaptive models that learn from both process data and operator actions, gradually aligning automated control strategies with expert human approaches. Fisher-Rosemount's MPC implementation features "human-readable" constraint handling, where the system can explain its decisions and predicted outcomes to operators in understandable terms. Their collaborative control framework enables a spectrum of automation levels, from advisory-only to fully autonomous operation, with seamless transitions between modes based on situation complexity and operator preference.

Strengths: Highly intuitive operator interfaces reduce training requirements and improve human-automation collaboration; extensive process industry experience enables practical, field-proven implementations. Weaknesses: Primary focus on process industries may limit applicability in other domains; systems typically require significant engineering effort during initial implementation.

Key Patents in Predictive Human-Machine Control

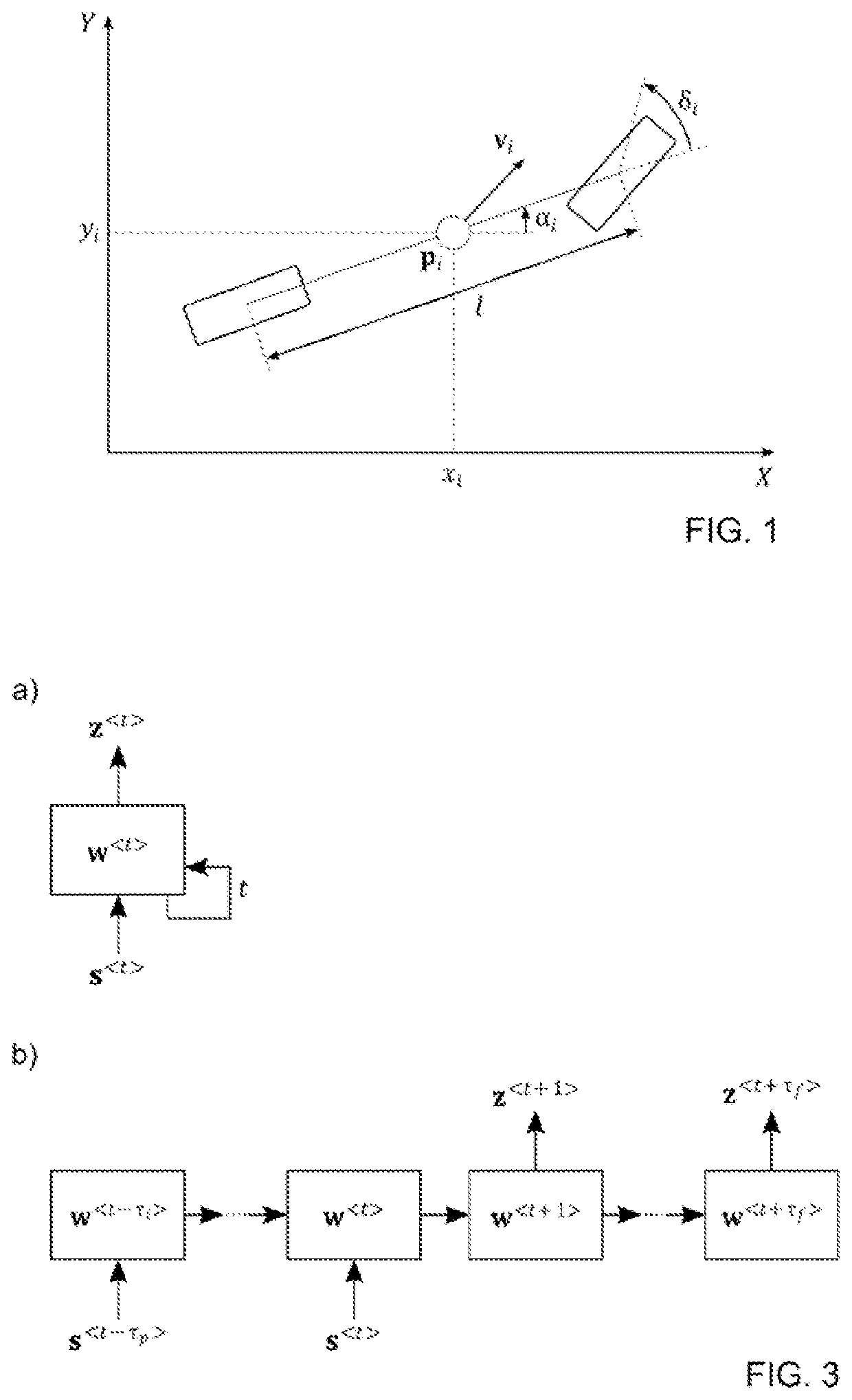

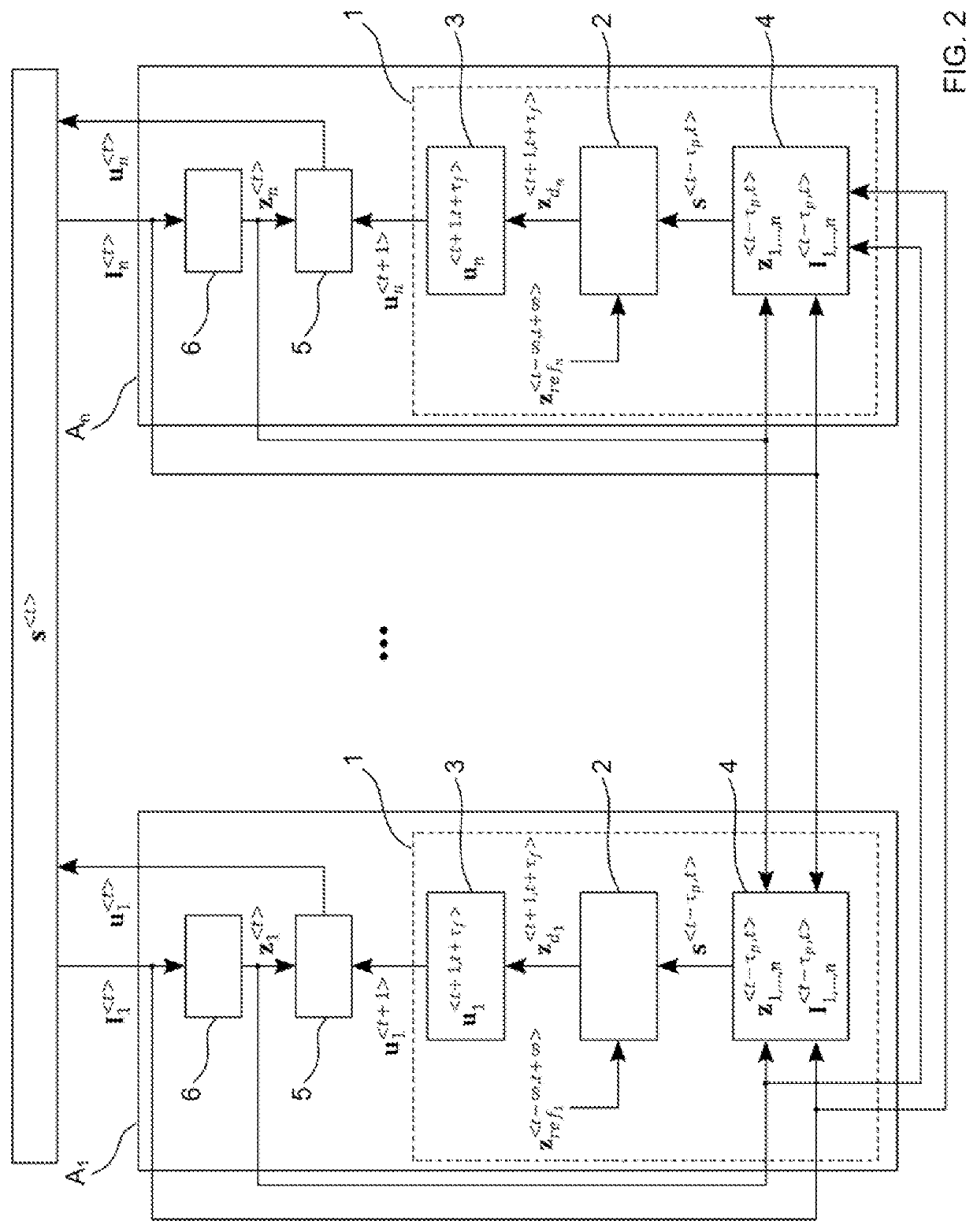

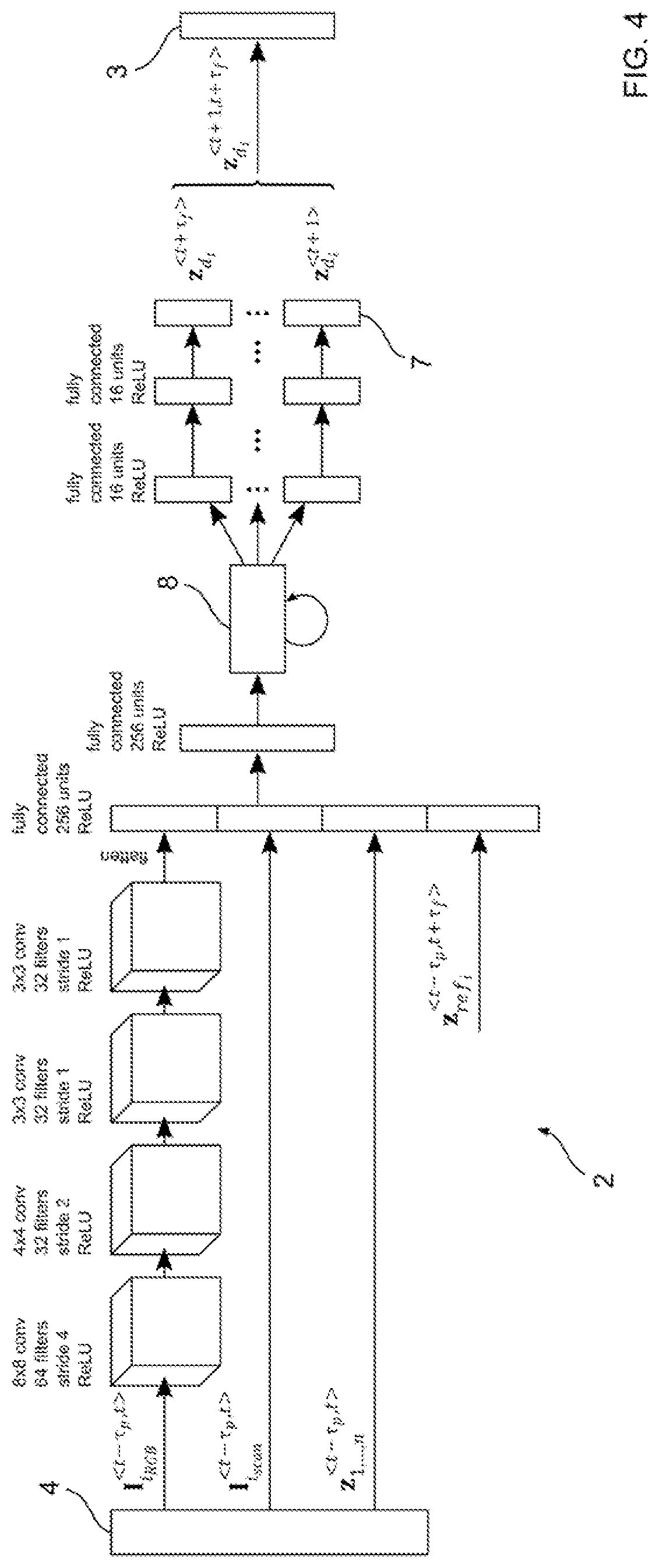

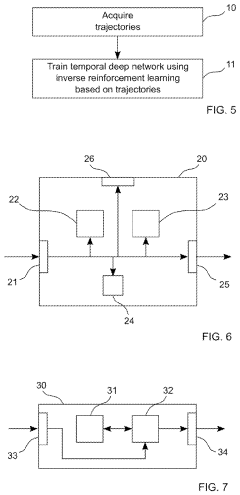

Deep learning based motion control of a group of autonomous vehicles

PatentActiveUS20210171024A1

Innovation

- A controller utilizing a temporal deep network and nonlinear model predictive control, integrated with an augmented memory for historic system states, to estimate optimal trajectories and compute commands while ensuring collision avoidance, leveraging long short-term memory recurrent neural networks and inverse reinforcement learning for training.

Deep causal learning for advanced model predictive control

PatentPendingUS20230060325A1

Innovation

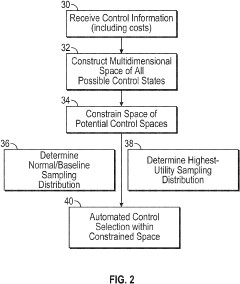

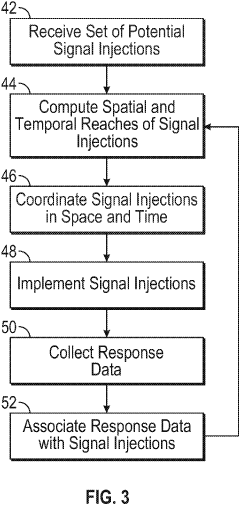

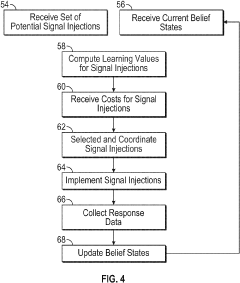

- Deep Causal Learning (DCL) introduces randomized controlled signals to subsystems, computes confidence intervals for causal relationships, and uses time-varying Jacobian and Hessian matrices to predict optimal control moves, accounting for non-linearities and temporal dynamics, thereby refining the internal model for MPC.

Human Factors in Control System Design

Human factors engineering represents a critical dimension in the development of Model Predictive Control (MPC) systems for human-centric automation. The integration of human cognitive capabilities, limitations, and behavioral patterns into control system design ensures that automated systems complement rather than conflict with human operators. This consideration becomes particularly important as MPC applications expand into domains with significant human interaction, such as autonomous vehicles, smart buildings, and collaborative robotics.

Effective human-centered MPC design begins with understanding the cognitive load placed on operators. Research indicates that humans can effectively monitor 7±2 variables simultaneously, suggesting that control interfaces should prioritize critical parameters while abstracting less essential information. Studies by Endsley and Kieras demonstrate that situational awareness decreases exponentially as system complexity increases, highlighting the need for thoughtful information presentation in MPC implementations.

Transparency in control logic represents another crucial aspect of human factors in MPC design. Users must understand not only what the system is doing but also why specific actions are being taken. This transparency builds trust and facilitates appropriate intervention when necessary. Recent work by Shneiderman and Norman emphasizes the importance of "explainable control" - providing users with clear mental models of system behavior without overwhelming them with technical details.

The allocation of control authority between human operators and automated systems presents significant design challenges. Adaptive automation approaches, where control authority shifts dynamically based on context, have shown promise in maintaining optimal system performance while keeping humans meaningfully engaged. Research by Parasuraman and Sheridan suggests that MPC systems should incorporate variable autonomy levels, allowing seamless transitions between human and machine control based on situational demands and operator workload.

Human error prediction and prevention mechanisms must be integrated into MPC frameworks. By modeling typical error patterns and implementing appropriate safeguards, systems can prevent potentially dangerous situations. Techniques such as boundary prediction, where the system forecasts when operations might approach unsafe conditions, allow for preemptive alerts or interventions before critical thresholds are crossed.

Feedback mechanisms in human-centric MPC must balance informativeness with cognitive accessibility. Multi-modal feedback (visual, auditory, and haptic) has demonstrated effectiveness in conveying system status without overwhelming operators. The timing of feedback is equally important - predictive displays that show anticipated system trajectories enable operators to understand future states and make informed decisions about potential interventions.

Effective human-centered MPC design begins with understanding the cognitive load placed on operators. Research indicates that humans can effectively monitor 7±2 variables simultaneously, suggesting that control interfaces should prioritize critical parameters while abstracting less essential information. Studies by Endsley and Kieras demonstrate that situational awareness decreases exponentially as system complexity increases, highlighting the need for thoughtful information presentation in MPC implementations.

Transparency in control logic represents another crucial aspect of human factors in MPC design. Users must understand not only what the system is doing but also why specific actions are being taken. This transparency builds trust and facilitates appropriate intervention when necessary. Recent work by Shneiderman and Norman emphasizes the importance of "explainable control" - providing users with clear mental models of system behavior without overwhelming them with technical details.

The allocation of control authority between human operators and automated systems presents significant design challenges. Adaptive automation approaches, where control authority shifts dynamically based on context, have shown promise in maintaining optimal system performance while keeping humans meaningfully engaged. Research by Parasuraman and Sheridan suggests that MPC systems should incorporate variable autonomy levels, allowing seamless transitions between human and machine control based on situational demands and operator workload.

Human error prediction and prevention mechanisms must be integrated into MPC frameworks. By modeling typical error patterns and implementing appropriate safeguards, systems can prevent potentially dangerous situations. Techniques such as boundary prediction, where the system forecasts when operations might approach unsafe conditions, allow for preemptive alerts or interventions before critical thresholds are crossed.

Feedback mechanisms in human-centric MPC must balance informativeness with cognitive accessibility. Multi-modal feedback (visual, auditory, and haptic) has demonstrated effectiveness in conveying system status without overwhelming operators. The timing of feedback is equally important - predictive displays that show anticipated system trajectories enable operators to understand future states and make informed decisions about potential interventions.

Safety Standards for Human-Centric Automation

The integration of human-centric automation systems necessitates robust safety standards to protect human operators and ensure reliable system performance. International safety standards such as ISO 13482:2014 specifically address personal care robots and human-robot interactions, establishing fundamental requirements for risk assessment and mitigation in collaborative environments. These standards emphasize the importance of predictable system behavior, which aligns perfectly with the principles of Model Predictive Control (MPC) methodologies.

Safety standards for human-centric automation typically require multi-layered protection mechanisms. The primary layer involves inherent safe design principles, where MPC contributes significantly by providing predictive capabilities that anticipate potential hazards before they materialize. The second layer includes protective measures such as safety-rated monitored stops and speed reduction when humans enter collaborative workspaces. The third layer consists of information for use, including training and warning systems.

IEC 61508 and its derivatives provide frameworks for functional safety of electrical/electronic/programmable electronic safety-related systems. When implementing MPC in human-centric automation, these standards require quantifiable reliability metrics such as Safety Integrity Levels (SILs). MPC algorithms must demonstrate deterministic behavior and fail-safe mechanisms to achieve appropriate SIL certification, particularly challenging given the complex mathematical optimization processes involved.

Recent developments in safety standards acknowledge the increasing sophistication of control algorithms. ISO/TS 15066:2016 for collaborative robots introduces concepts like power and force limiting, which can be effectively implemented through MPC frameworks that optimize control actions while respecting safety constraints. Similarly, ANSI/RIA R15.06-2012 provides guidelines for industrial robots and robot systems, emphasizing risk assessment methodologies compatible with predictive control approaches.

The emergence of AI-enhanced MPC systems has prompted regulatory bodies to develop new standards addressing autonomous decision-making. The IEEE P7009 standard for fail-safe design of autonomous systems directly impacts how MPC algorithms must be designed to ensure graceful degradation during system failures. Additionally, IEC 63243 (under development) specifically addresses AI applications in safety-critical systems, with implications for learning-based MPC implementations.

Compliance with these safety standards requires rigorous verification and validation processes. For MPC implementations, this includes formal methods to prove constraint satisfaction under all operating conditions, extensive simulation testing across the operational envelope, and hardware-in-the-loop validation. Documentation requirements are particularly stringent, demanding traceability between safety requirements and control algorithm specifications.

Safety standards for human-centric automation typically require multi-layered protection mechanisms. The primary layer involves inherent safe design principles, where MPC contributes significantly by providing predictive capabilities that anticipate potential hazards before they materialize. The second layer includes protective measures such as safety-rated monitored stops and speed reduction when humans enter collaborative workspaces. The third layer consists of information for use, including training and warning systems.

IEC 61508 and its derivatives provide frameworks for functional safety of electrical/electronic/programmable electronic safety-related systems. When implementing MPC in human-centric automation, these standards require quantifiable reliability metrics such as Safety Integrity Levels (SILs). MPC algorithms must demonstrate deterministic behavior and fail-safe mechanisms to achieve appropriate SIL certification, particularly challenging given the complex mathematical optimization processes involved.

Recent developments in safety standards acknowledge the increasing sophistication of control algorithms. ISO/TS 15066:2016 for collaborative robots introduces concepts like power and force limiting, which can be effectively implemented through MPC frameworks that optimize control actions while respecting safety constraints. Similarly, ANSI/RIA R15.06-2012 provides guidelines for industrial robots and robot systems, emphasizing risk assessment methodologies compatible with predictive control approaches.

The emergence of AI-enhanced MPC systems has prompted regulatory bodies to develop new standards addressing autonomous decision-making. The IEEE P7009 standard for fail-safe design of autonomous systems directly impacts how MPC algorithms must be designed to ensure graceful degradation during system failures. Additionally, IEC 63243 (under development) specifically addresses AI applications in safety-critical systems, with implications for learning-based MPC implementations.

Compliance with these safety standards requires rigorous verification and validation processes. For MPC implementations, this includes formal methods to prove constraint satisfaction under all operating conditions, extensive simulation testing across the operational envelope, and hardware-in-the-loop validation. Documentation requirements are particularly stringent, demanding traceability between safety requirements and control algorithm specifications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!