Model Predictive Control In Space Robotics Systems

SEP 9, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Space Robotics MPC Background and Objectives

Model Predictive Control (MPC) has emerged as a pivotal control methodology in space robotics systems over the past three decades. Initially developed for process industries in the 1970s, MPC has evolved significantly to address the unique challenges of space environments. The technology's trajectory shows a clear shift from theoretical frameworks to practical implementations aboard spacecraft and robotic systems operating in orbit and on planetary surfaces.

Space robotics systems face unprecedented control challenges including extreme environmental conditions, significant communication delays, limited computational resources, and the need for autonomous operation. These factors have driven the development of specialized MPC algorithms capable of handling the complex dynamics and constraints inherent in space operations.

The evolution of MPC in space applications has been marked by several key milestones. Early implementations focused on basic trajectory control, while contemporary systems incorporate advanced features such as robust uncertainty handling, fault tolerance, and real-time optimization capabilities. The integration of machine learning techniques with traditional MPC frameworks represents the cutting edge of current development efforts.

Current technical objectives for MPC in space robotics center around enhancing autonomy, improving computational efficiency, and increasing robustness against environmental uncertainties. Researchers aim to develop control systems capable of making optimal decisions with minimal human intervention, particularly for missions where communication delays make real-time Earth-based control impractical.

A significant goal is the development of MPC algorithms that can effectively balance multiple competing objectives such as fuel efficiency, mission time, safety constraints, and task completion. This multi-objective optimization represents a fundamental challenge in the field, particularly when operating under the severe resource constraints typical of space missions.

Another critical objective is the seamless integration of MPC with other spacecraft systems, including guidance, navigation, and fault detection mechanisms. This system-level integration is essential for achieving the high reliability standards required for space operations.

Looking forward, the field is moving toward predictive controllers capable of handling increasingly complex maneuvers such as autonomous docking, orbital assembly, and coordinated multi-robot operations. These applications demand advances in both theoretical frameworks and practical implementation techniques.

The technical trajectory suggests that future MPC systems for space robotics will increasingly incorporate elements of artificial intelligence, enabling more sophisticated decision-making capabilities while maintaining the formal guarantees of stability and constraint satisfaction that make MPC particularly valuable for critical space applications.

Space robotics systems face unprecedented control challenges including extreme environmental conditions, significant communication delays, limited computational resources, and the need for autonomous operation. These factors have driven the development of specialized MPC algorithms capable of handling the complex dynamics and constraints inherent in space operations.

The evolution of MPC in space applications has been marked by several key milestones. Early implementations focused on basic trajectory control, while contemporary systems incorporate advanced features such as robust uncertainty handling, fault tolerance, and real-time optimization capabilities. The integration of machine learning techniques with traditional MPC frameworks represents the cutting edge of current development efforts.

Current technical objectives for MPC in space robotics center around enhancing autonomy, improving computational efficiency, and increasing robustness against environmental uncertainties. Researchers aim to develop control systems capable of making optimal decisions with minimal human intervention, particularly for missions where communication delays make real-time Earth-based control impractical.

A significant goal is the development of MPC algorithms that can effectively balance multiple competing objectives such as fuel efficiency, mission time, safety constraints, and task completion. This multi-objective optimization represents a fundamental challenge in the field, particularly when operating under the severe resource constraints typical of space missions.

Another critical objective is the seamless integration of MPC with other spacecraft systems, including guidance, navigation, and fault detection mechanisms. This system-level integration is essential for achieving the high reliability standards required for space operations.

Looking forward, the field is moving toward predictive controllers capable of handling increasingly complex maneuvers such as autonomous docking, orbital assembly, and coordinated multi-robot operations. These applications demand advances in both theoretical frameworks and practical implementation techniques.

The technical trajectory suggests that future MPC systems for space robotics will increasingly incorporate elements of artificial intelligence, enabling more sophisticated decision-making capabilities while maintaining the formal guarantees of stability and constraint satisfaction that make MPC particularly valuable for critical space applications.

Market Analysis for MPC in Space Applications

The global market for Model Predictive Control (MPC) in space robotics systems is experiencing significant growth, driven by increasing space exploration activities and the need for autonomous robotic operations in challenging environments. Current market valuations estimate the space robotics sector at approximately 4.4 billion USD in 2023, with MPC technologies representing a growing segment within this market.

The demand for MPC solutions in space applications is primarily fueled by national space agencies such as NASA, ESA, JAXA, and CNSA, which collectively allocate substantial budgets toward advanced control systems for their missions. Commercial space companies including SpaceX, Blue Origin, and Astrobotic are also emerging as significant customers, particularly as they develop increasingly sophisticated robotic systems for orbital operations and planetary exploration.

Market analysis reveals distinct application segments where MPC technologies show particular promise. Satellite servicing represents the fastest-growing segment, with a projected annual growth rate of 17% through 2030. This includes applications such as in-orbit refueling, repair, and debris removal. Planetary rovers constitute another substantial market segment, valued at approximately 580 million USD, where MPC offers critical advantages in navigation and manipulation tasks under communication delays.

Regional market distribution shows North America leading with approximately 42% market share, followed by Europe at 28% and Asia-Pacific at 23%. The remaining 7% is distributed across other regions. This distribution closely follows the geographical concentration of space technology development capabilities and investment patterns.

Investment trends indicate increasing private capital flowing into space robotics startups focusing on MPC technologies, with venture capital funding reaching 1.2 billion USD in 2022, representing a 35% increase from the previous year. This investment surge suggests strong market confidence in the commercial potential of advanced control systems for space applications.

Customer requirements analysis shows a clear demand pattern: space agencies prioritize reliability and robustness under extreme conditions, while commercial entities place greater emphasis on cost-effectiveness and operational flexibility. Both customer segments value MPC's ability to handle complex constraints and optimize performance under uncertainty—key attributes in space environments.

Market barriers include high development costs, stringent qualification requirements for space-rated hardware, and the specialized expertise required to implement MPC algorithms for space applications. Despite these challenges, the market is expected to maintain strong growth as technological advancements reduce implementation costs and expand the range of viable applications.

The demand for MPC solutions in space applications is primarily fueled by national space agencies such as NASA, ESA, JAXA, and CNSA, which collectively allocate substantial budgets toward advanced control systems for their missions. Commercial space companies including SpaceX, Blue Origin, and Astrobotic are also emerging as significant customers, particularly as they develop increasingly sophisticated robotic systems for orbital operations and planetary exploration.

Market analysis reveals distinct application segments where MPC technologies show particular promise. Satellite servicing represents the fastest-growing segment, with a projected annual growth rate of 17% through 2030. This includes applications such as in-orbit refueling, repair, and debris removal. Planetary rovers constitute another substantial market segment, valued at approximately 580 million USD, where MPC offers critical advantages in navigation and manipulation tasks under communication delays.

Regional market distribution shows North America leading with approximately 42% market share, followed by Europe at 28% and Asia-Pacific at 23%. The remaining 7% is distributed across other regions. This distribution closely follows the geographical concentration of space technology development capabilities and investment patterns.

Investment trends indicate increasing private capital flowing into space robotics startups focusing on MPC technologies, with venture capital funding reaching 1.2 billion USD in 2022, representing a 35% increase from the previous year. This investment surge suggests strong market confidence in the commercial potential of advanced control systems for space applications.

Customer requirements analysis shows a clear demand pattern: space agencies prioritize reliability and robustness under extreme conditions, while commercial entities place greater emphasis on cost-effectiveness and operational flexibility. Both customer segments value MPC's ability to handle complex constraints and optimize performance under uncertainty—key attributes in space environments.

Market barriers include high development costs, stringent qualification requirements for space-rated hardware, and the specialized expertise required to implement MPC algorithms for space applications. Despite these challenges, the market is expected to maintain strong growth as technological advancements reduce implementation costs and expand the range of viable applications.

Current MPC Implementation Challenges in Space Robotics

Despite the significant advancements in Model Predictive Control (MPC) for space robotics, several critical implementation challenges persist that limit its widespread adoption in operational space systems. The computational burden remains a primary obstacle, as space-grade processors typically offer only a fraction of the computing power available in terrestrial applications. This limitation becomes particularly acute when implementing MPC algorithms that require solving complex optimization problems in real-time, often within milliseconds, to maintain control stability during critical maneuvers.

The harsh space environment introduces additional complications for MPC implementation. Radiation effects can cause single-event upsets in computing systems, potentially disrupting the execution of optimization algorithms. This necessitates radiation-hardened hardware which further constrains available computational resources, creating a challenging trade-off between robustness and performance.

Power constraints represent another significant challenge, as space systems operate with limited energy budgets. MPC algorithms, especially those involving iterative optimization solvers, can be power-intensive. This creates tension between control performance and power conservation, particularly for long-duration missions where energy management is critical.

Model uncertainty presents a fundamental challenge unique to space applications. The dynamics of spacecraft and robotic systems in microgravity environments are complex and can change significantly during a mission due to fuel consumption, structural flexibility, or contact with other objects. MPC performance depends heavily on model accuracy, yet obtaining precise models for space robotics remains difficult, especially when considering environmental disturbances like solar radiation pressure or gravitational perturbations.

Communication delays between ground stations and space assets further complicate MPC implementation. These delays, which can range from seconds to minutes depending on distance, make ground-based computation and control impractical for many applications, necessitating fully autonomous onboard implementation.

Verification and validation of MPC algorithms for space applications present regulatory challenges. Space agencies maintain stringent certification requirements for flight software, and the complex, often non-deterministic nature of MPC optimization solvers makes formal verification difficult compared to traditional control approaches.

Memory limitations on space-qualified hardware constrain the complexity and horizon length of implementable MPC formulations. This often forces engineers to make significant simplifications to algorithms, potentially reducing control performance or robustness.

The harsh space environment introduces additional complications for MPC implementation. Radiation effects can cause single-event upsets in computing systems, potentially disrupting the execution of optimization algorithms. This necessitates radiation-hardened hardware which further constrains available computational resources, creating a challenging trade-off between robustness and performance.

Power constraints represent another significant challenge, as space systems operate with limited energy budgets. MPC algorithms, especially those involving iterative optimization solvers, can be power-intensive. This creates tension between control performance and power conservation, particularly for long-duration missions where energy management is critical.

Model uncertainty presents a fundamental challenge unique to space applications. The dynamics of spacecraft and robotic systems in microgravity environments are complex and can change significantly during a mission due to fuel consumption, structural flexibility, or contact with other objects. MPC performance depends heavily on model accuracy, yet obtaining precise models for space robotics remains difficult, especially when considering environmental disturbances like solar radiation pressure or gravitational perturbations.

Communication delays between ground stations and space assets further complicate MPC implementation. These delays, which can range from seconds to minutes depending on distance, make ground-based computation and control impractical for many applications, necessitating fully autonomous onboard implementation.

Verification and validation of MPC algorithms for space applications present regulatory challenges. Space agencies maintain stringent certification requirements for flight software, and the complex, often non-deterministic nature of MPC optimization solvers makes formal verification difficult compared to traditional control approaches.

Memory limitations on space-qualified hardware constrain the complexity and horizon length of implementable MPC formulations. This often forces engineers to make significant simplifications to algorithms, potentially reducing control performance or robustness.

Current MPC Architectures for Space Robotics

01 Industrial process control applications

Model Predictive Control (MPC) is widely applied in industrial processes to optimize operations and improve efficiency. These systems use mathematical models to predict future behavior of processes and calculate optimal control actions. MPC algorithms can handle complex constraints and multiple variables simultaneously, making them suitable for manufacturing, chemical processing, and other industrial applications where precise control is critical.- Industrial process control applications: Model Predictive Control (MPC) is widely used in industrial process control to optimize operations while respecting constraints. These systems predict future behavior based on dynamic models and calculate optimal control actions. Applications include manufacturing, chemical processing, and energy systems where MPC helps maintain desired setpoints while minimizing resource consumption and maximizing efficiency.

- Advanced automotive control systems: Model Predictive Control is implemented in automotive applications for enhanced vehicle performance and safety. These systems use predictive models to optimize engine operation, transmission control, and vehicle dynamics. MPC algorithms enable real-time decision making for adaptive cruise control, collision avoidance, and autonomous driving features by predicting vehicle behavior and calculating optimal control actions under various constraints.

- Energy management and optimization: Model Predictive Control strategies are employed for energy management in buildings, power grids, and renewable energy systems. These controllers optimize energy consumption by predicting future demands and environmental conditions. MPC algorithms balance energy efficiency, cost reduction, and comfort requirements while managing the integration of renewable energy sources and storage systems to achieve optimal performance.

- Machine learning enhanced MPC: Integration of machine learning techniques with Model Predictive Control creates more adaptive and robust control systems. These hybrid approaches use data-driven methods to improve model accuracy and controller performance. Neural networks and other AI techniques are employed to handle nonlinearities, uncertainties, and time-varying dynamics that traditional MPC might struggle with, resulting in more efficient and responsive control systems.

- Distributed and networked MPC architectures: Distributed Model Predictive Control architectures enable coordination of multiple subsystems in large-scale applications. These frameworks allow for decentralized decision-making while maintaining overall system performance and stability. Communication protocols and coordination mechanisms ensure that individual controllers work together effectively, making them suitable for complex systems like smart grids, water networks, and large industrial processes where centralized control would be impractical.

02 Energy management and optimization

Model Predictive Control techniques are implemented in energy systems to optimize consumption, reduce costs, and improve sustainability. These controllers predict energy demands and adjust operations accordingly, balancing efficiency with performance requirements. Applications include building climate control, power grid management, and renewable energy integration, where the controller anticipates changes in conditions or demand to make proactive adjustments.Expand Specific Solutions03 Automotive and vehicle control systems

In automotive applications, Model Predictive Control enables advanced driver assistance systems and autonomous driving capabilities. These controllers predict vehicle dynamics and traffic conditions to optimize trajectory planning, speed control, and fuel efficiency. MPC algorithms can handle the complex constraints of vehicle operation while maintaining safety and performance objectives across varying driving conditions.Expand Specific Solutions04 Machine learning integration with MPC

The integration of machine learning techniques with Model Predictive Control creates adaptive systems that improve over time. These hybrid approaches use data-driven methods to refine predictive models and enhance controller performance. Neural networks and other AI techniques can be used to identify system dynamics, predict disturbances, or optimize control parameters, resulting in more robust and efficient control systems that adapt to changing conditions.Expand Specific Solutions05 Real-time implementation and computational efficiency

Advancements in computational methods have enabled real-time implementation of Model Predictive Control in systems with fast dynamics. These approaches focus on reducing computational complexity while maintaining control performance through techniques such as explicit MPC, fast optimization algorithms, and efficient model formulations. Hardware implementations on specialized processors or FPGAs further enhance the applicability of MPC to time-critical applications.Expand Specific Solutions

Leading Organizations in Space Robotics Control

Model Predictive Control (MPC) in space robotics is evolving rapidly in a market transitioning from early adoption to growth phase. The global space robotics market, valued at approximately $4-5 billion, is projected to expand significantly with increasing space exploration missions. Technologically, companies demonstrate varying maturity levels: established players like Robert Bosch, Mitsubishi Electric, and NVIDIA lead with advanced control algorithms and hardware integration, while research institutions such as Northwestern Polytechnical University and Beijing Institute of Technology contribute fundamental innovations. Space-focused entities like Utah State University Space Dynamics Laboratory and Tomahawk Robotics are developing specialized MPC applications for extreme environments. The competitive landscape is diversifying as automotive companies (Ford, Nissan) transfer autonomous control expertise to space applications, creating a dynamic ecosystem of established corporations and specialized innovators.

Mitsubishi Electric Corp.

Technical Solution: Mitsubishi Electric has developed a sophisticated MPC system for space robotics applications, leveraging their extensive experience in both industrial automation and space systems. Their approach integrates robust MPC algorithms with specialized hardware designed to withstand the harsh space environment. Mitsubishi's implementation features a multi-rate control architecture that allows for different update frequencies for different aspects of the control system, optimizing computational resource usage while maintaining control performance. Their system incorporates fault-tolerant features including analytical redundancy and graceful degradation capabilities, ensuring continued operation even if some sensors or actuators fail. Mitsubishi has implemented specialized constraint handling for space robotics applications, including thermal constraints, power limitations, and kinematic singularity avoidance. Their MPC solution has been flight-validated on several international space missions, including robotic arm operations on the International Space Station, demonstrating reliable performance in the space environment.

Strengths: Robust fault-tolerance features ensure mission continuity; extensive flight heritage provides proven reliability; optimized for space hardware constraints. Weaknesses: Proprietary system may limit integration with third-party components; relatively high implementation complexity.

Utah State University Space Dynamics Laboratory

Technical Solution: Utah State University Space Dynamics Laboratory has developed a robust MPC framework specifically tailored for space robotics applications. Their approach focuses on computational efficiency while maintaining control accuracy, implementing sparse optimization techniques that reduce the computational burden of MPC algorithms by up to 70% compared to traditional implementations. The laboratory's solution incorporates explicit handling of actuator saturation and slew rate constraints, which are critical for space robotics where actuator capabilities are often limited. Their MPC implementation features a novel disturbance observer that can identify and compensate for external forces such as solar radiation pressure and microgravity effects. The system has been validated through hardware-in-the-loop testing with flight-representative hardware, demonstrating the ability to perform precise manipulation tasks even under uncertain dynamic conditions. The laboratory has also developed specialized MPC formulations for specific space applications, including satellite servicing, debris removal, and on-orbit assembly.

Strengths: Computationally efficient implementation suitable for resource-constrained space systems; excellent disturbance rejection capabilities; extensively validated with flight-representative hardware. Weaknesses: May require mission-specific tuning; limited commercial deployment compared to industry solutions.

Key MPC Algorithms and Computational Frameworks

System and methods for pixel based model predictive control

PatentWO2019222597A1

Innovation

- Training a latent robot dynamics model using pixel-based data with an encoder, latent transition function, and decoder, combined with a reward function, to enable model predictive control and few-shot learning for robotic tasks, allowing the robot to plan actions in latent space without generating images.

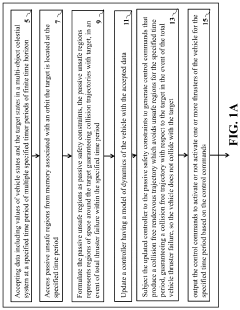

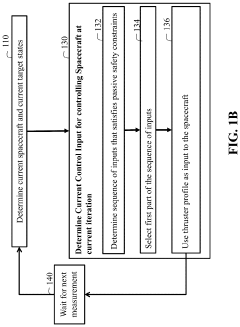

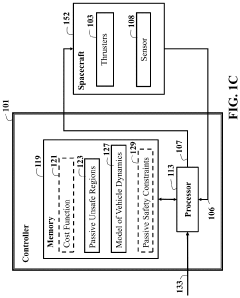

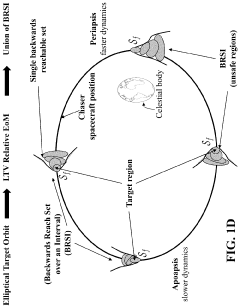

Fail-safe vehicle rendezvous in case of total control failure

PatentActiveUS11987396B2

Innovation

- A fail-safe control policy utilizing backwards reachable sets and model predictive control (MPC) is implemented to compute unsafe regions around the target, formulating these as passive safety constraints for online trajectory generation, ensuring the chaser spacecraft avoids collision trajectories even in the absence of thruster control.

Space Environment Constraints on MPC Implementation

The implementation of Model Predictive Control (MPC) in space robotics systems faces unique constraints imposed by the harsh and unforgiving space environment. Vacuum conditions significantly impact thermal management of computational hardware, as convective cooling is impossible, forcing reliance on radiative heat dissipation and specialized thermal control systems. This necessitates careful hardware selection and thermal design considerations when implementing computationally intensive MPC algorithms.

Radiation presents another critical challenge, with high-energy particles capable of causing single-event upsets (SEUs) and cumulative damage to electronic components. MPC implementations must incorporate radiation-hardened processors or field-programmable gate arrays (FPGAs) with error detection and correction capabilities, though these typically offer lower computational performance compared to their commercial counterparts, constraining algorithm complexity.

Power limitations represent a fundamental constraint in space applications. Spacecraft power generation is limited by solar panel size and efficiency, while battery capacity restricts operations during eclipse periods. MPC algorithms must be optimized for energy efficiency, potentially employing variable fidelity models that adjust computational intensity based on available power resources.

Communication delays and bandwidth limitations further complicate MPC implementation. Deep space missions experience round-trip light-time delays ranging from seconds to hours, rendering Earth-based computation and control impractical. This necessitates autonomous operation capabilities, with MPC algorithms designed to function with minimal ground intervention and to handle communication disruptions gracefully.

Microgravity and orbital dynamics introduce complex physical behaviors that must be accurately modeled within MPC frameworks. The absence of gravitational damping means disturbances persist indefinitely, requiring robust control strategies. Additionally, the coupling between attitude and orbital dynamics creates complex control scenarios that increase computational demands.

Launch constraints impose severe limitations on computational hardware mass, volume, and power consumption. MPC implementations must balance algorithm complexity against hardware constraints, often necessitating algorithm simplification or hardware acceleration techniques such as custom ASICs or FPGAs.

Reliability requirements in space applications exceed those of terrestrial systems by orders of magnitude. MPC implementations must incorporate redundancy, fault detection, isolation, and recovery mechanisms to ensure continued operation despite component failures. This often requires architectural approaches that can gracefully degrade performance rather than experiencing catastrophic failures.

Radiation presents another critical challenge, with high-energy particles capable of causing single-event upsets (SEUs) and cumulative damage to electronic components. MPC implementations must incorporate radiation-hardened processors or field-programmable gate arrays (FPGAs) with error detection and correction capabilities, though these typically offer lower computational performance compared to their commercial counterparts, constraining algorithm complexity.

Power limitations represent a fundamental constraint in space applications. Spacecraft power generation is limited by solar panel size and efficiency, while battery capacity restricts operations during eclipse periods. MPC algorithms must be optimized for energy efficiency, potentially employing variable fidelity models that adjust computational intensity based on available power resources.

Communication delays and bandwidth limitations further complicate MPC implementation. Deep space missions experience round-trip light-time delays ranging from seconds to hours, rendering Earth-based computation and control impractical. This necessitates autonomous operation capabilities, with MPC algorithms designed to function with minimal ground intervention and to handle communication disruptions gracefully.

Microgravity and orbital dynamics introduce complex physical behaviors that must be accurately modeled within MPC frameworks. The absence of gravitational damping means disturbances persist indefinitely, requiring robust control strategies. Additionally, the coupling between attitude and orbital dynamics creates complex control scenarios that increase computational demands.

Launch constraints impose severe limitations on computational hardware mass, volume, and power consumption. MPC implementations must balance algorithm complexity against hardware constraints, often necessitating algorithm simplification or hardware acceleration techniques such as custom ASICs or FPGAs.

Reliability requirements in space applications exceed those of terrestrial systems by orders of magnitude. MPC implementations must incorporate redundancy, fault detection, isolation, and recovery mechanisms to ensure continued operation despite component failures. This often requires architectural approaches that can gracefully degrade performance rather than experiencing catastrophic failures.

Reliability and Fault Tolerance in Space MPC Systems

Reliability and fault tolerance represent critical aspects of Model Predictive Control (MPC) systems deployed in space robotics. The harsh space environment, characterized by radiation, extreme temperatures, and vacuum conditions, poses significant challenges to electronic components and control systems. Space MPC systems must maintain operational integrity despite these adverse conditions, as maintenance or replacement opportunities are severely limited or non-existent.

Current reliability approaches in space MPC systems incorporate hardware redundancy, where critical components are duplicated or triplicated with voting mechanisms to detect and override faulty outputs. This traditional approach, while effective, adds considerable mass, power consumption, and complexity to space systems where resources are constrained.

Software-based fault tolerance mechanisms have emerged as complementary strategies, including analytical redundancy and robust MPC formulations. Analytical redundancy leverages mathematical models to detect inconsistencies between predicted and actual system behavior, enabling fault detection without hardware duplication. Robust MPC formulations explicitly account for uncertainties and potential component degradation in their optimization framework, ensuring stable performance despite system variations.

Recent advancements have introduced self-healing MPC algorithms capable of reconfiguring control parameters in response to detected faults. These adaptive systems can modify their internal models and constraints to accommodate degraded operational modes, maintaining mission-critical functions even when components fail partially.

Fault detection and isolation (FDI) techniques have been integrated with MPC frameworks to create comprehensive fault-tolerant control systems. These integrated approaches continuously monitor system performance, identify anomalies, and reconfigure control strategies accordingly. Machine learning methods have enhanced these capabilities, enabling more accurate fault prediction and preemptive reconfiguration before critical failures occur.

Verification and validation of fault-tolerant MPC systems present unique challenges due to the combinatorial explosion of potential fault scenarios. Hardware-in-the-loop testing combined with accelerated life testing has become standard practice, supplemented by formal methods to mathematically prove system behavior under specified fault conditions.

Industry standards for space systems reliability, such as ECSS (European Cooperation for Space Standardization) and NASA reliability standards, have begun incorporating specific guidelines for MPC implementations, addressing both hardware and algorithmic aspects of fault tolerance. These standards emphasize the importance of graceful degradation rather than catastrophic failure when faults occur.

The trade-off between computational complexity and fault tolerance remains a significant challenge, as more sophisticated fault-tolerant algorithms typically demand greater computational resources, which are limited in space applications. Future research directions focus on developing computationally efficient fault-tolerant MPC formulations that maintain robustness while minimizing resource requirements.

Current reliability approaches in space MPC systems incorporate hardware redundancy, where critical components are duplicated or triplicated with voting mechanisms to detect and override faulty outputs. This traditional approach, while effective, adds considerable mass, power consumption, and complexity to space systems where resources are constrained.

Software-based fault tolerance mechanisms have emerged as complementary strategies, including analytical redundancy and robust MPC formulations. Analytical redundancy leverages mathematical models to detect inconsistencies between predicted and actual system behavior, enabling fault detection without hardware duplication. Robust MPC formulations explicitly account for uncertainties and potential component degradation in their optimization framework, ensuring stable performance despite system variations.

Recent advancements have introduced self-healing MPC algorithms capable of reconfiguring control parameters in response to detected faults. These adaptive systems can modify their internal models and constraints to accommodate degraded operational modes, maintaining mission-critical functions even when components fail partially.

Fault detection and isolation (FDI) techniques have been integrated with MPC frameworks to create comprehensive fault-tolerant control systems. These integrated approaches continuously monitor system performance, identify anomalies, and reconfigure control strategies accordingly. Machine learning methods have enhanced these capabilities, enabling more accurate fault prediction and preemptive reconfiguration before critical failures occur.

Verification and validation of fault-tolerant MPC systems present unique challenges due to the combinatorial explosion of potential fault scenarios. Hardware-in-the-loop testing combined with accelerated life testing has become standard practice, supplemented by formal methods to mathematically prove system behavior under specified fault conditions.

Industry standards for space systems reliability, such as ECSS (European Cooperation for Space Standardization) and NASA reliability standards, have begun incorporating specific guidelines for MPC implementations, addressing both hardware and algorithmic aspects of fault tolerance. These standards emphasize the importance of graceful degradation rather than catastrophic failure when faults occur.

The trade-off between computational complexity and fault tolerance remains a significant challenge, as more sophisticated fault-tolerant algorithms typically demand greater computational resources, which are limited in space applications. Future research directions focus on developing computationally efficient fault-tolerant MPC formulations that maintain robustness while minimizing resource requirements.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!