Model Predictive Control In Constrained Systems

SEP 9, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

MPC Technology Evolution and Objectives

Model Predictive Control (MPC) emerged in the late 1970s as a revolutionary approach to process control, particularly in petrochemical industries where complex systems with multiple constraints required sophisticated control strategies. The evolution of MPC technology has been closely tied to advancements in computational capabilities, mathematical optimization techniques, and control theory.

The foundational concept of MPC was introduced through Dynamic Matrix Control (DMC) by Cutler and Ramaker in 1980, which represented one of the first practical implementations of predictive control in industrial settings. This early approach utilized step response models and quadratic programming to handle process constraints effectively.

Throughout the 1980s and 1990s, MPC technology expanded beyond its initial applications in refining and petrochemicals to various industrial sectors including power generation, automotive systems, and aerospace. This expansion was facilitated by theoretical developments in state-space formulations and robust control techniques that enhanced MPC's ability to handle model uncertainties and disturbances.

The 2000s witnessed significant advancements in computational efficiency, allowing for real-time implementation of MPC algorithms in systems with faster dynamics. Explicit MPC formulations emerged, pre-computing control laws offline to reduce online computational burden, making MPC viable for embedded systems with limited processing power.

Recent developments have focused on stochastic MPC approaches that explicitly account for uncertainties in system models and disturbances, providing probabilistic guarantees of constraint satisfaction. Machine learning integration has also become prominent, with data-driven techniques complementing traditional model-based approaches to improve prediction accuracy and adaptability.

The primary objective of MPC in constrained systems is to optimize system performance while explicitly respecting operational constraints. This includes maintaining process variables within safe operating regions, respecting actuator limitations, and ensuring product quality specifications are met consistently.

Another critical goal is to enhance system robustness against model uncertainties and external disturbances, ensuring reliable operation under varying conditions. This is particularly important in industrial applications where model inaccuracies are inevitable and disturbance rejection capabilities are essential for maintaining product quality and operational safety.

Looking forward, MPC technology aims to further reduce implementation complexity while expanding applicability to increasingly complex systems. Objectives include developing more efficient numerical algorithms for large-scale systems, improving computational methods for nonlinear MPC, and creating standardized frameworks that simplify deployment across diverse application domains.

The foundational concept of MPC was introduced through Dynamic Matrix Control (DMC) by Cutler and Ramaker in 1980, which represented one of the first practical implementations of predictive control in industrial settings. This early approach utilized step response models and quadratic programming to handle process constraints effectively.

Throughout the 1980s and 1990s, MPC technology expanded beyond its initial applications in refining and petrochemicals to various industrial sectors including power generation, automotive systems, and aerospace. This expansion was facilitated by theoretical developments in state-space formulations and robust control techniques that enhanced MPC's ability to handle model uncertainties and disturbances.

The 2000s witnessed significant advancements in computational efficiency, allowing for real-time implementation of MPC algorithms in systems with faster dynamics. Explicit MPC formulations emerged, pre-computing control laws offline to reduce online computational burden, making MPC viable for embedded systems with limited processing power.

Recent developments have focused on stochastic MPC approaches that explicitly account for uncertainties in system models and disturbances, providing probabilistic guarantees of constraint satisfaction. Machine learning integration has also become prominent, with data-driven techniques complementing traditional model-based approaches to improve prediction accuracy and adaptability.

The primary objective of MPC in constrained systems is to optimize system performance while explicitly respecting operational constraints. This includes maintaining process variables within safe operating regions, respecting actuator limitations, and ensuring product quality specifications are met consistently.

Another critical goal is to enhance system robustness against model uncertainties and external disturbances, ensuring reliable operation under varying conditions. This is particularly important in industrial applications where model inaccuracies are inevitable and disturbance rejection capabilities are essential for maintaining product quality and operational safety.

Looking forward, MPC technology aims to further reduce implementation complexity while expanding applicability to increasingly complex systems. Objectives include developing more efficient numerical algorithms for large-scale systems, improving computational methods for nonlinear MPC, and creating standardized frameworks that simplify deployment across diverse application domains.

Market Applications and Demand Analysis

The market for Model Predictive Control (MPC) in constrained systems has experienced significant growth over the past decade, driven by increasing industrial automation and the need for more efficient process control. The global MPC market was valued at approximately $4.3 billion in 2022 and is projected to reach $7.8 billion by 2028, representing a compound annual growth rate of 10.5%.

Industrial manufacturing represents the largest application segment, accounting for nearly 35% of the total market share. Within this sector, chemical processing, oil refining, and petrochemical industries have been early adopters of MPC technology due to their complex processes with multiple constraints and the high cost of inefficiencies. These industries benefit from MPC's ability to optimize operations while respecting equipment limitations and safety parameters.

Energy management has emerged as the fastest-growing application area, with a growth rate exceeding 14% annually. The integration of renewable energy sources into power grids has created new challenges in balancing supply and demand under various constraints, making MPC particularly valuable. Smart grid applications leverage MPC to manage energy distribution while considering transmission limitations, demand fluctuations, and renewable energy intermittency.

Automotive applications represent another significant market segment, particularly with the rise of electric and autonomous vehicles. MPC is increasingly deployed in advanced driver assistance systems (ADAS) and battery management systems where operating within constraints is critical for safety and efficiency. The automotive MPC market segment is expected to double in size by 2027.

Regionally, North America currently leads the market with approximately 38% share, followed by Europe at 31% and Asia-Pacific at 24%. However, the Asia-Pacific region is experiencing the fastest growth rate, driven by rapid industrialization in countries like China and India, and increasing adoption of automation technologies.

Customer demand is increasingly focused on MPC solutions that offer real-time implementation capabilities, integration with existing industrial control systems, and user-friendly interfaces that don't require extensive mathematical expertise. Cloud-based MPC solutions are gaining traction, allowing smaller companies to access sophisticated control capabilities without significant upfront investment in computational infrastructure.

Market challenges include the high initial implementation costs, complexity of model development, and the need for specialized expertise. These factors have limited adoption among small and medium enterprises, creating an opportunity for simplified, industry-specific MPC packages that address common control scenarios with minimal customization requirements.

Industrial manufacturing represents the largest application segment, accounting for nearly 35% of the total market share. Within this sector, chemical processing, oil refining, and petrochemical industries have been early adopters of MPC technology due to their complex processes with multiple constraints and the high cost of inefficiencies. These industries benefit from MPC's ability to optimize operations while respecting equipment limitations and safety parameters.

Energy management has emerged as the fastest-growing application area, with a growth rate exceeding 14% annually. The integration of renewable energy sources into power grids has created new challenges in balancing supply and demand under various constraints, making MPC particularly valuable. Smart grid applications leverage MPC to manage energy distribution while considering transmission limitations, demand fluctuations, and renewable energy intermittency.

Automotive applications represent another significant market segment, particularly with the rise of electric and autonomous vehicles. MPC is increasingly deployed in advanced driver assistance systems (ADAS) and battery management systems where operating within constraints is critical for safety and efficiency. The automotive MPC market segment is expected to double in size by 2027.

Regionally, North America currently leads the market with approximately 38% share, followed by Europe at 31% and Asia-Pacific at 24%. However, the Asia-Pacific region is experiencing the fastest growth rate, driven by rapid industrialization in countries like China and India, and increasing adoption of automation technologies.

Customer demand is increasingly focused on MPC solutions that offer real-time implementation capabilities, integration with existing industrial control systems, and user-friendly interfaces that don't require extensive mathematical expertise. Cloud-based MPC solutions are gaining traction, allowing smaller companies to access sophisticated control capabilities without significant upfront investment in computational infrastructure.

Market challenges include the high initial implementation costs, complexity of model development, and the need for specialized expertise. These factors have limited adoption among small and medium enterprises, creating an opportunity for simplified, industry-specific MPC packages that address common control scenarios with minimal customization requirements.

Current MPC Challenges in Constrained Systems

Despite significant advancements in Model Predictive Control (MPC) for constrained systems, several critical challenges persist that limit its broader industrial adoption and effectiveness. Computational complexity remains a primary obstacle, particularly for systems with high dimensionality or requiring fast sampling rates. The optimization problems at MPC's core must be solved within strict time constraints, often milliseconds, which becomes increasingly difficult as system complexity grows or when handling nonlinear dynamics.

Constraint handling, while a fundamental strength of MPC, introduces its own challenges. Hard constraints can lead to infeasibility issues when disturbances push the system beyond feasible regions, potentially causing controller failure. Soft constraints offer an alternative but require careful penalty tuning and may result in constraint violations during operation.

Model uncertainty presents another significant challenge. MPC performance depends heavily on model accuracy, yet real-world systems invariably contain uncertainties from parameter variations, unmodeled dynamics, and external disturbances. Traditional MPC formulations lack robust guarantees when facing these uncertainties, potentially leading to constraint violations or even instability.

Computational efficiency improvements remain an ongoing research focus. While explicit MPC solutions pre-compute control laws offline to reduce online computation, they face exponential memory requirements as problem dimensions increase. Alternative approaches like fast gradient methods and move blocking strategies offer partial solutions but introduce their own limitations.

State estimation quality significantly impacts MPC performance in practical applications. Sensor limitations, noise, and the inability to directly measure all states necessitate state estimators, whose errors propagate through the prediction horizon and affect control quality.

Implementation challenges further complicate MPC deployment. The gap between theoretical formulations and practical implementation includes issues like numerical stability, solver reliability, and integration with existing control systems. Additionally, tuning MPC controllers requires balancing multiple objectives and constraints, often demanding significant expertise and time.

Emerging applications in autonomous systems, renewable energy integration, and distributed control networks introduce new challenges related to safety guarantees, real-time adaptation, and coordination between multiple MPC controllers. These applications often require MPC to operate under more severe computational constraints while maintaining performance guarantees.

Constraint handling, while a fundamental strength of MPC, introduces its own challenges. Hard constraints can lead to infeasibility issues when disturbances push the system beyond feasible regions, potentially causing controller failure. Soft constraints offer an alternative but require careful penalty tuning and may result in constraint violations during operation.

Model uncertainty presents another significant challenge. MPC performance depends heavily on model accuracy, yet real-world systems invariably contain uncertainties from parameter variations, unmodeled dynamics, and external disturbances. Traditional MPC formulations lack robust guarantees when facing these uncertainties, potentially leading to constraint violations or even instability.

Computational efficiency improvements remain an ongoing research focus. While explicit MPC solutions pre-compute control laws offline to reduce online computation, they face exponential memory requirements as problem dimensions increase. Alternative approaches like fast gradient methods and move blocking strategies offer partial solutions but introduce their own limitations.

State estimation quality significantly impacts MPC performance in practical applications. Sensor limitations, noise, and the inability to directly measure all states necessitate state estimators, whose errors propagate through the prediction horizon and affect control quality.

Implementation challenges further complicate MPC deployment. The gap between theoretical formulations and practical implementation includes issues like numerical stability, solver reliability, and integration with existing control systems. Additionally, tuning MPC controllers requires balancing multiple objectives and constraints, often demanding significant expertise and time.

Emerging applications in autonomous systems, renewable energy integration, and distributed control networks introduce new challenges related to safety guarantees, real-time adaptation, and coordination between multiple MPC controllers. These applications often require MPC to operate under more severe computational constraints while maintaining performance guarantees.

State-of-the-Art MPC Implementation Approaches

01 MPC optimization techniques for improved control performance

Advanced optimization techniques are employed in Model Predictive Control to enhance control performance. These techniques include mathematical algorithms that optimize control actions while considering constraints and multiple objectives. By implementing efficient optimization solvers and formulations, MPC systems can achieve faster computation times, better convergence, and more accurate predictions, ultimately leading to improved control performance in complex industrial processes.- MPC performance optimization techniques: Various techniques can be used to optimize the performance of Model Predictive Control systems. These include advanced algorithms for constraint handling, computational efficiency improvements, and optimization methods that enhance the controller's ability to predict and respond to system changes. These optimization techniques help to improve the overall control performance by reducing computational load while maintaining or improving control accuracy.

- Industrial applications of MPC: Model Predictive Control has been successfully implemented across various industrial applications to improve process control performance. These applications include manufacturing processes, chemical plants, energy systems, and other complex industrial environments. MPC provides benefits such as improved product quality, reduced energy consumption, and enhanced operational efficiency through its ability to handle multivariable systems and constraints.

- MPC integration with other control technologies: The integration of Model Predictive Control with other control technologies enhances overall control performance. This includes combining MPC with artificial intelligence, machine learning algorithms, adaptive control systems, and traditional PID controllers. Such integration allows for more robust control systems that can adapt to changing conditions, handle uncertainties, and optimize performance across a wider range of operating conditions.

- MPC performance monitoring and assessment: Effective monitoring and assessment of Model Predictive Control performance is crucial for maintaining optimal operation. This involves techniques for real-time performance evaluation, detection of model-plant mismatch, identification of control degradation, and methods for controller tuning and adaptation. Performance metrics and diagnostic tools help identify when the controller is not performing as expected and guide appropriate adjustments.

- Advanced MPC formulations for improved performance: Advanced formulations of Model Predictive Control have been developed to address specific performance challenges. These include robust MPC for handling uncertainties, economic MPC for optimizing economic objectives, nonlinear MPC for complex systems, and distributed MPC for large-scale applications. These advanced formulations provide improved control performance by better addressing the specific characteristics and requirements of different control problems.

02 Adaptive and robust MPC strategies

Adaptive and robust MPC strategies are designed to maintain control performance despite uncertainties and disturbances. These approaches dynamically adjust model parameters based on real-time process data, enabling the controller to adapt to changing conditions. Robust MPC formulations explicitly account for model uncertainties and external disturbances, ensuring stable performance even when the actual process deviates from the nominal model. These strategies are particularly valuable in applications with varying operating conditions or model inaccuracies.Expand Specific Solutions03 MPC implementation in specific industrial applications

Model Predictive Control has been successfully implemented across various industrial applications to enhance control performance. These implementations include process industries, manufacturing systems, energy management, and automotive applications. By tailoring MPC algorithms to specific industry requirements and process characteristics, significant improvements in product quality, energy efficiency, and operational stability can be achieved. Industry-specific MPC solutions often incorporate domain knowledge and specialized constraints to maximize performance benefits.Expand Specific Solutions04 Integration of MPC with machine learning and AI

The integration of Model Predictive Control with machine learning and artificial intelligence techniques represents a significant advancement in control performance. Machine learning algorithms can improve model accuracy by learning from historical data, while AI techniques can optimize controller tuning and decision-making processes. This hybrid approach combines the predictive capabilities of MPC with the adaptive learning abilities of AI, resulting in more intelligent control systems that continuously improve performance over time and handle complex nonlinear dynamics more effectively.Expand Specific Solutions05 Real-time implementation and computational efficiency

Real-time implementation and computational efficiency are critical factors affecting MPC control performance. Various techniques have been developed to reduce computational burden while maintaining control quality, including model reduction, efficient algorithm design, and hardware acceleration. Fast sampling rates and reduced solution times enable MPC to respond quickly to process changes, while distributed computing architectures allow for handling more complex control problems. These advancements make high-performance MPC feasible even for systems with fast dynamics or limited computational resources.Expand Specific Solutions

Leading Companies and Research Institutions in MPC

Model Predictive Control (MPC) in constrained systems is evolving through a mature yet still developing technological landscape. The market is experiencing robust growth, estimated at approximately $500 million annually with a CAGR of 8-10%, driven by industrial automation and autonomous vehicle applications. Leading industrial players include Siemens AG, Mitsubishi Electric, and Honeywell International, who have established strong commercial implementations across manufacturing and process control. Automotive companies like Toyota and Nissan are advancing MPC for vehicle dynamics control. Technology maturity varies by sector - highly mature in process industries but still evolving in emerging applications like autonomous systems. NVIDIA is pushing computational boundaries for real-time implementation, while academic institutions like Harbin Engineering University and University of Florida are developing next-generation algorithms for complex constrained optimization problems.

Honeywell International Technologies Ltd.

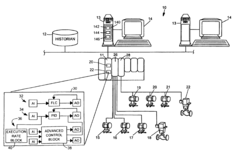

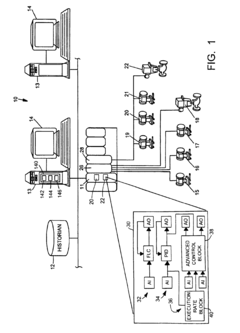

Technical Solution: Honeywell has developed a sophisticated Model Predictive Control framework for constrained systems through their Profit Controller technology. Their approach implements a multivariable control strategy that explicitly handles both input and output constraints while optimizing process performance. The technology utilizes state-space models to predict future behavior across multiple time horizons, enabling proactive constraint management rather than reactive responses[1]. Honeywell's implementation features a unique two-stage optimization process: first solving for feasibility within constraints, then optimizing for performance objectives within the feasible region. This ensures constraint satisfaction takes precedence over optimization goals[3]. Their MPC solution incorporates robust techniques to handle model uncertainty and disturbances, maintaining stable operation even when the actual process behavior deviates from model predictions. The system includes specialized algorithms for constraint softening that allow temporary constraint relaxation with appropriate penalty functions, providing a balance between strict constraint enforcement and practical operation flexibility[5]. Honeywell's technology also features adaptive constraint management that can automatically adjust constraint boundaries based on current operating conditions and equipment status.

Strengths: Robust handling of model uncertainties and disturbances; sophisticated constraint prioritization and softening mechanisms; proven track record in complex industrial applications with multiple interacting constraints. Weaknesses: Complex implementation requiring specialized expertise; computational demands can be significant for large-scale applications; requires comprehensive process models which may be difficult to develop for some systems.

Rockwell Automation Technologies, Inc.

Technical Solution: Rockwell Automation has pioneered an innovative approach to Model Predictive Control in constrained systems through their Pavilion8 MPC technology. Their solution implements a multi-tier architecture that separates the prediction model from the control algorithm, allowing for more flexible deployment in highly constrained industrial environments. The technology utilizes empirical, first-principles, and hybrid modeling techniques to create accurate predictive models that account for both process dynamics and constraints[2]. Rockwell's implementation features a unique constraint handling mechanism that dynamically prioritizes constraints based on their criticality and feasibility, enabling graceful degradation when all constraints cannot be simultaneously satisfied[4]. Their MPC solution incorporates economic objectives directly into the control algorithm, optimizing not just for setpoint tracking but also for operational efficiency and cost reduction while respecting equipment limitations. The system includes adaptive capabilities that automatically detect and adjust to changes in process dynamics or constraint boundaries, maintaining optimal performance even as conditions evolve over time.

Strengths: Flexible architecture allows deployment across diverse industrial applications; economic optimization directly integrated into control objectives; adaptive capabilities for changing process conditions. Weaknesses: Higher initial implementation costs compared to conventional control; requires significant process expertise during model development phase; may need substantial computational resources for complex applications with many constraints.

Key Algorithms and Mathematical Foundations

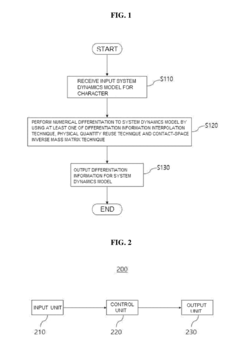

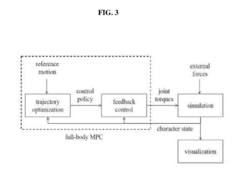

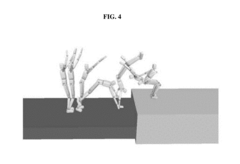

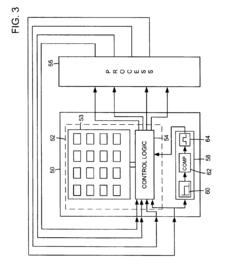

Model predictive control method and model predictive control apparatus

PatentInactiveUS20170315518A1

Innovation

- The method employs techniques like differentiation information interpolation, physical quantity reuse, and contact-space inverse mass matrix (CIMM) to enhance the speed of numerical differentiation for system dynamics models in iLQG-based model predictive control, allowing for more efficient and natural motion production.

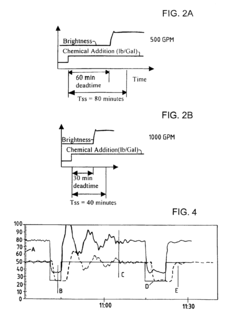

Adaptation of advanced process control blocks in response to variable process delay

PatentInactiveUS6901300B2

Innovation

- An advanced control system employs a compensation block and a single control model that adjusts its execution period based on process variables affecting delay, eliminating the need for multiple models by dynamically adjusting the control logic's execution rate.

Computational Efficiency and Real-time Performance

Computational efficiency remains one of the most significant challenges in implementing Model Predictive Control (MPC) for constrained systems. Traditional MPC algorithms require solving complex optimization problems at each sampling interval, which historically limited their application to slow processes with sampling times in minutes or hours. Recent advancements have dramatically improved execution speeds, enabling MPC implementation on systems with sampling rates in milliseconds.

The computational burden of MPC stems primarily from the online solution of constrained optimization problems. For linear systems with quadratic cost functions and linear constraints, this translates to solving quadratic programming (QP) problems. Several specialized QP solvers have emerged specifically for MPC applications, including OSQP, qpOASES, and FORCES Pro, which exploit the particular structure of MPC problems to achieve significant speed improvements.

Explicit MPC represents a paradigm shift in addressing computational challenges by pre-computing control laws offline. This approach partitions the state space into regions where the control law is affine, effectively transforming the online computation into a point location problem. While explicit MPC offers deterministic execution times, its application remains limited to small-scale systems due to exponential growth in memory requirements with problem dimensions.

Hardware acceleration has become increasingly important for real-time MPC implementation. Field-Programmable Gate Arrays (FPGAs) and Graphics Processing Units (GPUs) have demonstrated the ability to solve MPC problems orders of magnitude faster than general-purpose CPUs. These platforms enable parallel computation of matrix operations central to optimization algorithms, with recent implementations achieving solution times under 100 microseconds for medium-sized problems.

Warm-starting techniques leverage the solution from previous time steps to initialize the optimization algorithm, significantly reducing the number of iterations required for convergence. This approach is particularly effective in MPC since consecutive optimization problems typically differ only slightly, allowing for computational savings of 30-70% in practical applications.

Approximation methods that trade optimality for speed have gained traction in embedded applications. These include suboptimal MPC formulations, move blocking strategies that reduce decision variables, and early termination of iterative solvers. Recent research demonstrates that carefully designed approximations can maintain control performance while reducing computation time by up to 90% compared to exact solutions.

The emergence of specialized embedded optimization software frameworks has democratized real-time MPC implementation. Tools like ACADO, GRAMPC, and EMBOCON generate efficient code tailored for embedded platforms, enabling engineers to deploy MPC on resource-constrained hardware without deep expertise in numerical optimization or embedded programming.

The computational burden of MPC stems primarily from the online solution of constrained optimization problems. For linear systems with quadratic cost functions and linear constraints, this translates to solving quadratic programming (QP) problems. Several specialized QP solvers have emerged specifically for MPC applications, including OSQP, qpOASES, and FORCES Pro, which exploit the particular structure of MPC problems to achieve significant speed improvements.

Explicit MPC represents a paradigm shift in addressing computational challenges by pre-computing control laws offline. This approach partitions the state space into regions where the control law is affine, effectively transforming the online computation into a point location problem. While explicit MPC offers deterministic execution times, its application remains limited to small-scale systems due to exponential growth in memory requirements with problem dimensions.

Hardware acceleration has become increasingly important for real-time MPC implementation. Field-Programmable Gate Arrays (FPGAs) and Graphics Processing Units (GPUs) have demonstrated the ability to solve MPC problems orders of magnitude faster than general-purpose CPUs. These platforms enable parallel computation of matrix operations central to optimization algorithms, with recent implementations achieving solution times under 100 microseconds for medium-sized problems.

Warm-starting techniques leverage the solution from previous time steps to initialize the optimization algorithm, significantly reducing the number of iterations required for convergence. This approach is particularly effective in MPC since consecutive optimization problems typically differ only slightly, allowing for computational savings of 30-70% in practical applications.

Approximation methods that trade optimality for speed have gained traction in embedded applications. These include suboptimal MPC formulations, move blocking strategies that reduce decision variables, and early termination of iterative solvers. Recent research demonstrates that carefully designed approximations can maintain control performance while reducing computation time by up to 90% compared to exact solutions.

The emergence of specialized embedded optimization software frameworks has democratized real-time MPC implementation. Tools like ACADO, GRAMPC, and EMBOCON generate efficient code tailored for embedded platforms, enabling engineers to deploy MPC on resource-constrained hardware without deep expertise in numerical optimization or embedded programming.

Industry-Specific Implementation Considerations

The implementation of Model Predictive Control (MPC) varies significantly across different industries due to their unique operational environments, constraints, and performance requirements. In manufacturing sectors, MPC implementations must account for production line dynamics, where rapid response times are critical. These systems typically operate with tight physical constraints related to equipment capabilities, material properties, and safety thresholds. Manufacturing MPC deployments often require robust handling of disturbances from material variations and equipment wear, necessitating adaptive control strategies.

In the chemical and process industries, MPC implementations face challenges related to complex reaction kinetics and thermodynamic constraints. These applications typically involve longer time horizons and must account for batch processing requirements, reaction stability limits, and quality control parameters. The economic impact of control decisions is particularly significant in these sectors, requiring MPC formulations that explicitly balance production efficiency against quality constraints.

The automotive sector presents unique implementation considerations for MPC, particularly in powertrain control and advanced driver assistance systems. These applications demand extremely fast computation times, often in milliseconds, while operating under rapidly changing environmental conditions. Automotive MPC must function reliably across wide operating ranges and accommodate both physical constraints (actuator limits) and regulatory constraints (emissions standards).

Energy management systems represent another distinct implementation domain for MPC. In power grid applications, MPC must handle large-scale distributed systems with significant communication delays and uncertainties in renewable energy production. These implementations typically incorporate economic objectives directly into the control formulation, balancing energy costs against demand satisfaction and grid stability constraints.

Healthcare applications of MPC, such as in anesthesia delivery or glucose control, present perhaps the most stringent implementation requirements. These systems must prioritize patient safety above all other considerations, incorporating physiological constraints and maintaining robust performance despite significant inter-patient variability. Regulatory approval processes add additional layers of validation requirements not present in other industrial implementations.

Across all industries, computational efficiency remains a critical implementation consideration. The selection of appropriate solver technologies, model reduction techniques, and hardware platforms must be tailored to the specific time constraints and computational resources available in each application domain. Modern implementations increasingly leverage specialized hardware accelerators and distributed computing architectures to meet these demands.

In the chemical and process industries, MPC implementations face challenges related to complex reaction kinetics and thermodynamic constraints. These applications typically involve longer time horizons and must account for batch processing requirements, reaction stability limits, and quality control parameters. The economic impact of control decisions is particularly significant in these sectors, requiring MPC formulations that explicitly balance production efficiency against quality constraints.

The automotive sector presents unique implementation considerations for MPC, particularly in powertrain control and advanced driver assistance systems. These applications demand extremely fast computation times, often in milliseconds, while operating under rapidly changing environmental conditions. Automotive MPC must function reliably across wide operating ranges and accommodate both physical constraints (actuator limits) and regulatory constraints (emissions standards).

Energy management systems represent another distinct implementation domain for MPC. In power grid applications, MPC must handle large-scale distributed systems with significant communication delays and uncertainties in renewable energy production. These implementations typically incorporate economic objectives directly into the control formulation, balancing energy costs against demand satisfaction and grid stability constraints.

Healthcare applications of MPC, such as in anesthesia delivery or glucose control, present perhaps the most stringent implementation requirements. These systems must prioritize patient safety above all other considerations, incorporating physiological constraints and maintaining robust performance despite significant inter-patient variability. Regulatory approval processes add additional layers of validation requirements not present in other industrial implementations.

Across all industries, computational efficiency remains a critical implementation consideration. The selection of appropriate solver technologies, model reduction techniques, and hardware platforms must be tailored to the specific time constraints and computational resources available in each application domain. Modern implementations increasingly leverage specialized hardware accelerators and distributed computing architectures to meet these demands.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!