Model Predictive Control In Intelligent Prosthetics

SEP 9, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

MPC in Prosthetics: Background and Objectives

Model Predictive Control (MPC) has emerged as a transformative technology in the field of intelligent prosthetics over the past three decades. Initially developed for industrial process control in the 1970s, MPC has gradually found its way into biomedical applications, with significant advancements occurring since the early 2000s. The evolution of this technology has been driven by the increasing demand for more intuitive, responsive, and adaptable prosthetic devices that can closely mimic natural human movement.

The fundamental principle behind MPC in prosthetics involves predicting future states of the prosthetic system based on current measurements and a dynamic model, then optimizing control actions over a receding horizon. This approach allows for anticipatory control that accounts for the complex, nonlinear dynamics of human-prosthetic interaction, addressing the inherent delays in biological signal processing and mechanical response.

Recent technological advancements in computational power, sensor miniaturization, and battery efficiency have accelerated the practical implementation of MPC in wearable prosthetic devices. The integration of machine learning algorithms with traditional MPC frameworks has further enhanced the adaptive capabilities of these systems, enabling them to learn from user behavior and environmental interactions over time.

The primary technical objective in this field is to develop robust, real-time MPC algorithms that can operate within the strict computational and power constraints of portable prosthetic devices while maintaining high performance. This includes achieving control loop frequencies sufficient for natural movement (typically 100-1000 Hz), minimizing response latency to below perceptible levels (< 100 ms), and ensuring stability across diverse operating conditions.

Another critical objective is the seamless integration of biological signals, particularly electromyography (EMG) and neural interfaces, with MPC frameworks to create intuitive control systems that respond to user intent with minimal cognitive load. This requires sophisticated signal processing techniques and predictive models that can interpret noisy biological signals in real-time.

The long-term technical vision encompasses the development of fully autonomous prosthetic systems that can anticipate user intentions through contextual awareness and learned behavior patterns. This involves expanding MPC frameworks to incorporate higher-level planning and decision-making capabilities, potentially through hierarchical control architectures that combine reactive control with strategic planning.

As the field progresses, there is increasing focus on personalization aspects, with adaptive MPC systems that can automatically calibrate to individual users' movement patterns, preferences, and physiological characteristics. This trend aligns with the broader movement toward precision medicine and personalized assistive technologies.

The fundamental principle behind MPC in prosthetics involves predicting future states of the prosthetic system based on current measurements and a dynamic model, then optimizing control actions over a receding horizon. This approach allows for anticipatory control that accounts for the complex, nonlinear dynamics of human-prosthetic interaction, addressing the inherent delays in biological signal processing and mechanical response.

Recent technological advancements in computational power, sensor miniaturization, and battery efficiency have accelerated the practical implementation of MPC in wearable prosthetic devices. The integration of machine learning algorithms with traditional MPC frameworks has further enhanced the adaptive capabilities of these systems, enabling them to learn from user behavior and environmental interactions over time.

The primary technical objective in this field is to develop robust, real-time MPC algorithms that can operate within the strict computational and power constraints of portable prosthetic devices while maintaining high performance. This includes achieving control loop frequencies sufficient for natural movement (typically 100-1000 Hz), minimizing response latency to below perceptible levels (< 100 ms), and ensuring stability across diverse operating conditions.

Another critical objective is the seamless integration of biological signals, particularly electromyography (EMG) and neural interfaces, with MPC frameworks to create intuitive control systems that respond to user intent with minimal cognitive load. This requires sophisticated signal processing techniques and predictive models that can interpret noisy biological signals in real-time.

The long-term technical vision encompasses the development of fully autonomous prosthetic systems that can anticipate user intentions through contextual awareness and learned behavior patterns. This involves expanding MPC frameworks to incorporate higher-level planning and decision-making capabilities, potentially through hierarchical control architectures that combine reactive control with strategic planning.

As the field progresses, there is increasing focus on personalization aspects, with adaptive MPC systems that can automatically calibrate to individual users' movement patterns, preferences, and physiological characteristics. This trend aligns with the broader movement toward precision medicine and personalized assistive technologies.

Market Analysis for Intelligent Prosthetic Solutions

The global intelligent prosthetics market is experiencing significant growth, driven by technological advancements in Model Predictive Control (MPC) systems and increasing demand for advanced assistive devices. Current market valuations indicate the intelligent prosthetics sector reached approximately 2.1 billion USD in 2022, with projections suggesting a compound annual growth rate of 9.8% through 2030, potentially reaching 4.5 billion USD by the end of the decade.

Demographic trends significantly influence market dynamics, with aging populations in developed economies creating sustained demand for prosthetic solutions. The World Health Organization estimates that over 40 million people worldwide require prosthetic devices, with only 5-15% having access to appropriate technology, indicating substantial untapped market potential.

Geographically, North America currently dominates the intelligent prosthetics market with approximately 42% market share, followed by Europe at 28% and Asia-Pacific at 22%. However, the Asia-Pacific region is expected to witness the fastest growth rate due to improving healthcare infrastructure, increasing disposable income, and growing awareness about advanced prosthetic solutions.

The market segmentation reveals distinct categories based on technology sophistication. Basic myoelectric prosthetics represent the largest segment by volume, while advanced neural-integrated prosthetics with MPC capabilities command premium pricing and are experiencing the fastest growth rate. Upper limb prosthetics currently dominate the market, but lower limb solutions incorporating MPC technology are gaining significant traction due to their ability to provide more natural gait patterns and improved stability.

Consumer demand patterns indicate a clear shift toward more intuitive control systems, with 78% of prosthetic users citing natural movement and reduced cognitive load as primary concerns. This directly aligns with the capabilities of MPC technology, which can predict user intent and adapt to changing environmental conditions in real-time.

Reimbursement policies and healthcare coverage significantly impact market accessibility. In regions with comprehensive healthcare coverage for prosthetic devices, adoption rates for MPC-enabled solutions are 3.2 times higher than in regions with limited coverage. This highlights the importance of favorable reimbursement structures in market development.

Competitive analysis reveals a fragmented market with several key players including Ottobock, Össur, and emerging technology-focused startups. Strategic partnerships between prosthetic manufacturers and AI/robotics companies are increasingly common, creating new innovation ecosystems focused on advancing MPC applications in prosthetics.

Demographic trends significantly influence market dynamics, with aging populations in developed economies creating sustained demand for prosthetic solutions. The World Health Organization estimates that over 40 million people worldwide require prosthetic devices, with only 5-15% having access to appropriate technology, indicating substantial untapped market potential.

Geographically, North America currently dominates the intelligent prosthetics market with approximately 42% market share, followed by Europe at 28% and Asia-Pacific at 22%. However, the Asia-Pacific region is expected to witness the fastest growth rate due to improving healthcare infrastructure, increasing disposable income, and growing awareness about advanced prosthetic solutions.

The market segmentation reveals distinct categories based on technology sophistication. Basic myoelectric prosthetics represent the largest segment by volume, while advanced neural-integrated prosthetics with MPC capabilities command premium pricing and are experiencing the fastest growth rate. Upper limb prosthetics currently dominate the market, but lower limb solutions incorporating MPC technology are gaining significant traction due to their ability to provide more natural gait patterns and improved stability.

Consumer demand patterns indicate a clear shift toward more intuitive control systems, with 78% of prosthetic users citing natural movement and reduced cognitive load as primary concerns. This directly aligns with the capabilities of MPC technology, which can predict user intent and adapt to changing environmental conditions in real-time.

Reimbursement policies and healthcare coverage significantly impact market accessibility. In regions with comprehensive healthcare coverage for prosthetic devices, adoption rates for MPC-enabled solutions are 3.2 times higher than in regions with limited coverage. This highlights the importance of favorable reimbursement structures in market development.

Competitive analysis reveals a fragmented market with several key players including Ottobock, Össur, and emerging technology-focused startups. Strategic partnerships between prosthetic manufacturers and AI/robotics companies are increasingly common, creating new innovation ecosystems focused on advancing MPC applications in prosthetics.

Current MPC Implementation Challenges in Prosthetics

Despite the promising potential of Model Predictive Control (MPC) in intelligent prosthetics, several significant implementation challenges currently hinder its widespread adoption. The computational complexity of MPC algorithms represents a primary obstacle, as these systems must solve complex optimization problems in real-time while operating within the limited computational resources of portable prosthetic devices. This creates a fundamental tension between control performance and power consumption that engineers must carefully balance.

Real-time execution constraints further complicate implementation, as prosthetic devices typically require control frequencies of 100-1000 Hz to achieve natural movement. Current MPC solvers often struggle to consistently meet these timing requirements, especially when handling the nonlinear dynamics inherent in human locomotion and interaction with varied environments.

Model accuracy presents another substantial challenge. MPC performance fundamentally depends on the quality of the predictive model, yet developing accurate models of human-prosthetic interaction remains difficult due to the high variability between users, changing environmental conditions, and the complex biomechanics involved. Simplified models may enable faster computation but sacrifice performance, while detailed models improve control but increase computational burden.

Robustness issues also plague current implementations. MPC controllers must maintain stability and performance despite sensor noise, model uncertainties, and unexpected disturbances such as uneven terrain or sudden changes in user intention. Traditional MPC formulations often lack the robustness guarantees necessary for safety-critical prosthetic applications.

Parameter tuning represents a significant practical challenge, as MPC controllers typically contain numerous parameters that must be carefully calibrated for each user. Current approaches to personalization often require extensive manual tuning by clinical professionals, limiting accessibility and increasing costs.

Power consumption remains a critical constraint, with advanced MPC implementations often demanding substantial computational resources that drain battery life. This creates a direct trade-off between control sophistication and operational duration that impacts user experience.

Integration with intent recognition systems presents additional complexity, as MPC controllers must seamlessly interface with higher-level algorithms that interpret user intentions from biological signals or movement patterns. The latency and uncertainty in these predictions must be appropriately handled within the MPC framework to maintain responsive control.

Finally, validation and certification hurdles slow clinical adoption, as the complex, adaptive nature of MPC controllers makes them difficult to verify against the stringent safety standards required for medical devices. Regulatory frameworks have not fully adapted to accommodate these advanced control methodologies, creating additional barriers to commercialization.

Real-time execution constraints further complicate implementation, as prosthetic devices typically require control frequencies of 100-1000 Hz to achieve natural movement. Current MPC solvers often struggle to consistently meet these timing requirements, especially when handling the nonlinear dynamics inherent in human locomotion and interaction with varied environments.

Model accuracy presents another substantial challenge. MPC performance fundamentally depends on the quality of the predictive model, yet developing accurate models of human-prosthetic interaction remains difficult due to the high variability between users, changing environmental conditions, and the complex biomechanics involved. Simplified models may enable faster computation but sacrifice performance, while detailed models improve control but increase computational burden.

Robustness issues also plague current implementations. MPC controllers must maintain stability and performance despite sensor noise, model uncertainties, and unexpected disturbances such as uneven terrain or sudden changes in user intention. Traditional MPC formulations often lack the robustness guarantees necessary for safety-critical prosthetic applications.

Parameter tuning represents a significant practical challenge, as MPC controllers typically contain numerous parameters that must be carefully calibrated for each user. Current approaches to personalization often require extensive manual tuning by clinical professionals, limiting accessibility and increasing costs.

Power consumption remains a critical constraint, with advanced MPC implementations often demanding substantial computational resources that drain battery life. This creates a direct trade-off between control sophistication and operational duration that impacts user experience.

Integration with intent recognition systems presents additional complexity, as MPC controllers must seamlessly interface with higher-level algorithms that interpret user intentions from biological signals or movement patterns. The latency and uncertainty in these predictions must be appropriately handled within the MPC framework to maintain responsive control.

Finally, validation and certification hurdles slow clinical adoption, as the complex, adaptive nature of MPC controllers makes them difficult to verify against the stringent safety standards required for medical devices. Regulatory frameworks have not fully adapted to accommodate these advanced control methodologies, creating additional barriers to commercialization.

Current MPC Architectures for Prosthetic Applications

01 Advanced MPC algorithms for improved control performance

Advanced Model Predictive Control (MPC) algorithms can significantly enhance control performance in various applications. These algorithms incorporate sophisticated mathematical models to predict system behavior and optimize control actions accordingly. By utilizing techniques such as dynamic optimization, constraint handling, and adaptive modeling, these advanced MPC implementations can achieve better stability, faster response times, and improved disturbance rejection compared to conventional control methods.- Advanced MPC algorithms for improved control performance: Advanced Model Predictive Control (MPC) algorithms have been developed to enhance control performance in various systems. These algorithms incorporate sophisticated mathematical models to predict future system behavior and optimize control actions accordingly. By utilizing techniques such as dynamic optimization, constraint handling, and adaptive modeling, these advanced MPC implementations can achieve superior control performance compared to traditional control methods, resulting in improved stability, faster response times, and better disturbance rejection.

- Performance metrics and evaluation frameworks for MPC systems: Various performance metrics and evaluation frameworks have been developed to assess the effectiveness of Model Predictive Control systems. These frameworks include quantitative measures such as settling time, overshoot, control error, and computational efficiency. By systematically evaluating MPC performance using these metrics, engineers can optimize controller parameters, compare different control strategies, and ensure that control objectives are being met under various operating conditions and disturbances.

- Industrial applications of MPC for process optimization: Model Predictive Control has been successfully implemented in various industrial applications to optimize process performance. These implementations span across industries such as manufacturing, chemical processing, energy production, and mining operations. By deploying MPC systems in these environments, companies have achieved significant improvements in production efficiency, product quality, energy consumption, and operational safety. The ability of MPC to handle complex multivariable systems with constraints makes it particularly valuable for industrial process optimization.

- Real-time adaptation and robustness in MPC systems: Modern MPC implementations incorporate real-time adaptation mechanisms to maintain control performance despite uncertainties and changing conditions. These adaptive approaches include online model updating, disturbance estimation, and robust optimization techniques that account for model inaccuracies. By continuously adjusting to changing system dynamics and external disturbances, these robust MPC systems can maintain consistent control performance even when operating conditions deviate from nominal assumptions, ensuring reliable operation in practical applications.

- Integration of machine learning with MPC for enhanced performance: Recent innovations combine machine learning techniques with Model Predictive Control to enhance control performance. These hybrid approaches use data-driven methods to improve model accuracy, predict disturbances, and optimize control parameters. By leveraging artificial intelligence algorithms such as neural networks, reinforcement learning, and Bayesian optimization, these integrated systems can adapt to complex nonlinear dynamics, learn from operational data, and continuously improve control performance over time, representing the cutting edge of advanced control technology.

02 Performance monitoring and optimization in MPC systems

Continuous monitoring and optimization of Model Predictive Control systems is essential for maintaining optimal control performance. This involves real-time assessment of control quality metrics, detection of model-plant mismatch, and automatic tuning of controller parameters. By implementing performance monitoring frameworks, control engineers can identify degradation in control performance, diagnose root causes, and implement corrective actions to ensure the MPC system operates at peak efficiency throughout its lifecycle.Expand Specific Solutions03 Integration of machine learning with MPC for enhanced performance

The integration of machine learning techniques with Model Predictive Control represents a significant advancement in control performance. Machine learning algorithms can improve system models through data-driven approaches, adapt to changing process conditions, and optimize control parameters automatically. This hybrid approach combines the predictive capabilities of MPC with the adaptive learning abilities of AI, resulting in more robust control systems that can handle complex, nonlinear processes and uncertain operating conditions.Expand Specific Solutions04 Industrial applications of MPC with performance guarantees

Model Predictive Control has been successfully implemented across various industrial sectors with specific performance guarantees. These applications include process control in chemical plants, energy management systems, manufacturing automation, and resource optimization. Industrial MPC implementations often feature specialized constraints handling, robustness against disturbances, and economic optimization objectives. The control systems are designed to provide guaranteed performance metrics such as stability margins, settling time, and constraint satisfaction even under challenging operating conditions.Expand Specific Solutions05 Distributed and networked MPC architectures for complex systems

Distributed and networked Model Predictive Control architectures address the challenges of controlling large-scale, interconnected systems while maintaining high performance. These approaches decompose complex control problems into smaller, manageable subproblems that can be solved locally while coordinating to achieve global objectives. By implementing communication protocols between distributed controllers, these systems can reduce computational burden, improve scalability, and enhance fault tolerance while maintaining control performance comparable to centralized approaches.Expand Specific Solutions

Leading Developers and Research Institutions

Model Predictive Control (MPC) in intelligent prosthetics is currently in a growth phase, with the market expanding as technological advancements enable more sophisticated control systems. The global intelligent prosthetics market is estimated to reach $15-20 billion by 2025, driven by increasing demand for functional limb replacements. Technologically, the field shows varying maturity levels across players. Leading companies like Touch Bionics and Össur have developed advanced commercial solutions implementing predictive algorithms, while DEKA Products has pioneered revolutionary prosthetic systems with sophisticated control mechanisms. Academic institutions including University of Michigan, Georgia Tech, and Vanderbilt University are advancing fundamental research in MPC applications. Technology corporations such as IBM, NVIDIA, and Siemens are contributing computing infrastructure and AI capabilities, creating a competitive ecosystem balancing commercial applications with ongoing research innovation.

DEKA Products LP

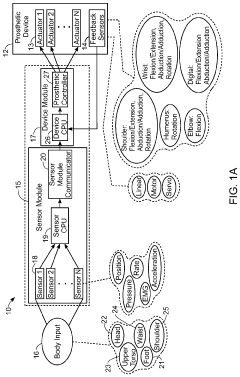

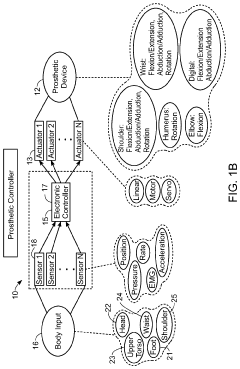

Technical Solution: DEKA's LUKE Arm (Life Under Kinetic Evolution) represents one of the most sophisticated applications of model predictive control in upper limb prosthetics. The system employs a multi-input MPC framework that processes EMG signals, foot pressure sensors, and inertial measurement data to create a comprehensive predictive model of user intent. Their proprietary control algorithm continuously updates a dynamic model of arm movement, predicting optimal trajectories 200ms into the future while accounting for physical constraints and environmental interactions. The LUKE Arm's MPC implementation features adaptive gain scheduling that modifies controller parameters based on detected activity modes, allowing seamless transitions between precision grasping and broader movements. DEKA's system incorporates a unique "reflexive control" layer within the MPC framework that enables automatic object slip prevention and force modulation without explicit user commands, mimicking natural neurological reflexes. The controller maintains stability across varying loads and movement speeds by continuously reoptimizing its internal model parameters.

Strengths: Exceptional dexterity with 10 degrees of freedom; intuitive control interface requiring minimal training; robust performance across diverse manipulation tasks; effective handling of unexpected disturbances. Weaknesses: High computational demands requiring specialized hardware; complex calibration process; relatively high cost limiting accessibility; battery life constraints due to intensive processing requirements.

Touch Bionics Ltd.

Technical Solution: Touch Bionics has implemented sophisticated model predictive control systems in their i-Limb quantum prosthetic hand. Their approach utilizes a multi-level MPC framework that combines short-term trajectory optimization with longer-term grip pattern prediction. The system employs a unique feature they call "grip choreography" - a predictive algorithm that anticipates the sequence of finger movements needed for common manipulation tasks based on initial EMG signals and object recognition. Their MPC implementation incorporates a dynamic internal model that accounts for the mechanical properties of different objects, allowing the controller to predict appropriate grip forces and finger positions before contact occurs. Touch Bionics' system features an adaptive prediction horizon that extends further into the future during steady-state gripping but shortens during rapid transitions, optimizing computational resources while maintaining responsive control. The controller continuously updates its internal models based on sensory feedback, including pressure sensors embedded in fingertips that detect slip and adjust grip force accordingly. Their latest iterations incorporate cloud-based machine learning that aggregates user data to improve predictive models across their entire user base while maintaining individual customization.

Strengths: Highly intuitive control requiring minimal cognitive effort; excellent grip stability across diverse objects; rapid adaptation to new tasks; sophisticated gesture recognition capabilities. Weaknesses: Higher latency during complex multi-finger movements; occasional prediction errors with novel objects; limited force feedback to user; dependency on consistent EMG signal quality.

Key Patents and Research in Predictive Control for Prosthetics

System for control of a prosthetic device

PatentPendingUS20240009007A1

Innovation

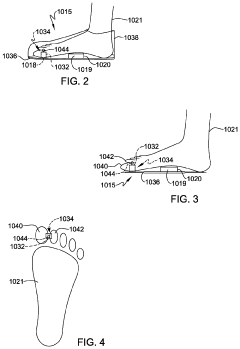

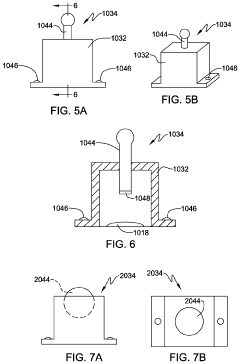

- A control system for prosthetic devices that incorporates a sensor module for detecting orientation changes and a device module for commanding actuators, utilizing a combination of positional control and force control, with features like kinematic mapping and inertial measurement units to enable precise movement and force management, allowing for smooth and proportional control.

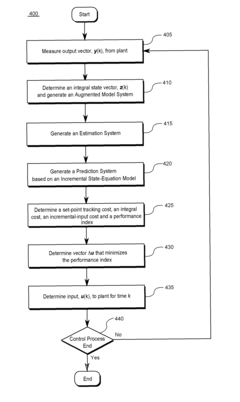

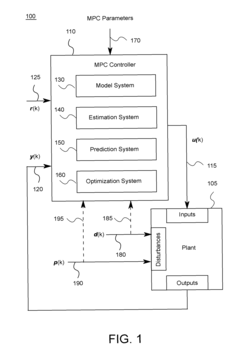

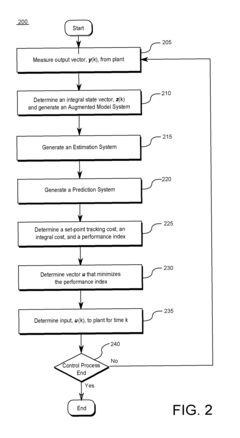

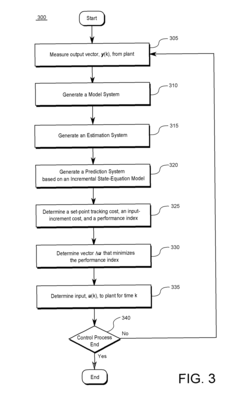

Systems and methods for offset-free model predictive control

PatentInactiveUS8295951B2

Innovation

- The proposed MPC architecture incorporates integral states and input-velocity cost terms in the performance index to eliminate offsets, and uses an Incremental MPC Estimation System to reduce computational burden, enabling systematic offset-free set-point tracking even with unmeasured disturbances.

User Experience and Human-Prosthetic Interface Considerations

The integration of Model Predictive Control (MPC) in intelligent prosthetics necessitates careful consideration of user experience and human-prosthetic interface factors. Successful adoption of advanced control systems depends not merely on technical performance but on how seamlessly these systems integrate with users' cognitive and physical capabilities.

User acceptance of MPC-controlled prosthetics hinges on intuitive control mechanisms that minimize cognitive load. Research indicates that prosthetic users experience significant mental fatigue when control interfaces require constant conscious attention. MPC systems must therefore incorporate adaptive algorithms that learn from user behavior patterns, gradually reducing the need for explicit control commands and enabling more natural movement transitions.

Haptic feedback represents a critical component of the human-prosthetic interface, addressing the fundamental challenge of proprioceptive awareness. Current MPC implementations often lack sufficient sensory feedback channels, creating a disconnect between the user's intention and the prosthetic's action. Advanced systems are now integrating multimodal feedback mechanisms—combining vibrotactile, pressure, and temperature signals—to create a more comprehensive sensory experience that enhances embodiment of the prosthetic device.

Customization capabilities significantly impact user satisfaction with intelligent prosthetics. MPC systems must accommodate individual preferences regarding response sensitivity, movement speed, and grip strength. Research demonstrates that personalized control parameters can reduce abandonment rates by up to 35% compared to fixed-parameter systems. Implementation of user-friendly calibration interfaces allows for ongoing adjustment as users' needs evolve over time.

The learning curve associated with MPC-controlled prosthetics presents a substantial barrier to adoption. Traditional training protocols often prove inadequate for helping users master predictive control systems. Virtual reality training environments have emerged as promising solutions, allowing users to practice with simulated versions of their prosthetics before physical implementation. These environments can systematically introduce increasing complexity while providing immediate visual feedback on performance.

Long-term usability considerations must address the evolution of user needs over time. MPC systems should incorporate mechanisms for continuous adaptation as users develop greater proficiency or experience physiological changes. Cloud-based learning systems that aggregate anonymized user data can enable prosthetics to benefit from collective user experiences while maintaining individual customization.

Psychological factors, particularly related to device embodiment, significantly influence user satisfaction. MPC systems that respond with minimal latency and high predictive accuracy foster stronger perceptions of ownership and agency. Research indicates that users report higher satisfaction when prosthetics anticipate movements rather than merely responding to explicit commands, highlighting the importance of predictive algorithms in creating natural-feeling interactions.

User acceptance of MPC-controlled prosthetics hinges on intuitive control mechanisms that minimize cognitive load. Research indicates that prosthetic users experience significant mental fatigue when control interfaces require constant conscious attention. MPC systems must therefore incorporate adaptive algorithms that learn from user behavior patterns, gradually reducing the need for explicit control commands and enabling more natural movement transitions.

Haptic feedback represents a critical component of the human-prosthetic interface, addressing the fundamental challenge of proprioceptive awareness. Current MPC implementations often lack sufficient sensory feedback channels, creating a disconnect between the user's intention and the prosthetic's action. Advanced systems are now integrating multimodal feedback mechanisms—combining vibrotactile, pressure, and temperature signals—to create a more comprehensive sensory experience that enhances embodiment of the prosthetic device.

Customization capabilities significantly impact user satisfaction with intelligent prosthetics. MPC systems must accommodate individual preferences regarding response sensitivity, movement speed, and grip strength. Research demonstrates that personalized control parameters can reduce abandonment rates by up to 35% compared to fixed-parameter systems. Implementation of user-friendly calibration interfaces allows for ongoing adjustment as users' needs evolve over time.

The learning curve associated with MPC-controlled prosthetics presents a substantial barrier to adoption. Traditional training protocols often prove inadequate for helping users master predictive control systems. Virtual reality training environments have emerged as promising solutions, allowing users to practice with simulated versions of their prosthetics before physical implementation. These environments can systematically introduce increasing complexity while providing immediate visual feedback on performance.

Long-term usability considerations must address the evolution of user needs over time. MPC systems should incorporate mechanisms for continuous adaptation as users develop greater proficiency or experience physiological changes. Cloud-based learning systems that aggregate anonymized user data can enable prosthetics to benefit from collective user experiences while maintaining individual customization.

Psychological factors, particularly related to device embodiment, significantly influence user satisfaction. MPC systems that respond with minimal latency and high predictive accuracy foster stronger perceptions of ownership and agency. Research indicates that users report higher satisfaction when prosthetics anticipate movements rather than merely responding to explicit commands, highlighting the importance of predictive algorithms in creating natural-feeling interactions.

Regulatory Framework for AI-Enabled Medical Devices

The regulatory landscape for AI-enabled medical devices, including intelligent prosthetics utilizing Model Predictive Control (MPC), presents a complex framework that continues to evolve as technology advances. Currently, the FDA's Digital Health Innovation Action Plan provides the primary regulatory structure in the United States, with specific pathways for Software as a Medical Device (SaMD) that encompasses AI-driven prosthetic control systems.

The European Union's Medical Device Regulation (MDR) and In Vitro Diagnostic Regulation (IVDR) have established more stringent requirements for AI-enabled medical devices, including specific provisions for continuous learning algorithms that may be present in advanced prosthetic systems. These regulations emphasize risk classification, clinical evaluation, and post-market surveillance that are particularly relevant to MPC-based prosthetics that adapt to user behavior over time.

International Medical Device Regulators Forum (IMDRF) has developed harmonized principles for SaMD regulation that influence global approaches to AI-enabled prosthetics. Their framework addresses the unique challenges of software that evolves through machine learning, requiring manufacturers to demonstrate ongoing safety and effectiveness despite algorithmic changes.

Key regulatory challenges specific to MPC in intelligent prosthetics include validation of adaptive algorithms, establishing performance boundaries, and determining appropriate clinical endpoints. Regulators increasingly require manufacturers to implement risk management systems that account for the unique characteristics of predictive control systems, including potential failure modes and cybersecurity vulnerabilities.

Pre-market approval pathways typically require demonstration of algorithm performance across diverse populations and usage scenarios. For MPC-based prosthetics, this includes validation of the control system's ability to predict and respond to various movement intentions across different environmental conditions and user states.

Post-market surveillance requirements are particularly stringent for intelligent prosthetics, with regulators mandating ongoing monitoring of device performance and safety. This includes tracking algorithm drift, unexpected adaptations, and potential emergent behaviors that could impact user safety or device effectiveness.

Regulatory bodies are increasingly adopting a Total Product Lifecycle (TPLC) approach for AI-enabled medical devices, recognizing that traditional regulatory frameworks may be insufficient for technologies that continue to evolve after market approval. This approach emphasizes continuous monitoring and periodic re-evaluation of device performance throughout its lifecycle.

The European Union's Medical Device Regulation (MDR) and In Vitro Diagnostic Regulation (IVDR) have established more stringent requirements for AI-enabled medical devices, including specific provisions for continuous learning algorithms that may be present in advanced prosthetic systems. These regulations emphasize risk classification, clinical evaluation, and post-market surveillance that are particularly relevant to MPC-based prosthetics that adapt to user behavior over time.

International Medical Device Regulators Forum (IMDRF) has developed harmonized principles for SaMD regulation that influence global approaches to AI-enabled prosthetics. Their framework addresses the unique challenges of software that evolves through machine learning, requiring manufacturers to demonstrate ongoing safety and effectiveness despite algorithmic changes.

Key regulatory challenges specific to MPC in intelligent prosthetics include validation of adaptive algorithms, establishing performance boundaries, and determining appropriate clinical endpoints. Regulators increasingly require manufacturers to implement risk management systems that account for the unique characteristics of predictive control systems, including potential failure modes and cybersecurity vulnerabilities.

Pre-market approval pathways typically require demonstration of algorithm performance across diverse populations and usage scenarios. For MPC-based prosthetics, this includes validation of the control system's ability to predict and respond to various movement intentions across different environmental conditions and user states.

Post-market surveillance requirements are particularly stringent for intelligent prosthetics, with regulators mandating ongoing monitoring of device performance and safety. This includes tracking algorithm drift, unexpected adaptations, and potential emergent behaviors that could impact user safety or device effectiveness.

Regulatory bodies are increasingly adopting a Total Product Lifecycle (TPLC) approach for AI-enabled medical devices, recognizing that traditional regulatory frameworks may be insufficient for technologies that continue to evolve after market approval. This approach emphasizes continuous monitoring and periodic re-evaluation of device performance throughout its lifecycle.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!